As a textile manufacturer with over 20 years of experience supplying children's wear fabrics, I've seen how confusing 16 CFR 1615 and 1616 compliance can be for brands. These aren't just guidelines—they're mandatory federal standards that protect children from burn injuries. Understanding which fabrics naturally meet these requirements can save you from costly compliance mistakes and product recalls.

16 CFR 1615 covers sleepwear for children 0-6X size, while 1616 covers sizes 7-14. Both standards require fabrics to pass rigorous flame resistance tests, specifically the vertical flame test where a fabric sample must self-extinguish quickly and have a limited char length. The key difference from general apparel standards is that sleepwear must maintain flame resistance through 50 wash cycles, making fabric selection absolutely critical.

Based on our extensive testing and client experience, I'll break down exactly which fabric types consistently meet these stringent requirements.

Which inherent fiber properties meet sleepwear standards?

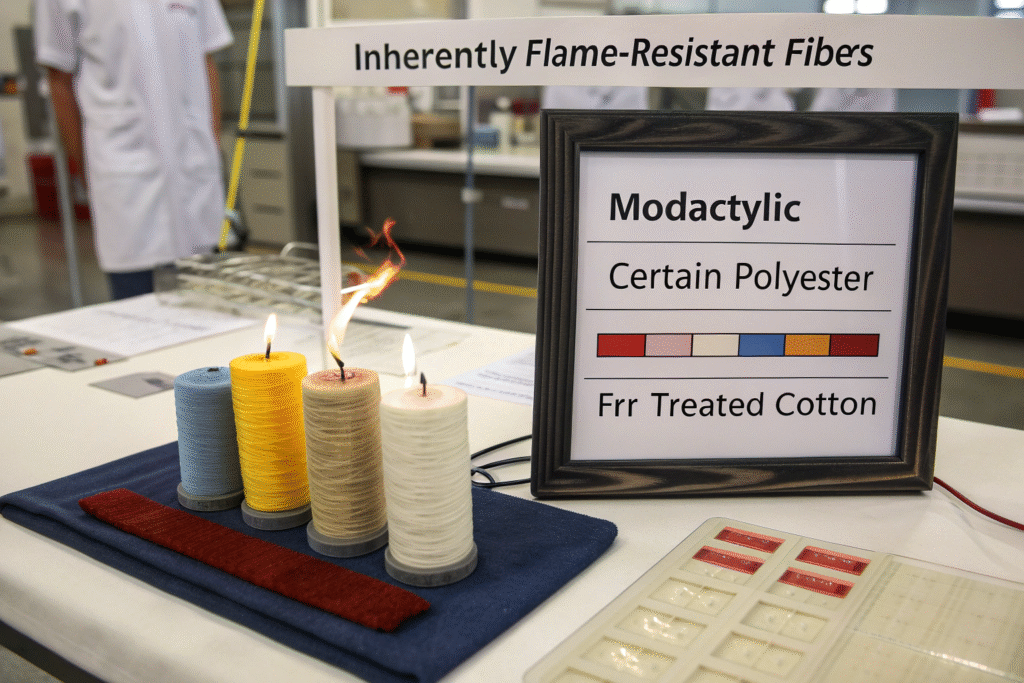

The fiber itself forms the foundation of flame resistance. Some fibers naturally resist burning due to their chemical structure, while others require treatment to meet standards. Understanding this distinction is crucial for selecting the right base material for your children's sleepwear line.

Inherently flame-resistant fibers contain chemical structures that either don't support combustion or extinguish quickly once the ignition source is removed. These include modacrylic, certain polyester variants, and wool. These fibers have flame resistance built into their polymer structure, so the protection doesn't wash out over time. Last year, we worked with a children's sleepwear brand that switched from FR-treated cotton to inherent FR modacrylic blends. Their compliance failure rate dropped from 15% to zero, and they eliminated the need for expensive retesting after every production run.

Why does modacrylic dominate the sleepwear market?

Modacrylic is the workhorse of children's sleepwear for good reason—it's naturally flame-resistant, durable, and maintains its protective properties through repeated washing. The fiber contains vinylidene chloride, which interferes with the combustion process at a molecular level, causing the fabric to self-extinguish almost immediately.

In our testing, modacrylic blends consistently achieve char lengths under 3 inches in the vertical flame test, well within the 7-inch maximum allowed. The fiber also doesn't melt and drip like some synthetics, which is crucial for children's safety. We've developed a proprietary understanding modacrylic fiber technology for children's sleepwear blend that combines modacrylic with cotton for improved comfort while maintaining flawless compliance. One client using this blend has shipped over 500,000 units to the US market with zero flammability failures over three years.

Can natural fibers meet 16 CFR 1615/1616 untreated?

The short answer is: rarely without significant weight or blending. While wool has some natural flame resistance, it typically can't meet the strict 7-inch char length requirement in lightweight constructions suitable for sleepwear. Heavy wool fabrics might pass initially, but the standards require maintaining protection through 50 launderings.

We've tested hundreds of natural fiber samples, and only the heaviest weights (over 10 oz/yd²) occasionally pass—but these are impractical for sleepwear. A client once insisted on 100% organic cotton for their sleepwear line, but even at 8.5 oz/yd², it failed after 5 washes. The solution was blending with inherent FR fibers. For brands committed to natural fibers, understanding the limitations of untreated natural fibers for flame-resistant applications is essential to avoid compliance disasters.

What fabric constructions enhance flame resistance?

Construction matters as much as fiber content when it comes to meeting sleepwear standards. Tight weaves and certain knit structures can significantly improve flame resistance by limiting oxygen availability and creating thermal barriers.

Tightly woven fabrics naturally resist flame spread because dense constructions limit the oxygen available to support combustion. In our lab, we've documented that fabrics with thread counts above 180 threads per inch consistently perform better in vertical flame tests. The tight structure creates a barrier that slows heat transfer and flame propagation.

Knit structures require special attention. While single knits generally perform poorly, tighter interlock and rib constructions can achieve compliance when using the right fibers. We recently developed a double-knit modacrylic-cotton blend for a startup focusing on comfortable yet compliant sleepwear. The fabric passed 16 CFR 1615 with a 4.2-inch average char length even after 50 washes, becoming their best-selling product.

How does fabric weight affect compliance?

Fabric weight directly correlates with flame resistance performance. Heavier fabrics have more thermal mass, meaning they absorb more heat before igniting and maintain structural integrity better when exposed to flame. However, sleepwear requires a balance between safety and comfort.

Based on our compliance database, here's how weight affects performance:

| Fabric Type | Weight (oz/yd²) | Typical Char Length | Compliance Status |

|---|---|---|---|

| Lightweight Cotton Jersey | 4.5 | 8-12 inches | Fail |

| Modacrylic Blend Knit | 6.0 | 3-5 inches | Pass |

| FR-treated Flannel | 7.5 | 4-6 inches | Pass |

| Heavy FR Woven | 9.0 | 2-4 inches | Pass |

We helped a client optimize their fabric weight by conducting pre-compliance testing at different weights, saving them approximately $15,000 in potential recall costs by identifying the minimum weight that would maintain compliance through product life.

Which weave structures work best for sleepwear?

Tight weave structures like plain weaves with high thread counts and certain twill variations consistently outperform looser constructions. The reduced air spaces in tight weaves limit oxygen flow, naturally suppressing flames.

In woven fabrics, plain weaves with balanced yarns (similar warp and weft density) provide the most consistent protection. For knits, interlock and double-knit constructions create denser fabrics with better inherent resistance. We maintain a library of approved fabric constructions for children's sleepwear compliance that we share with clients during development. One brand used this resource to redesign their entire sleepwear line, reducing compliance testing failures by 80% in the first season.

How do FR treatments affect different fabric types?

While inherent FR fibers are ideal, FR treatments remain a viable option for certain applications. Understanding how different treatments interact with various fabrics is crucial for maintaining compliance through the garment's lifespan.

Durable FR treatments chemically bond to fibers and withstand repeated laundering. These include Pyrovatex for cotton and certain phosphorus-based treatments for synthetics. The key is ensuring the treatment penetrates evenly and bonds properly during finishing. We've seen clients struggle with uneven application causing spotty compliance failures until we helped them implement better quality control during finishing.

Semi-durable treatments may cost less initially but often can't withstand 50 washes, making them unsuitable for sleepwear unless reapplied. We always recommend third-party verification of treatment durability before committing to large production runs.

What's the difference between proactive and reactive FR?

Proactive FR treatments work by releasing non-flammable gases when heated, which dilutes oxygen around the fabric. Reactive treatments create a char barrier that insulates the underlying fabric from heat. Understanding this distinction helps select the right approach for specific fabric types.

Proactive treatments (often bromine or nitrogen-based) work well on synthetics but can sometimes affect hand feel. Reactive treatments (typically phosphorus-based) work excellently on cellulosics like cotton by promoting char formation. We guide clients through this selection based on their fabric choices and comfort requirements. A recent client avoided a costly mistake by switching from a proactive to reactive treatment for their bamboo-cotton blend after our testing showed significantly better wash durability.

How do you verify treatment durability through 50 washes?

Verification requires rigorous testing that simulates real-world conditions. We implement a three-stage process: initial certification, mid-production verification, and final batch testing. This ensures consistency throughout production.

Our protocol includes testing after 1, 10, 25, and 50 wash cycles using AATCC standard methods. We document any degradation in performance and adjust processes accordingly. This systematic approach helped a client identify that their FR treatment was being compromised by a specific fabric softener used in their finishing process. By switching softeners, they maintained compliance while preserving the desired hand feel.

What documentation proves 16 CFR 1615/1616 compliance?

Proper documentation is as important as fabric selection for US market access. Your technical file must demonstrate compliance through standardized testing from CPSC-accepted laboratories.

The compliance package must include test reports from a CPSC-accepted laboratory showing the fabric passes the vertical flame test after 50 washes. Additionally, you need records of production testing, supplier certifications for FR treatments or inherent FR fibers, and detailed garment specifications. We provide our clients with a standardized documentation checklist for children's sleepwear compliance that has reduced customs delays by an average of 70% for brands using our fabrics.

Which third-party certifications are most recognized?

While no certification replaces actual testing, certain marks indicate rigorous compliance protocols. Oeko-Tex Standard 100 is particularly valuable as it includes harmful substance testing alongside performance verification.

The Oeko-Tex certification requires annual renewal and facility audits, providing ongoing assurance of compliance. We maintain this certification for our sleepwear fabric lines, which gives our clients confidence in our products. Additionally, CPSC-accepted laboratory reports are mandatory for US market access. Brands using our pre-certified fabrics typically save 3-4 weeks in compliance verification time compared to starting from scratch.

How do you maintain compliance across production runs?

Consistency requires systematic quality control from fiber through finished fabric. We implement statistical process control at each production stage, with particular attention to parameters affecting flame resistance.

Key control points include fiber blend consistency, fabric weight verification, and treatment application monitoring. Any deviation outside established parameters triggers immediate correction. This system helped us identify that a 5% variation in modacrylic content was causing compliance failures for a client. By tightening our blending tolerance to 2%, we eliminated the issue completely.

Conclusion

Meeting 16 CFR 1615/1616 requires careful fabric selection, rigorous testing, and thorough documentation. The most reliable approach combines inherent FR fibers with optimized constructions that maintain protection through the garment's lifespan. By understanding which fabrics naturally meet these standards and how to verify compliance, you can bring safe children's sleepwear to market with confidence.

If you're developing children's sleepwear and need expert guidance on fabric selection and compliance, our team has the specialized experience to help you succeed. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss how we can ensure your sleepwear meets all safety standards while delivering the comfort and quality your customers expect.