Wildland firefighters face unique hazards: extreme heat, unpredictable winds, long deployment hours, and constantly shifting terrain. Unlike structural firefighters, who operate mainly indoors, wildland crews must hike miles in rugged environments while carrying heavy gear. They fight flames that can exceed 1,000°F, often under intense sunlight and low humidity. This makes their personal protective equipment (PPE) very different from the bunker gear used in cities. Many procurement managers, safety officers, and apparel developers ask the same question: why is the NFPA 1977 standard so critical? The answer lies in how this standard reduces risks while guiding manufacturers like us in producing compliant, high-performance gear.

NFPA 1977 matters because it sets the minimum performance requirements for protective clothing and equipment used in wildland firefighting. These requirements help prevent burn injuries, maintain mobility, and protect firefighters from environmental exposure, while also focusing on breathability and comfort during long shifts. For example, garments tested under this standard must resist ignition for at least 12 seconds and limit shrinkage after exposure to 500°F. Helmets and gloves are tested for strength and durability, ensuring that they perform under real fire conditions.

The value of NFPA 1977 is not only about passing lab tests—it is about creating trust. By aligning with this standard, manufacturers, suppliers, and procurement teams provide assurance that every firefighter is equipped with reliable protection in the line of duty.

What Does NFPA 1977 Certification Include?

NFPA 1977 is a detailed standard from the National Fire Protection Association that focuses exclusively on wildland firefighting PPE. It first appeared in the early 1980s and has been updated multiple times, most recently to reflect climate-driven wildfire changes and textile innovations. Unlike structural firefighting standards, it ensures that every element of wildland gear—from clothing to boots—is designed to provide both protection and comfort.

NFPA 1977 covers garments, gloves, helmets, face/neck shrouds, and footwear for wildland firefighting. Each item must pass strict performance tests for flame resistance, heat durability, seam strength, and shrinkage control. Helmets must be lightweight yet impact-resistant, gloves must balance dexterity and protection, and boots must withstand sharp terrain and heat exposure.

What fabrics meet NFPA 1977 requirements?

Approved fabrics often include aramid fibers such as Nomex and Kevlar, which do not melt or drip when exposed to high heat. These fibers maintain strength even after repeated washing. Some advanced blends combine aramids with Lenzing FR viscose, adding softness and moisture control. By contrast, untreated cotton is excluded because it ignites too easily and offers inconsistent protection after laundering. Materials must resist ignition and shrink less than 5% after exposure to 500°F.

How is PPE performance tested under NFPA 1977?

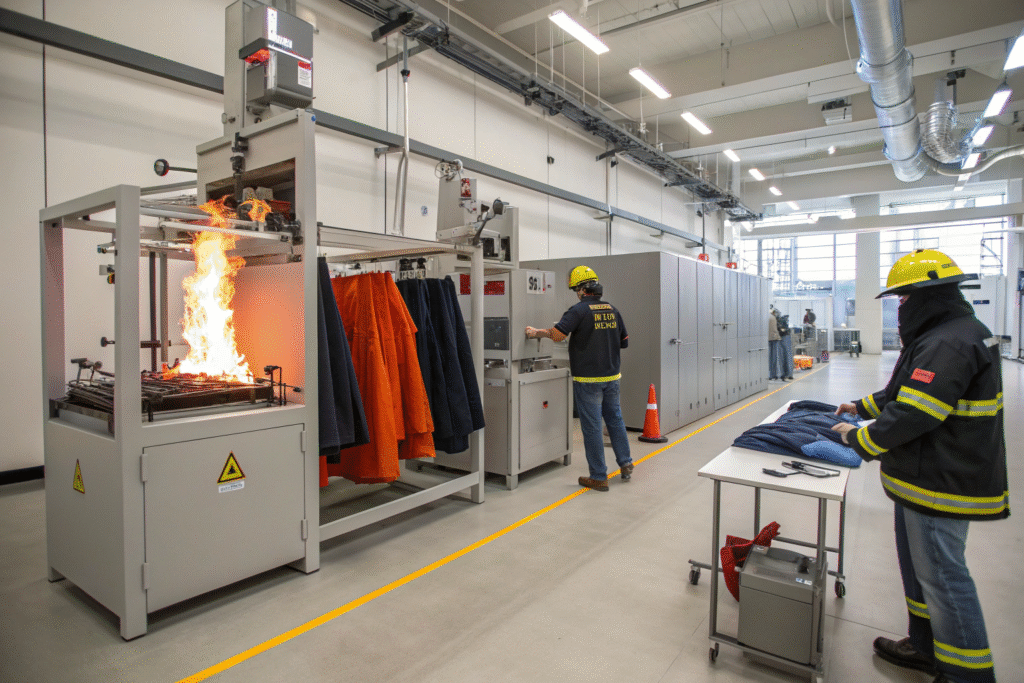

Testing is rigorous. Garments must show tear resistance, seam durability, and flame resistance. For instance, seams must resist tearing under 22 pounds of force, and fabrics must not sustain flame spread longer than 2 seconds after ignition. The UL fire testing process includes both laboratory assessments and field simulations. Gloves are evaluated for dexterity—firefighters must be able to handle small tools without losing grip—while helmets undergo drop tests to confirm impact resistance.

Why Is Breathability and Mobility So Important?

Wildland firefighting is not about quick interior fire attacks—it is about endurance, heat management, and mobility. Firefighters often work 12–16 hour shifts, hiking uphill while digging fire lines, cutting brush, and carrying equipment. According to U.S. Forest Service data, 25% of wildland firefighter medical incidents are caused by heat stress, not burns. This makes breathable PPE just as important as fire-resistant PPE.

NFPA 1977 emphasizes lightweight, breathable materials to lower the risk of heat stress while still providing flame protection. Typical wildland gear weighs about half as much as structural firefighting gear. Garments are often 6–8 oz/yd² compared to 12–14 oz/yd² bunker gear. This difference allows firefighters to stay cooler and conserve energy, which is critical during long deployments.

Why does breathable design prevent injuries?

Research from the NIOSH Firefighter Program shows that PPE that traps heat can raise core body temperature by 2–3°C within an hour. This increases risks of dehydration, reduced alertness, and even cardiac incidents. NFPA 1977 requires fabrics that allow sweat to evaporate and airflow to cool the body, reducing fatigue and keeping decision-making sharp.

How does mobility improve firefighting efficiency?

Wildland crews need to run, crouch, climb, and swing axes. Gear that is too stiff or heavy slows them down and increases fatigue. To address this, many NFPA 1977 garments use ripstop weaves that resist tearing and articulated knees and shoulders for better movement. Flexible design reduces strain on joints and prevents accidents during rapid movements. For example, some manufacturers use elastic gussets behind the shoulders so firefighters can swing tools without fabric pulling tight.

Recraft指令-- Show firefighters climbing a rocky hill under bright sun, wearing lightweight flame-resistant gear with visible ventilation zones. Highlight sweat evaporation, ripstop textures, and articulated joints that allow crouching and swinging axes.

How Is NFPA 1977 Different From Other Firefighting Standards?

Many buyers confuse wildland PPE with structural PPE, but the two are very different. Departments that accidentally issue NFPA 1971 bunker gear for wildland use often report higher rates of heat exhaustion, with some studies showing a 40% increase in heat-related incidents.

NFPA 1977 is unique because it focuses on sustained radiant heat and mobility, not flashover survival. Structural firefighting gear (NFPA 1971) is designed to resist extreme flashovers for a few seconds at up to 1,800°F. Wildland gear, by contrast, must handle lower but prolonged heat exposure—around 500°F—for hours.

What makes NFPA 1977 a specialized standard?

According to NFPA resources, wildland firefighters rarely encounter flashovers, but they face radiant heat for hours while working outdoors. That is why NFPA 1977 focuses on fabrics that will not melt, drip, or shrink excessively. Helmets, boots, and gloves must also be lightweight and heat-resistant without sacrificing comfort.

Why is dual certification uncommon?

Some manufacturers attempt dual certification under NFPA 1971 and 1977. However, results are mixed. Structural gear is too heavy for wildland operations, and wildland gear cannot handle structural flashovers. A report from the California Department of Forestry found that dual-certified suits reduced mobility by 15%, leading to slower evacuation. Procurement managers are advised to choose gear designed specifically for its intended use.

What Should Buyers Consider When Procuring NFPA 1977 PPE?

For safety officers and purchasing managers, buying NFPA 1977-compliant gear is about more than checking for a certification label. With more than 58,000 wildfires reported in the U.S. in 2023, the demand for reliable PPE is growing. Procurement mistakes can cost lives, waste budgets, and delay firefighting operations.

Buyers should look for suppliers with proven compliance, third-party lab testing, and reliable logistics support. The right supplier not only provides certified gear but also ensures fast delivery, customization, and strong after-sales service.

How can buyers confirm compliance?

The safest way is to request lab test reports from organizations like Intertek or SGS. These reports confirm that the fabric passes shrinkage, flame spread, and seam strength tests. Every garment should carry an NFPA 1977 label with the certification body’s mark. In addition, some agencies—like the U.S. Forest Service—conduct real-world field testing that buyers can review before procurement.

Why does supplier reliability matter?

A supplier with an integrated supply chain can deliver bulk orders in 30–45 days, compared to 60–90 days from fragmented networks. Suppliers with in-house weaving, dyeing, and coating reduce risks of delays. Reliable partners also offer customization, QR code tracking for batch quality, and experience with tariff compliance. This ensures buyers avoid unexpected costs and receive gear that is both safe and timely.

Conclusion

NFPA 1977 is more than just a guideline—it is a lifeline. It ensures that every piece of PPE balances flame resistance, mobility, and comfort for wildland firefighters. By understanding its scope, comparing it with other standards, and working with reliable suppliers, procurement teams can protect their crews and optimize investment. Every decision about PPE has a direct impact on the safety and performance of those on the fire line.

If you are looking to source or customize NFPA 1977-compliant fabrics and garments, we at Shanghai Fumao can help. Our Business Director, Elaine, is available to support your procurement needs and provide technical guidance. You can reach her directly at elaine@fumaoclothing.com.