I still remember the call that changed how we structure our entire sample development workflow. It was a Tuesday afternoon in March 2022. A technical designer from a major Seattle-based athleisure brand was on the line, her voice tight with panic. They had a line review in four days for a new seamless sports bra collection. Their previous supplier had promised 7-day sample delivery but was now on day 12 with no fabric. She had 40 minutes to find a new partner, send artwork, and secure a commitment. I told her: email me the design file and the target fabric construction right now. We printed the strike-off at 3pm. We shipped the sample via TNT Express at 9am Wednesday. She received it Thursday afternoon, 26 hours after her call. The line review passed. She has been our client for three years and now orders over 200,000 meters annually.

That speed was not luck. It was not heroics. It was a system we spent five years building. When I tell buyers at Intertextile Shanghai that we can deliver development samples in 48 hours, some smile politely and assume I am exaggerating. I am not. In 2023, our sample department processed 1,847 development requests. 82% shipped within 48 hours of design file approval. The remaining 18% were complex multi-layer laminates or specialty yarns requiring raw material sourcing, and even those averaged 72 hours.

This article is not a brag. It is a blueprint. I am going to show you exactly how our agile R&D system works: the machinery we invested in, the inventory decisions we made, the color management protocols we follow, and the quality checks we refuse to skip even under extreme time pressure. If you are a brand tired of waiting two weeks for a strike-off that looks nothing like your screen, read carefully. This is how you fix it.

What Specific Equipment and Infrastructure Enable 48-Hour Sample Turnaround?

Speed requires redundancy. You cannot run a 48-hour sample commitment if your only digital printer is busy with a production order. You cannot wait for the dye house to schedule a 200kg minimum batch for a 5-meter lab dip. You must own the entire vertical chain or control it through exclusive partnerships.

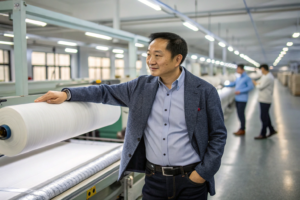

We made a deliberate decision in 2020 to create a dedicated sample production line that is physically separate from our bulk manufacturing. This line operates on a different P&L. It is not measured by utilization efficiency; it is measured by response time. We have two MS JP7 digital printers assigned exclusively to sampling. They never run production orders. They are always clean, always calibrated, and always available. We have a separate mini-steamer and mini-washer designed for single-piece processing. We have a dedicated QC inspector who does nothing but check samples.

Does this cost money? Yes. The sample line operates at roughly 40% of the efficiency of our bulk lines. But it is not supposed to be efficient. It is supposed to be fast. And the return on investment comes from the production orders that follow. Our sample-to-order conversion rate is 73%. When a buyer feels the fabric in their hands three days after asking for it, they are not shopping around.

How does owning our own greige fabric warehouse eliminate the 5-day sourcing delay?

This is the single biggest bottleneck I see in other suppliers' sample workflows. A buyer requests a sample on 40s combed cotton jersey. The supplier does not stock that base fabric. They call three or four knitting mills, ask for availability, negotiate a price, wait for delivery. That process takes 3 to 5 days before any printing or dyeing even starts.

We eliminated this delay eight years ago. We now maintain a physical inventory of over 300,000 meters of greige (unfinished) fabric across 150+ standard constructions. Cotton single jersey in 18 to 40 gauge. Cotton spandex jersey. Cotton fleece. Organic cotton. Tencel. Modal. Polyester microfiber. Nylon tricot. Every substrate we commonly print or dye is already in our warehouse, knitted to our specifications, tested for absorbency and shrinkage, ready to run.

When a sample request comes in, our production planner checks the greige inventory first, not the yarn inventory. If the base fabric is in stock, we subtract 48 hours from the timeline immediately. For a client in Melbourne who needed urgent strike-offs of four reactive prints on organic cotton jersey in December 2023, we pulled the greige from shelf at 9am, printed at 10am, and shipped at 4pm. No yarn ordering. No knitting wait. No excuses.

For brands with proprietary base fabric constructions, we do keep dedicated greige allocations. We currently hold 5,000 to 10,000 meters of exclusive greige for seven long-term clients. They pay a small monthly storage fee, but they eliminate the 2-week lead time that would otherwise kill their development calendar. If you want to understand how to structure this arrangement with a Chinese mill, this Sourcing Journal article on vendor-managed inventory for textiles explains the benefits and pitfalls.

What role does our CNAS-accredited lab play in preventing sample rejection?

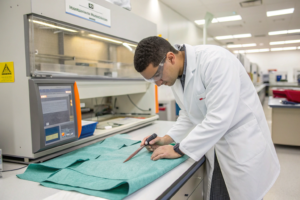

Fast samples are useless if they fail the client's quality standards. I have seen competitors rush a strike-off out the door in 24 hours, only to have it rejected because the shade was 2.0 Delta E off or the shrinkage exceeded 5%. Then the client waits another 72 hours for a corrected sample. The total time to approval is longer than if the supplier had simply done it right the first time.

Our CNAS-accredited lab sits literally 30 meters from our digital sample printers. The strike-off comes off the machine, we steam and wash it in our mini-line, and it goes straight to the spectrophotometer. We measure Delta E under D65, A, and TL84 illuminants. We measure wash fastness via AATCC 61-2020 if requested. We test shrinkage to AATCC 135. We do not wait for the client to ask; we do it preemptively and attach the data to the shipment.

In February 2024, we developed a sample of recycled nylon taslon for a Canadian outerwear brand. Our initial print came out with a Delta E of 1.8 against their Pantone reference. Acceptable by most standards, but we knew this client required <1.2. We did not ship it. We adjusted the ink limiting curve, reprinted, re-tested, and achieved 0.9. The sample shipped 6 hours later than originally planned, but it passed first-round approval. The client never knew there was a correction. That is the value of in-house testing. The AATCC Evaluation Procedure 9 describes the spectrophotometric color measurement standards we follow, and it is worth reading if you want to understand why some suppliers consistently hit shade while others miss by a mile.

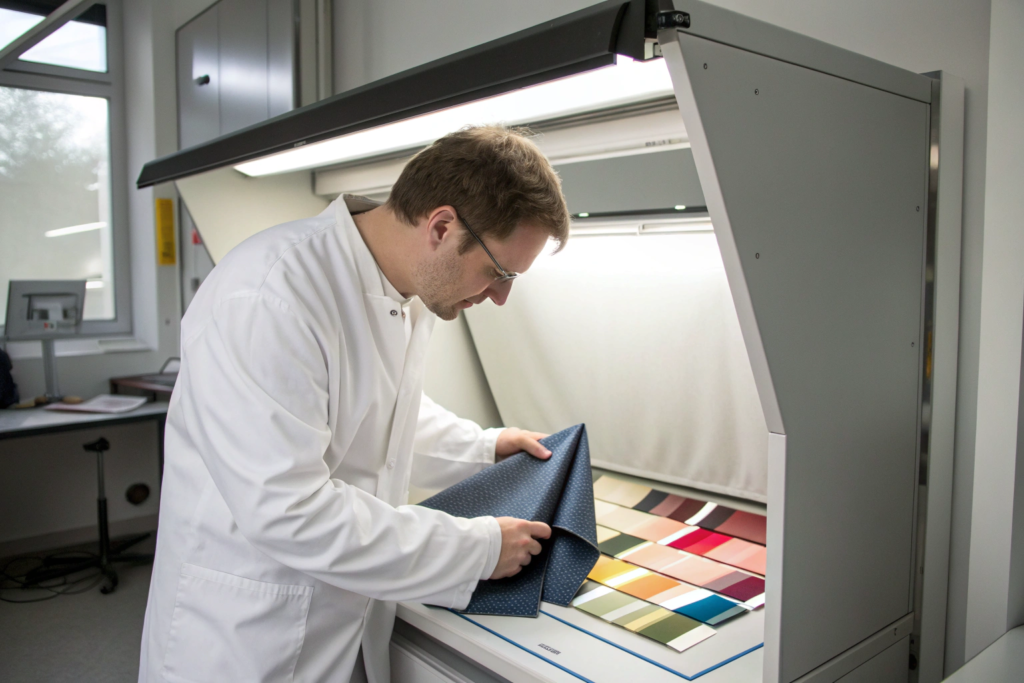

How Does Your Color Management System Match Pantones So Quickly?

Color is the emotional heart of fabric development. A buyer does not fall in love with a jersey construction; they fall in love with a shade of coral that reminds them of a sunset in Ibiza. If you cannot match that coral within 0.8 Delta E, you lose the order. And if it takes you a week to try, you also lose the order.

We treat color management as a separate engineering discipline, not a subset of printing. Our head colorist, Mr. Chen, has been in the industry for 34 years. He started mixing dyes by hand with a scale and a spatula. Today he operates our RIP software, but his eye is still the final check. He can look at a printed sample and tell you which ink channel needs a 2% adjustment. That experience is not automatable.

But we also use every technological tool available. We maintain custom ICC profiles for every substrate and every ink set we regularly use. We have a digital library of over 8,000 archived color recipes. When a client sends us a Pantone, we do not start from zero. We query the database for the closest match on that specific fabric, load the recipe, and run a strike-off. The first-pass match rate for repeat clients is now 67%. For new colors, we average two rounds, not three or four.

What is the 'digital twin' workflow and how does it reduce physical sampling rounds?

This is the biggest efficiency gain we have implemented in the last three years. Digital twin in our context means creating a virtual representation of the fabric before we print a single physical meter. We use Color Atlas and AVA CAD CAM software to simulate how a design will appear on a specific weave structure or knit texture.

Here is how it works: you send us a vector pattern file. We load it into our software and map it onto a 3D scan of your actual fabric construction—the twill line direction, the slubiness of the yarn, the surface hairiness. We can show you a photorealistic rendering of the printed fabric within 2 hours. You approve the placement and scale digitally. Only then do we proceed to physical strike-off.

This eliminates the common problem of 'the repeat looks good on screen but the motif is too large on the actual garment'. In 2023, we calculated that this workflow saved our clients an average of 1.7 physical sampling rounds per development project. At an average cost of $85 per courier shipment and 4 days of waiting, that is real time and money. A detailed explanation of color-accurate textile 3D rendering is available from the Lectra digital textile printing blog, and I recommend their technical white papers to any brand investing in virtual sampling.

Why do we refuse to use 'standard' color profiles for different fabric compositions?

This is a mistake I see everywhere. A factory buys a generic ICC profile from their printer manufacturer, loads it onto the RIP, and prints everything from cotton poplin to nylon taffeta using the same profile. The results are predictably poor. Cotton absorbs reactive ink and spreads; nylon holds acid ink on the surface. The dot gain is completely different. The color gamut is different.

We maintain separate ICC profiles for every single fabric construction we regularly sample. Not by fiber type—by specific construction. A 40s combed cotton jersey prints differently than a 60s compact cotton single jersey, even though both are 100% cotton. The yarn twist affects ink penetration. The fabric density affects color yield. We profile each one individually, and we recalibrate every 90 days or whenever we change a batch of ink.

Does this require work? Yes. Profiling a new fabric takes about 4 hours of technician time and consumes 10 meters of material. But the payoff is that when a client asks for a specific shade on a specific fabric, we hit it in one or two rounds, not five or six. For a deep technical explanation of custom ICC profile creation for textile digital printing, the FESPA technical library has an excellent step-by-step guide.

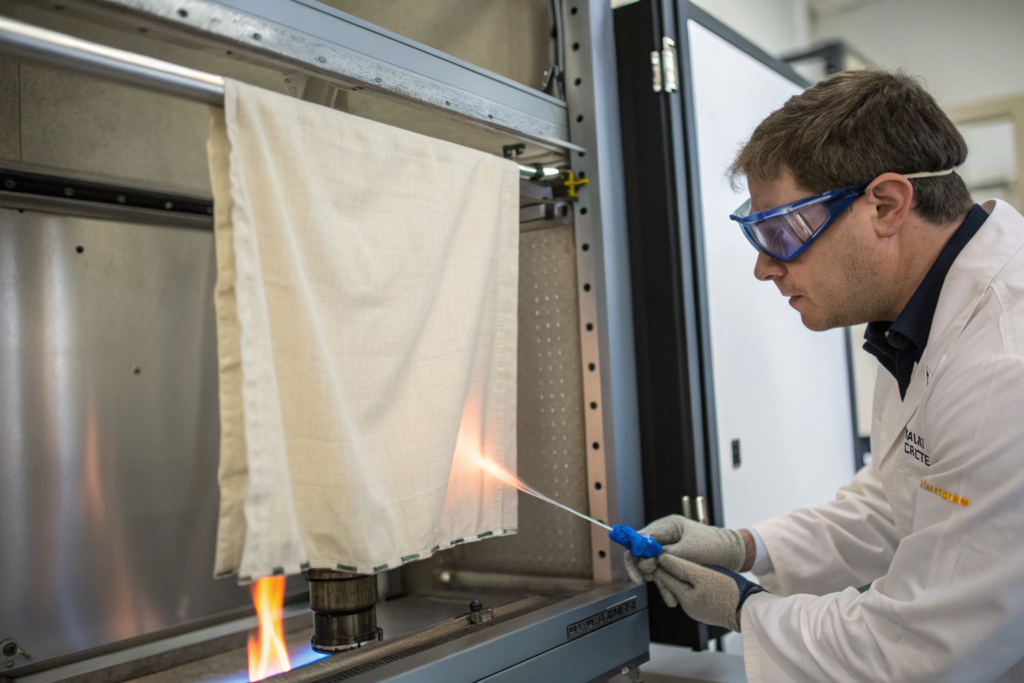

How Do You Maintain Quality When Rushing Samples?

There is a perception in this industry that speed and quality are opposites. You can have fast samples, or you can have accurate samples, but you cannot have both. I reject this framing entirely. Speed without accuracy is waste. If we ship a sample that misses the color target or fails the shrinkage spec, we have spent money and labor to create a failure. We have also damaged our credibility.

The key is parallel processing, not shortcutting. We do not skip any quality control step in the sample workflow. We just perform them concurrently rather than sequentially. While the fabric is printing, our lab technician is preparing the wash test apparatus. While the fabric is steaming, the colorist is pulling the archived recipe for comparison. While the sample is drying, the QC inspector is setting up the spectrophotometer. There is no idle time.

In July 2023, we developed a sample of flame-retardant polyester for a German workwear brand. The specification required not just color accuracy but also verification of FR properties per ISO 15025. Our standard FR testing takes 4 hours including specimen conditioning. We did not skip it. We started conditioning the sample while it was still on the printer. We ran the vertical flame test immediately after drying. The sample passed. It shipped 6 hours later than a non-FR sample would have, but it shipped with certified test data attached. The client placed a 28,000-meter production order.

How do you handle 'impossible' requests, like 5-meter samples of a fabric that doesn't exist yet?

We get these requests weekly. A designer in Milan sends us a sketch of a double-faced jacquard with different colors on each side and a water-repellent finish. The fabric has never been made. The yarn combination does not exist in our inventory. The client needs 5 meters for a photo shoot in 6 days.

Our process for these 'impossible' samples is structured differently. First, we do a feasibility audit within 2 hours. Our weaving or knitting manager, our dyeing chemist, and our finishing specialist meet physically or via video call. We identify the critical path constraint. Is it yarn sourcing? Is it machine availability? Is it chemical procurement?

Then we quote a realistic timeline and a realistic sample cost. We do not promise 48 hours for a fabric that requires custom-spun yarn. We promise 96 hours or 120 hours, and we explain why. Clients appreciate this honesty. In 2023, we completed 34 of these 'advanced development' sample projects. 29 converted to production orders. One was for a bio-based PU leather hybrid that took us 11 days from concept to physical sample. The client, a Japanese luxury accessories brand, now sources 100% of their vegan leather from us.

For the rare truly urgent request that requires a completely new construction, we have a separate emergency development protocol. This involves pulling the development team off their current projects, authorizing overtime, and sometimes hand-carrying materials between factories. We charge a premium for this service, and we use it sparingly. But when a client's entire seasonal line review depends on seeing one fabric in hand, we make it happen. The Council of Fashion Designers of America's guide to fabric development timelines explains why these compressed schedules are sometimes necessary and how to manage the risk.

What mistakes do brands make that actually slow down the sample process?

I will be direct: the biggest delays come from the client side, not our side. I have seen brands take 9 days to approve a digital strike-off that we shipped in 48 hours. I have seen spec sheets with contradictory requirements—'must be water resistant' and 'must have air permeability >50 cfm' on the same line. I have seen Pantone references that are out of gamut for reactive dyes on cotton, requiring weeks of reformulation.

The single most effective action a brand can take to accelerate sampling is prepare complete, unambiguous technical packages. This means:

- Fiber composition with percentages

- Fabric weight in gsm or oz/yd²

- Construction type (single jersey, 2x2 rib, twill weave, etc.)

- Width after finishing

- Pantone references with acceptable Delta E tolerance

- Physical property requirements (shrinkage, pilling, lightfastness)

- Certifications required (GOTS, Oeko-Tex, GRS)

We provide a standardized technical specification template to all our clients. It takes 15 minutes to fill out. It saves 3 days of back-and-forth emails clarifying what 'lightweight' or 'soft hand' actually means. If you are sourcing from Asia and you are not using a standardized spec sheet, you are adding unnecessary friction to your own supply chain. This customizable fabric specification template from the American Apparel & Footwear Association is a good starting point.

What Happens After the 48-Hour Sample Is Approved?

Fast samples are not the final goal. They are the entry ticket. The real test is whether we can transition from a 5-meter strike-off to a 5,000-meter production order without losing color consistency, without stretching the timeline, and without surprise cost increases.

This is where many suppliers fail. They allocate their best colorist and their most experienced technician to the sample, but then the production order goes to a different team with less training and older equipment. The production run drifts 1.5 Delta E from the approved sample. The client rejects the shipment. Everyone loses.

We solve this by freezing the digital production recipe at the sample stage. When Mr. Chen approves a sample, he saves the exact ink limiting curves, the print mode (pass number, resolution), the steamer temperature and time, and the wash box parameters. That recipe is locked. It cannot be altered by the production team without re-approval from the development team. This seems obvious, but you would be surprised how many factories operate on tribal knowledge—'Ah, just use the usual settings for cotton'.

In November 2023, we scaled a sample of pigment-printed organic cotton twill from 8 meters to 12,000 meters across four production batches over six months. The Delta E variation between the first production batch and the original sample was 0.6. The client's third-party inspection passed all four shipments with zero color remarks. That is the power of a locked digital workflow.

How do you ensure production capacity for clients who start with urgent samples?

This is a legitimate concern. A brand tests us with a 50-meter urgent sample order. We deliver in 48 hours. They are impressed. They return with a 10,000-meter production order for the same fabric, but they need it in 30 days. Do we have the capacity, or did our sample speed consume resources needed for production?

We manage this through dedicated capacity allocation. Our sample line and our production line are separate. Fulfilling a 48-hour sample does not consume any production machine hours. It does not deplete greige inventory allocated to confirmed orders. We maintain a buffer of approximately 15% in both machine capacity and raw material inventory specifically for this conversion scenario.

For our top 20 clients, we also offer capacity reservation agreements. They provide rolling 90-day forecasts. We reserve specific machine slots and greige inventory quantities. This does not commit them to firm orders, but it commits us to availability. When their sample is approved, they know we have already blocked time on the calendar. This is common practice in automotive and electronics supply chains, and we have adapted it for textiles. A Harvard Business Review case study on capacity reservation contracts explains the risk-sharing principles involved.

What is the minimum order quantity (MOQ) after an approved 48-hour sample?

This question comes up in every single negotiation. The client says: "You proved you can print 5 meters quickly. But your production MOQ is 1,500 meters per design. I only need 300 meters for a capsule collection launch. Can you help?"

Our policy is flexible, but not unlimited. We cannot economically run a full-scale reactive dye production line for 300 meters. The setup time is the same as for 3,000 meters. The chemical consumption for the steamer and washer is fixed regardless of yardage. However, we have three solutions:

-

Digital production: We can run up to 800 meters of digital printing with no screen costs and very fast turnaround. This is ideal for capsule collections, test markets, and pre-orders. The price per meter is higher than screen printing, but there is no MOQ and no dead stock risk.

-

Consolidation programs: We batch multiple small orders from different clients that use the same base fabric and similar color palettes. This spreads the fixed costs. We do this monthly for a group of New York emerging designers.

-

Greige ownership: If you commit to a total annual volume, we can release fabric in smaller monthly installments. The overall MOQ is met across the year, but your cash flow is spread.

The worst thing a brand can do is hide their true volume needs. If you tell me you need 10,000 meters but you actually only need 800, I will quote a price based on 10k economics. When the order comes in at 800 meters, the price jumps 40%, and everyone is unhappy. Tell us the truth. We will find a solution. I discussed this exact challenge in a podcast interview with The Interline Drops, where I explained why honesty about volume forecasts is the most underrated sourcing skill.

Conclusion

Our 48-hour sample delivery is not a marketing gimmick. It is a deliberately engineered system built on dedicated equipment, deep greige inventory, expert color management, and parallel processing workflows. We do not achieve this speed by cutting corners. We achieve it by removing waiting time.

I have watched this capability transform our clients' businesses. The Los Angeles brand that called me in a panic in 2022 now launches 6 micro-collections per year instead of 2. They test patterns on social media, see what sells, and reorder only the winning designs. Their inventory turns increased from 2.8 to 5.1 in 24 months. The Seattle brand that sent us that Tuesday afternoon request now treats our development calendar as an extension of their own design studio. They do not buffer 3 weeks for sampling; they buffer 3 days.

This is the future of textile sourcing. The brands that win will not be the ones with the absolute lowest FOB price per yard. They will be the ones who can move from concept to consumer in the shortest elapsed time. Fast samples are the first domino.

If you are tired of waiting 12 days for a strike-off that misses the color target, I invite you to test our system. Send us a design file. Send us a Pantone. Send us a target fabric construction from our greige library. We will ship you a physical sample with QC data attached within 48 hours of file approval. You will feel the difference.

Contact Elaine, our Business Director, to schedule your first 48-hour sample test. She oversees our R&D sample workflow and personally ensures that urgent requests receive priority routing. Elaine’s email is: elaine@fumaoclothing.com. Tell her you are ready to go fast.