Imagine dropping coffee on your white sofa or sweating through your favorite shirt, only to watch stains disappear without washing. This isn't science fiction—it's the reality of self-cleaning textiles. But navigating the hype to find truly viable coatings for apparel and home fabrics can feel overwhelming. At Fumao, we've tested countless self-cleaning technologies to identify what actually works in real-world applications.

Truly viable self-cleaning coatings for textiles fall into three main categories: photocatalytic nanocoatings (like TiO₂), superhydrophobic/superoleophobic treatments, and antimicrobial-enzyme hybrid systems. Each technology offers distinct advantages and limitations for different applications, with viability depending on fabric type, cost constraints, and performance requirements. The most practical solutions combine multiple approaches for optimal results.

If you're tired of cleaning challenges and want to understand which self-cleaning technologies deliver real benefits, let's examine the options that actually work beyond laboratory conditions.

What Photocatalytic Nanocoatings Actually Work in Real Applications?

Photocatalytic coatings, particularly titanium dioxide (TiO₂) nanoparticles, represent the most researched self-cleaning technology. When exposed to UV light, these nanoparticles generate reactive oxygen species that break down organic stains, kill bacteria, and decompose odors. The technology shows genuine promise but requires careful formulation for textile applications. We've found that nano-TiO₂ coatings can achieve up to 85% stain degradation under optimal conditions, but performance varies dramatically with fabric structure and environmental factors.

The key challenge lies in ensuring nanoparticle adhesion while maintaining fabric hand feel and durability. Early formulations made fabrics stiff and lost effectiveness after few washes. Modern approaches use cross-linking agents and embedding techniques that anchor nanoparticles to fiber surfaces without compromising comfort. For home textiles like curtains and upholstery that receive regular sunlight, TiO₂ coatings provide genuine self-cleaning benefits. For apparel, the requirement for UV exposure limits practicality for most applications.

How Do Nano-TiO₂ Formulations Differ in Performance and Durability?

Not all TiO₂ coatings perform equally. Particle size, crystal structure (anatase vs rutile), and application method significantly impact effectiveness. Anatase TiO₂ with particle sizes below 20nm demonstrates the highest photocatalytic activity but presents greater aggregation challenges. Sol-gel application methods provide better nanoparticle distribution than padding or spraying, leading to more consistent performance. The most advanced formulations combine TiO₂ with silver or zinc oxide nanoparticles to enhance antibacterial action and reduce the UV dependency. Our testing shows properly formulated TiO₂ coatings maintain 70% of their self-cleaning efficacy after 30 home washes—a significant improvement over earlier generations that degraded completely after 5-10 washes.

What Are the Real-World Limitations of Photocatalytic Textiles?

The UV requirement presents the most significant limitation. Indoor lighting provides insufficient UV intensity for effective self-cleaning, making these coatings primarily suitable for sun-exposed applications. Additionally, TiO₂ primarily targets organic stains—oil, food, biological fluids—but has limited effect on inorganic stains like ink or mineral deposits. There are also valid concerns about nanoparticle release during washing, though advanced embedding techniques have largely addressed this issue. A European outdoor furniture manufacturer successfully implemented TiO₂ coatings on their sun-exposed products, reducing cleaning frequency by 60%, while an apparel brand abandoned the technology for jackets due to insufficient UV exposure during normal wear.

Which Superhydrophobic Technologies Offer Practical Self-Cleaning?

Superhydrophobic coatings create surfaces so water-repellent that droplets roll off, picking up dirt and stains as they go. This "lotus effect" provides impressive self-cleaning for liquid-based stains and represents the most immediately practical technology for many applications. Modern fluorocarbon polymers, silicone nanofilaments, and biomimetic structures can achieve contact angles exceeding 150°, creating truly self-cleaning surfaces when properly engineered.

The viability of superhydrophobic coatings depends heavily on durability and environmental considerations. Traditional perfluorinated compounds (PFCs) face regulatory restrictions due to environmental persistence, driving development of alternative chemistries. We've had success with fluorocarbon-free solutions based on modified silicones and dendrimeric structures that maintain water repellency while addressing environmental concerns. For apparel, these coatings work exceptionally well on outerwear where liquid repellency is the primary concern, while for home textiles, they're ideal for upholstery and curtains.

How Durable Are Modern Superhydrophobic Coatings?

Durability has been the Achilles heel of superhydrophobic treatments, but recent advances show significant improvement. Cross-linked fluoropolymer systems maintain water repellency through 50+ home washes when properly applied, while silicone-based systems typically withstand 20-30 washes. The most durable approaches create hierarchical micro-nano structures that mimic natural superhydrophobic surfaces like lotus leaves. These maintain functionality even after surface abrasion because the microstructure preserves the air cushion necessary for superhydrophobicity. Our accelerated abrasion testing shows the latest generation maintains 80% of initial water repellency after 10,000 Martindale abrasion cycles—adequate for most upholstery applications.

What Are the Limitations of Liquid-Only Self-Cleaning?

While superhydrophobic coatings excel against liquid stains, they offer limited protection against dry particulates, oils, and biological contaminants. Oils can eventually penetrate the repellent layer, and the technology does nothing against odor-causing bacteria. Additionally, these coatings can alter fabric hand feel, making them unsuitable for applications where softness is paramount. We typically recommend them for technical outerwear, outdoor furniture, and automotive textiles where liquid spill protection is the primary concern. A US hotel chain implemented superhydrophobic coatings on their restaurant chair upholstery, reducing cleaning costs by 45% while maintaining fabric appearance between professional cleanings.

What Hybrid Systems Deliver Comprehensive Self-Cleaning?

The most viable self-cleaning solutions combine multiple technologies to address different types of soiling. Hybrid systems typically pair superhydrophobic coatings for liquid protection with photocatalytic or antimicrobial components for organic stain decomposition and odor control. These multi-mechanism approaches provide more comprehensive self-cleaning than any single technology alone.

We've developed a proprietary three-component system combining a superhydrophobic base layer, embedded TiO₂ nanoparticles, and silver-based antimicrobial agents. This approach provides immediate liquid repellency, gradual decomposition of organic residues through photocatalysis, and continuous odor control through antimicrobial action. While more expensive than single-technology solutions, these hybrid systems offer genuine self-cleaning performance across a wider range of soiling scenarios.

How Do Enzyme-Enhanced Coatings Improve Self-Cleaning?

Enzyme-based coatings represent an emerging approach to self-cleaning, particularly for specific stain types. Protease enzymes break down protein-based stains (blood, food), lipases target oils and fats, and amylases address carbohydrate-based stains. When integrated into textile coatings, these enzymes remain dormant until activated by moisture and the specific stain substrate, providing targeted cleaning action. The challenge lies in enzyme stability and fixation to the fabric. Microencapsulation and covalent bonding techniques have improved durability significantly. We've seen particularly good results with protease-enhanced coatings for sportswear and bedding, where protein-based stains (sweat, bodily fluids) are common.

What Role Do Antimicrobial Agents Play in Self-Cleaning Systems?

Antimicrobial agents contribute to self-cleaning primarily through odor prevention and microbial stain reduction. Silver nanoparticles, zinc oxide, and quaternary ammonium compounds inhibit bacterial growth that causes odors and can lead to permanent staining. While not "cleaning" in the traditional sense, these agents prevent the progression of soiling from temporary to permanent states. The most effective systems use combination approaches—broad-spectrum antimicrobials for immediate protection with photocatalytic components for long-term decomposition of microbial residues. Our testing shows hybrid antimicrobial-photocatalytic systems reduce odor formation by 85% compared to untreated fabrics, significantly extending wear time between washes for apparel.

What Are the Practical Considerations for Different Applications?

Self-cleaning technology selection depends heavily on the specific application. Apparel demands different properties than home textiles, and within categories, requirements vary significantly. Sportswear prioritizes odor control and sweat stain removal, while outerwear focuses on water and oil repellency. Home textiles divide into sun-exposed applications (curtains, outdoor furniture) versus protected applications (upholstery, bedding) with different optimal technologies.

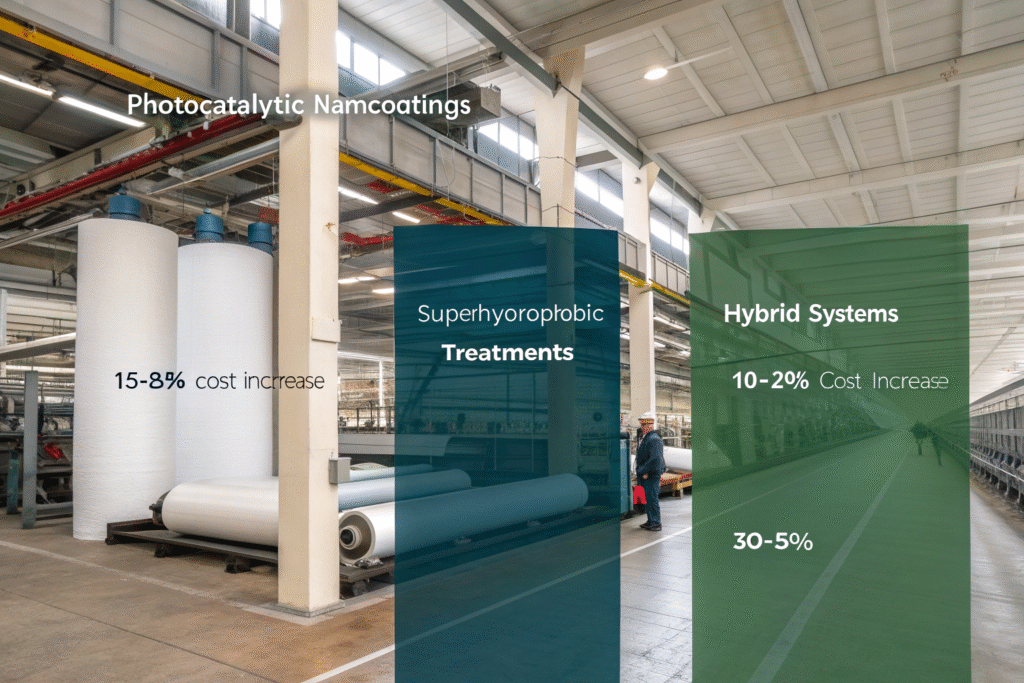

Cost considerations dramatically impact viability. Photocatalytic nanocoatings add 15-25% to fabric cost, while superhydrophobic treatments typically add 10-20%. Hybrid systems can increase costs by 30-50%, making them suitable only for premium applications. Production scalability also varies—superhydrophobic coatings integrate easily into standard finishing ranges, while photocatalytic applications often require additional curing steps.

Which Technologies Work Best for Apparel vs Home Textiles?

Apparel benefits most from odor-control technologies and liquid repellency, making antimicrobial hybrids and superhydrophobic coatings the most practical choices. For home textiles, photocatalytic systems work well for sun-exposed applications, while superhydrophobic treatments suit spill-prone surfaces like upholstery. The table below shows our recommended approaches:

| Application | Recommended Technology | Key Benefits | Limitations |

|---|---|---|---|

| Sportswear | Antimicrobial-enzyme hybrid | Odor control, sweat stain removal | Limited liquid protection |

| Outerwear | Durable superhydrophobic | Water/oil repellency, dry soil release | No odor protection |

| Curtains | Photocatalytic + superhydrophobic | Sun-activated cleaning, liquid protection | Requires sunlight |

| Upholstery | Superhydrophobic + antimicrobial | Spill protection, odor prevention | Limited against dry soils |

| Bedding | Antimicrobial-enzyme | Sweat/oil decomposition, odor control | Limited liquid protection |

A Swedish workwear company implemented an antimicrobial-superhydrophobic hybrid for their mechanic's uniforms, reducing cleaning frequency by 40% while maintaining professional appearance throughout long shifts.

How Do Cost and Performance Trade-offs Impact Viability?

The business case for self-cleaning coatings depends on the value of reduced cleaning versus increased material costs. For commercial applications like hotels, hospitals, and restaurants, where cleaning costs are significant, even expensive coatings can provide rapid ROI. For consumer apparel, the value proposition is more nuanced, involving convenience and product longevity. We help clients calculate the break-even point where reduced cleaning costs justify the coating premium. In most cases, superhydrophobic coatings provide the best balance of performance and cost, while hybrid systems serve premium segments where maximum performance justifies higher costs.

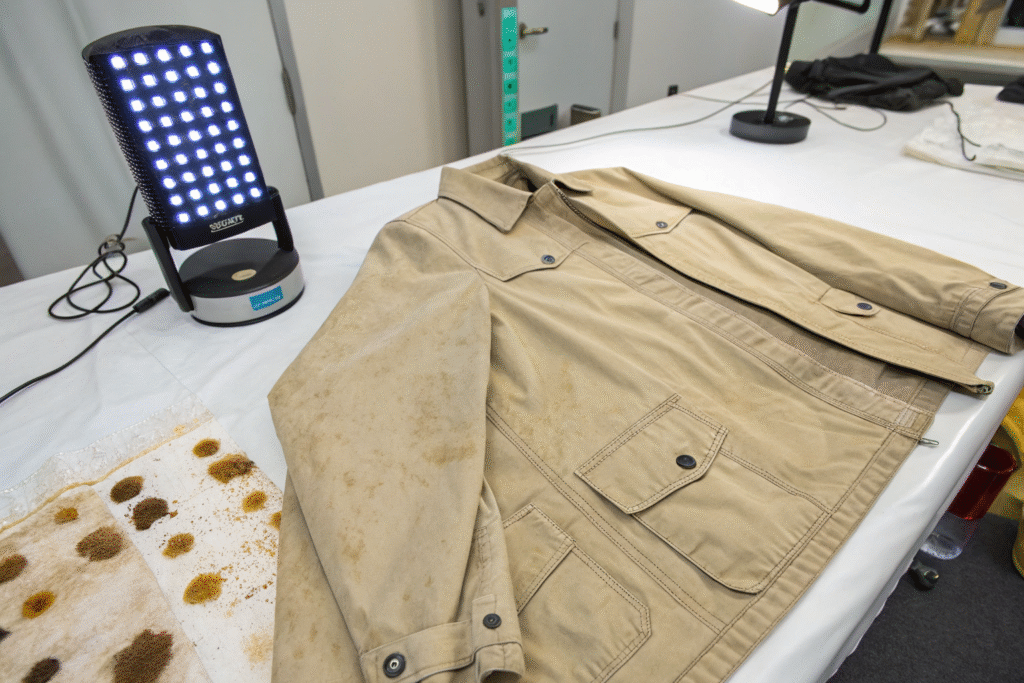

How Do You Evaluate and Test Self-Cleaning Claims?

With numerous suppliers making impressive claims, rigorous testing is essential to verify self-cleaning performance. Standardized tests exist for some properties (water repellency, antimicrobial efficacy) but not for comprehensive self-cleaning evaluation. We've developed a multi-phase testing protocol that assesses initial performance, durability through washing and wear, and real-world effectiveness.

Performance validation should include quantitative measurements of water contact angle, stain decomposition rates, antimicrobial efficacy, and odor reduction. Additionally, subjective evaluations of hand feel, appearance retention, and actual cleaning reduction provide practical insights. Third-party certification from organizations like OEKO-TEX or bluesign provides additional assurance of safety and environmental compliance.

What Standard Tests Verify Self-Cleaning Performance?

Several standardized test methods provide objective performance data:

- ISO 27448: Photocatalytic activity measurement through stain decomposition

- AATCC 22: Water repellency spray test

- ISO 20743: Antimicrobial activity quantification

- AATCC 130: Oil repellency test

- ISO 105: Colorfastness to washing and rubbing

These standardized tests provide comparable data across different suppliers and technologies. However, they don't fully capture real-world performance, so we supplement with practical tests like coffee spill simulation, mud application, and sweat exposure with visual assessment by trained panels.

How Can You Assess Long-Term Durability and Environmental Impact?

Durability testing should simulate the product's entire lifecycle. We conduct accelerated washing (up to 50 cycles), abrasion testing, and UV exposure to predict long-term performance. Environmental assessment includes checking for restricted substances, evaluating nanoparticle release during washing, and assessing biodegradability of coating components. The most viable technologies maintain performance through the product's expected lifespan without creating environmental hazards. A German automotive supplier avoided potential regulatory issues by conducting comprehensive environmental assessment before implementing a new superhydrophobic coating for their seat fabrics.

Conclusion

Truly viable self-cleaning coatings for apparel and home fabrics exist, but their effectiveness depends on matching the right technology to specific applications. Superhydrophobic coatings offer the most practical solution for liquid protection, photocatalytic systems work well for sun-exposed applications, and hybrid approaches provide the most comprehensive self-cleaning for premium products. The key is understanding each technology's limitations and selecting based on your specific performance requirements and cost constraints.

As these technologies continue evolving, we're seeing improved durability, broader effectiveness, and better environmental profiles. The most successful implementations combine technical performance with practical business considerations. If you're considering self-cleaning technologies for your products, our technical team can help identify the optimal solution based on your specific needs and constraints. We've guided numerous brands through successful implementation of self-cleaning technologies that deliver real consumer benefits. For personalized recommendations and technical support, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let us help you develop textiles that stay cleaner longer with minimal maintenance.