You're designing a pair of leggings or a sleek dress that needs to move with the body. You know you need "stretch fabric," but when you start looking, the options are overwhelming: Spandex, Elastane, Lycra, stretch cotton, stretch denim... Which one is actually best? Choosing the wrong stretch fabric can lead to bagging, loss of shape, pilling, or an uncomfortable fit that disappoints your customers. The right choice, however, creates garments that look good, feel incredible, and perform flawlessly—whether on the yoga mat or the dance floor.

The "best" stretch fabric isn't a single material; it's the optimal blend and construction tailored for a specific purpose. For high-performance athletic wear, you need synthetics like Nylon-Spandex or Polyester-Spandex blends that offer superior moisture management, recovery, and durability. For fashion-forward everyday wear, natural blends like Cotton-Spandex or innovative fabrics like Stretch Linen provide comfort, breathability, and a more natural hand feel. The key lies in understanding the core mechanics of stretch: the fiber (usually Spandex/Elastane/Lycra, which are all polyurethane-based) provides the elasticity, while the companion fiber (Nylon, Polyester, Cotton, etc.) dictates the fabric's primary characteristics.

At Shanghai Fumao, we develop and supply stretch fabrics for global brands daily. We've seen collections succeed or stumble based on this crucial choice. This guide will cut through the marketing terms and dive into the technical and practical differences, so you can select the perfect stretch foundation for your designs with confidence. Let's unravel what makes stretch fabrics work and which ones truly deliver.

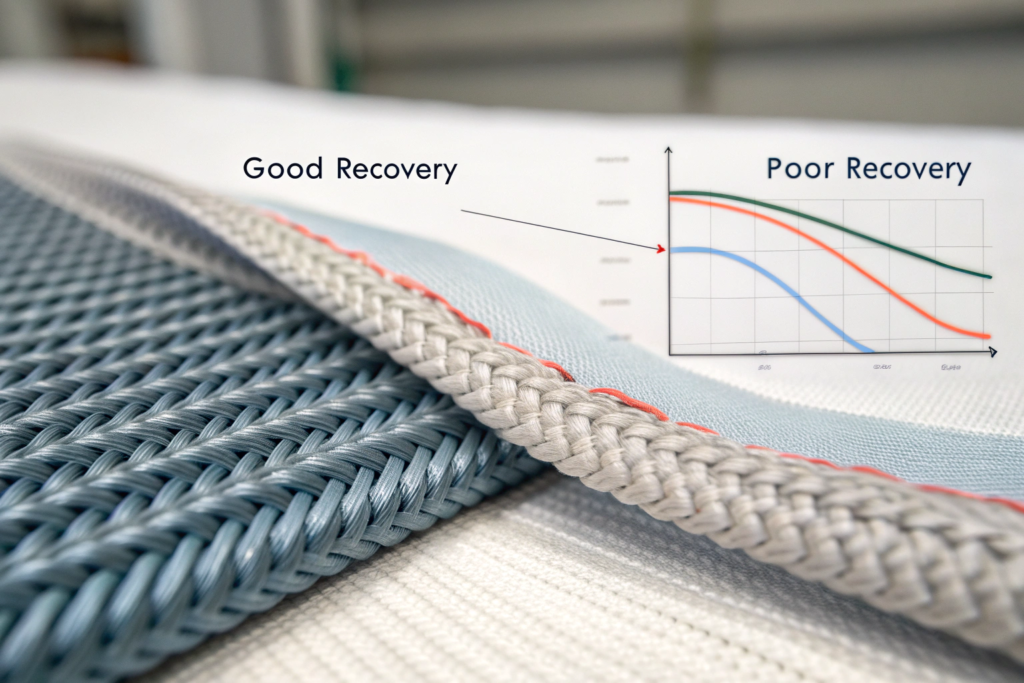

What Makes a Fabric Stretch, and Why Does Recovery Matter?

At its heart, stretch is a simple mechanical property: a fabric's ability to extend under tension and then return to its original shape. But not all stretch is created equal. The magic (and the science) is in the recovery—the fabric's ability to snap back completely after being stretched. Poor recovery is the culprit behind knee bags in leggings, sagging seat panels in jeans, and overall garment distortion.

Stretch is primarily imparted by a small percentage of elastane fibers (the generic term; Spandex is the U.S. brand name, Lycra is a DuPont brand) woven or knitted into the fabric. Typically constituting 5%-20% of the blend, these polyurethane-based fibers act like microscopic springs. The surrounding "hard fibers" (like nylon or cotton) provide structure, durability, and surface characteristics. The construction (knit vs. woven) also plays a huge role. Knits are inherently stretchy due to their looped structure, while wovens achieve stretch primarily through the elastane yarns.

How Do Elastane Percentages Affect Performance and Durability?

The percentage of elastane is a critical specification that dictates power, comfort, and longevity. It's a balancing act.

- Low Elastane (2%-5%): Found in stretch wovens like denim, chinos, and shirting. Provides comfort and ease of movement for fashion applications but not for compression or high-stretch activities. Offers good durability as the elastane is less stressed.

- Medium Elastane (10%-15%): The sweet spot for most activewear (leggings, sports bras). Provides significant stretch and compression for support, with strong recovery. This is where fabric engineering is key—the companion fiber must be strong enough to handle the repeated stress.

- High Elastane (15%-20%+): Used for swimwear and high-compression garments (like recovery wear). Offers maximum stretch and hug, but places immense stress on the elastane, making the quality of the elastane yarn and the dyeing/finishing process paramount to prevent degradation from chlorine, sweat, and UV exposure.

A common mistake is assuming "more elastane = better." We had a client in 2023 who sourced a 20% elastane polyester blend for lounge leggings, wanting "super stretch." The result was a fabric that felt overly tight, heated up quickly, and showed premature wear at the seams. We advised a switch to a 12% elastane, air-textured polyester blend for better moisture wicking and a more comfortable, durable hand. The lesson: the percentage must match the end-use.

Why is Two-Way vs. Four-Way Stretch a Critical Distinction?

This defines the direction of the stretch and is fundamental to garment design and function.

- Two-Way Stretch: Fabric stretches in one direction only, typically along the width (weft) of the fabric. Common in many woven stretch fabrics and some basic knits. It provides comfort but not the all-around flexibility needed for form-fitting, active garments.

- Four-Way Stretch (or 360° Stretch): Fabric stretches both widthwise and lengthwise, and crucially, on the bias (diagonally). This is the hallmark of high-performance activewear. It allows for unrestricted, multi-directional movement, ensures the garment moves with the body without riding up or down, and provides comfortable, even compression.

For a yoga brand we work with, specifying a true four-way stretch fabric with mechanical recovery was non-negotiable. Their tech packs require that fabric recovers to within 98% of its original length after a cyclic stretch test. This ensures their leggings don't become loose and baggy after a few months of downward dogs. Understanding the technical specifications for athletic stretch fabrics is essential for any performance line.

Nylon-Spandex vs. Polyester-Spandex: Which is Better for Performance?

This is the great debate in activewear. Both are champions, but for slightly different events. Your choice will impact moisture management, softness, durability, color vibrancy, and cost. There's no universal "best," only the best for your specific design goals and price point.

Think of it like this: Nylon-Spandex is often the premium choice for feel and performance, while Polyester-Spandex is the versatile, durable, and often more cost-effective workhorse. The decision should be driven by the garment's primary function. Is it for high-sweat, high-intensity training? Is it for everyday athleisure where color retention and easy care are priorities?

When Should You Choose Nylon-Spandex Blends?

Nylon (polyamide) is renowned for its exceptionally soft, smooth, and luxurious hand feel. It dyes beautifully, producing rich, vibrant colors. From a performance perspective, it has excellent moisture-wicking properties, pulling sweat away from the skin efficiently. However, it is generally less resistant to chlorine and UV degradation than polyester and can be more prone to pilling if a lower-quality yarn is used.

Choose Nylon-Spandex when:

- Premium Feel is Key: For luxury activewear or lingerie where softness against the skin is a primary selling point.

- Vibrant Color is Required: For designs with deep, saturated hues or color-blocking.

- High-Intensity, Short-Duration Activity: Its excellent wicking is ideal for workouts where managing sweat quickly is crucial.

We developed a custom 40-denier circular knit nylon-spandex fabric for a European dancewear brand. Their priority was a "second-skin" feel with dramatic color saturation for stage wear. The nylon base delivered the dazzling color, while a specific matte finishing process we applied reduced shine and enhanced the premium hand. The key was using a high-tenacity nylon yarn to mitigate pilling.

What are the Advantages of Polyester-Spandex Fabrics?

Polyester is the durable, resilient, and often more affordable synthetic. It has superior resistance to chlorine, UV rays, and abrasion, making it the go-to for swimwear and outdoor activewear. It dries incredibly quickly and holds its shape well. Modern polyester yarns, especially recycled polyester (rPET), have overcome the "plastic-y" feel of the past, with technologies like micro-encapsulation and texturing creating softer, more breathable fabrics.

Choose Polyester-Spandex when:

- Durability & Value are Priorities: For everyday athleisure, school uniforms, or budget-conscious lines.

- Swimwear or Outdoor Use: Its chlorine and UV resistance are unmatched.

- Sustainability is a Focus: rPET blends offer a strong eco-story with performance.

- Easy Care is Important: It's generally more resistant to wrinkles and easier to care for.

A client making hiking tights needed fabric that could withstand sun, abrasion from rocks, and frequent washing. We recommended a recycled polyester-spandex blend with a bi-elastic weave and a DWR (Durable Water Repellent) finish. The polyester provided the durability and UV protection, while the construction and finish managed moisture and added a layer of weather resistance. For reliable sourcing of these functional blends, reviewing directories of performance fabric suppliers can be helpful.

Can Natural Fiber Blends (Cotton, Linen) Offer True Comfort Stretch?

Absolutely. While they won't provide the high-power compression of synthetic performance fabrics, natural fiber stretch blends are the cornerstone of modern, comfortable casual and fashion wear. They combine the beloved natural properties of breathability, moisture absorption, and skin-friendliness with the practical benefits of stretch for improved fit and mobility.

The challenge with natural fibers is that cotton, linen, and wool aren't inherently elastic. The stretch comes entirely from the integrated elastane (usually 2%-5% for wovens, up to 10% for knits). The resulting fabric offers what's often called "comfort stretch"—enough give to move with you throughout the day without the constriction of a rigid fabric. Think of the perfect pair of jeans that don't gap at the waist, or a linen-blend blazer that allows you to reach without pulling.

Why is Cotton-Spandex the King of Everyday Casual Wear?

Cotton-Spandex, especially in jersey knits, is the workhorse of the fashion world. It's affordable, breathable, easy to dye, and comfortable. The stretch allows for more forgiving, body-skimming silhouettes without the need for complex patterning. The key to a good cotton-spandex is the quality of the cotton (combed vs. carded, long-staple) and the placement of the elastane.

- Core-Spun Yarn: The elastane filament is wrapped in cotton fibers. This hides the elastane, gives a more natural cotton hand, and protects it during dyeing and finishing, leading to better recovery and longevity.

- Bare Lycra/Elastane: The elastane is knitted in alongside cotton yarns. This can sometimes be felt as a slightly rubbery texture and may be less durable.

At Shanghai Fumao, our best-selling fashion knit is a 94% Combed Cotton, 6% Spandex single jersey. We use a core-spun yarn and a special enzyme wash finish for vintage cotton softness. This fabric has virtually no shrinkage (<3%) and maintains its shape wash after wash, which is a major selling point for our brand clients who need reliability. For basic, high-volume items, understanding global cotton-spandex jersey market trends helps in forecasting and costing.

How are Designers Successfully Using Stretch Linen and Wool?

Innovation in spinning and weaving has brought stretch to traditionally rigid natural fabrics, opening new design possibilities.

- Stretch Linen: Pure linen is crisp and can wrinkle. By blending with 3-5% elastane (or using a stretch woven construction with elastane in the weft), you get a fabric that retains linen's beautiful drape and breathability but with added give. It's perfect for tailored-but-comfortable trousers, relaxed blazers, and summer dresses that need to move. The finish is critical here—too much chemical softener can kill linen's character.

- Stretch Wool/Wool Blends: Adding 2-5% elastane to wool suiting creates garments with incredible comfort and wrinkle recovery. It allows for slimmer, more modern suiting silhouettes without sacrificing comfort. For a high-end Italian menswear client, we developed a stretch wool-twill that passed rigorous Woolmark certification for performance criteria, including stretch recovery and dimensional stability, making it a premium offering in their line.

What are the Latest Innovations in Sustainable and High-Tech Stretch?

The stretch fabric market is rapidly evolving beyond basic synthetics and blends. The demand for sustainability and enhanced functionality is driving exciting new developments. The "best" fabrics now are those that address environmental concerns without compromising performance, or that offer smart new benefits to the wearer.

This innovation happens at the fiber level, in blending technologies, and through advanced finishing. It’s no longer just about stretch; it’s about stretch plus: plus biodegradability, plus thermoregulation, plus smart sensing capabilities. Brands that leverage these innovations can differentiate themselves in a crowded market.

Are Bio-Based and Recycled Elastanes the Future?

The environmental footprint of traditional, petroleum-based elastane is a significant concern. The industry is responding with:

- Recycled Elastane: Made from post-industrial waste, reducing reliance on virgin petroleum.

- Bio-Based Elastane: Derived from renewable resources like corn sugar. These fibers, such as some new-generation Lycra® offerings, offer comparable performance with a significantly reduced carbon footprint.

- Circularity Initiatives: Development of elastane that is easier to separate and recycle at a garment's end-of-life.

Sourcing these fibers requires closer partnership with advanced mills. We are currently working with a forward-thinking sportswear brand on a capsule collection using a fabric made from 100% recycled polyester and bio-based elastane. The challenge is ensuring the dyeing and finishing processes are also optimized for lower environmental impact. Tracking Textile Exchange's material insights is a great way to stay updated on these evolving sustainable fiber options.

What are Phase-Change and Smart Stretch Fabrics?

These are functional fabrics engineered for specific high-end performance.

- Phase-Change Materials (PCM): Microcapsules embedded in the fabric absorb, store, and release heat to help regulate body temperature. Ideal for athletes training in variable conditions or for outdoor apparel.

- Compression & Graduated Stretch: Engineered knits with varying levels of elastane placement to provide targeted muscular support and improve blood flow, used in medical recovery wear and high-end athletic gear.

- Conductive Stretch Fabrics: Integrate metallic or carbon-based yarns to enable touch-sensitive controls, biometric sensing (heart rate, muscle activity), or heating elements. This is the cutting edge of wearable technology.

Developing these requires deep R&D partnerships. Our in-house lab at Shanghai Fumao allows us to test and validate these advanced claims. For instance, we can verify the thermoregulating effect of a PCM finish through standardized testing, providing our clients with the data they need to market these innovations credibly. Exploring market reports on smart textile growth can reveal commercial opportunities.

Conclusion

Choosing the best stretch fabric is a strategic decision that balances performance, aesthetics, cost, and increasingly, sustainability. There is no single winner. The optimal choice is a deliberate match between the fabric's engineered properties and the garment's intended function: Nylon-Spandex for premium feel and intense sweat-wicking, Polyester-Spandex for durable, weather-resistant value, and Natural Fiber Blends for breathable, everyday comfort. The future lies in innovative, sustainable elastanes and smart fabrics that add new dimensions to performance.

Your success depends on moving beyond generic terms and understanding the specifications behind the stretch—the fiber quality, the percentage, the construction, and the finish. This knowledge empowers you to write precise tech packs, communicate effectively with suppliers, and ultimately deliver garments that exceed customer expectations for fit, comfort, and durability.

If navigating the complex world of stretch fabrics feels daunting, partner with experts who live and breathe these details every day. The team at Shanghai Fumao specializes in developing and sourcing the perfect stretch solution for any application, from high-performance athletic wear to the most comfortable fashion staples. Bring us your design challenge, and let's create the fabric that will make your next collection move. Contact our Business Director Elaine at elaine@fumaoclothing.com to start the conversation.