Static electricity in hazardous environments is a silent but dangerous threat. If it’s not managed, a tiny spark can ignite flammable gases, dust, or liquids — causing catastrophic accidents. For industries like petrochemicals, pharmaceuticals, or fuel handling, protective clothing isn’t just a precaution — it’s a life-saving necessity.

The EN 1149-1 standard sets the testing framework for measuring a fabric’s surface resistivity, ensuring that anti-static suits can dissipate electrical charges effectively. This is critical for worker safety, compliance with international regulations, and maintaining a company’s operational integrity.

I have spent over two decades in the textile manufacturing industry, supplying high-performance fabrics for global industrial clients. Over the years, I’ve seen how EN 1149-1 compliance has become a decisive factor in procurement decisions — especially for multinational companies operating in strict safety-regulated sectors.

What Is EN 1149-1 and How Does It Work?

EN 1149-1 is a European standard that specifies the test method for surface resistivity of protective clothing materials. It evaluates how well the fabric can dissipate static electricity from its surface to prevent electrostatic discharges.

It’s a lab-based test, where a defined voltage is applied to the fabric, and the resulting electrical resistance is measured. The lower the resistance, the faster the static charge can disperse.

How Does Surface Resistivity Measurement Ensure Safety?

Surface resistivity testing determines if the fabric can conduct static charges safely. According to BSI Group’s explanation, a compliant material ensures that electrostatic energy won’t accumulate to dangerous levels.

Why Do Some Fabrics Fail EN 1149-1?

Fabrics can fail due to poor conductive fiber integration, environmental factors like humidity, or fabric degradation over time. According to Textile World, improper yarn blending can drastically increase resistivity.

Why Is EN 1149-1 Compliance Essential in Hazardous Industries?

Hazardous industries — such as petrochemical plants, grain silos, and explosive manufacturing — are high-risk environments where a single static spark can lead to massive explosions.

What Risks Do Non-Compliant Suits Pose?

A non-compliant suit may allow static buildup, which could ignite volatile substances. According to HSE UK guidelines, electrostatic ignition is a documented cause of industrial fires.

How Does EN 1149-1 Support Regulatory Compliance?

Meeting EN 1149-1 helps companies comply with broader PPE regulations like the EU PPE Regulation (EU) 2016/425. As per EU OSHA, compliance also ensures legal protection for employers in case of accidents.

How to Test and Certify Anti-Static Fabrics?

Testing anti-static fabrics involves more than just one measurement. While EN 1149-1 focuses on surface resistivity, related standards like EN 1149-3 test charge decay, and EN 1149-5 covers garment design requirements.

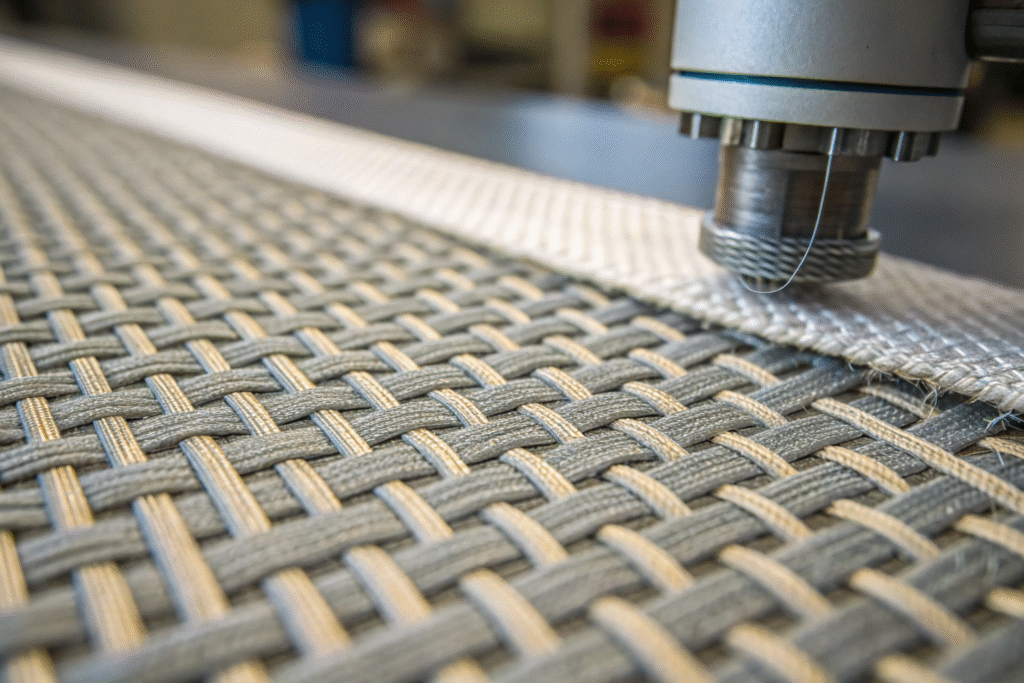

What Equipment Is Used in EN 1149-1 Testing?

Labs use high-precision resistivity meters and climate-controlled test chambers. Intertek explains that controlling humidity is crucial since moisture affects conductivity.

How Long Does Certification Take?

Certification can take weeks to months depending on lab capacity, sample availability, and documentation. SGS notes that pre-testing fabrics in-house can shorten approval time.

How Can Manufacturers Ensure Ongoing Compliance?

Even after certification, maintaining compliance is an ongoing responsibility. Fabrics must be consistently produced to the same specifications, with regular batch testing.

What Role Does Quality Control Play?

A robust QC process ensures every batch meets EN 1149-1 before shipment. ISO guidelines stress that in-process checks reduce failure rates dramatically.

Can Environmental Changes Affect Performance?

Yes — high humidity or contamination can lower performance. As Occupational Safety and Health Administration points out, storage and handling conditions are just as critical as production.

Conclusion

The EN 1149-1 standard is more than a technical requirement — it’s a safeguard for human life and industrial safety. For companies in high-risk sectors, compliance ensures both legal and operational security. As a manufacturer deeply involved in producing certified anti-static fabrics, we understand that safety begins with the right materials.

If you’re sourcing anti-static hazard suit fabrics, Shanghai Fumao can deliver tested, certified, and ready-for-use solutions. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your production needs.