Many performance wear brands and apparel buyers are looking for the next breakthrough in textile innovation. In high-demand environments—whether it's running, skiing, or military gear—maintaining the body’s ideal temperature can define comfort, endurance, and even safety. The textile industry’s answer? Graphene.

Graphene-infused textiles regulate body temperature by conducting, dissipating, and storing heat, thanks to the unique thermal properties of graphene—a one-atom-thick layer of carbon. These textiles respond to environmental changes, improving warmth in cold conditions and cooling under stress.

As a textile manufacturer rooted in Keqiao, China, we’ve seen a surge in demand for functional fabrics with graphene coatings. This article will unpack what graphene textiles are, how they work, and why they’re transforming thermal regulation in fashion and techwear.

What Makes Graphene Ideal for Thermal Regulation?

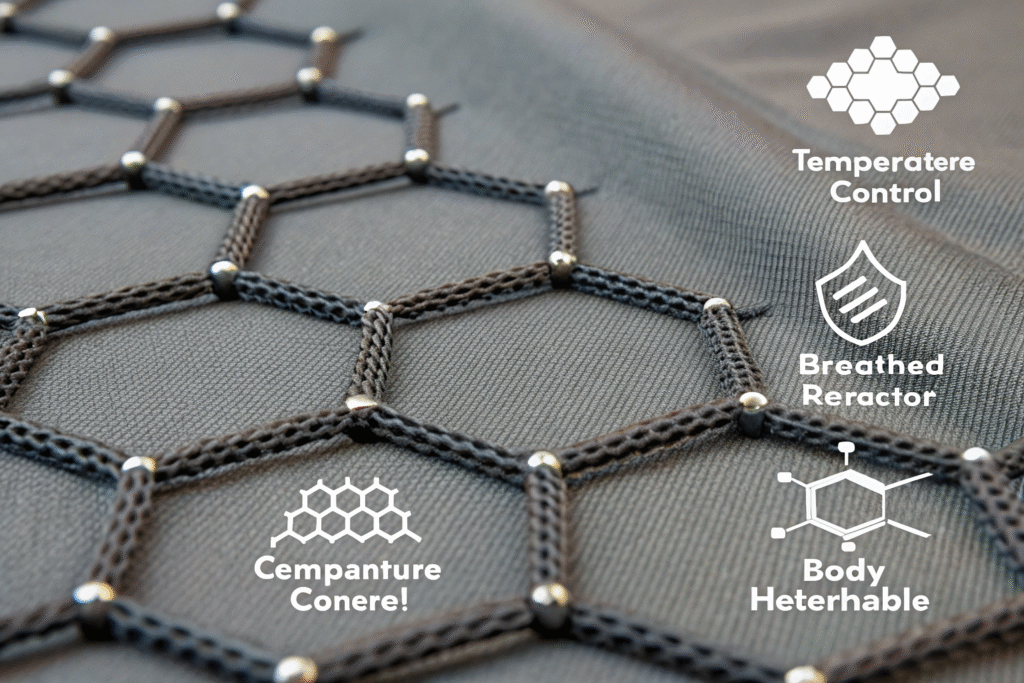

Graphene is a single layer of carbon atoms arranged in a honeycomb lattice. Despite being only one atom thick, it's 200 times stronger than steel and conducts heat better than copper. These thermal characteristics make it uniquely suited for smart textile applications.

When applied to fabric, graphene forms a conductive and breathable surface that regulates heat flow and reduces hot spots on the skin.

How Does Graphene Work in Fabric?

Here’s what happens when you wear graphene-infused apparel:

- Body Heat Distribution: Graphene spreads heat evenly across the fabric to avoid overheating.

- Heat Storage: It stores ambient warmth and slowly releases it to keep you warm in cold environments.

- Moisture Control: Graphene absorbs sweat and allows quick evaporation, keeping the wearer dry.

- UV Shielding: The dark pigment naturally blocks UV rays.

Leading sportswear brands like Columbia and The North Face have begun integrating graphene into outerwear linings, improving adaptability in varying climates.

Is Graphene Safe and Breathable?

Yes—graphene used in textiles is typically in nanoplatelet or coating form. It is REACH-certified and tested to ensure non-toxicity and skin safety. We coat fabrics in ultra-thin graphene layers that maintain softness and breathability while enhancing function.

Which Applications Benefit Most from Graphene Textiles?

Graphene's smart thermal behavior benefits clothing that must perform across temperature extremes or prolonged wear. From base layers to jackets, its versatility enables year-round comfort.

Graphene textiles are now used in activewear, military uniforms, thermal underwear, and cold-weather accessories.

What Garments Benefit Most?

| Product Type | Benefit from Graphene |

|---|---|

| Thermal Underwear | Body heat retention and breathability |

| Outerwear & Jackets | Cold resistance and heat balance |

| Sportswear Tops | Sweat-wicking, odor control |

| Tactical Clothing | IR camouflage, anti-static, insulation |

| Sleepwear | Maintains comfortable night temp |

Brands using Graphene Plus (G+) have launched collections where fabric adapts to body heat output. In our own lab in Keqiao, we’ve supported international buyers developing yoga wear that cools when workouts intensify, yet keeps warmth at rest.

Can It Replace Traditional Insulation?

Graphene doesn’t replace insulation like down or fleece. Rather, it enhances it by spreading retained heat, reducing the need for bulk. For instance, our 3-layer softshell with graphene inner coating achieves warmth comparable to fleece-lined shells—at 30% less weight.

How Is Graphene Applied to Fabric?

Graphene is typically added through coating, spinning into yarn, or printing via screen/digital methods. The approach depends on the intended performance and base textile.

We use eco-certified methods to apply uniform graphene coatings without impacting stretch, breathability, or dye performance.

What Methods Are Used in Manufacturing?

- Coating: Water-based graphene ink is spread on fabric via knife coating or padding.

- Extrusion: Graphene particles are blended into polymer before being spun into yarn (e.g., polyester/nylon).

- Printing: Screen or digital printed graphene zones can target shoulders, back, or thighs for heat mapping.

At Fumao Fabric, our coating lines work with graphene dispersions certified by SGS, ensuring safety and wash durability. Our standard fabric options include:

| Fabric | Finish | Features |

|---|---|---|

| Nylon + Spandex | Printed Graphene | Stretch + quick-dry + thermal |

| Polyester Fleece | Coated Graphene | Insulated + lightweight |

| Cotton Jersey | Graphene Yarn | Antibacterial + breathable |

Is It Wash Durable?

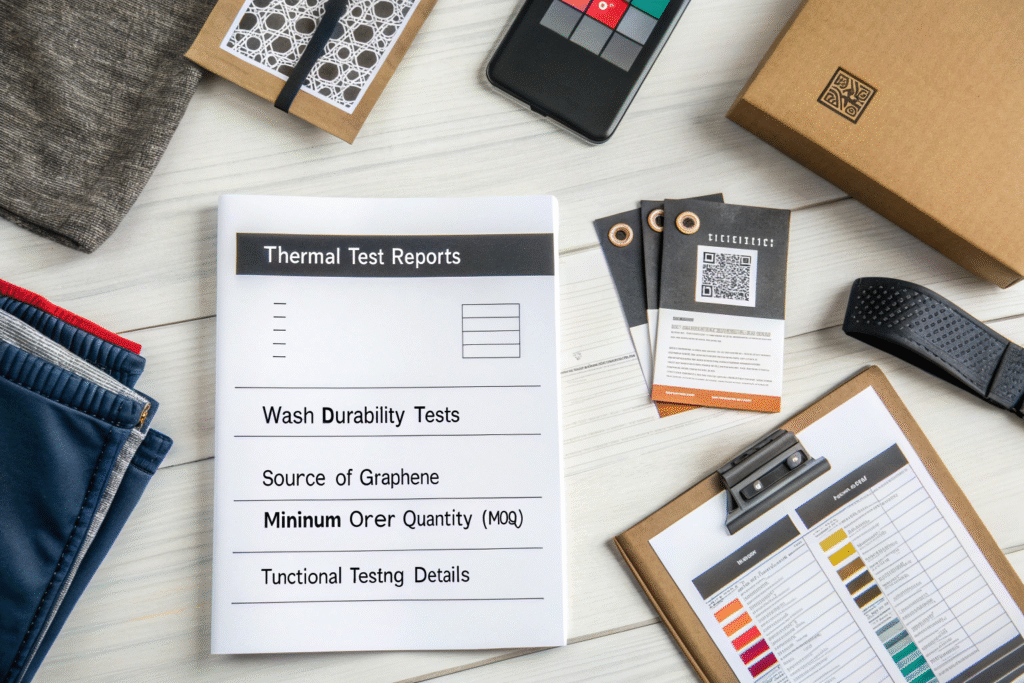

Yes—properly bound graphene particles remain effective up to 30–50 washes under ISO 6330 protocols. Our lab tracks thermal emissivity across cycles to ensure consistent performance for both branded and OEM clients.

What to Ask When Sourcing Graphene-Infused Fabrics?

Sourcing graphene fabrics isn’t just about buzzwords—it requires data. Not all "graphene" textiles are genuine or effective. Many suppliers overstate performance without providing lab tests.

Ask for validated graphene content, thermal resistance charts, and functional wear data before buying.

What Should a Trusted Supplier Provide?

- Graphene Source Document: E.g., Graphene Plus®, NanoXplore®, etc.

- Coating or Blend Method Explanation

- Thermal Testing Data (e.g., ISO 11092)

- Skin Contact Safety Reports (REACH, OEKO-TEX)

- Washing Resistance Reports

- MOQ & Lead Time Transparency

We also provide QR-tagged batches, allowing buyers to trace fiber content, coating method, and batch testing results. You can validate our performance via our SGS-certified lab and request video walkthroughs of our dyeing and finishing lines.

What Is the MOQ for Graphene Textiles?

Due to higher material cost, typical MOQs range from:

- 500 meters/color (coated)

- 800 kg/batch (yarn blend)

- Lead Time: 18–22 days, depending on finish

For brands prototyping smartwear lines or eco-activewear, we offer custom development starting at 300 meters, using stocked graphene dispersions and base fabrics like nylon jersey or polyester fleece.

Conclusion

Graphene-infused textiles represent a new frontier in performance apparel—offering dynamic temperature regulation, durability, and next-generation comfort. Whether you're developing outdoor gear, thermal base layers, or advanced uniform solutions, graphene technology can elevate your brand’s innovation profile.

At Fumao Fabric, we offer fully customized graphene fabrics with verified coatings, performance tests, and global shipping support. From bulk production to small-run prototypes, we help activewear and techwear brands bring intelligent thermoregulation to life.

To explore graphene fabric solutions or request certified samples, contact our Business Director Elaine at elaine@fumaoclothing.com. Let’s build smarter apparel together—layer by layer.