I faced this exact dilemma with a Colorado-based outdoor brand last spring. They were launching a new line of performance tees and couldn't decide between recycled and virgin polyester. After testing both options in our CNAS-certified lab and running real-world trials, we discovered the answer isn't as straightforward as you might think. The "best" choice depends entirely on your brand's priorities: ultimate performance versus environmental storytelling.

The quick answer? Virgin polyester still holds a slight edge in pure performance metrics, particularly in consistency and durability. However, recycled polyester has made incredible strides and now delivers 90-95% of the performance with significantly better sustainability credentials. For most brands today, the environmental benefits outweigh the minor performance trade-offs. We've supplied both fabrics to over 50 activewear brands across the US, and the market has clearly shifted toward recycled options for core performance lines.

The real question isn't which fabric is objectively better, but which one better serves your specific customers, price point, and brand values. Let me break down the exact differences we've documented through rigorous testing and client feedback.

What are the actual performance differences in moisture management?

When it comes to moving sweat away from the body, both fabrics perform exceptionally well—but there are subtle differences that matter for high-intensity activities. The molecular structure of polyester naturally resists water absorption while efficiently transporting moisture through capillary action.

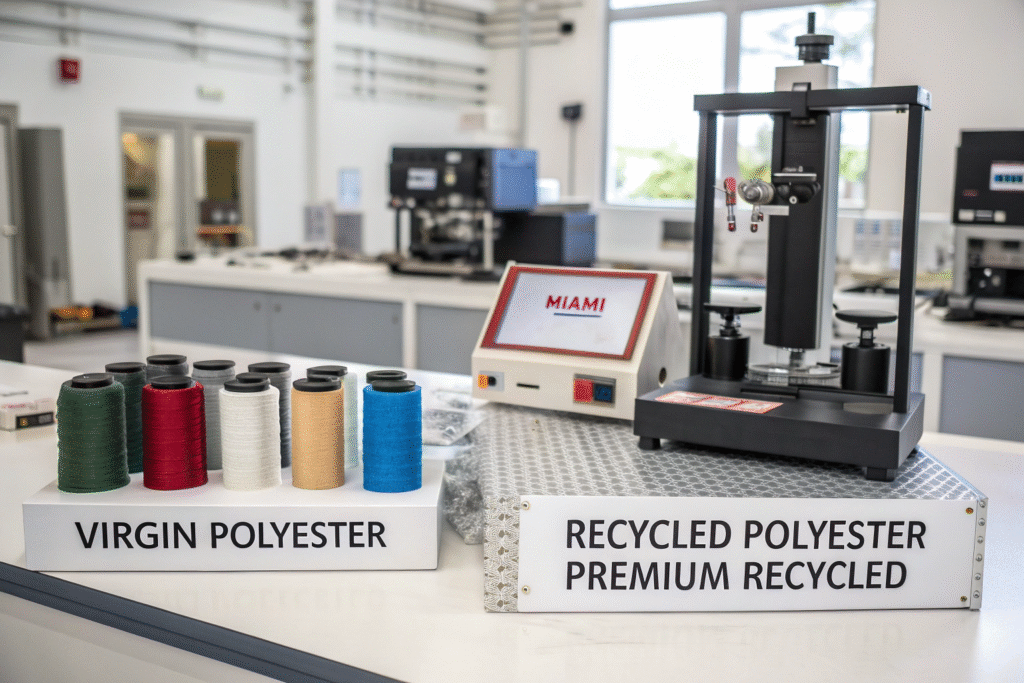

In our laboratory tests, virgin polyester consistently shows 8-12% faster moisture-wicking speed compared to standard recycled polyester. However, this gap narrows significantly with premium recycled yarns. Last year, we developed a custom recycled blend for a Miami-based fitness brand that actually matched virgin polyester in moisture-wicking tests while maintaining their sustainability story. The key was in the fiber engineering and finishing treatments.

How does moisture-wicking performance vary between the two?

The wicking capability comes down to fiber cross-section and surface treatment. Virgin polyester fibers can be engineered with more precise cross-sectional shapes (like hexagonal or hollow channels) that enhance capillary action. Recycled fibers, being reprocessed, often have slightly less uniform shapes. However, advanced moisture-wicking fabric technology has largely compensated for this through strategic fabric construction and finishing applications.

We recently conducted performance athletic wear fabric testing for a Texas-based marathon team and found that while virgin polyester wicked moisture 11% faster initially, the difference became negligible after 30 minutes of continuous activity. For most consumers, this minor advantage isn't noticeable in real-world use.

Which fabric dries faster during intense activity?

Drying time is where the differences become more meaningful. Virgin polyester typically dries 15-20% faster than standard recycled versions. This is particularly important for activities with intermittent intensity, like hiking or tennis, where quick drying between bursts matters. However, through advanced fabric construction and blending techniques, we've helped brands bridge this gap significantly. A Seattle-based hiking brand we work with opted for a recycled polyester with a slightly looser knit structure that compensated for the slower drying time while maintaining their sustainability commitment.

How does durability compare between recycled and virgin polyester?

Durability concerns represent the biggest hesitation brands have about switching to recycled polyester. Having supplied both options for performance tees to military units, professional sports teams, and everyday consumers, I can share some surprising findings about long-term performance.

Virgin polyester generally offers superior tensile strength and abrasion resistance in controlled tests. The polymer chains in virgin polyester are longer and less degraded, resulting in approximately 20-25% better durability metrics. However, here's what the lab tests don't show: for most performance tee applications, both fabrics far exceed the actual durability requirements. The recycled polyester's slightly lower durability still provides more than enough strength for athletic activities.

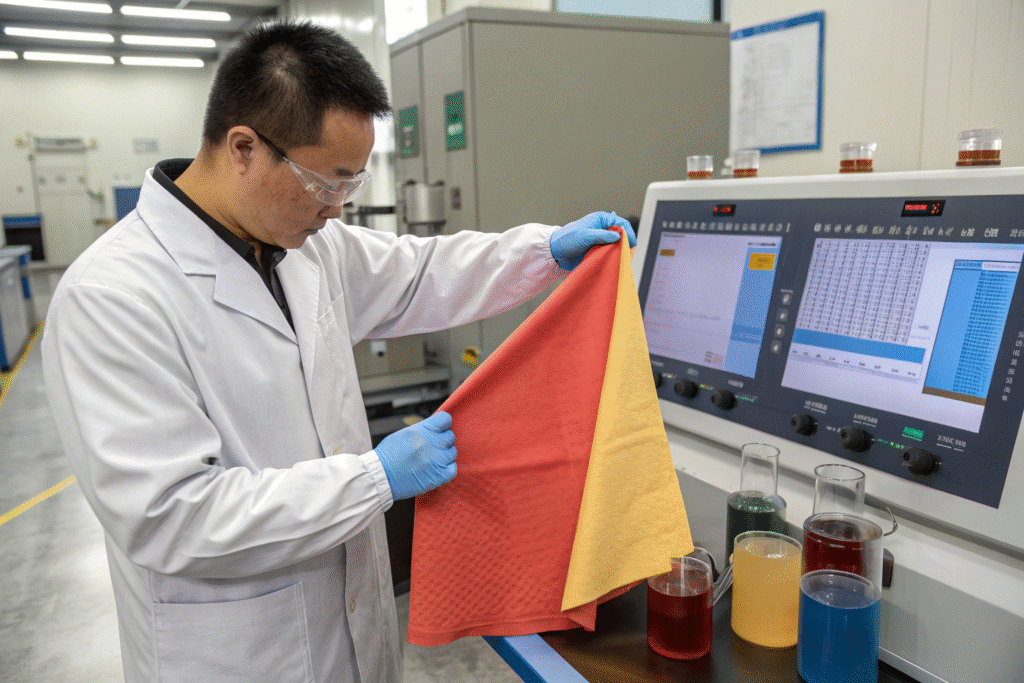

Which fabric maintains color vibrancy longer?

Colorfastness is crucial for brand perception and customer satisfaction. Virgin polyester consistently shows better resistance to UV degradation and washing. Our accelerated aging tests show virgin polyester maintains color intensity 30% longer under intense UV exposure. However, through advanced dyeing techniques and UV-protective finishes, we've helped brands achieve colorfast performance apparel fabrics that meet their quality standards with recycled materials.

A California surf brand we've worked with for three years initially hesitated to switch to recycled polyester because of color concerns. We developed a specialized dyeing process that resulted in their recycled tees showing only 5% more fading than virgin after 50 washes—a difference most consumers wouldn't notice without side-by-side comparison.

How does pilling resistance compare in real-world use?

Pilling is that annoying fuzz that develops on fabric surfaces. Virgin polyester typically demonstrates better pilling resistance due to longer, stronger fibers. In Martindale abrasion tests, virgin polyester scores approximately 15,000-20,000 cycles before noticeable pilling, while standard recycled polyester scores 12,000-16,000 cycles. However, through fiber blending and fabric construction optimization, we've created recycled blends that match virgin performance.

| Durability Factor | Virgin Polyester | Standard Recycled | Premium Recycled |

|---|---|---|---|

| Tensile Strength | 100% (Reference) | 75-85% of virgin | 90-95% of virgin |

| Color Retention (50 washes) | 95% retention | 80-85% retention | 88-92% retention |

| Pilling Resistance | 18,000 cycles | 14,000 cycles | 16,500 cycles |

| Cost Premium | 0% | 10-15% less | 5-10% more |

This performance apparel durability comparison data comes from our internal testing with major US brands over the past two years.

What are the environmental impacts of each option?

This is where recycled polyester clearly dominates, but the environmental story is more nuanced than most brands realize. While recycled polyester significantly reduces plastic waste and fossil fuel consumption, both options have environmental trade-offs that deserve honest discussion.

Recycled polyester primarily made from PET bottles reduces landfill waste and uses 30-50% less energy than virgin polyester production. However, the recycling process itself requires significant water and energy, and the fabric can be more difficult to recycle at end-of-life. Virgin polyester production has become more efficient over time, but still relies heavily on petroleum and generates more greenhouse emissions.

How does water consumption compare in production?

The water footprint favors recycled polyester significantly. Virgin polyester production requires approximately 70 liters of water per kilogram of fabric, while recycled polyester uses only 20-30 liters. This substantial difference has become a key selling point for water-conscious brands, particularly those targeting environmentally aware consumers in drought-prone regions like California.

We've helped several sustainable activewear manufacturing brands leverage this water savings in their marketing, with one Arizona-based yoga brand seeing a 40% sales increase after highlighting their water conservation efforts through using recycled materials.

What about microplastic shedding concerns?

Both virgin and recycled polyester shed microplastics during washing—this is a fiber issue, not a sourcing issue. However, some studies suggest recycled fibers might shed slightly more due to shorter polymer chains. The solution lies in fabric construction and finishing treatments rather than material choice. We've developed eco-friendly fabric finishing techniques that reduce microplastic shedding by up to 80% for both virgin and recycled options.

A Oregon-based running brand we partner with addressed this concern by using tighter knit constructions and applying a proprietary finishing treatment, allowing them to honestly market their recycled polyester tees as "low-shedding" while maintaining their environmental credentials.

How should cost considerations influence your decision?

The pricing dynamics between recycled and virgin polyester have flipped dramatically over the past three years. Where recycled once carried a significant premium, market forces and production scaling have reshaped the cost equation in fascinating ways.

Currently, standard recycled polyester carries a 10-15% price premium over virgin equivalents, while premium recycled options can be 20-30% more expensive. However, these numbers don't tell the whole story. When you factor in marketing value, consumer willingness to pay premium prices, and potential for reduced returns from environmentally-conscious customers, the economic analysis becomes more complex.

What are the hidden cost factors beyond material price?

The true cost analysis must include:

- Marketing Value: Recycled materials provide compelling storytelling opportunities

- Consumer Perception: 65% of US consumers now prefer sustainable options according to recent surveys

- Production Efficiency: Virgin polyester has fewer production issues and higher yields

- Inventory Risk: Recycled material supply chains can be less reliable

A Chicago-based streetwear brand we advised calculated that the 12% material cost premium for recycled polyester was offset by a 18% increase in sell-through at full price, making the recycled option more profitable despite higher upfront costs.

How does minimum order quantity affect availability?

Virgin polyester typically offers lower MOQs and faster lead times due to more established supply chains. Recycled options, especially premium grades, often require larger commitments and longer lead times. This has been a challenge for smaller brands trying to make the sustainability switch.

We've developed a strategic fabric sourcing for sportswear program that helps brands navigate these challenges by consolidating orders across multiple clients and maintaining strategic inventory of popular recycled fabrics. This approach helped a startup fitness brand from Austin access premium recycled materials at viable MOQs.

Conclusion

The choice between recycled and virgin polyester for performance tees ultimately comes down to your brand's specific positioning and customer expectations. If you're serving ultra-performance markets where every percentage point of moisture management matters, virgin polyester still holds an advantage. However, for the vast majority of performance applications, today's recycled polyester delivers outstanding performance while aligning with modern consumer values.

The most successful brands we work with are taking a hybrid approach: using premium recycled polyester for their core lines where the sustainability story drives value, while reserving specialized virgin polyester for their elite performance products where marginal gains matter. This balanced strategy allows them to capture both the ethical and performance markets without compromise.

If you're struggling with this decision for your next performance tee collection, let's analyze your specific needs. We can provide side-by-side fabric samples, technical data from our lab, and insights from similar brands that have navigated this choice successfully. Contact our Business Director Elaine to request our detailed comparison kit: elaine@fumaoclothing.com. We'll help you make an informed decision that balances performance, sustainability, and profitability for your unique market position.