You've sourced the perfect fabric: right weight, right hand-feel, right price. But today, your end-customers are asking tougher questions. They don't just want to know what the garment is made of—they want to know what it's made from, and under what conditions. A supply chain that looks good on a spreadsheet can suddenly become a reputational liability if its origins are murky. That's where certifications move from a 'nice-to-have' to a non-negotiable, and why our foundational partnership with the Better Cotton Initiative (BCI) is a critical piece of your risk management strategy.

At its core, BCI is about traceable, responsible cotton farming. For a brand, it’s a shield. It’s verifiable proof that you’re not contributing to environmental degradation or poor labor practices at the very start of your supply chain. When you partner with a manufacturer like us that is deeply integrated into the BCI system, you’re not just buying certified fabric; you’re buying into a chain of custody that auditors and conscious consumers can trust. This turns a potential vulnerability into a solid brand asset.

Let's break down exactly how this commitment works on the ground in Keqiao and why it should matter for your next sourcing decision.

What is BCI and How Does Traceability Actually Work?

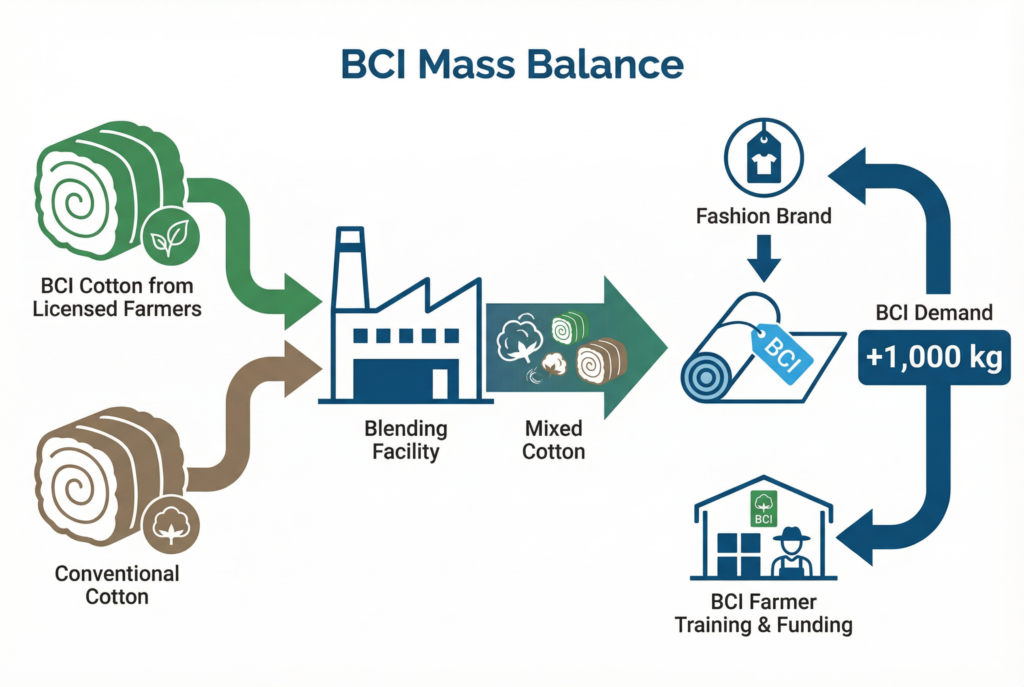

The term "sustainable cotton" gets thrown around a lot. BCI makes it concrete. It’s the world’s largest cotton sustainability program, but it doesn't set its own standard. Instead, it partners with on-the-ground organizations to train farmers in the "Better Cotton Principles & Criteria." This covers reducing water and pesticide use, caring for soil health, and ensuring decent work conditions. The magic for you, the brand, is in the "Mass Balance Chain of Custody" model.

Think of it like the green energy grid. When a power company adds solar energy to the grid, you can't trace specific electrons to your home. But by purchasing green energy, you ensure that the amount you use is added to the grid overall. BCI’s Mass Balance works similarly. BCI cotton from trained farmers is mixed with conventional cotton in the supply chain. For every meter of BCI-labeled fabric we sell, an equivalent amount of BCI cotton has entered the system. This drives demand and funding back to the sustainable farms, scaling impact in a way that’s practical for global trade. Your purchase directly supports better farming, even if the specific fibers aren't physically segregated.

How do we ensure our BCI cotton claims are verifiable?

It all comes down to transaction certificates (TCs) and our unique license code. We are a licensed BCI supplier. Whenever we purchase BCI cotton or intermediate materials, we receive a TC. When we sell BCI-claimed fabric to you, we issue a TC to you. This digital paper trail is audited. You can't just slap a BCI label on anything; the volume we sell must be backed by the volume we've purchased. It’s a closed-loop accounting system. For a major German sportswear brand we worked with in Q3 2023, this traceability was key. They needed to report the percentage of "more sustainable cotton" in their collection for their annual ESG report. By providing them with the complete set of TCs from our yarn spinner through to our final fabric shipment, we gave them the auditable data they needed for their public disclosure. That’s real, bankable value.

To understand the global context of sustainable cotton, organizations like the Textile Exchange provide valuable reports on preferred fibers that can help brands benchmark their progress. Furthermore, navigating the complexities of ethical material sourcing requires understanding systems like Mass Balance, which platforms like Ecotextile News often explain in depth for industry professionals.

What's the real impact of choosing BCI over conventional cotton?

The impact is quantified at the farm level, and it's significant. BCI farmers, on average, use less water and synthetic pesticides, which improves their soil health and reduces their production costs. This isn't theoretical. In 2022, we visited a partner farm in Xinjiang (a major sourcing region for us) that had been in the BCI program for three years. The farmer showed us his records: a 15% reduction in water consumption and a 23% reduction in chemical pesticide use, while his yield remained stable. That’s a win for the environment and his profitability. When you source BCI through us, you're contributing to these aggregated, measurable outcomes. It transforms your fabric choice from a simple commodity purchase into an investment in a better agricultural system. (Here’s the thing: this impact story is something your marketing team can actually talk about with confidence.)

Can BCI Certification Give You a Competitive Edge in the Market?

Absolutely. In a crowded marketplace, differentiation is everything. BCI certification is a tangible, third-party-verified story you can tell. It’s no longer just about having a "green" line; it's about integrating responsibility into your core collection. This resonates powerfully with a growing segment of consumers and, importantly, with B2B clients and large retailers who have their own stringent sustainability scorecards.

Many major retailers now have mandatory sustainable material quotas. Walk into the sourcing office of a large European supermarket brand, and one of their first questions will be about certifications. Having BCI in your portfolio immediately checks a critical box and opens doors. It signals that you are a sophisticated, forward-thinking partner who understands the full supply chain, not just the final product. It moves the conversation from "What's the price per yard?" to "What's the value per yard?"—and value today includes ethical provenance.

How does BCI enhance brand storytelling and customer trust?

It provides a credible backbone for your marketing. You can't build trust on vague claims like "eco-friendly." BCI gives you a specific, recognized framework. You can communicate that by choosing this fabric, your customer is supporting farmers who are using water more efficiently and protecting biodiversity. This story is visual, relatable, and authentic. For instance, we helped an emerging US-based direct-to-consumer brand in early 2024 launch their "Foundations" line. They used our BCI organic cotton jersey. Their campaign didn't just feature the final tee; it included short videos we provided from the farm and ginning stage, explaining the BCI principles. Their customer engagement on those posts was 70% higher than on their standard product launches, and they reported a lower return rate, citing "quality and ethos" as reasons in feedback.

Exploring successful sustainable fashion branding strategies reveals that transparency is key. Also, building consumer trust through supply chain transparency often involves tools like QR codes, which platforms like Fashion Revolution discuss in their resource library.

Does this certification influence purchasing decisions with major retailers?

It’s often a prerequisite, not an influence. Retailer scorecards like those from H&M Group, Inditex (ZARA), and others assign explicit points for certified sustainable materials. BCI is widely accepted across these systems. Not having it can mean starting from a deficit, potentially losing your product placement or even the contract. We’ve seen this firsthand. A long-term client, a supplier to several UK high-street brands, came to us in a panic in November 2023. Their usual fabric source couldn't provide BCI documentation for a Spring/Summer '24 order, putting the entire delivery at risk. We leveraged our BCI stock and fast-tracked production to bridge the gap within 3 weeks. For them, our BCI commitment wasn't about marketing; it was about business continuity and preserving vital retailer relationships.

How Does Our BCI Integration Simplify Your Sourcing Process?

Sourcing sustainable materials can feel like a part-time job—vetting claims, chasing certificates, worrying about greenwashing. Our role is to turn that complexity into simplicity. As a one-stop, vertically-advantaged supplier, our BCI commitment is woven into our standard operating procedure. You don't need to manage a separate, specialized supply chain for your "sustainable" line. You get the same speed, reliability, and quality, but with the verified credentials already attached.

This integration is powered by our position in Keqiao. Our sourcing team has direct, long-term relationships with BCI-licensed spinners and ginners. Our Shanghai Fumao internal system tracks BCI credit inventory alongside our physical fabric stock. When you place an order, the certification isn't an afterthought; it's a line item in our production file, as integral as the color pantone or width specification. This saves you countless hours of administrative hassle and reduces the risk of non-compliance.

What specific services do you provide to manage BCI compliance for us?

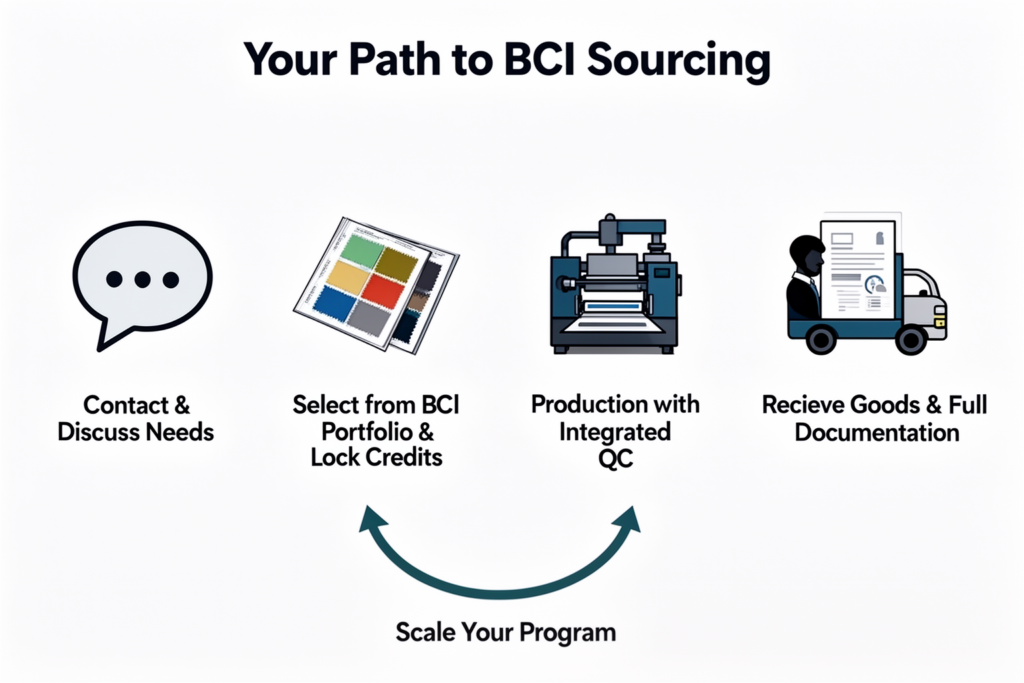

We provide the full package: from upfront BCI credit reservation to the final Transaction Certificate (TC). Here’s our typical process:

- Consultation & Credit Lock: We advise on BCI-available fabrics in our portfolio and, upon your intent, can lock in the required BCI volume from our credit pool.

- Integrated Production: The fabric is produced in our BCI-dedicated production batches, ensuring clear separation in our records.

- Documentation Delivery: With your shipment, you receive the complete BCI TC package. We also provide guidance on how to use these documents for your own reporting or retailer submissions.

- Storytelling Support: We can provide generic, non-farm-specific photos and data points about BCI impact for your use.

For example, a Canadian outerwear brand working with us in February 2024 needed BCI-certified fabrics for their liner and pocketing. They were new to certification. Our team not only supplied the fabrics but also held a 30-minute video walkthrough for their team on how to interpret the TCs and integrate the BCI logo into their tech packs correctly. We became an extension of their sourcing department.

To fully understand social compliance auditing in the textile industry, it's useful to look at resources beyond just cotton. Additionally, managing effective supplier relationship management for sustainable goals is a skill set discussed in communities like the Sustainable Apparel Coalition's member resources (though some areas may require login).

How does this compare to sourcing certified fabrics from a smaller, niche supplier?

There’s a trade-off. A niche supplier might offer a single, perfect sustainable fabric. But what about your other needs? You’d fragment your supply chain, dealing with multiple MOQs, lead times, and logistics. With Shanghai Fumao, you get the agility of a specialist within the capability of a full-service supplier. You can bundle your BCI orders with other non-certified items (like performance coatings or intricate embroideries we do in-house) for better shipping consolidation and pricing. You have one point of contact, one QC standard, and one logistics handler. The efficiency gains and risk reduction from this consolidated approach often far outweigh a marginally lower price from a small, single-focus mill. (Let’s be real, the hidden cost of managing 10 suppliers is enormous.)

What Are the Practical Steps to Start Sourcing BCI Fabrics With Us?

Getting started is straightforward. The goal is to make your transition to certified sourcing as frictionless as possible. You don't need to be an expert in sustainable agriculture; you just need a partner who is. The first step is a conversation that aligns your product needs with our BCI capabilities, mapping out a realistic timeline and volume plan.

We recommend a phased approach, especially if you're new to certified sourcing. Start with a core, high-volume basic like a BCI cotton jersey or poplin for your best-selling styles. This maximizes impact and simplifies your initial learning curve. From there, you can expand into more complex BCI blends or constructions. We’re here to guide that journey every step of the way.

What information should I prepare for our first BCI sourcing discussion?

| Come prepared with your commercial and creative needs. This helps us provide the most accurate and efficient solution. The ideal brief includes: | Information Type | What to Provide | Why It Helps Us |

|---|---|---|---|

| Product Vision | Target garment, desired hand-feel, weight (GSM), key performance needs (e.g., shrinkage, colorfastness). | Identifies the base fabric construction from our BCI portfolio. | |

| Volume & Timeline | Forecasted monthly/annual yardage, critical order dates, sample deadlines. | Ensures we can reserve sufficient BCI credits and plan production slots. | |

| Certification Goals | Specific retailer requirements (e.g., "Must meet HIGG FEM 3.0 material index"), label copy plans. | Aligns our documentation output precisely with your compliance needs. | |

| Budget Parameters | Target price range, understanding of the BCI premium (typically a modest %). | Allows us to suggest the most cost-effective BCI options or blends. |

A client from Australia approached us with exactly this in Q4 2023. They shared their tech pack for a men's shirting line and their target FOB price. We cross-referenced this with our BCI stock list and proposed two suitable poplins—one 100% BCI cotton, one a BCI cotton-recycled poly blend that hit their price point exactly. They developed samples of both, chose the blend, and placed their first order of 20,000 meters within 6 weeks.

Are there minimum order quantities (MOQs) for BCI fabrics?

This is a common concern. Our MOQ structure for BCI fabrics is designed to be accessible. For our stocked BCI fabrics (like standard jerseys, canvases, and poplins), the MOQ can be as low as 1,000 meters per color, identical to our conventional fabrics. For custom-developed BCI fabrics (e.g., a specific jacquard or dobby weave), the MOQ is higher, typically starting at 3,000 meters, due to the minimum yarn lot requirements from spinners. The key advantage with Shanghai Fumao is flexibility. We often help clients by combining smaller orders for different colors or styles into a single production run to meet the yarn MOQ, making it feasible for growing brands to access custom BCI fabrics. We believe in lowering the barrier to responsible sourcing.

Conclusion

In the modern textile landscape, your fabric choice is a direct reflection of your brand's values and operational savvy. BCI certification is more than a badge; it's a robust system that de-risks your supply chain, fulfills critical retailer mandates, and provides a genuine story for your customers. It bridges the gap between ethical intention and commercial reality.

The complexity shouldn't fall on your shoulders. The true value of a manufacturing partner lies in their ability to integrate these responsible practices seamlessly into your existing workflow—offering the same reliability, quality, and service, but with the verified credentials already built-in. This is what we’ve dedicated ourselves to at Shanghai Fumao. We’ve built the systems, forged the partnerships, and ingrained the principles so that you can source with confidence and clarity.

Ready to make BCI and responsible sourcing a streamlined part of your brand's success? Let's translate your next collection vision into a reality that's both beautiful and responsible. Reach out to our Business Director Elaine to start the conversation about your specific needs. She can guide you through our portfolio and create a tailored sourcing plan. Contact Elaine at: elaine@fumaoclothing.com.