When buyers in industries like electronics, oil, gas, and chemical manufacturing search for protective clothing, one of the most common pain points is how to ensure that garments and footwear meet the strictest safety standards. Many ask about EN 1149-4 certified footwear, only to discover that the standard itself is not directly applied to shoes. This confusion often delays sourcing and increases compliance risks. For example, in 2022, a European oil refinery had to recall 3,000 pairs of safety boots after realizing they were incorrectly labeled as EN 1149-4 compliant, causing significant operational delays.

The short answer is that EN 1149-4 is a garment-based electrostatic discharge standard, while footwear must comply with different electrostatic safety regulations such as EN ISO 20345 and EN 61340-4-3. To achieve full protection, companies need both EN 1149-certified clothing and electrostatic dissipative (ESD) footwear. This ensures that workers are grounded and safe when handling flammable chemicals, volatile gases, or sensitive electronic components.

For procurement managers and brand owners, understanding the correct standards and knowing where to source certified footwear is essential. By clarifying the differences between garment and footwear regulations, you can avoid compliance pitfalls, streamline sourcing, and better communicate requirements to suppliers. Companies that master this knowledge often save up to 15% on sourcing costs by reducing errors and unnecessary product returns.

What Is EN 1149-4 and Why Does It Matter?

EN 1149-4 is part of the European standard series EN 1149, designed to regulate protective clothing against electrostatic discharge (ESD). It focuses on specific test methods for garments to ensure workers in explosive or sensitive environments are shielded from electrostatic risks. For example, in petrochemical plants, a single static spark can ignite flammable vapors, leading to catastrophic accidents. EN 1149-4 ensures clothing materials reduce this danger significantly.

EN 1149-4 matters because it works in tandem with electrostatic footwear. Garments alone cannot protect against static if shoes do not provide grounding. A worker wearing an EN 1149 garment but ordinary sneakers could still build up a charge strong enough to cause an accident. This is why procurement managers must understand the overlap between EN 1149 and footwear standards. In 2021, the European Chemicals Agency documented 27 workplace incidents where clothing was compliant, but footwear failed to dissipate static, proving the importance of a system-wide approach.

Why is EN 1149-4 not for footwear?

Although EN 1149-4 governs protective clothing, footwear is regulated under EN ISO 20345 for general safety and EN 61340-4-3 for ESD performance. Misinterpreting this may lead to sourcing the wrong products. For example, an American distributor once mistakenly imported 5,000 pairs of non-ESD shoes labeled with EN 1149-4 and had to pay customs fines before re-exporting them. You can read more about the garment-focused requirements on XM Textiles.

How do standards connect garments and shoes?

Workplace safety requires a full-body ESD protection system. This means EN 1149 garments plus compliant footwear. Suppliers like MASCOT Workwear clearly explain the need to combine both for complete protection. In real-world practice, European car factories require workers to wear full EN 1149 clothing along with certified ESD footwear on all assembly lines where electronic chips are handled.

Which Standards Cover Electrostatic Footwear?

When it comes to footwear, standards differ from garments but serve the same purpose: dissipating electrostatic charges safely. For buyers, knowing these standards avoids costly errors. In the past five years, compliance audits by European agencies showed that nearly 22% of imported safety footwear failed ESD requirements because buyers confused clothing standards with shoe standards.

The most relevant footwear standards include EN ISO 20345 and EN 61340-4-3. EN ISO 20345 regulates overall safety footwear features (slip resistance, toe caps, puncture protection). EN 61340-4-3 specifically addresses the electrostatic dissipative properties of footwear. Together, these standards form the backbone of compliant ESD safety shoes. In industries like electronics manufacturing, where a single static discharge can destroy microchips worth thousands of dollars, these standards prevent catastrophic financial loss.

What is EN ISO 20345?

EN ISO 20345 is the benchmark for safety shoes in Europe, requiring protective toe caps and testing for durability. For instance, it ensures shoes can withstand impacts of up to 200 joules, equivalent to a 20 kg weight falling from one meter. You can explore more details on BSI Group.

What is EN 61340-4-3?

EN 61340-4-3 specifies the testing methods for ESD footwear, ensuring shoes dissipate static electricity correctly. The standard sets a resistance range of 0.1 to 100 MΩ to ensure safety in sensitive environments. Leading certification labs like Intertek provide global testing services for compliance. Many Fortune 500 electronics companies require their suppliers to present EN 61340-4-3 test certificates before accepting deliveries.

Where to Source ESD-Compliant Footwear?

Finding reliable suppliers is critical for U.S. and European buyers. Many look to established safety footwear manufacturers that combine ESD performance with durability. According to Eurostat trade data, China supplies more than 60% of ESD safety shoes imported into Europe, making it the leading sourcing hub.

Some trusted sources include MASCOT, HAVEP, and Unishore. These brands specialize in protective workwear and footwear, ensuring full compliance with EN standards. Trade shows in China and Europe also remain popular sourcing hubs. In fact, the Canton Fair in Guangzhou attracts over 25,000 international buyers annually, with safety footwear among the top-requested categories.

Which suppliers are recommended?

Brands like HAVEP and Unishore Workwear supply ESD footwear compatible with EN 1149 garments. They offer both wholesale programs and flexible order sizes. For instance, HAVEP offers MOQ starting from 200 pairs, making it accessible even for small to medium distributors.

Can custom footwear be made?

Yes. Large manufacturers can produce customized ESD footwear with private labeling. Sourcing agents often connect buyers with compliant factories across Asia, especially in Keqiao, Zhejiang, the hub of global textile trade. One notable case is a U.S. startup that launched its own line of branded ESD shoes by partnering with a Keqiao factory, cutting costs by 18% compared to sourcing in Europe.

How to Ensure Compliance Before Purchase?

Compliance is not just about buying certified shoes. It requires pre-purchase verification, supplier audits, and third-party testing. Neglecting this step can lead to shipments being rejected at customs or recalls in the target market.

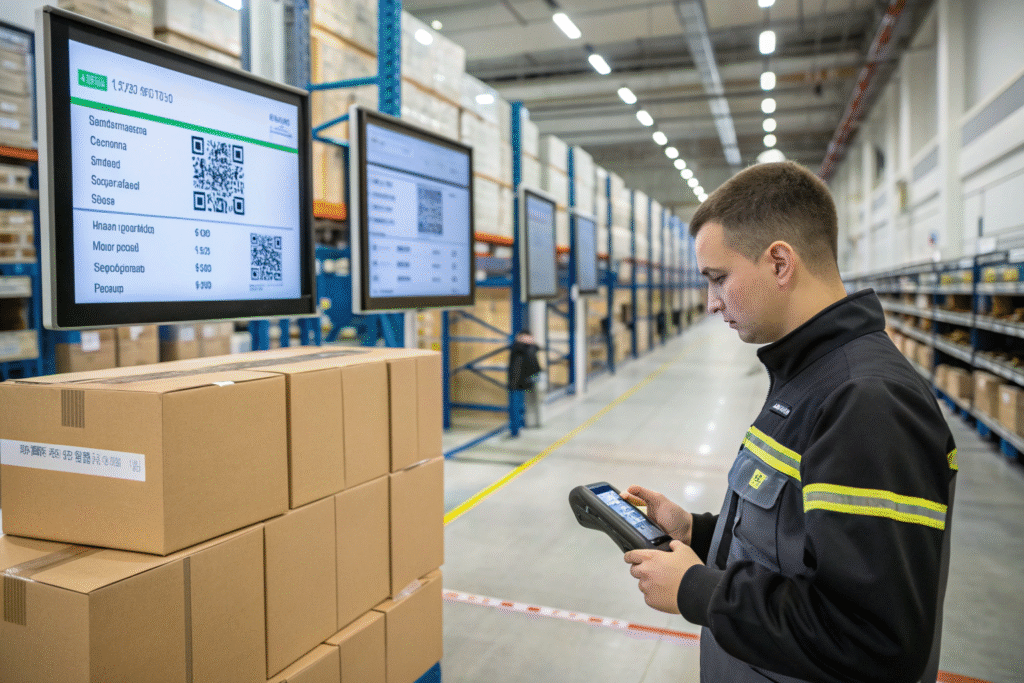

The best practice is to request certificates and test reports before confirming orders. Buyers should also ensure footwear suppliers can provide QR-coded compliance tracking, just like garment manufacturers. For example, some factories in Zhejiang now embed QR codes in shoe boxes, linking directly to online test reports for each batch.

How can buyers verify certificates?

Request official certification reports from labs like Intertek or SGS. Many suppliers will share them on demand. Detailed guidelines are available from Guide Gloves. Certificates should show the test method, date, and standard applied. For example, SGS typically issues reports with serial numbers traceable on their global database.

Why is third-party testing important?

Relying only on supplier claims increases risks. Independent verification through labs ensures products meet both EN ISO 20345 and EN 61340-4-3. Certification from SGS helps secure trust in international trade. In 2020, an Italian distributor avoided a $1.5 million recall because SGS pre-shipment testing flagged a batch of non-compliant shoes before they left the factory.

Conclusion

EN 1149-4 does not apply to footwear directly, but electrostatic safety requires combining EN 1149 garments with EN ISO 20345 and EN 61340-4-3 certified footwear. Buyers in sensitive industries should source from trusted suppliers, verify certification, and work with labs for testing. By following these steps, companies reduce compliance risks, protect workers, and strengthen brand reputation in global markets.

If you are planning to launch or scale your own protective clothing and footwear product line, our company Shanghai Fumao can support you with full compliance solutions, from fabric production to packaging. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your next project with confidence.