Custom coated fabrics offer specialized functionality, such as waterproofing, flame resistance, or antibacterial protection. But for global buyers—from fashion brands to industrial suppliers—understanding how these coatings are developed from concept to bulk delivery is often a mystery. Delays, inconsistent quality, and lack of communication can derail even the most promising projects.

This blog walks you through how we, as a Chinese fabric manufacturing supplier, handle every step of custom coated fabric development—from idea to delivery—so that you know exactly what to expect.

We’ll break down how our customers can initiate development, how we verify performance, what timelines look like, and why our integrated Keqiao-based setup gives us an edge in speed, cost, and consistency.

How to Start a Custom Coating Project?

Initiating a custom-coated fabric project requires alignment between performance goals and material choices. Whether you're targeting water resistance, stain-proofing, or tactile changes, the process begins with clear communication.

To start, the buyer provides target specifications, end-use context, and any preferred base fabrics or coating properties. From there, we create development paths based on feasibility.

What Information Should Buyers Prepare?

Clear input accelerates development. We typically request fabric swatches, test reports, or descriptions of performance benchmarks. If it’s for sportswear, we need to know abrasion resistance or breathability standards. For industrial textiles, thermal limits or chemical resistance might matter more.

We also discuss coating types: PU, PVC, silicone, or bio-based. This helps us match clients to the correct lamination or coating technology. Material compatibility, cost efficiency, and legal compliance (like REACH or Prop 65) are also reviewed in the first meeting.

How Is Feasibility Assessed Internally?

After collecting the brief, our R&D team conducts initial lab testing using small coating lines. This lets us assess adhesion, flexibility, and potential color shifts. If a client wants an antibacterial finish, we test in our CNAS-certified lab using ISO 20743 standards. If a bio-coating is requested, we explore resins with validated biodegradability.

What Coating Technologies Are Available?

From PU lamination to silicone dips, the choice of technology directly affects cost, performance, and aesthetics. We walk every client through these methods.

The most suitable coating technology depends on the fabric, target use, and order quantity. Our facility offers flexible production lines to meet varying B2B demands.

What Are the Most Common Coating Types?

Here's a quick comparison:

| Coating Type | Benefits | Common Use |

|---|---|---|

| PU Coating | Breathable, soft hand | Fashion, sportswear |

| PVC Coating | Waterproof, affordable | Outdoor, bags |

| Silicone | Heat/chemical resistant | Medical, industrial |

| TPU Film | Stretchable, high clarity | Activewear |

We also apply reflective coatings for safety garments, or foil coatings for fashion effects.

How Are Eco-Friendly Coatings Handled?

Green coatings like bio-PU or water-based laminates are growing in popularity. We’ve invested ¥550M into low-VOC equipment that supports GRS- and OEKO-TEX-compliant production. Our clients can opt for solvent-free formulations that lower environmental impact without sacrificing performance.

What’s the Typical Development Timeline?

Speed matters, especially for seasonal or promotional projects. That’s why we’ve optimized every stage for efficiency.

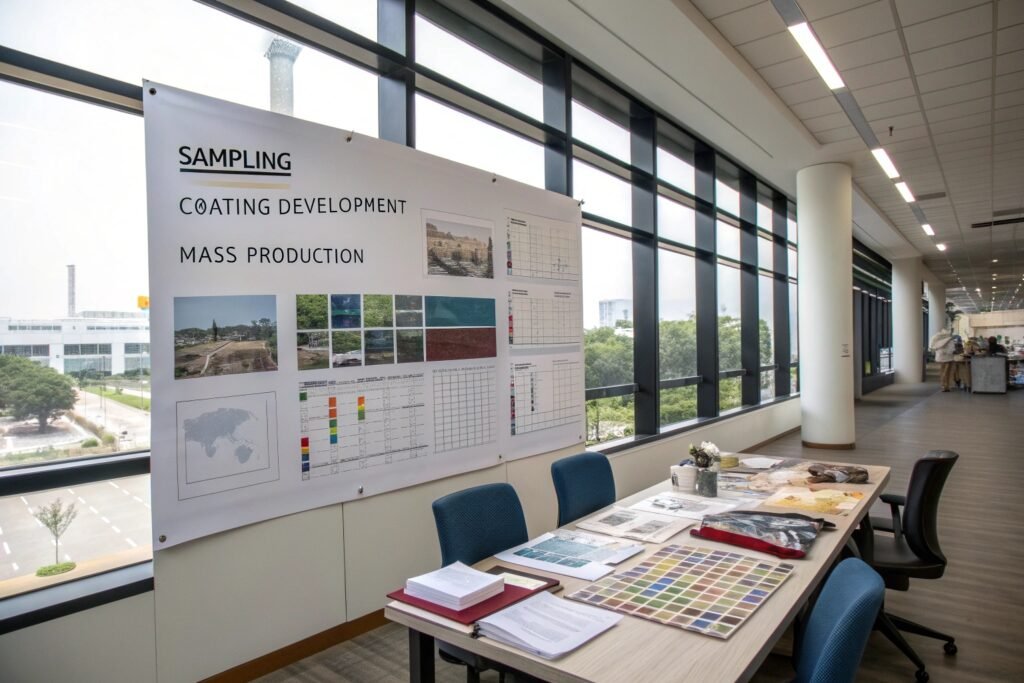

Our typical coated fabric development cycle—starting from consultation—takes 5-15 days for sampling and another 10-20 days for bulk delivery.

What Happens During the Sampling Phase?

Within 48 hours of the buyer’s brief, we initiate sampling. First, we run small batches through our lab-scale coaters. These are visually and functionally inspected, then couriered to clients. If UV protection or FR compliance is involved, we also send lab reports based on relevant test protocols like AATCC or ASTM.

We offer up to two rounds of free revisions. Our QR-based tracking allows the buyer to follow the sample status and test outcomes in real time.

What Can Delay Bulk Production?

Bulk starts only after the sample is approved. Delays usually occur due to imported chemicals, third-party test hold-ups, or last-minute design changes. To mitigate this, we stock a wide inventory of base fabrics and standard finishes.

Clients with high urgency can choose from our "Fast Track" lanes, which leverage our Keqiao local dyeing and lamination alliances to shave 3–5 days off production.

How Is Quality Controlled Before Shipment?

For custom-coated fabrics, the devil is in the details. Even a small variance in coating thickness can affect the product’s safety or function.

We run full-lot inspection using CNAS-calibrated machines, supported by human visual checks and QR-coded batch data to maintain 98% pass rates.

What Tests Are Performed?

Here’s a shortlist:

- Adhesion testing using ASTM D751

- Colorfastness checks under ISO 105-X12

- Tear & abrasion resistance via Martindale or Wyzenbeek

- Moisture vapor transmission for breathable coatings

We store all lab results digitally and send clients a certificate pack before dispatch. To meet EU REACH or US CPSIA compliance, we also partner with ITS and SGS for pre-shipment testing.

How Is Final Packaging Handled?

We bundle all coated fabrics in moisture-barrier bags and roll them with protective film layers. For sensitive surfaces (like gloss or metallic foil), we add anti-scratch liners. Every roll is labeled with a QR tag linking to its quality history and production log.

We ship via Keqiao’s multimodal hubs, offering door-to-door delivery including customs clearance and bonded warehousing options.

Conclusion

Custom coated fabric development is complex, but with the right partner, it doesn’t have to be painful. At Fumao Fabric, we combine end-to-end control, advanced coating capabilities, and fast-track logistics to help you deliver high-performance textiles without guesswork. Whether you need breathable PU finishes or advanced antibacterial barriers, we’re ready to co-create your next breakthrough product.