As a fabric supplier with over two decades in the textile hub of Keqiao, I often get asked by clients like Ron in the U.S. about blocking out light completely. They want a dark room for better sleep or to protect furniture from sun damage. The right blackout curtain is crucial, but the choice can be confusing. Many people focus only on the fabric itself. However, the coating technology is what truly makes a curtain block light effectively. Getting both elements right is key to high performance.

The best fabric for blackout curtains is typically a dense, heavyweight woven fabric like polyester or a polyester-cotton blend. These fabrics provide a tight structure that forms a good base. However, the real secret to total blackout performance lies in its coating—a layer of acrylic foam or PVC laminated onto the fabric's back. This coating is what completely blocks light, adds insulation, and improves sound absorption. At our factory, we combine robust base cloths with advanced coating techniques to ensure no light leaks through.

Let's break down the components of a perfect blackout curtain. We will look at the ideal base fabrics, the science behind the coatings, and how to ensure quality from production to your window.

What is the best base fabric for blackout curtains?

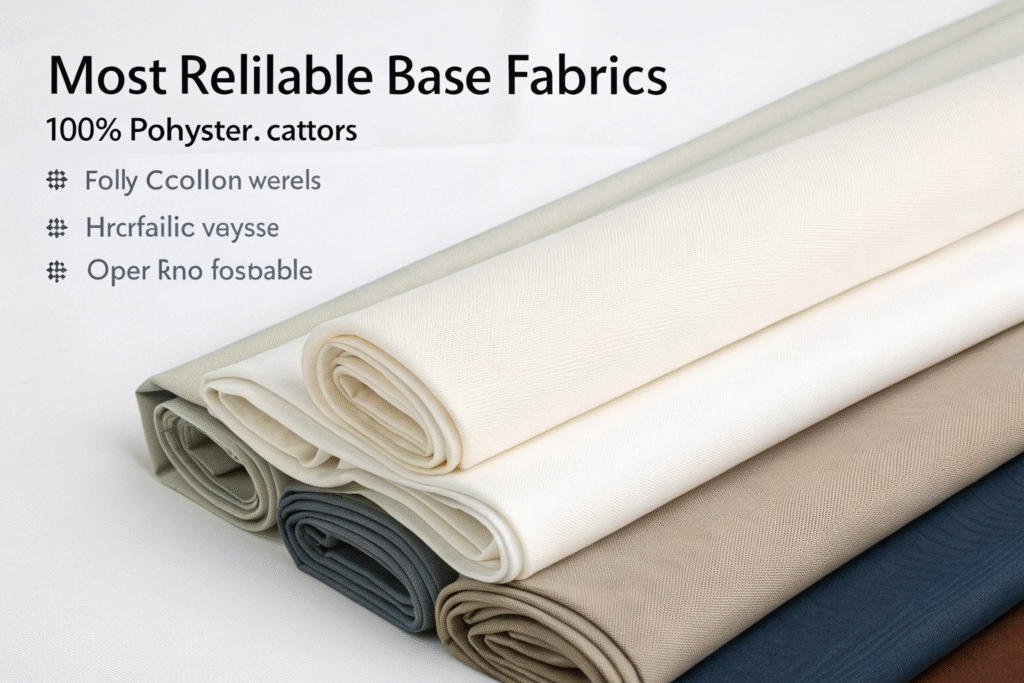

For a blackout curtain to work well, it needs a strong and dense base fabric. The base cloth is the foundation. Loose weaves or lightweight materials will allow light to penetrate, no matter how good the coating is. We need a fabric that is tightly constructed and has a high density.

The most reliable base fabrics are 100% polyester or poly-cotton blends in a plain or twill weave. Polyester is a synthetic fiber known for its durability and stability. It does not shrink or wrinkle easily, which is vital for maintaining the curtain's shape and appearance. A plain weave or a tight twill weave creates a smooth, uniform surface. This smooth surface is perfect for applying the blackout coating evenly. At our Fumao factory, we use specialized weaving machines to produce these high-density fabrics. This ensures a perfect canvas for the subsequent coating process. Fabrics like chiffon or loose linen are not suitable because their open weaves let light through.

Why is fabric density more important than fiber type?

While the fiber is important, the construction of the fabric is critical. A dense weave means the yarns are packed closely together. This leaves minimal gaps for light to pass through. Think of it like an umbrella. A tightly woven umbrella keeps you dry in a storm. A loosely woven one will leak. It is the same principle with blackout curtains. We prioritize the Thread Count and the weave style to achieve maximum density. A high thread count indicates more threads per square inch, creating a tighter shield. Our quality control team uses specialized equipment to measure this density, ensuring every batch meets the standard before it goes for coating.

How does fabric weight impact blackout effectiveness?

Fabric weight, measured in GSM (Grams per Square Meter), is a direct indicator of density and thickness. Heavier fabrics are generally better at blocking light and sound. For effective blackout curtains, we recommend a base fabric with a GSM of at least 220. This weight provides a substantial barrier. Here is a quick comparison:

| Fabric Weight (GSM) | Blackout Performance | Typical Use |

|---|---|---|

| Below 180 GSM | Poor | Standard curtains, not for blackout |

| 180 - 220 GSM | Good | Basic blackout, some light may seep |

| Above 220 GSM | Excellent | Full blackout, enhanced insulation |

Heavier fabrics also drape better. They hang more elegantly at your window, adding to the room's aesthetic. Our production line is set up to handle these heavier textiles, from weaving to final inspection.

What are the common types of blackout coatings?

The coating is the magic layer that turns a regular fabric into a blackout curtain. It is a compound applied to the back of the fabric. This layer is responsible for reflecting and absorbing light. The two most common types are acrylic foam and PVC coatings. Each has its own properties and advantages.

Acrylic foam coating is a popular choice for modern blackout curtains. It is a water-based coating that is more environmentally friendly. This coating is applied as a liquid and then foamed and dried, creating a thick, light-blocking layer. It is also breathable, which helps to prevent moisture buildup and mildew. This makes it a healthier option for indoor spaces. Many of our European clients prefer this type due to strict EU eco-certifications. We use advanced coating machines to ensure an even and consistent application every time.

How does a PVC coating differ from an acrylic one?

PVC (Polyvinyl Chloride) coating is another effective blackout solution. It is a plastic-based layer that is often laminated onto the fabric. PVC coatings provide excellent total blackout and are very durable. They are also good at providing thermal insulation, keeping rooms warmer in winter and cooler in summer. However, they are less breathable than acrylic foam and can have a stronger chemical smell initially, which needs to air out. For clients needing maximum durability and insulation, such as for hotels or home theaters, we often recommend PVC coated options. Our partner coating factory is CNAS-certified, ensuring all coatings meet safety and performance standards.

What is the role of triple-weave technology in blackout?

Besides coatings, there is another method: triple-weave technology. This is a construction where three layers of fabric are woven together. The middle layer is usually a black yarn that traps light. The result is a thick, heavy fabric that is naturally blackout without any chemical coating. This is a great eco-friendly alternative. While it can be more expensive, it offers a soft, textile feel on both sides. We have the weaving capability to produce these sophisticated triple-weave fabrics for clients focused on sustainable and chemical-free home textiles.

How to ensure quality and durability in blackout curtains?

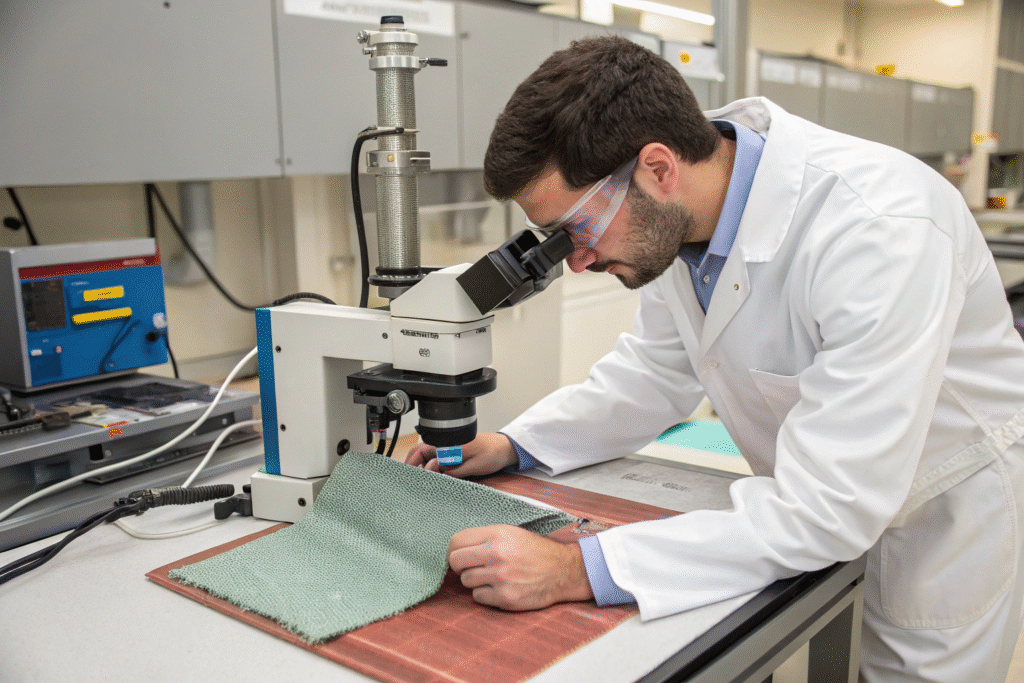

Making a blackout curtain is not just about blocking light today. It needs to last for years without cracking, peeling, or fading. Quality control is essential at every stage. From the strength of the base cloth to the adhesion of the coating, every detail matters.

The first step is testing the base fabric. We check for tensile strength and colorfastness. The fabric must be strong enough to support the heavy coating without tearing. We also test for shrinkage. If the fabric and coating shrink at different rates, it can cause warping or bubbling. In our CNAS-accredited lab, we simulate various temperature and humidity conditions. This ensures the final product remains stable in different climates, like the varying conditions across the U.S.

Why is coating adhesion testing critical?

The bond between the fabric and the coating must be perfect. Poor adhesion will cause the coating to peel off over time, especially after washing or dry cleaning. We perform rigorous adhesion tests. A common method is the peel test, where we measure the force required to separate the coating from the fabric. We also conduct repeated bending tests to simulate long-term use. For clients who need washable blackout curtains, we use a special polymer in our coating formula. This enhances flexibility and adhesion, ensuring the coating stays intact.

What certifications should you look for?

Certifications are your guarantee of safety and quality. For blackout curtains, especially for home use, look for fire safety and chemical content certifications. Key standards include:

- OEKO-TEX Standard 100: This certifies that the fabric and coating are free from harmful levels of more than 100 substances. This is crucial for children's rooms.

- ISO 9001: This confirms the manufacturer has a robust quality management system.

Our company holds both SGS and OEKO-TEX certifications. We provide these reports to our clients, giving them confidence in the product's safety and our commitment to quality.

How to source blackout fabric from China efficiently?

For international buyers like Ron, sourcing from China offers great value but comes with challenges. These include communication gaps, logistics delays, and hidden costs. An efficient sourcing process requires a supplier with a transparent and integrated supply chain.

The key is to find a supplier that controls the entire process. We have our own weaving and cooperative coating factories. This means we manage everything under one roof. There is no middleman. This control allows us to offer faster sampling. We can develop a blackout fabric sample within 48 hours. It also allows for better pricing. Because we produce the base fabric ourselves, we can guarantee the quality from the very beginning and avoid price markups.

What are the advantages of a one-stop supplier?

A one-stop supplier simplifies everything. Instead of coordinating with a weaver, a coater, and a finisher separately, you have one point of contact. This saves time and reduces errors. For example, at Fumao, we handle yarn sourcing, weaving, coating, inspection, and packaging. We even assist with shipping and customs clearance. Our professional QC team inspects the fabric at every stage. This integrated approach is why we can promise a 98% client pass rate on quality inspections. It solves the pain points of timeliness and quality control directly.

How can you mitigate tariff and logistics risks?

Tariff costs and sailing schedules are major concerns for U.S. importers. To mitigate this, we have a diversified logistics strategy. We work with reliable freight forwarders and have experience shipping under various trade terms. Furthermore, our location in Keqiao gives us direct access to the Ningbo and Shanghai ports, ensuring quick shipment. While we cannot avoid US tariffs, our efficient production and direct factory pricing often offset these costs, providing a competitive total price. We also provide all necessary documentation to ensure smooth customs clearance.

Conclusion

Choosing the right blackout curtain involves understanding both its core components: a dense, heavyweight base fabric like polyester and a functional coating like acrylic foam or PVC. The fabric provides the structure, while the coating delivers the light-blocking power. Remember to prioritize quality checks on coating adhesion and look for relevant safety certifications to ensure you get a durable and safe product.

If you are looking to manufacture your own line of high-quality blackout curtains or other home textile products, partnering with a reliable supplier is the most important step. We, at Fumao Textiles, have the expertise, vertical integration, and quality control systems to bring your designs to life efficiently and reliably. For a direct conversation about your specific needs, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's co-create value for your market.