In global fabric and medical textile sourcing, one recurring challenge remains: many fabrics marketed as “protective” are not scientifically validated. This gap becomes serious when suppliers aim at U.S. and European healthcare markets, where regulations are unforgiving. Shipments can be rejected, contracts canceled, and reputations damaged when virus filtration standards are not met. From my academic background and professional work in textiles, I have seen how lack of compliance can cost both suppliers and buyers more than money—it can cost trust.

ASTM F2298 stands as the international benchmark for virus filtration efficiency (VFE), providing a standardized and scientific evaluation method. This test defines whether a fabric can be trusted to protect against airborne viruses. For manufacturers, distributors, and medical procurement specialists, ASTM F2298 is not a “nice-to-have”—it is a global requirement that ensures readiness for healthcare use.

At Fumao Fabric, rooted in the heart of Keqiao, Zhejiang, we understand that compliance is the lifeline of exports. Meeting ASTM F2298 not only builds confidence but also reinforces our credibility in over 100 countries, where buyers expect proof of performance, not just promises.

What Does ASTM F2298 Measure?

When global buyers search for reliable fabrics, they often confront contradictory claims. Some suppliers emphasize “virus resistance,” while others highlight bacterial standards. The question becomes: how can buyers differentiate?

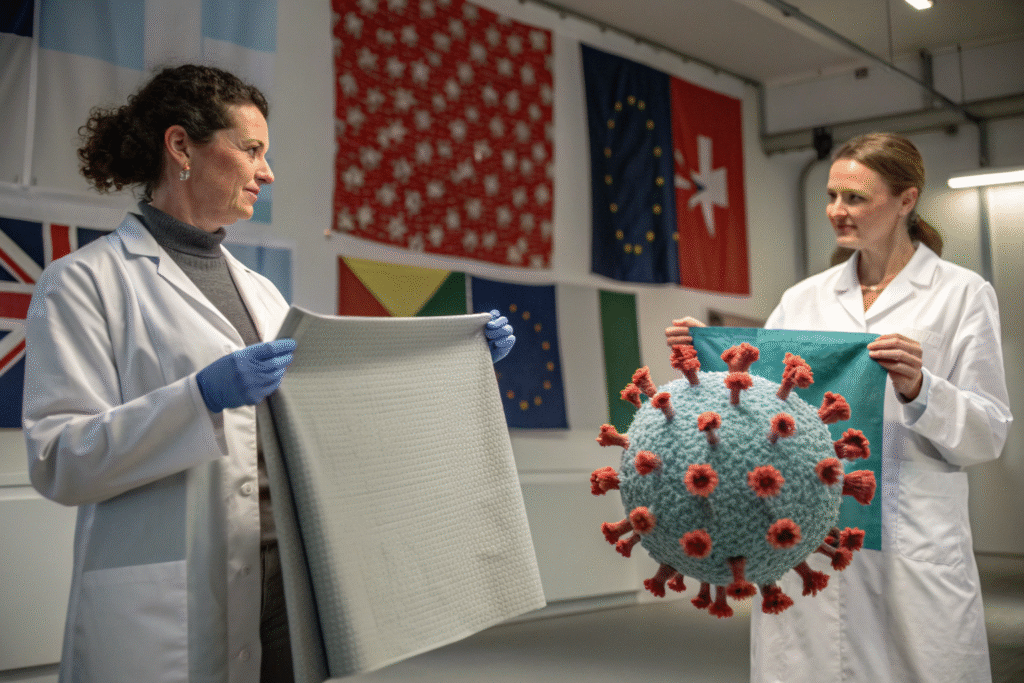

ASTM F2298 directly measures a fabric’s virus filtration efficiency (VFE) using the bacteriophage phiX174 as the test organism. This allows fabrics to be ranked with precise data, making procurement decisions clearer and safer. Unlike marketing claims, this is a repeatable, laboratory-proven evaluation that ensures confidence for both medical and non-medical buyers.

How Is VFE Testing Conducted?

The test involves generating an aerosolized suspension of the phiX174 bacteriophage and passing it through the textile. The concentration of viral particles is measured before and after filtration. The resulting efficiency percentage shows how effectively the fabric blocks viruses. A VFE of 98% means almost total protection, which is crucial for hospital-grade materials. More about the technical framework is explained in ASTM International’s official documentation and reinforced by the FDA’s PPE guidance.

Why Does Standardization Matter?

Without a recognized benchmark, buyers would face incomparable claims and uncertain protection. ASTM F2298 ensures that all fabrics undergo the same rigorous testing, producing data that global hospitals, governments, and buyers can trust. It levels the playing field, especially in international tenders where compliance documentation is mandatory. Suppliers without this certification often find themselves excluded regardless of fabric quality.

How Does ASTM F2298 Compare to Other Standards?

Confusion often arises when buyers ask if VFE testing is equivalent to bacterial or particle filtration standards. The short answer is no.

ASTM F2298 is unique in focusing on virus-level filtration, unlike bacterial filtration efficiency (BFE) or particle filtration efficiency (PFE). This makes it indispensable in contexts where viral protection is paramount.

Is VFE More Demanding Than BFE?

Yes. Viruses, including the phiX174 used in ASTM testing, are significantly smaller than bacteria. This makes VFE testing more stringent and more representative of real viral exposure. For instance, while BFE may be sufficient for general protective masks, healthcare settings demand virus-specific validation. Detailed comparisons can be reviewed at Nelson Labs BFE testing and CDC’s NIOSH filtration overview.

Where Does It Fit With Global Certifications?

- ASTM F2100: Evaluates overall mask performance.

- EN 14683: Governs European mask quality, focusing on bacterial filtration.

- ISO 22611: Measures protective clothing against liquid-borne contaminants.

ASTM F2298 fills the missing link by targeting virus-level filtration. It complements rather than replaces these standards, making it indispensable for full compliance.

Why Is It Critical for Global Buyers?

Buyers like Ron in the U.S. face major challenges—tariffs, logistics delays, and regulatory rejections. In this climate, having ASTM F2298-certified fabrics is a way to reduce risk and ensure smooth entry into Western markets.

Compliance with ASTM F2298 accelerates approvals, reduces duplicate testing costs, and increases buyer confidence in supply chain reliability.

How Does It Affect Supply Chain Decisions?

When buyers receive ASTM F2298 reports upfront, they eliminate the need for re-testing in destination countries. This saves weeks of lead time and thousands of dollars. In addition, many U.S. hospital tenders list ASTM F2298 as a prerequisite, which streamlines acceptance. Guidance from U.S. Trade.gov on compliance and Textile World confirm this procurement shift.

Does It Influence Brand Trust?

Yes. Trust is not only earned by product performance but also by providing verifiable certification. During crises such as COVID-19, suppliers with ASTM F2298 reports had immediate credibility, while others struggled. Today, proof of compliance is a branding tool as much as a regulatory requirement.

How Do We Support Clients With ASTM F2298 Compliance?

From my years of academic and professional engagement in fabric testing, I know compliance cannot be treated as optional. It is a guarantee that connects science, safety, and trade.

At Fumao Fabric, ASTM F2298 testing is embedded into our export process, ensuring buyers receive fabrics backed by proven virus filtration performance.

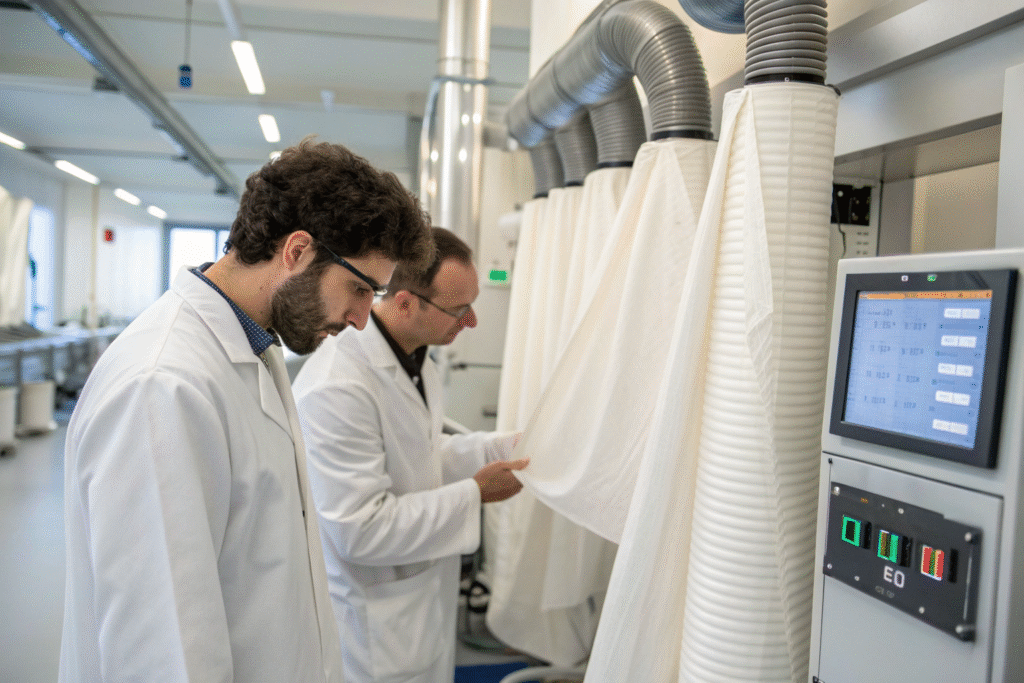

Do We Provide In-House or Third-Party Testing?

We use a dual approach: in-house CNAS-accredited pre-screening and third-party laboratory validation. This reduces risks for clients and ensures impartial test results. Buyers can rely on both technical credibility and efficient turnaround. For reference, accreditation details are available at the CNAS official portal.

What Is Our Commitment to Buyers?

Our commitment is simple: we deliver fabrics with proof. From QR code traceability to detailed test reports, we guarantee that every meter aligns with ASTM F2298 requirements. Whether serving U.S. hospitals or European procurement hubs, our clients can confidently proceed without compliance worries. References from WHO PPE guidance and ISO testing standards illustrate the global framework we follow.

Conclusion

ASTM F2298 defines the future of virus filtration efficiency in textiles. For suppliers, it is the pathway to global trust. For buyers, it is the assurance that products are not only effective but also verifiable in international markets.

At Shanghai Fumao, we combine Keqiao’s deep textile expertise with rigorous testing and certified logistics to ensure that every fabric meets global standards. If you are ready to produce fabrics compliant with ASTM F2298 and secure your supply chain, please reach out to our Business Director Elaine at elaine@fumaoclothing.com to begin your order with confidence.