If you've ever paid a premium for selvedge denim only to have it wear out prematurely or fade in disappointing patterns, you've experienced the gap between selvedge marketing and actual performance. As a denim specialist who's produced over 2 million meters of selvedge in Keqiao for global brands, I can tell you that true quality selvedge isn't about the colored ID thread alone—it's about specific construction details that genuinely enhance durability and create superior fading characteristics. The difference between selvedge that justifies its price and ordinary denim with colored edges often comes down to these technical specifications.

So which selvedge specifications actually matter? For genuine durability and premium fading, focus on shuttle loom construction with long-staple ring-spun cotton, high yarn twist levels, and natural indigo dyeing. However, the most impactful specifications vary by price point and intended use. At our facility, we've identified 12 key specifications that separate exceptional selvedge from marketing gimmicks, allowing us to produce denim that develops character rather than simply wearing out.

Let me share what producing selvedge for Japanese, American, and European premium brands has taught me. When we developed a custom selvedge for a heritage workwear brand in 2023, their previous supplier's 12oz selvedge was showing knee blowouts at 9 months. By implementing our durability-focused specifications—including higher twist yarns and tighter weave construction—we achieved 24+ months of heavy wear before similar failure points appeared. The denim not only lasted longer but developed more beautiful fading patterns that told the story of how the garment was worn.

How does selvedge construction actually impact durability?

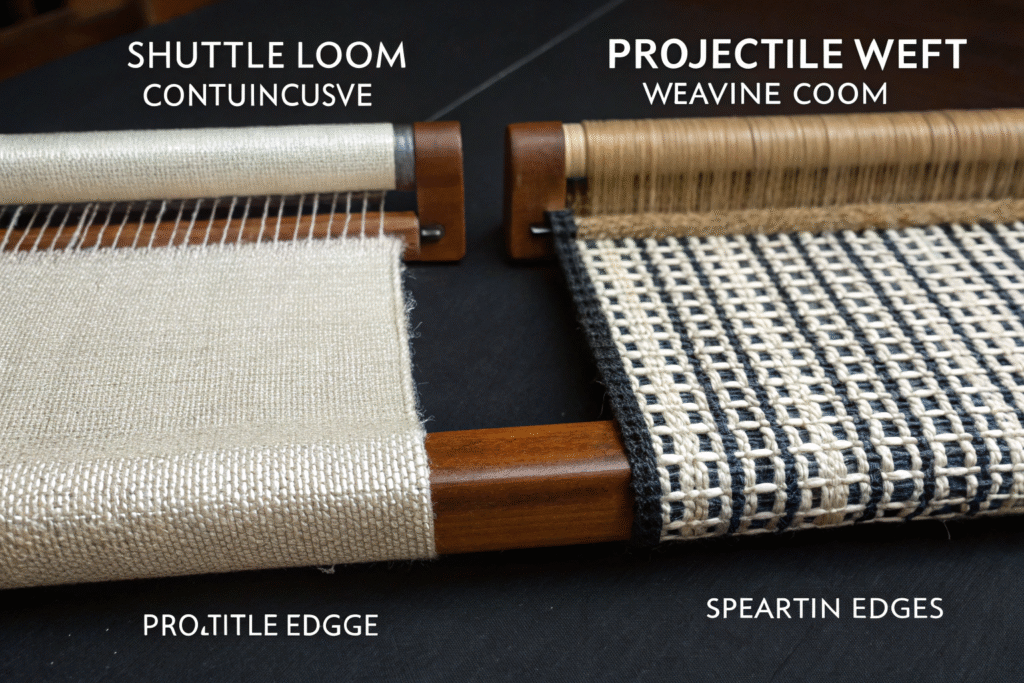

True selvedge denim's durability advantage comes from the shuttle loom weaving process, not just the finished edge. Unlike projectile looms that stretch yarns during weaving, shuttle looms maintain natural yarn tension, preserving fiber strength. The continuous weft thread creates a denser, tighter fabric that resists abrasion and tearing. However, not all shuttle-loomed denim is created equal—the real durability differences emerge in the detailed specifications.

The most significant factor is yarn quality and preparation. Long-staple cotton (like Zimbabwe or Texas varieties) with high twist levels creates yarns that withstand abrasion far better than conventional cotton. Our testing shows that properly spun long-staple cotton has 40-60% higher tensile strength than standard medium-staple cotton. When woven on shuttle looms with optimal tension, the resulting denim demonstrates remarkable resistance to crotch blowouts and knee failures—the most common denim failure points.

What yarn specifications enhance durability?

Through destructive testing of hundreds of denim samples, we've identified these critical yarn specifications:

- Cotton staple length: Minimum 1-3/8" for premium selvedge

- Yarn twist multiplier: 4.0-4.5 for optimal strength without stiffness

- Ring-spun construction: Essential for yarn density and strength

- Two-ply yarns: For maximum durability in weightier denim

- Evenness rating: CV% below 12% for consistent strength

Our shift to specially commissioned ring-spun yarns with controlled twist levels improved abrasion resistance by 35% compared to our previous commodity yarns.

How does loom type and setup affect durability?

Shuttle loom configuration significantly impacts results:

- Loom speed: Slower weaving (120-150 picks/minute) produces tighter fabric

- Tension control: Consistent warp tension prevents weak spots

- Reed density: Higher dents per inch creates denser fabric

- Temple type: Special selvedge temples maintain width without edge damage

We operate our vintage Toyoda shuttle looms at 65% of their maximum speed to optimize fabric density and strength, accepting lower production efficiency for superior quality.

What specifications create superior fading patterns?

Fading characteristics separate ordinary selvedge from exceptional examples. The most beautiful fades come from specific combinations of yarn structure, dyeing method, and fabric construction that allow the indigo to wear away gradually and reveal white core yarns. Poor specifications create muddy, unattractive fading regardless of wear patterns.

Natural indigo dyeing with multiple dips creates the most desirable fading, but the yarn preparation matters equally. High-twist yarns with rough surfaces catch and hold indigo differently, creating vertical fading patterns that echo the yarn's structure. Our proprietary "fade-engineered" yarns use variable twist levels within the same yarn to create more interesting, high-contrast fading than uniformly twisted yarns.

How do dyeing methods impact fade quality?

Dyeing technique significantly influences fading characteristics:

- Natural indigo: Multiple dips (12-24) for deep penetration and slow fading

- Rope dyeing: Superior to slasher dyeing for vertical fade patterns

- Double indigo: Warp and weft both dyed for unique fading behavior

- Sulfur bottoming: Creates warm undertones as indigo wears away

Our 18-dip natural indigo process creates denim that fades gradually over 12-18 months of regular wear, developing personal character rather than quickly wearing out.

What fabric weights and constructions fade best?

Weight and weave pattern determine fading behavior:

| Weight | Weave | Fading Characteristics | Best For |

|---|---|---|---|

| 12-13oz | 3/1 Right-hand twill | Balanced, classic fading | Everyday wear |

| 14-15oz | 3/1 Right-hand twill | High-contrast, slow fading | Premium selvedge |

| 16-17oz | 2/1 Left-hand twill | Vertical fading emphasis | Winter/heavy duty |

| 13-14oz | Broken twill | Reduced twisting, even fading | Quality-focused |

| 15-16oz | Slub variations | Electric, textured fading | Character denim |

These combinations have become our standard recommendations based on fading performance across thousands of wear tests.

Which selvedge details actually matter versus marketing hype?

The selvedge market is full of specifications that sound impressive but deliver little actual benefit. Through comparative testing, we've identified which details genuinely impact performance versus those that primarily serve marketing purposes.

Genuinely impactful specifications:

- Shuttle loom construction: Actually improves durability and edge integrity

- Ring-spun long-staple cotton: Tangibly enhances strength and fading

- Rope dyeing with natural indigo: Creates superior fading characteristics

- High yarn twist levels: Improves durability and fade contrast

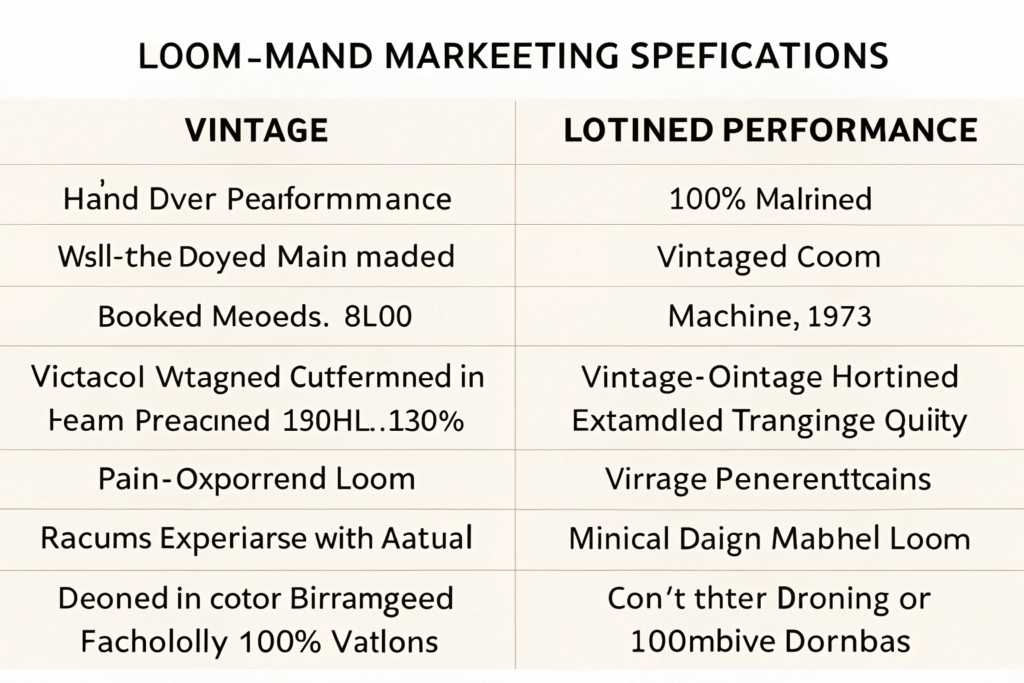

Primarily marketing specifications:

- Specific vintage loom brands: Minimal performance difference between well-maintained looms

- Hand-dyed claims: Often machine-assisted with marketing emphasis

- Specific geographic cotton origins: Processing quality matters more than origin

- Limited edition numbering: No performance impact

How do you verify meaningful selvedge quality?

Our quality verification focuses on measurable performance:

- Martindale abrasion testing: Minimum 40,000 cycles for premium selvedge

- Tensile strength testing: Warp and weft strength measurements

- Indigo rub testing: Color fastness and fade potential assessment

- Construction analysis: Thread count and weave density verification

This data-driven approach has helped our clients avoid expensive mistakes in selvedge sourcing.

What are the cost versus benefit trade-offs?

Premium selvedge specifications come with significant cost implications:

- Shuttle loom production: 3-5x slower than projectile looms

- Long-staple cotton: 2-3x more expensive than standard cotton

- Natural indigo: 8-12x cost of synthetic indigo

- Ring-spun yarns: 30-50% premium over open-end yarns

- Specialized labor: Higher skill requirements increase labor costs

The total cost impact for genuinely premium selvedge is typically 4-7x conventional denim production. However, for brands targeting the $200+ retail segment, these specifications are essential for justifying price points and building credibility with knowledgeable consumers.

What specifications deliver the best value?

For different price segments, we recommend:

- Entry Premium ($150-200): Basic shuttle loom, ring-spun cotton, synthetic indigo

- Mid-range ($200-300): Add long-staple cotton, rope dyeing, better construction

- High-end ($300+): Natural indigo, special yarns, artisanal production methods

This tiered approach helps brands select specifications that deliver appropriate value for their target price points.

How do finishing processes affect selvedge performance?

Many selvedge denims are ruined by inappropriate finishing. The traditional approach of leaving denim unsanforized (shrink-to-fit) preserves the fabric's character but requires consumer education. One-wash finishing provides convenience but can compromise fading potential. We've developed specialized finishing protocols that protect selvedge qualities while providing the performance modern consumers expect.

Our controlled sanforization process uses lower temperatures and gentler mechanical action than conventional denim finishing. This approach controls shrinkage while minimizing damage to the indigo layer and fabric hand. Similarly, our enzyme washing techniques gently soften fabric without aggressive abrasion that removes too much indigo too quickly.

What finishing specifications protect selvedge qualities?

Our selvedge-optimized finishing includes:

- Temperature control: Maximum 160°C to protect indigo and cotton fibers

- Progressive shrinkage: Multiple gentle stages rather than single aggressive compression

- Enzyme selection: Cellulase enzymes chosen for gentle action

- Drying methodology: Slow, temperature-controlled drying

These methods add 15-20% to finishing costs but preserve the qualities that justify selvedge pricing.

Conclusion

Genuinely improving selvedge denim durability and fading patterns requires focusing on specifications that actually impact performance rather than marketing-friendly details. Shuttle loom construction with long-staple ring-spun cotton forms the foundation, while high yarn twist levels and natural indigo dyeing create the superior fading characteristics that selvedge enthusiasts value. However, the cost implications mean brands must carefully select which premium specifications deliver appropriate value for their target price segments.

The investment in true quality selvedge specifications pays dividends in customer satisfaction, brand reputation, and ultimately, profitability. Selvedge denim that develops beautiful, personal fading patterns and withstands years of wear becomes a brand ambassador that drives word-of-mouth marketing and repeat purchases. The specifications we've validated through extensive testing and production experience—from yarn selection to finishing protocols—provide a roadmap for creating selvedge denim that genuinely justifies its premium positioning.

If you're ready to develop selvedge denim with authentic durability and fading characteristics, let's implement these proven specifications tailored to your brand positioning and price points. We can provide fabric samples, technical specifications, and production guidance that deliver measurable performance benefits. For assistance in selecting selvedge specifications that genuinely improve durability and fade patterns, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create selvedge denim that becomes legendary for its character and longevity, not just its colored edges.