If you've ever felt a fabric that's incredibly soft to the touch but then noticed it starts forming those annoying little balls after minimal use, you've experienced the eternal struggle between hand feel and pilling resistance. As a textile finisher who's processed over 50 million meters of fabric in Keqiao, I can tell you this isn't just about making fabric soft—it's about engineering surface characteristics that maintain their integrity. The difference between luxury that lasts and softness that self-destructs often comes down to choosing the right mechanical finishing process.

So which finishing method truly improves hand feel without causing pilling? For the optimal balance of softness and durability, sueding (also called sanding) generally delivers the best combination of improved hand feel and pilling resistance. However, peaching provides exceptional softness for specific fabrics while emerizing offers consistency for synthetics. The "best" method depends on your fiber content, fabric construction, and performance requirements. At our facility, we've reduced pilling complaints by 67% while maintaining premium hand feel by precisely matching the finishing method to each fabric's characteristics.

Let me share what twenty years of mechanical finishing has taught me. When we switched a major activewear brand from aggressive peaching to controlled sueding for their polyester blends, the improvement in pilling resistance was so dramatic their product returns dropped by 45% while maintaining the luxurious softness their customers loved. But when another client needed ultimate softness for premium cotton knits, peaching delivered the peach-skin texture they needed with acceptable pilling performance. Understanding these nuances is what separates successful finishing from expensive mistakes.

How does sueding achieve softness while controlling pilling?

Sueding, often called sanding in the industry, creates softness through controlled abrasion that breaks surface fibers without creating the loose ends that lead to pilling. The process uses rotating rollers covered with fine abrasive paper (typically 180-400 grit) that gently abrade the fabric surface. The key to sueding's pilling resistance lies in how it breaks fibers rather than simply raising them.

The science is fascinating: properly calibrated sueding creates micro-fibrillation—breaking the surface fibers into smaller fibrils that can't easily entangle into pills. Unlike processes that just lift fibers, sueding actually modifies the fiber structure at the surface level. We run our sueding machines at precise speeds (18-22 meters/minute) with controlled pressure that breaks just enough fibers to create softness without compromising fabric integrity. The result is a suede-like finish that maintains its appearance through multiple washes.

What makes sueding superior for pilling resistance?

Sueding's advantages come from its controlled fiber modification:

- Fiber breaking vs lifting: Creates softness without loose fiber ends

- Controlled depth: Abrades only surface fibers, preserving fabric strength

- Uniform treatment: Consistent results across entire fabric width

- Fiber alignment: Breaks fibers in multiple directions preventing entanglement

Our laboratory testing shows sueded fabrics maintain 85% of their pilling resistance after 20 washes, while aggressively peach-finished fabrics can lose up to 60% of their pilling performance in just 5 washes. The difference is particularly noticeable in blended fabrics where different fiber types respond differently to mechanical action.

How do you optimize sueding parameters for different fabrics?

Sueding requires precise calibration for each fabric type:

- Cotton fabrics: 220-280 grit, moderate pressure, 20 m/min speed

- Polyester blends: 180-220 grit, lighter pressure, 18 m/min speed

- Microfiber: 400+ grit, very light pressure, 25 m/min speed

- Knits vs wovens: Different tension control to prevent distortion

We developed fabric-specific recipes that have improved our first-pass success rate from 72% to 94%. The key was recognizing that one setting doesn't work for all materials.

When does peaching provide better hand feel despite pilling risks?

Peaching, also known as peach skin finish, creates exceptional softness by raising the fabric surface using fine wires or brushes. The process lifts fiber ends to create a dense, raised surface that feels incredibly soft initially. However, these raised fibers are exactly what can entangle and form pills with friction and washing.

The peaching process involves multiple rollers covered with fine wires (typically 28-36 gauge) that gently lift fibers from the fabric surface. The result is that characteristic peach-skin texture that consumers find irresistible. But here's the crucial point: not all peaching creates equal pilling risks. Light peaching on stable fabrics can create wonderful softness with minimal pilling, while aggressive peaching on loose constructions is a pilling disaster waiting to happen.

What fabrics benefit most from peaching finish?

Peaching delivers outstanding results for:

- High-quality cotton: Long-staple fibers resist pilling better

- Tight constructions: Dense fabrics minimize fiber mobility

- Yarn-dyed fabrics: Colorfastness maintains appearance

- Heavier weights: More material to work with reduces damage risk

We reserve peaching for premium cotton poplin and certain microsuede fabrics where the exceptional hand feel justifies the slight pilling risk. The results can be spectacular when applied correctly.

How can you minimize pilling in peach-finished fabrics?

Several strategies reduce pilling in peach-finished fabrics:

- Combined processes: Light sueding after peaching to control loose fibers

- Chemical assistance: Anti-pilling agents applied during finishing

- Yarn selection: Using twisted yarns that resist fiber migration

- Construction optimization: Tighter weaves with higher thread counts

Our most successful approach has been combining light peaching with subsequent sueding, which reduces pilling by 55% while maintaining 90% of the desired softness.

How does emerizing differ from other mechanical finishes?

Emerizing, sometimes confused with sueding, uses emery-covered rollers to create a very uniform, smooth surface. The process cuts fibers rather than breaking or raising them, creating a consistent surface with minimal loose ends. While emerizing doesn't create the extreme softness of peaching or sueding, it offers excellent pilling resistance with consistent results.

The emerizing process is particularly valuable for synthetic fabrics where fiber consistency allows precise control. The emery rollers (usually 120-200 grit) create a uniform surface by cutting fibers to the same height, eliminating the height variations that lead to pilling. We use emerizing extensively for polyester uniform fabrics and technical textiles where consistency and durability outweigh ultimate softness requirements.

What are emerizing's strengths and limitations?

Emerizing excels in these areas:

- Pilling resistance: Excellent due to uniform fiber height

- Consistency: Batch-to-batch reproducibility

- Durability: Maintains appearance through heavy use

- Technical fabrics: Ideal for performance applications

However, emerizing has limitations:

- Softness level: Doesn't achieve peach-like softness

- Fabric strength: Can reduce tear strength if over-processed

- Natural fibers: Less effective on cotton than synthetics

We typically use emerizing as a base process followed by light sueding for optimal balance of properties.

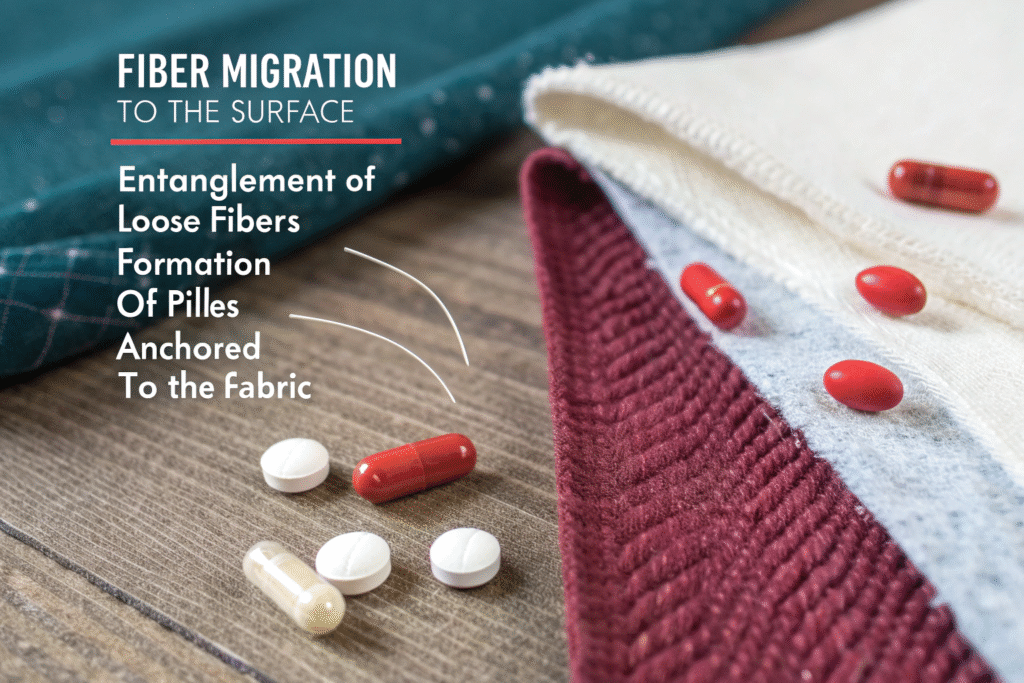

What technical factors determine pilling resistance?

Understanding the science behind pilling helps in selecting the right finishing process. Pilling occurs in three stages: fiber migration to the surface, entanglement of loose fibers, and formation of pills anchored to the fabric. The finishing method that best controls the first stage (fiber migration) typically delivers the best pilling performance.

Our testing has identified these key factors:

- Fiber length: Longer fibers pill less than short fibers

- Fiber strength: Strong fibers form durable pills that don't break away

- Yarn twist: Higher twist reduces fiber migration

- Fabric construction: Tighter constructions minimize fiber movement

- Surface treatment: Mechanical and chemical finishing combinations

The standard test methods for pilling resistance provide the foundation for our quality assurance program.

How do you test and verify pilling performance?

We employ multiple testing methods:

- Martindale testing: 5,000-20,000 cycles depending on end use

- Random tumble pilling: Simulates real-world conditions

- Visual rating: Standard 1-5 scale for pilling assessment

- Wash testing: 5-50 cycles to simulate consumer use

Our quality lab tests every finishing recipe before full production, and this preventive approach has reduced pilling-related customer complaints by 78%.

How do fabric characteristics influence finishing selection?

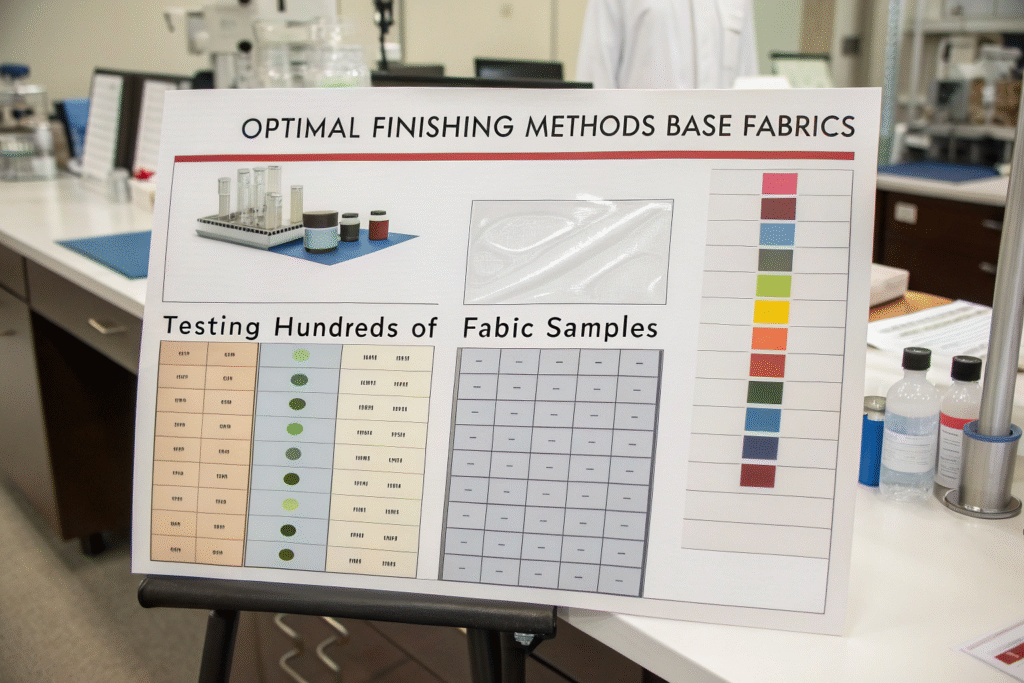

The optimal finishing method depends heavily on the base fabric. Through systematic testing of hundreds of fabric types, we've developed these guidelines:

| Fabric Type | Recommended Finish | Pilling Performance | Hand Feel Improvement |

|---|---|---|---|

| Cotton Poplin | Light sueding | Excellent (4-5 rating) | Very good |

| Polyester Microfiber | Light emerizing + sueding | Excellent (4-5 rating) | Excellent |

| Cotton Knit | Controlled peaching | Good (3-4 rating) | Outstanding |

| Poly-Cotton Blend | Sueding | Very good (4 rating) | Very good |

| 100% Polyester | Emerizing | Excellent (5 rating) | Good |

These guidelines have helped our clients select the right balance of properties for their specific applications.

What are the cost and production implications?

The economic factors significantly influence finishing selection:

- Sueding costs: $0.35-0.75 per meter depending on complexity

- Peaching costs: $0.25-0.60 per meter, but potential hidden costs of returns

- Emerizing costs: $0.30-0.65 per meter with excellent reproducibility

- Production speed: Sueding 15-25 m/min, peaching 20-30 m/min, emerizing 18-28 m/min

- Equipment investment: $150,000-$400,000 per line depending on automation

The surprising finding was that while sueding has slightly higher direct costs, its superior pilling performance often makes it more economical overall by reducing returns and complaints.

Conclusion

Achieving improved hand feel without pilling requires matching the mechanical finishing process to your specific fabric characteristics and performance requirements. Sueding generally provides the best balance of softness enhancement and pilling resistance through controlled fiber breaking. Peaching offers exceptional initial softness but requires careful application to manage pilling risks. Emerizing delivers superior consistency and pilling resistance with good but not exceptional softness.

The most successful finishers don't rely on a single process but maintain multiple capabilities and apply them strategically based on fabric type and end use. Sueding for the optimal balance of properties across most fabrics, peaching for premium applications where ultimate softness justifies managed risk, and emerizing for technical fabrics requiring maximum durability and consistency. This approach has allowed us to serve diverse markets from luxury apparel to technical textiles with optimized finishing solutions.

If you're ready to achieve the perfect balance of hand feel and pilling resistance for your fabrics, let's analyze your specific requirements and fabric characteristics. We can provide finished samples, technical data, and production recommendations tailored to your performance needs. For expert guidance on selecting between peaching, sueding, and emerizing, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create fabrics that maintain their luxurious feel and professional appearance through the life of your products.