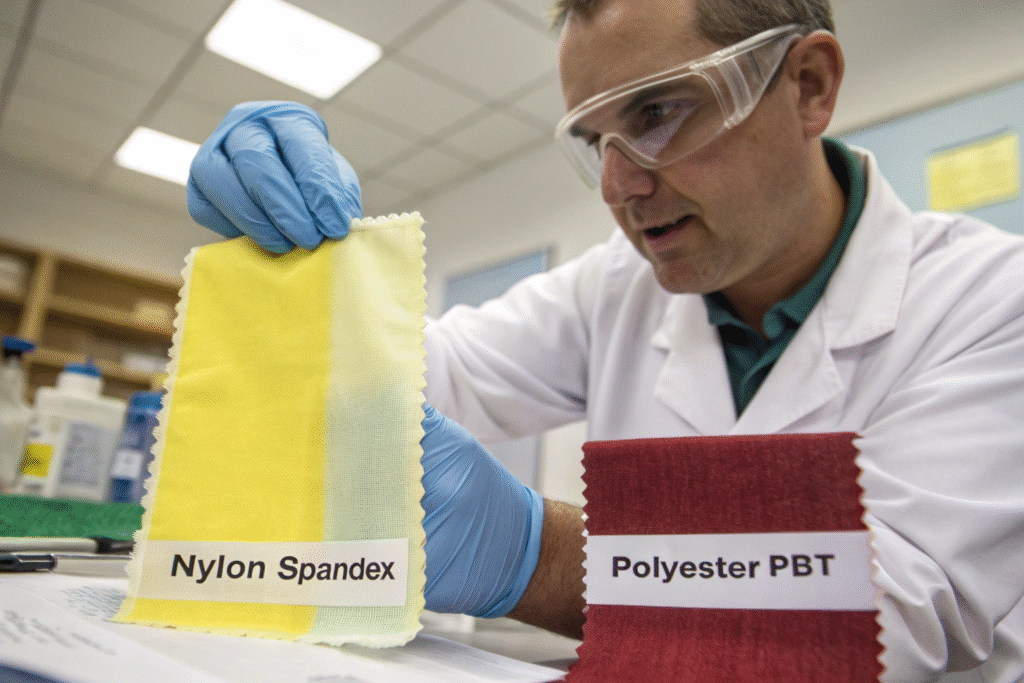

As a fabric supplier with over two decades in the industry, I get this question all the time. Choosing the right swimwear fabric is critical. It can make or break your collection. You need a fabric that looks great, lasts long, and feels comfortable against the skin. The two main contenders in the ring are Nylon Spandex and Polyester PBT. Both are excellent, but they serve slightly different masters.

The best fabric for your swimwear depends on your brand's priority. If you want superior softness, a luxurious matte finish, and excellent color vibrancy, Nylon Spandex is often the preferred choice. If your focus is on exceptional chlorine resistance, durability, and quick drying, then Polyester PBT is the undisputed champion. Your choice directly impacts customer satisfaction and product longevity.

Let's break down this common dilemma for fashion brands and designers. We will explore the key properties of each fabric. This will help you make an informed decision that aligns with your brand's vision and your customers' needs.

What are the key properties of Nylon Spandex for swimwear?

Nylon Spandex, often called Polyamide Elastane, is a classic in the swimwear world. It's loved for its feel and drape. When you pick up a piece of swimwear that feels soft and smooth, it's likely Nylon Spandex. This fabric combination brings a certain luxury to swimwear lines.

Its most notable feature is its incredible softness. The fabric feels gentle and comfortable against the skin. It also has a high level of elasticity. This allows the swimsuit to hug the body's contours beautifully without feeling restrictive. The matte finish of Nylon Spandex provides a sophisticated, non-shiny look. It is also a great canvas for printing, resulting in bright and vibrant patterns.

How does Nylon Spandex enhance swimwear comfort?

Comfort is king in swimwear, and Nylon Spandex delivers. The nylon component is naturally very soft. When combined with spandex, it creates a fabric that moves with the wearer. This blend offers a second-skin feel that is hard to beat. It provides excellent stretch and recovery. This means the swimsuit will return to its original shape after being stretched. It also dries reasonably fast. This quick-drying property helps in maintaining comfort after a swim.

What are the limitations of using Nylon Spandex?

While excellent, Nylon Spandex has its weaknesses. Its main drawback is its lower resistance to chlorine and UV radiation compared to polyester. Prolonged exposure to chlorinated pool water can cause the fabric to weaken and the colors to fade over time. It is also generally less durable than Polyester PBT when subjected to harsh conditions. This is why you often see it in fashion-forward swimwear rather than performance-oriented or heavy-duty swimwear. For brands targeting the luxury resort-wear market, this is often a calculated and acceptable trade-off for the superior hand-feel.

Why is Polyester PBT known for durability?

Polyester PBT (Polybutylene Terephthalate) is the workhorse of performance swimwear. It is engineered for resilience. If you are creating swimwear for athletes, frequent swimmers, or children, this is your go-to fabric. Its reputation for durability is well-earned and stems from its chemical structure.

PBT is a type of polyester with exceptional elastic recovery. It is incredibly strong and resistant to wear and tear. The fibers can withstand repeated stretching and exposure to harsh elements without breaking down. This makes swimwear made from Polyester PBT last significantly longer, especially under heavy use. It's the fabric of choice for swim teams and anyone who spends a lot of time in the pool.

How does Polyester PBT resist chlorine damage?

Chlorine resistance is the superpower of Polyester PBT. Unlike nylon, the molecular chains in polyester fibers are not easily broken down by chlorine. This means swimwear made from PBT will maintain its integrity and color far longer in chlorinated pools. It doesn't degrade or become weak and brittle. This is a critical factor for competitive swimwear, where longevity and consistent performance are paramount. For your customers, this translates to a swimsuit that doesn't sag or lose its shape after multiple pool visits.

Is Polyester PBT less comfortable than Nylon Spandex?

Historically, polyester had a reputation for being less soft. However, modern textile innovation has closed this gap significantly. Today's high-quality Polyester PBT fabrics are engineered to be much softer and more comfortable. While it may not always achieve the exact initial silky feel of premium Nylon Spandex, its performance benefits often outweigh this for many users. Furthermore, its excellent quick-drying capability adds to comfort by pulling moisture away from the skin rapidly, preventing that cold, clammy feeling.

How do you choose based on color and design?

Your fabric choice directly impacts the visual appeal of your swimwear line. Color fastness and design potential are major deciding factors for brands. This is where the inherent properties of each fiber really show through. You need to think about how the colors will look initially and how they will hold up over time.

Nylon is known for its excellent dye affinity. It absorbs dye deeply, resulting in rich, vibrant colors. It is also the preferred base for digital printing, allowing for complex and photorealistic patterns. Polyester PBT, on the other hand, excels in color retention. The colors may not be quite as deep initially, but they are locked in and resist fading from chlorine and sunlight much better.

Which fabric offers better printing capabilities?

For intricate designs, Nylon Spandex is often the winner. Its fiber structure allows dyes to penetrate deeply, making it ideal for sophisticated digital printing techniques. This process can produce stunning, high-definition patterns with a wide color gamut. The matte surface of nylon provides a perfect, non-reflective canvas that makes these colors pop. If your brand identity is built on bold, artistic prints, Nylon Spandex is typically the superior material.

Which fabric maintains its color longer?

When it comes to color longevity, Polyester PBT takes the lead. The dyeing process for polyester involves embedding the color at a high temperature, which essentially seals the dye within the fiber. This makes the fabric highly resistant to fading from chlorine, salt water, and UV exposure. Your designs will stay looking new and vibrant for the entire lifespan of the garment. This is a key selling point for consumers who are tired of their swimwear fading after one season.

What about cost and sustainability?

In today's market, price and environmental impact are crucial considerations. Your fabric choice affects your cost per unit and your brand's ecological footprint. Understanding the balance between these factors can give you a competitive edge.

Generally, Nylon Spandex and Polyester PBT are in a similar price range, but fluctuations depend on raw material costs and specific fabric constructions. From a sustainability perspective, the conversation is evolving rapidly. Both fibers are synthetic, but the industry is making significant strides in offering recycled alternatives for each.

| Feature | Nylon Spandex | Polyester PBT |

|---|---|---|

| Primary Strength | Softness & Comfort | Durability & Chlorine Resistance |

| Color Vibrancy | Excellent for printing | Excellent retention |

| Environmental Choice | Recycled Nylon (e.g., ECONYL) | Recycled Polyester (rPET) |

| Ideal For | Fashion swimwear, resort wear | Performance swimwear, daily wear |

Are there eco-friendly options available?

Yes, absolutely. The demand for sustainable swimwear fabric is growing. We now offer both recycled Nylon and recycled Polyester PBT. Recycled Nylon, often sourced from discarded fishing nets and industrial plastic, recreates a high-quality fiber. Recycled Polyester (rPET) is made from post-consumer plastic bottles. Both options significantly reduce the environmental impact without compromising on the key performance properties of their virgin counterparts. Promoting your use of recycled materials can be a powerful marketing tool.

How does fabric choice impact the final product cost?

The base fabric cost is one part of the equation. However, you must consider the total cost of ownership. While a Nylon Spandex swimsuit might have a slightly lower material cost in some cases, a Polyester PBT suit will likely last longer. This means your customers get more value for their money, and you may face fewer returns or complaints about durability. Offering a blend of both fabrics in your collection can cater to different price points and consumer expectations, maximizing your market reach.

Conclusion

Choosing between Nylon Spandex and Polyester PBT isn't about finding a single "best" fabric. It's about finding the best fabric for your specific needs. Nylon Spandex offers unbeatable softness and brilliant printability, perfect for fashion-forward brands. Polyester PBT provides unmatched durability and chlorine resistance, ideal for performance and everyday swimwear. Many successful brands now leverage both, using them for different lines within their collection to cater to various customer segments.

Your swimwear line deserves a foundation of quality and reliability. At Fumao Textiles, we specialize in producing both high-grade Nylon Spandex and Polyester PBT fabrics. We control the process from weaving to finishing, ensuring strict quality control, fast production times, and competitive pricing. We can guide you through this exact choice, helping you select the perfect fabric that aligns with your design vision and business goals. Let's create amazing swimwear together. For a personal consultation on your next order, please contact our Business Director, Elaine, at elaine@fumaoclothing.com.