Finding authentic NASA-approved aerogel insulation blanket fabric can be overwhelming, especially when you need it for high-stakes applications like aerospace, cryogenics, or extreme-environment protective clothing. Many buyers get stuck in endless online searches, sifting through unreliable suppliers and inconsistent product data. The stakes are high—one wrong choice could result in failed insulation performance or failed compliance tests.

The good news? NASA-grade aerogel fabrics are available through specialized, vetted suppliers who meet strict certification standards. If you know where to look, you can secure top-quality insulation material that offers unmatched thermal protection, ultra-lightweight performance, and verified space-grade durability.

In this guide, I’ll share where to source NASA-approved aerogel insulation fabrics, how to identify authentic certification, and what to compare when choosing a supplier for high-performance projects.

What Is NASA-Approved Aerogel Blanket Fabric?

NASA-approved aerogel blanket fabric is not your average insulation. It is a composite material, typically made of a silica-based aerogel integrated into a flexible fiber matrix. This structure delivers extreme thermal resistance at minimal weight, which is why it is favored in spacecraft, satellites, and deep-space probes.

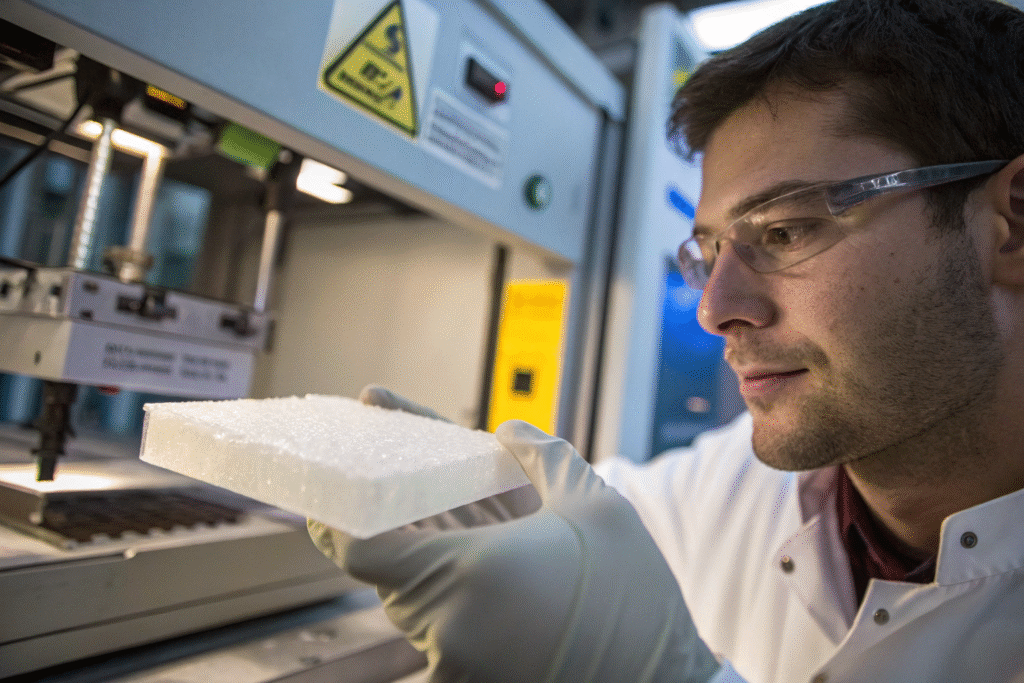

NASA's evaluation process involves rigorous testing—thermal conductivity at cryogenic and high-heat ranges, flammability tests, off-gassing analysis, and durability under vacuum. Only fabrics passing these tests can be labeled NASA-approved.

How Does Aerogel Insulation Work?

Aerogel is mostly air trapped within a silica network, creating a nanostructure that blocks heat transfer. This is why it has one of the lowest thermal conductivity values of any known solid. The NASA Glenn Research Center has extensively studied its use for protecting spacecraft from extreme temperatures.

Another common variant is Pyrogel, a commercial aerogel blanket widely used in industrial insulation, which you can find through suppliers like Aspen Aerogels.

Why Is NASA Approval Important?

NASA approval is not just a marketing term—it’s proof the fabric meets aerospace-grade safety and performance standards. For example, insulation used in the Orion spacecraft undergoes extreme cold soak and thermal cycling tests. Using uncertified fabric could cause insulation failure, potentially damaging sensitive instruments.

Best Global Suppliers for Aerogel Insulation Fabric

When sourcing NASA-grade aerogel fabrics, you must look beyond basic online listings. Some suppliers specialize in aerospace and defense-grade materials, while others cater to cryogenic and industrial markets.

Which Countries Lead in Aerogel Fabric Production?

The U.S., China, and select European countries dominate production. The European Space Agency also certifies certain aerogel fabrics for its missions.

China, in particular, benefits from a strong textile manufacturing base and integrated supply chains, making it a competitive source for large-volume orders. Companies like ours can integrate aerogel technology into fabrics while offering end-to-end quality control.

How to Connect with Reliable Suppliers?

The most effective ways include attending aerospace and industrial textile trade shows, using Alibaba to find verified vendors, and checking supplier backgrounds on ThomasNet. Always ask for test reports, NASA or equivalent certifications, and references from aerospace clients.

How to Verify NASA-Grade Certification for Fabrics

Certification is your safety net. Without verified proof, “NASA-grade” is just a label.

What Documents Should You Request?

Ask for a Certificate of Conformance (CoC) and thermal performance test reports. These should be issued by accredited labs like SGS or Intertek. For U.S. buyers, verify whether the material meets ASTM C518 thermal conductivity standards.

Can You Cross-Check with NASA Databases?

Yes. NASA’s Technical Standards Program maintains records of approved materials. While not all are public, you can request verification through NASA contractors or project partners. If the supplier refuses to share test data, it’s a red flag.

Comparing Aerogel Blanket Fabrics for Industrial Use

Not all aerogel blankets are created equal. The right choice depends on your application—spacecraft thermal shields require different specifications than LNG pipeline insulation.

Which Properties Matter Most?

Key metrics include thermal conductivity, flexibility, moisture resistance, and density. For example, Cryogel Z is optimized for cryogenic temperatures, while Pyrogel XTE handles higher heat.

Industrial buyers often prefer blends that maintain aerogel performance while improving mechanical durability.

Should You Consider Custom Blends?

Yes—many suppliers, including us, can integrate aerogel into coated fabrics or laminated composites to meet specific project needs. A custom blend might combine aerogel with Kevlar for impact resistance or with PTFE for chemical resistance.

Conclusion

NASA-approved aerogel insulation blanket fabrics are specialized materials that require careful sourcing, strict certification checks, and a deep understanding of your application needs. From aerospace projects to industrial pipelines, the right fabric can mean the difference between success and failure in extreme environments.

If you want to co-develop your own aerogel insulation fabric or source NASA-grade materials with verified certifications, you can contact our Business Director Elaine at elaine@fumaoclothing.com. We handle weaving, coating, finishing, and quality testing—all in-house—to ensure your project meets both technical and budget requirements.