Let's be honest—finding the perfect fabric is only half the battle. The real magic (and often the biggest headache) begins when you need that fabric in your specific shade of blush, forest green, or heather grey. I've been on both sides of this table for twenty years. I've seen designers fly across the world with a scrap of vintage fabric, and I've watched production managers pull their hair out because batch three doesn't match batch one. The difference between a successful custom color run and a costly mistake isn't luck; it's a process. A good supplier doesn't just take your Pantone number; they become your partner in translating an idea into a consistent, producible reality.

Working with a fabric supplier on custom color matching is a collaborative, multi-step process that moves from inspiration to lab dip to bulk approval. Success hinges on clear communication, understanding material limitations, and rigorous quality control. It's a dance between your creative vision and the supplier's technical expertise in dyes, fibers, and production.

Think of it like this: you're the architect with a vision for a unique paint color, and we're the master painters who know exactly how the paint reacts to different surfaces, light, and weather. My goal here is to give you the insider's playbook—the exact steps, questions, and red flags that we use inside Shanghai Fumao to ensure every meter of fabric is not just close, but perfect. This will save you time, money, and immense frustration.

What Are the Key Steps in the Color Matching Process?

The journey from "I want this color" to having 5,000 meters of it on your cutting table is a defined path. Skipping steps or making assumptions at any stage is where things go wrong. A structured process is your best defense against surprises.

A professional color matching workflow is a funnel. It starts wide with inspiration and narrows down through precision and verification. Each step has a clear deliverable and a decision point. Let me outline the standard flow we follow with our clients, which has given us a 98% first-bulk-pass rate.

How Do You Start with an Effective Color Brief?

This is the most critical, and often most rushed, phase. A vague brief guarantees multiple, costly lab dip rounds. Your brief must be specific, physical, and contextualized.

- Provide a Physical Standard: Never rely solely on a Pantone number or a digital image. Pantone textiles are printed on paper, which dyes differently than fabric. A digital screen is not color-managed. The gold standard is a physical fabric swatch in the color you want. Second best is a Pantone cotton chip. Tell us, "Match to THIS." In 2023, a client from Denmark sent us a 50-year-old wool scarf as their color standard for a new coat line. The challenge wasn't just the color, but replicating the faded, heathered quality. Our lab had to deconstruct the dye composition.

- Define the Conditions: Under what light is this color most important? Metamerism is the phenomenon where a color looks different under different light sources. A perfect match in our lab (D65 daylight simulation) might look off in store lighting (TL84) or outdoor sunlight. Specify: "Must match under north daylight and standard office LED."

- Know Your Fiber: You can't match a color on polyester to a wool swatch perfectly; the fibers take dyes differently. Be clear on your base fabric. The brief for our Shanghai Fumao team always includes: 1) Physical standard, 2) Target fabric composition, 3) Critical viewing light, 4) Acceptable tolerance (e.g., "commercial match" vs. "very close match").

For a deeper understanding of how professionals build a technical package for apparel sourcing, which includes the color brief, resources like Techpacker's blog offer practical templates and explanations.

What Happens During the Lab Dip Stage?

This is where our magic starts. Once we have your brief, our lab technicians get to work.

- Dye Recipe Formulation: Using a spectrophotometer, we analyze your physical standard to get digital LAB values. Our database of thousands of dye recipes suggests a starting formula.

- Small-Batch Dyeing: We dye a small swatch (the "lab dip") of your actual production fabric (or a very close substitute) using this recipe.

- Measurement & Submission: We measure the lab dip under controlled light (using a light box) against your standard. We then send you at least 3 lab dips with slight variations (a little redder, a little greener, a little deeper). This gives you a choice and shows the color's neighborhood.

Your job is to review them under the lighting conditions you specified. Do not review them on your desk under mixed lighting! Use a portable light box. Mark your feedback clearly: "#2 is closest, but please make it 10% less yellow and 5% deeper." Clear, directional feedback is key. A forum like Wet Canvas for artists surprisingly has great threads on the science of color perception and matching, which underscores why consistent viewing conditions are non-negotiable.

How to Communicate Clearly and Avoid Costly Mistakes?

Communication in color matching is a technical language. "Make it pop more" or "make it creamier" leads to confusion, delays, and cost overruns. You need to speak in terms both creative and technical teams understand.

Ambiguity is the enemy of accuracy. Establishing a clear, objective vocabulary and feedback loop with your supplier is what separates amateurs from professionals. This is where your partnership truly forms.

What is the Right Vocabulary for Color Feedback?

Stop using subjective adjectives. Start using the industry-standard parameters of color:

- Depth/Darkness: "Please make the shade deeper/darker" or "lighter."

- Chroma/Saturation: "Increase the chroma (make it more vivid)" or "reduce the chroma (make it duller/more muted)."

- Hue: "Shift the hue slightly more towards red/green/blue/yellow."

- Metamerism: "The lab dip and standard match in daylight but mismatch under fluorescent light. Please correct."

The best feedback references a physical sample with markup. We provide feedback forms where you can tick boxes and write brief comments next to each swatch. For example, a client once wrote: "Lab Dip A: Depth good. Hue: Shift slightly from orange-red to true red. Chroma: Reduce by 15%." That instruction allowed us to adjust the dye recipe with precision and get approval in the next round.

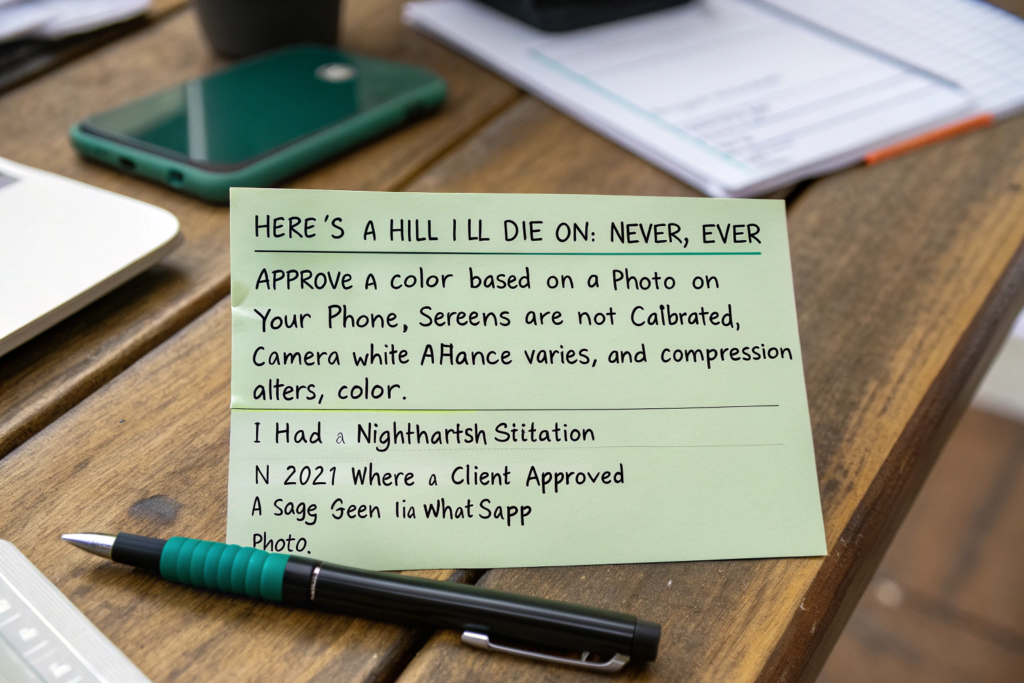

Why are Digital Approvals Risky?

(Here’s a hill I’ll die on: never, ever approve a color based on a photo on your phone.) Screens are not calibrated, camera white balance varies, and compression alters colors. I had a nightmarish situation in 2021 where a client approved a "sage green" via WhatsApp photo. In person, it was mint. The entire 3,000-meter batch was rejected. We now have a strict policy: Physical sample approval is mandatory for the first bulk production. We even offer expedited courier services for samples because it's cheaper than a remake.

For managing the approval workflow digitally while still using physical samples, platforms like Backbone are used by major brands to centralize feedback and maintain an audit trail, ensuring everyone is literally on the same page.

What Technical Factors Influence Color Matching?

Color isn't just about the dye; it's a conversation between the dye, the fiber, the water, and the machine. Understanding these variables helps set realistic expectations and troubleshoot issues before they become disasters.

You wouldn't expect the same paint to look identical on wood, metal, and drywall. Fabric is the same. The substrate dictates the result. A professional supplier controls these variables so you don't have to.

How Does Fiber Content Affect the Outcome?

Different fibers have different affinities for dye types.

- Natural Fibers (Cotton, Wool, Silk): Use different dye classes (reactive, acid) than synthetics. They often yield softer, more nuanced colors but can be less colorfast. Matching a color across a cotton-polyester blend is a classic challenge because you're essentially dyeing two different fibers in one bath. Our lab has to find a dye cocktail that works on both.

- Synthetic Fibers (Polyester, Nylon): Require disperse dyes at high temperatures. They can achieve very vibrant, sharp colors with excellent wash fastness. However, matching a specific matte, dusty tone on polyester can be harder than on cotton.

- Blends: This is advanced-level matching. For a 65% Polyester, 35% Cotton heather grey, the goal is for both fibers to be dyed to the same shade so the fabric looks uniform, not speckled. This requires precise dye selection and timing.

What Role Do Dyeing Methods and Finishes Play?

The machine and the final finish dramatically alter the color's appearance.

- Jet Dyeing vs. Jig Dyeing: Jet dyeing (for knits) is more turbulent and can produce slightly different results than jig dyeing (for wovens), even with the same recipe.

- Finishing: Applying a water-repellent (DWR) finish or a softener will change the hand and often deepen the shade slightly. A calendaring or brushing process will alter how light reflects off the surface, affecting perceived color. Your approved lab dip and strike-off must go through the same finishing process planned for bulk. We learned this the hard way early on; now, our strike-offs are finished on miniaturized versions of our finishing lines.

A resource like the SDC (Society of Dyers and Colourists) website, while technical, offers foundational knowledge on the chemistry of textile dyes and their application methods, which can help you ask smarter questions.

How to Ensure Consistency from Sample to Bulk Production?

Approving a beautiful lab dip and strike-off feels like victory. But the real test is when the 10-ton dyeing machine starts up. Consistency at scale is the ultimate mark of a superior supplier.

Bulk production introduces variables that don't exist in the lab: water chemistry, bath exhaustion, temperature gradients. The process from this point is about control, measurement, and verification.

What is a Strike-Off and Why is it Crucial?

A strike-off (or handloom sample) is your final checkpoint before bulk. It is a 1-3 meter length of fabric, dyed and finished on the actual production machinery that will be used for the bulk order, using the final approved dye recipe.

This is non-negotiable. It confirms that the color works in production conditions and that the hand, weight, and finish are correct. You must approve the strike-off. At Shanghai Fumao, we include a spectrophotometer report with the strike-off, showing the delta-E (color difference) value against the standard. A delta-E of less than 1.0 is typically imperceptible to the human eye, and we aim for that.

How is Quality Control Maintained During Bulk Dyeing?

This is where our systems earn their keep.

- Batch Standardization: The first 50 meters from the dyeing machine are cut, finished, and checked against the approved strike-off under the light box. This is the "bulk standard."

- In-Line Monitoring: Parameters like temperature, pH, and dye concentration are monitored throughout the run.

- Lot-to-Lot Consistency: For orders larger than one dye lot, we use the first lot as the standard for the next. Our lab technicians are present on the dye house floor to make micro-adjustments between lots to ensure seamless consistency. For a major US activewear brand in 2022, we dyed 8 lots of a performance navy blue over 6 weeks for a 50,000-meter order. The delta-E variation across all lots was under 0.8, which is exceptional.

We also conduct post-dyeing fastness tests (wash, rub, light, perspiration) on bulk fabric to ensure the color won't fail in use. This data is part of our QR code traceability system, so you can access the test reports for your specific batch.

Conclusion

Mastering custom color matching is about embracing it as a structured, collaborative science, not a mysterious art. It's a partnership built on clear physical standards, precise technical communication, and a deep understanding of the materials and processes involved. The goal is to move from a subjective "I'll know it when I see it" to an objective, measurable, and repeatable production standard.

The most successful brands view their fabric supplier's color lab as an extension of their own design studio. They involve us early, share their challenges, and trust our technical guidance. This partnership turns color from a major risk into a reliable, brand-defining asset.

If you're ready to move beyond the guesswork and frustration of color matching and want a partner with the technical depth, vertical control, and commitment to consistency that this process demands, let's connect. At Shanghai Fumao, we have the CNAS-accredited lab, the experienced technicians, and the rigorous processes to deliver your color, batch after batch. Contact our Business Director, Elaine, to start a conversation about your next custom color project. She'll arrange for you to send your standards and connect you with our lab team. Email Elaine at elaine@fumaoclothing.com.