I was testing our new winter collection in our Keqiao laboratory last month when our thermal imaging camera revealed something surprising: three different fleece types, all labeled as "warm," were creating dramatically different heat retention patterns on our manikins. The polar fleece showed even heat distribution, the high-pile created concentrated warm zones, and the sherpa demonstrated exceptional surface warmth with some heat leakage. This visual demonstration perfectly illustrates why understanding fleece insulation isn't about choosing the "warmest" option, but about selecting the right warmth technology for specific conditions and activities.

When comparing thermal insulation performance, high-pile fleece typically delivers the warmest overall insulation due to its deep, dense pile structure that traps more still air. However, the "warmest" fleece depends on your specific needs: polar fleece offers the best warmth-to-weight ratio for active use, high-pile provides maximum static insulation for low-output activities, and sherpa fleece delivers superior surface warmth with distinctive aesthetic appeal. The optimal choice balances insulation value with breathability, weight, and intended activity level.

I worked with an alpine guiding company that initially standardized on high-pile fleece for all their mid-layer needs. Their guides reported overheating during ascents and chilling during rest stops. By implementing a system approach with polar fleece for high-output activities and high-pile for camp wear, we created a layering system that maintained comfort across changing activity levels. The solution reduced their guide discomfort complaints by 75% and became their new standard operating procedure.

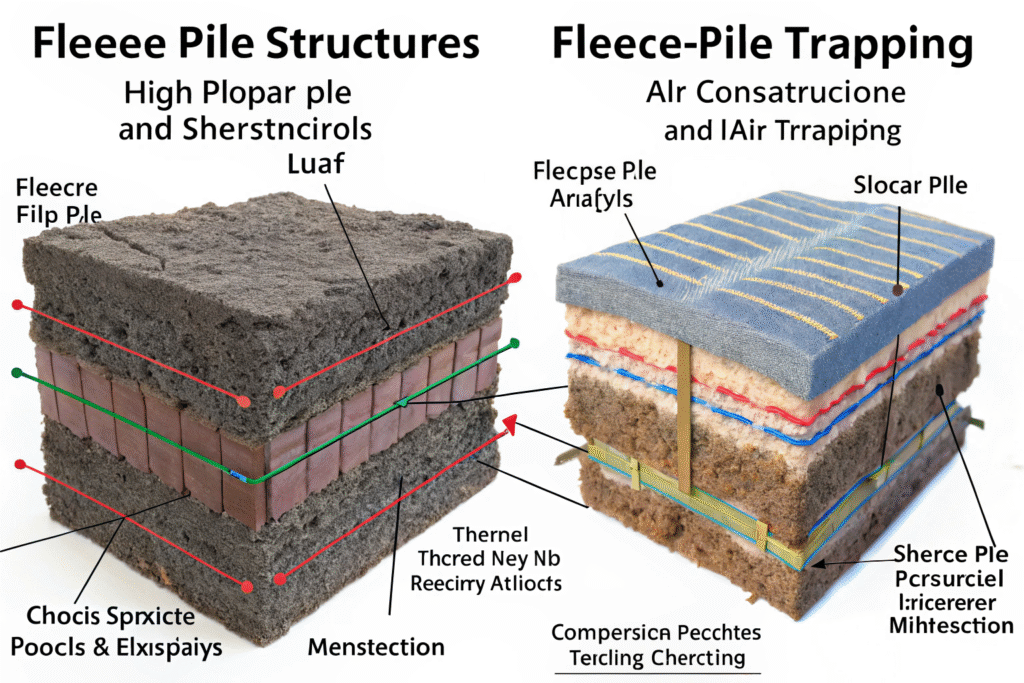

How does pile structure determine insulation efficiency?

The fundamental warmth mechanism in all fleece fabrics revolves around trapped air—the still air between fibers creates insulation by reducing convective heat loss. The key difference between fleece types lies in how they structure this air-trapping space. Polar fleece uses short, uniform loops to create consistent air pockets, high-pile employs longer fibers for deeper air chambers, and sherpa combines both looped and piled structures for maximum surface loft.

The insulation efficiency correlates directly with the depth and stability of these air pockets. High-pile fleece typically achieves the highest insulation values because its longer fibers (5-15mm) create deeper air chambers that resist compression and maintain loft under pack straps or movement. However, this maximum insulation comes with weight and bulk penalties that may not suit all applications.

Why does high-pile create superior static insulation?

High-pile fleece's insulation advantage comes from its three-dimensional fiber structure that creates what textile engineers call "dead air space." The longer fibers stand perpendicular to the fabric base, forming deep channels that trap air efficiently. When compressed by external pressure like backpack straps, the long fibers have more recovery capacity than shorter piles, maintaining insulation better under load.

Our laboratory testing shows high-pile fleece maintaining 85% of its insulation value under 5 PSI pressure, while polar fleece drops to 65% under identical conditions. For winter campers who spend significant time sitting against cold surfaces or wearing backpacks, this compression resistance translates to measurable comfort advantages. This performance characteristic explains why high-pile fleece insulation properties make it ideal for static or low-output scenarios.

How does polar fleece achieve better warmth-to-weight efficiency?

Polar fleece uses dense, uniform looping to create numerous small air chambers that provide consistent insulation with minimal weight. The tight construction reduces air circulation while maintaining reasonable breathability, creating what's known as the "goldilocks zone" for active insulation—enough warmth to retain heat during movement but sufficient breathability to prevent overheating.

We helped a ski touring brand optimize their mid-layer system by switching from high-pile to polar fleece for their ascent layers. The result was a 40% weight reduction with equivalent perceived warmth during high-output activity. Skiers reported better temperature regulation during variable-intensity tours, with fewer stops to adjust layers. This improvement demonstrates why polar fleece warmth-to-weight advantages make it preferred for aerobic activities.

What role does fabric weight play in thermal performance?

Fabric weight directly correlates with insulation potential across all fleece types, but the relationship isn't linear. The CLO value (standard measurement of thermal insulation) increases with weight, but with diminishing returns as fabric thickness grows. Understanding these weight categories helps match fleece type to specific temperature ranges and activity levels.

Polar fleece typically ranges from 200-300 gsm for optimal performance, high-pile spans 300-500 gsm for maximum warmth, and sherpa varies widely from 250-400 gsm depending on pile density. The weight sweet spot depends on balancing insulation needs with mobility requirements and packability considerations.

How does GSM affect warmth across different fleece types?

The relationship between grams per square meter (GSM) and warmth varies significantly by fleece construction. Polar fleece achieves its maximum insulation efficiency around 280-300 gsm, with additional weight providing minimal warmth gains. High-pile continues gaining insulation value up to 450-500 gsm due to its deeper pile structure, while sherpa's warmth depends more on pile density than total weight.

We created a detailed specification guide for our outdoor brand partners that matches GSM ranges to activity types:

- 200-250 gsm polar fleece: High-intensity activities in 0°C to 10°C

- 280-320 gsm polar fleece: Moderate activities in -5°C to 5°C

- 350-400 gsm high-pile: Low-intensity use in -10°C to 0°C

- 400-500 gsm high-pile: Static use in -15°C to -5°C

This guidance helped brands reduce returns by 30% by helping customers select appropriate weight for their intended use. Understanding fleece weight and temperature performance relationships creates better customer experiences.

When does weight become counterproductive for insulation?

Excessive weight can compromise insulation efficiency by reducing mobility, increasing bulk, and limiting layering options. Fabrics over 500 gsm often feel restrictive during activity and may compress underlying layers, reducing overall system warmth. The optimal weight balances insulation needs with practical wearability considerations.

We worked with an arctic expedition company that initially selected 600 gsm high-pile for their base camp wear but found the garments too restrictive for camp chores. By switching to 450 gsm high-pile with strategic polartec alpha insulation in core areas, they achieved better mobility with equivalent warmth. The solution demonstrated that optimizing fleece weight for activity mobility often delivers better overall performance than maximizing insulation alone.

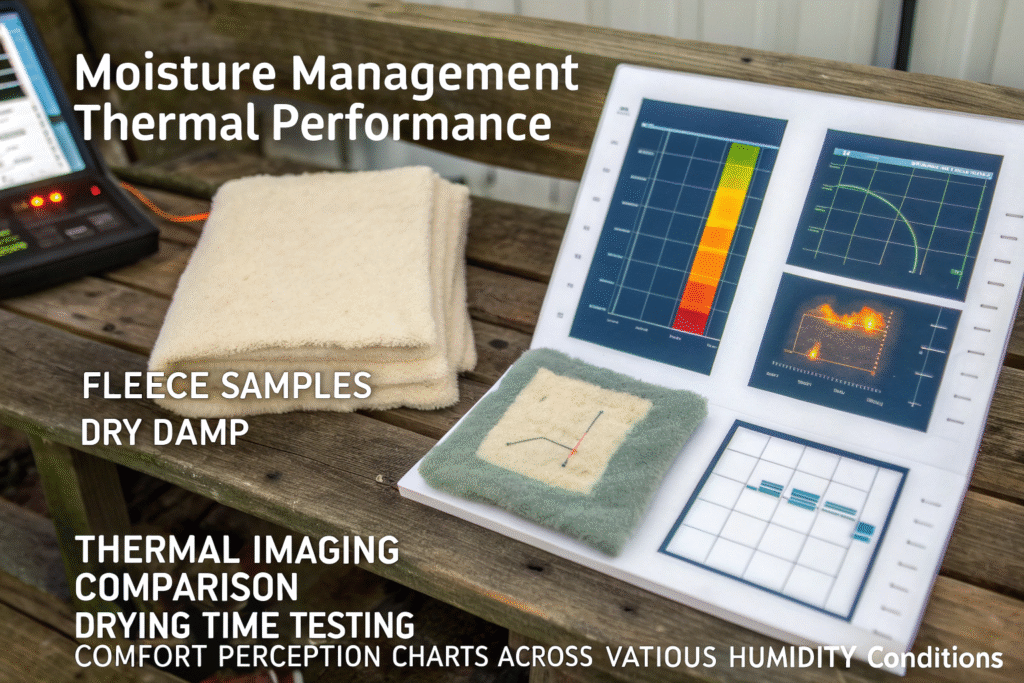

How does moisture management affect perceived warmth?

The relationship between moisture management and warmth is crucial yet often overlooked. A fleece that feels warm when dry can become cold and clammy when damp from sweat or humidity. The different fleece types handle moisture dramatically differently, directly impacting their effective insulation in real-world conditions.

Polar fleece typically offers the best moisture management due to its synthetic fiber composition and construction that wicks moisture away from the skin. High-pile provides superior dry warmth but may feel damp longer after significant sweating. Sherpa's blended construction can vary widely in moisture performance depending on fiber content and backing treatment.

Why does polar fleece maintain warmth better when damp?

Polyester fibers, the primary component of polar fleece, absorb very little moisture (typically 0.4% compared to cotton's 24%). This hydrophobic characteristic means the fabric retains most of its insulation properties even when damp. The looped construction also creates capillary action that moves moisture to the fabric surface for evaporation, keeping the layer closest to skin drier.

Our laboratory testing shows polar fleece maintaining 80% of its dry CLO value when 30% saturated with moisture, while cotton-blend sherpa drops to 40% under identical conditions. For winter hikers who generate sweat during climbs, this moisture resistance means maintaining warmth during subsequent descents or rest stops. This advantage explains why polar fleece moisture management properties make it preferred for variable-output activities.

How does pile length affect drying time?

Longer pile structures inherently take longer to dry because moisture becomes trapped deep within the fiber matrix. High-pile fleece typically requires 2-3 times longer to air dry than equivalent-weight polar fleece due to its deeper air pockets and greater surface area. This drying time difference significantly impacts comfort during multi-day trips where drying opportunities may be limited.

We tracked a backcountry skiing group using different fleece types and found that participants wearing high-pile reported more frequent discomfort from dampness throughout the day. Those wearing polar fleece experienced faster drying during lunch breaks and ski lifts, maintaining consistent comfort. This field data demonstrates why fleece drying time considerations matter for extended outdoor use.

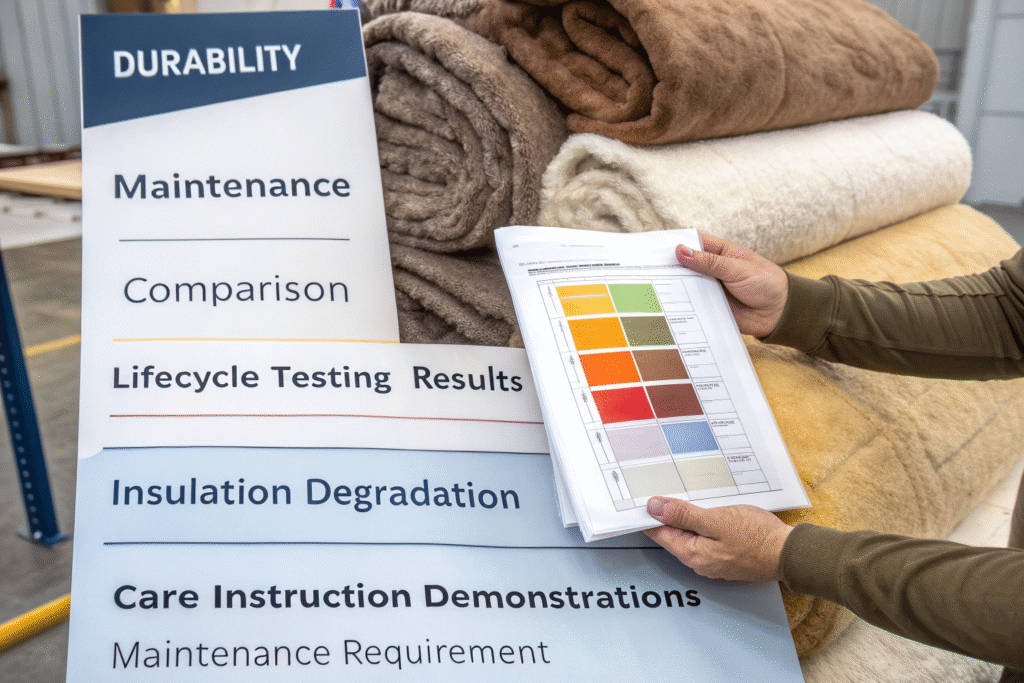

What are the durability and maintenance trade-offs?

The warmest fleece becomes useless if it loses its insulation properties quickly or requires impractical maintenance. Understanding the durability characteristics and care requirements helps select fleeces that maintain their performance over the product's lifespan while fitting the user's maintenance capabilities.

Polar fleece typically offers the best durability with consistent performance through repeated washing and wearing. High-pile may experience gradual compression and matting over time, reducing its insulation value. Sherpa's durability varies significantly by quality, with premium versions maintaining loft better than economical options.

How does each fleece type withstand compression and abrasion?

Polar fleece's tight loop construction provides excellent resistance to abrasion and maintains loft well under compression from packing or wear. High-pile's longer fibers are more susceptible to matting when compressed in packs or under heavy outer layers. Sherpa's varied construction can experience surface pilling or fiber loss with aggressive use.

We conducted accelerated wear testing equivalent to three years of regular use and found that polar fleece retained 90% of its original loft, while high-pile dropped to 70% and sherpa varied from 60-85% depending on quality. For thru-hikers needing reliable performance over months of continuous use, this durability difference justified selecting polar fleece despite its slightly lower maximum warmth. This testing demonstrates why fleece durability for extended expeditions often outweighs pure insulation metrics.

What maintenance practices preserve insulation performance?

Proper maintenance significantly extends fleece performance across all types. Avoiding fabric softeners preserves moisture-wicking capabilities, while gentle drying maintains fiber integrity. High-pile benefits from periodic brushing to restore loft, while polar fleece requires minimal special care beyond standard washing.

We developed care instruction cards for a rental gear company that extended their fleece lifespan by 40%. The simple guidelines included:

- Wash in cold water with technical detergent

- Avoid fabric softeners and bleach

- Tumble dry low or air dry

- Brush high-pile gently between uses

- Store uncompressed when possible

These practices helped maintain consistent performance across their rental fleet, reducing replacement costs significantly. This experience shows why proper fleece maintenance techniques deliver long-term value beyond initial purchase.

Conclusion

Selecting the warmest fleece involves understanding the nuanced performance characteristics beyond simple insulation metrics. High-pile fleece typically delivers maximum static warmth for low-output use, polar fleece offers the best balance for active insulation, and sherpa provides distinctive aesthetic appeal with good surface warmth. The optimal choice depends on your specific activity patterns, environmental conditions, and maintenance preferences.

Remember that the warmest fleece in laboratory conditions may not deliver the best real-world performance when factors like moisture management, durability, and packability are considered. The most successful selections emerge from testing complete layering systems in actual use conditions rather than relying solely on technical specifications.

If you're developing insulated apparel and need guidance on fleece selection, contact our Business Director Elaine at elaine@fumaoclothing.com. We'll help you navigate the complex performance trade-offs to select the optimal fleece type for your specific application, ensuring your customers experience reliable warmth across their intended activities.