When a customer buys a shirt and it shrinks after one wash, they may never buy from that brand again. For garment makers, even a small percentage of shrinkage can ruin fit, cause returns, and damage brand trust. That’s why fabric shrinkage testing is not just a lab formality—it’s a foundational quality control step.

Fabric shrinkage testing allows garment makers to predict how fabrics will behave after washing and drying, ensuring size stability and product consistency. This testing informs pattern design, garment finishing, and even how you label the washing instructions. Without it, your product is vulnerable to fit complaints and high return rates.

At Fumao, we test every fabric batch—whether it's for a kid’s t-shirt, a formal dress, or sportswear. Over the years, we’ve seen how shrinkage issues can ripple through a supply chain if not handled early. In this article, I’ll share exactly why shrinkage testing is essential, what methods work best, and how you can interpret and act on test results.

What Causes Fabric Shrinkage After Washing?

Every fiber reacts differently to heat, water, and agitation. Whether you’re using cotton, polyester, rayon, or blends, understanding how fabrics contract is critical to making stable garments.

Fabric shrinkage occurs when the yarns or fibers relax after mechanical tension is released through heat or moisture, resulting in dimensional changes. Knowing these tendencies helps adjust for shrinkage in design and production.

How Do Natural Fibers Behave in Shrinkage?

Natural fibers like cotton, linen, and wool are prone to shrinkage because they swell and contract under moisture and heat. Cotton, for instance, can shrink up to 3–5%, especially if not pre-shrunk.

Learn more about how cotton responds to laundering and why pre-treatment is often required to stabilize it before cutting.

What About Synthetic and Blended Fabrics?

Synthetics like polyester or nylon shrink less because their filaments are heat-set during production. However, when blended with unstable fibers (e.g., rayon or modal), overall shrinkage increases.

Refer to this guide to fabric shrinkage behaviors to compare common textile types and how they react to laundering.

How Is Fabric Shrinkage Testing Conducted?

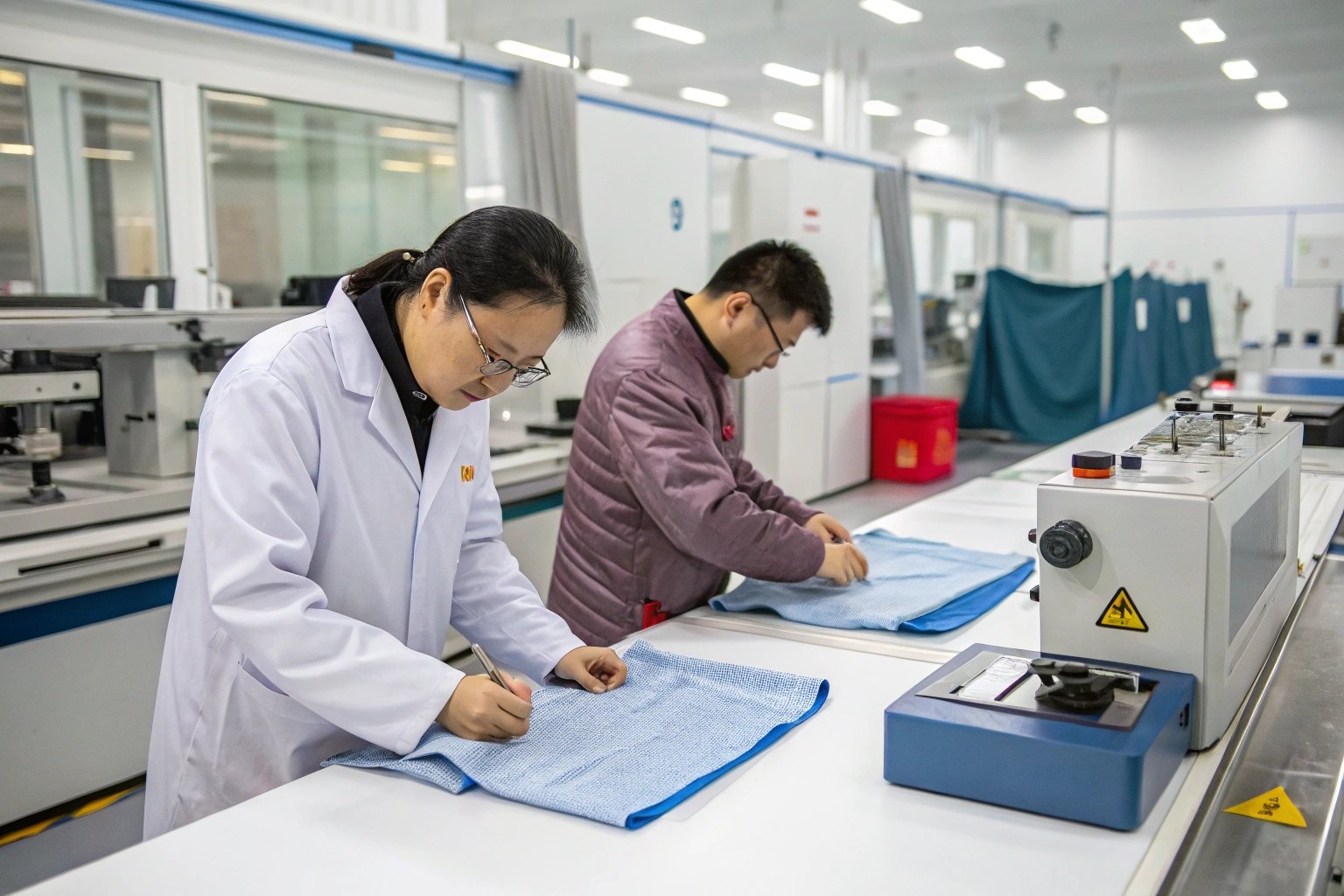

Testing may sound technical, but it’s actually standardized and straightforward. At Fumao, we use international testing methods like ISO and AATCC to ensure global compliance.

The most common method for fabric shrinkage testing is washing a marked sample under controlled conditions, then measuring dimensional change. The results are expressed as a percentage of shrinkage or growth in warp and weft directions.

What Are the Standard Testing Methods?

Two major standards dominate shrinkage testing:

- AATCC 135 & AATCC 150 (U.S. standard): Simulate home laundry methods

- ISO 6330: Used internationally, especially in Europe and China

Each test involves washing and drying samples using specified cycles. For deeper info, review the AATCC official shrinkage test protocols for garment durability labs.

How Are Results Interpreted?

Shrinkage is calculated using this formula:

Shrinkage % = ((Original Length - Final Length) ÷ Original Length) × 100

For example, if a fabric originally measured 100cm and ended up 97cm, it has shrunk 3%. This result informs the need for pre-shrinking or pattern adjustments.

Get sample calculations from this shrinkage test report format to understand how to read professional lab outputs.

Why Is Shrinkage Data Crucial During Pattern Making?

Imagine cutting 1,000 dresses and discovering post-production that they’re all too tight after washing. Pattern misalignment caused by ignoring shrinkage can become a costly mistake.

Shrinkage data allows patternmakers to adjust garment dimensions proactively, ensuring the final product fits as intended even after laundering. This is especially important in form-fitting or structured apparel.

How Do Designers Use Shrinkage Data?

Patternmakers apply shrinkage allowances during CAD pattern development. For example, if a knit fabric shrinks 4% in length, the designer may add 4% to vertical seams to compensate.

Modern CAD software like Gerber AccuMark or Lectra lets users input shrinkage values to auto-adjust pattern pieces.

What If You Skip This Step?

Without accurate compensation, garments may shrink too much, twist at seams, or develop tension points. This not only hurts brand reputation but can lead to failed inspections and retail rejections.

A recent case study on apparel QC failures showed shrinkage issues accounted for 15–20% of size-related returns in some ecommerce brands.

How Can Shrinkage Testing Reduce Returns and Complaints?

Returns are expensive. Whether you’re selling on Amazon or to a department store, every return cuts into profit and reputation. Most shrinkage complaints come not from cheap fabric—but from untested fabric.

Shrinkage testing reduces returns by ensuring garments maintain their labeled size and fit across real-world washing conditions. It’s a small step that prevents big problems.

How Much Return Risk Comes from Shrinkage?

Surveys show that fit issues account for over 40% of apparel returns in ecommerce. And within those, fabric shrinkage is a major hidden cause. Customers rarely understand why a garment “doesn’t fit anymore”—they just assume poor quality.

Read how ReturnLogic breaks down common reasons for return in fashion retail.

Can Testing Be a Sales Advantage?

Yes. Brands now use “pre-shrunk” or “shrink-tested” as marketing features. Some even include a note in packaging or product pages about shrinkage compliance, giving confidence to the customer.

This REI example on fabric shrinkage labeling shows how simple language can reduce buyer hesitation.

Conclusion

Fabric shrinkage testing is not optional—it’s essential. Whether you're developing basics, luxury apparel, or sportswear, this test saves you from returns, redesigns, and reputation risk. At Fumao, we don’t just offer fabric—we provide full shrinkage testing reports with every development sample. Our CNAS-certified lab ensures your garments fit perfectly wash after wash, helping you keep your customers happy and your sizing consistent across every batch.