As textile technology evolves, more industries are looking for innovative fabrics that not only provide comfort but also deliver data-driven functionality. One of the most exciting developments is the emergence of piezo-resistive pressure mapping textiles, which are widely used in healthcare, smart wearables, and industrial monitoring. Many buyers, especially from the U.S. and Europe, often ask me where to find reliable suppliers of these specialized textiles.

You can find piezo-resistive pressure mapping textiles through established technical textile manufacturers, specialized e-textile suppliers, and trusted global platforms such as Alibaba and industrial distributors. These fabrics are engineered to sense and map pressure, making them essential for wearable devices, sports monitoring, and ergonomic seating solutions.

The challenge lies not just in finding a supplier but in choosing one that can guarantee consistency, performance, and global logistics. Let’s explore the leading sourcing options and what makes them trustworthy.

Best Global Suppliers for Piezoresistive Fabrics

Global suppliers play a critical role in providing ready-to-use piezoresistive fabrics. Buyers from fashion tech, healthcare, and industrial fields prefer working with companies that already have a proven track record in advanced e-textiles.

The most trusted suppliers include EeonTex™ (Marktek Inc.), Faraday Fiber, and Sefar. Each of these companies specializes in conductive and piezoresistive fabrics that are widely adopted for pressure sensing and mapping applications.

For any American buyer like Ron, these suppliers offer the peace of mind that comes from certifications, export readiness, and sustainable manufacturing practices.

What makes EeonTex™ fabrics popular?

EeonTex™ fabrics are well known for their versatility. They are engineered in different surface resistivities, allowing them to be customized for sportswear, medical equipment, or industrial sensors. Many buyers appreciate that the fabrics are washable and durable, which is often a concern when dealing with electronic textiles. A deeper advantage is that they come with strong conductive fabric technology and multiple forms, such as woven, knitted, or nonwoven options.

Another reason buyers trust EeonTex™ is that it works across industries. The fabrics are already applied in biometric pressure sensors and rehabilitation products, which shows their adaptability and reliability.

Why should you consider Faraday Fiber?

Faraday Fiber offers piezoresistive fabrics that can handle repeated wash cycles without losing performance. Buyers from sportswear and ergonomics industries often prefer them because they provide consistent readings even after long use. Their fabrics have adjustable resistivity, making them adaptable for custom designs.

The durability claim is backed by research and product tests available directly on Faraday Fiber’s official site. Customers also value their ability to integrate fabrics into wearable medical textile solutions, which highlights their multi-sector applications.

Buying Through Trusted Platforms

For many global buyers, trade platforms are often the fastest way to locate suppliers. These platforms provide direct access to manufacturers who specialize in piezoresistive fabrics.

Platforms like Alibaba now offer flexible piezo-resistive sensing fabrics that combine silver fibers and textile durability, making them ideal for smart clothing and sensor patches.

However, the challenge for many buyers is differentiating between reliable manufacturers and small resellers who lack long-term capability.

Can Alibaba be a reliable source?

Alibaba has become a powerful sourcing platform for piezo-resistive fabrics. Many manufacturers list specialized products such as silver-fiber piezoresistive textiles. These listings often include technical details like resistivity ranges, washability, and custom options.

Still, buyers must perform careful checks. Reading verified buyer reviews and requesting fabric certifications from suppliers helps minimize risks.

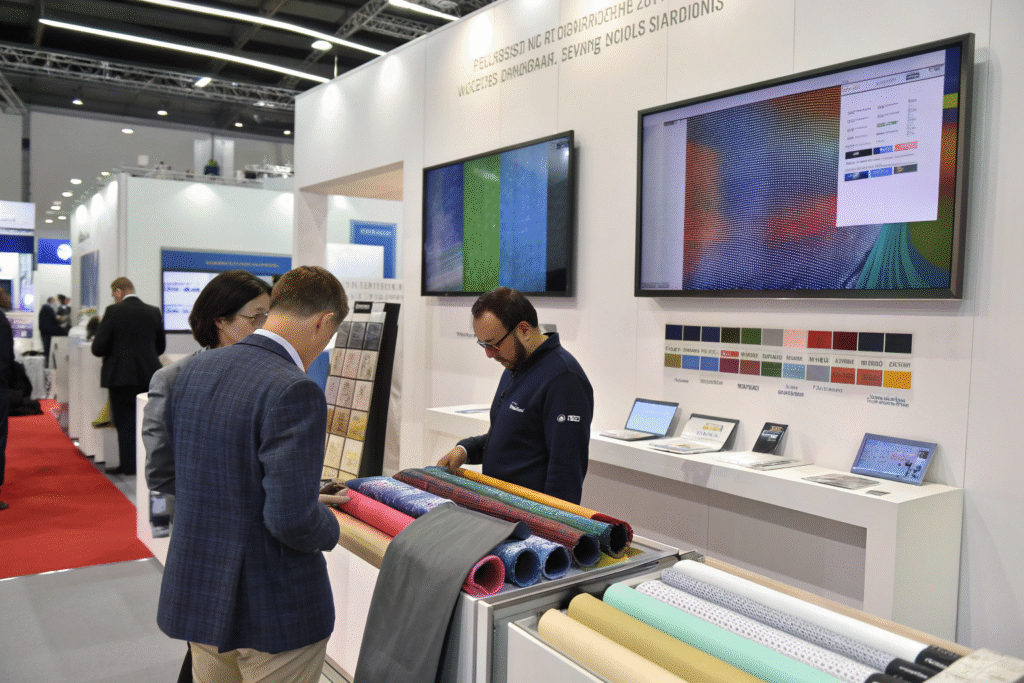

What about trade shows?

Trade shows remain a strong channel for discovering new suppliers. In China’s Keqiao or international hubs like Frankfurt’s Heimtextil, textile innovators present the latest in smart fabrics. Visitors often get hands-on experience with piezoresistive textile demos and direct access to factory representatives.

This method provides confidence because buyers can test the fabrics in real time and discuss logistics, certifications, and custom development directly with suppliers.

Innovations in Academic Research

Another way to access piezo-resistive fabrics is to collaborate with academic labs that specialize in textile engineering. While not direct suppliers, universities and research institutes often pioneer advanced technologies.

Recent innovations include embroidered conductive sensors, microneedled neoprene structures, and 3D woven pressure fabrics. These prototypes often become the foundation for future commercial textile products.

These collaborations are particularly attractive for companies seeking custom designs that standard suppliers may not yet offer.

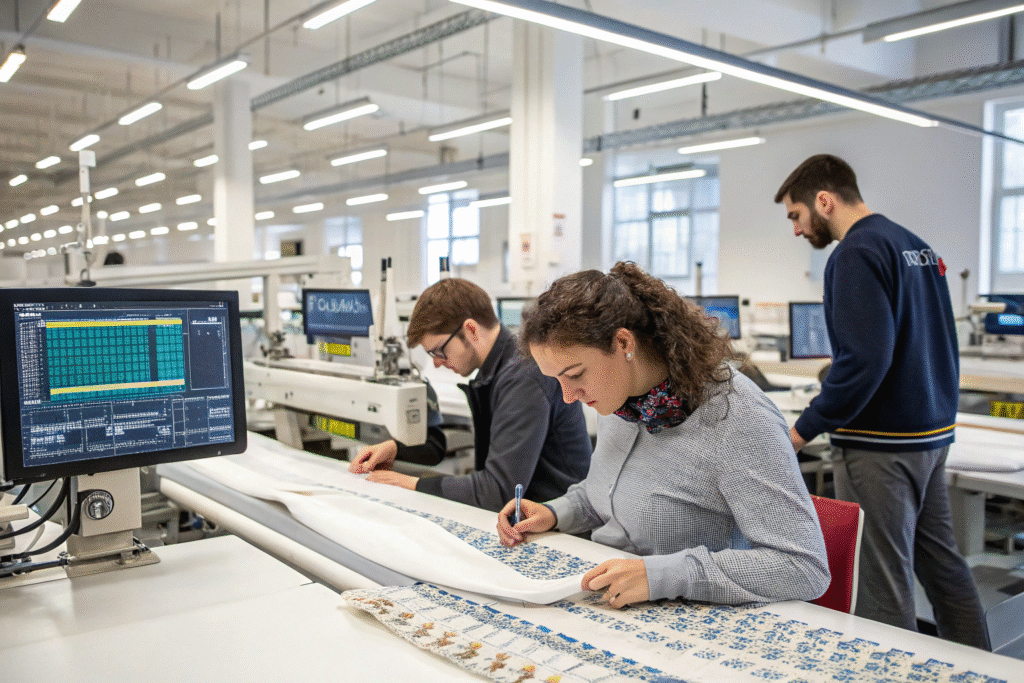

How can embroidery enhance sensor textiles?

Embroidery is one of the most promising techniques in creating programmable piezoresistive fabrics. By integrating conductive yarns into standard garments, researchers achieve flexible and scalable textile sensors. Studies like this research on embroidered sensors show the potential for wearable applications.

For buyers, this means future opportunities to integrate custom textile sensors directly into apparel without sacrificing comfort.

What role does microneedling play?

Microneedling is another exciting method where tiny perforations are filled with conductive particles to create high-sensitivity fabrics. A recent study on neoprene-based sensors demonstrates how microneedling significantly improves performance.

These findings are relevant for companies seeking fabrics that are not only sensitive but also durable under stress, making them ideal for industrial and medical applications.

Practical Applications in Healthcare and Wearables

Beyond sourcing, it is important to understand why these fabrics are in demand. Healthcare and wearables are two major industries driving adoption of piezo-resistive pressure mapping textiles.

From pressure-mapping beds in hospitals to smart insoles for athletes, piezoresistive fabrics deliver measurable improvements in performance and care.

This application-driven demand ensures that suppliers continue to invest in research and product refinement.

Why is healthcare adopting pressure mapping fabrics?

Hospitals increasingly use piezo-resistive fabrics for pressure ulcer prevention. Fabrics placed under patients map pressure points in real time, which helps reduce injuries and improve comfort. Many companies have turned to smart healthcare textiles as part of their innovation strategy.

This approach combines the benefits of patient safety and operational efficiency, making suppliers of these fabrics essential to the medical industry.

How are wearables benefiting?

Wearables like smart insoles and sportswear rely heavily on piezo-resistive fabrics. Athletes use them to measure foot pressure, balance, and gait. For example, 3D woven piezoresistive sensors have shown great promise in athletic applications.

Sports brands are now working with functional textile manufacturers to integrate these fabrics directly into training gear, providing athletes with precise data while maintaining comfort.

Conclusion

Piezo-resistive pressure mapping textiles are no longer a futuristic concept—they are already shaping healthcare, wearables, and industrial applications. Reliable sources like EeonTex™, Faraday Fiber, and Sefar provide immediate solutions, while platforms like Alibaba and trade shows connect buyers to global suppliers. Academic research continues to expand the possibilities for custom designs.

If you are considering placing your own fabric orders, we at Shanghai Fumao can support you in developing customized textiles with full production and export services. For inquiries, please contact our Business Director Elaine at elaine@fumaoclothing.com.