Electronics packaging demands more than cushioning—it must also protect sensitive components from electrostatic discharge (ESD). Static buildup can destroy microchips, capacitors, or PCBs during handling and transport. That’s where anti-static lining fabrics come in. They’re the hidden shield behind safe ESD packaging solutions like bags, boxes, and foam inserts.

This article will help you understand which fabrics offer effective anti-static performance, what to look for in certifications, and where to source them globally—including suppliers in China, the US, and EU with export-ready stock.

What Makes a Lining Fabric Anti-Static?

Anti-static fabrics are engineered to safely dissipate electrical charges. They’re essential in any packaging that comes into contact with sensitive electronic components, especially for OEMs, PCB factories, and fulfillment centers.

How Do These Fabrics Work?

There are three main types of anti-static materials:

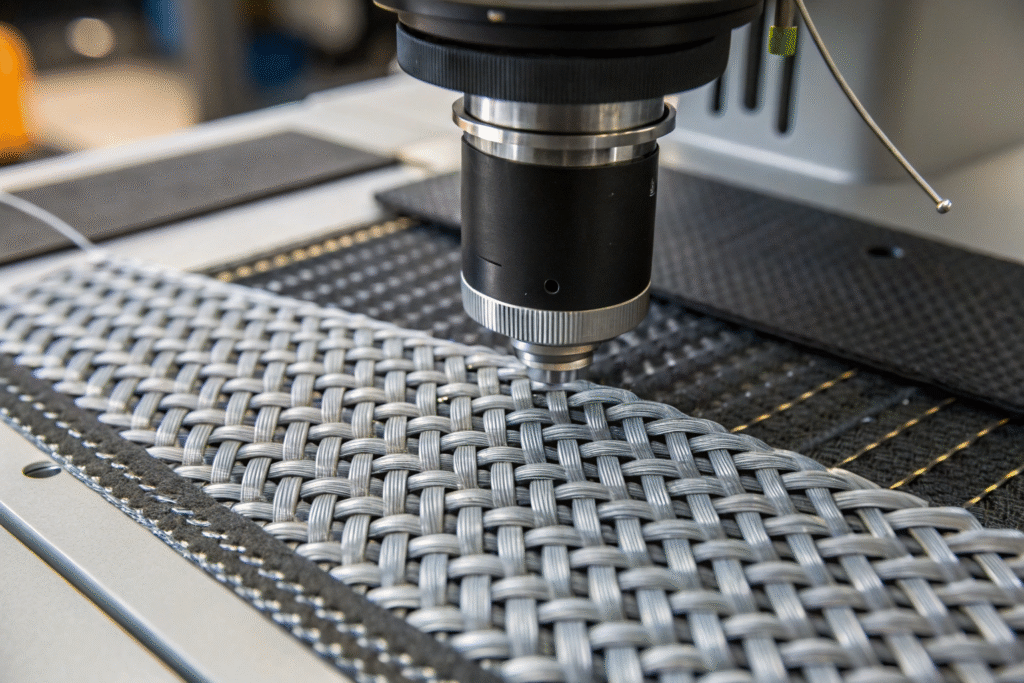

- Conductive: Provide a low-resistance path to ground; made with carbon or metal fibers.

- Dissipative: Slowly transfer charges to a grounded surface; used for fabric linings.

- Shielding: Block fields entirely; often used in multilayer pouches.

In lining fabrics, anti-static function is often achieved by carbon or metallic filaments woven into synthetic polyester, polypropylene, or nylon. More details are provided by ESDA.org and NASA’s ESD guidelines.

What Standards Should These Fabrics Meet?

When sourcing anti-static fabric, ensure they meet:

- ANSI/ESD S20.20 for ESD-safe workspaces

- IEC 61340-5-1 for international ESD protection

- RoHS & REACH for restricted chemical compliance

You can verify ESD test results through third-party labs like TÜV Rheinland or SGS.

What Fabric Types Are Suitable for Electronics Packaging?

The best anti-static fabrics for packaging are typically synthetic and coated or embedded with conductive elements. Key materials include carbon-blended polyester, conductive grid nylon, and metallized layers laminated with foam.

What Are the Most Common Options?

-

Black carbon grid polyester

- Often used in box linings, tote dividers

- Resistance: 10⁶–10⁸ ohms/sq

- Woven with 5mm carbon threads

- Source: Kinetic Polymers, Desco

-

Pink anti-static polyester taffeta

- Lightweight, non-conductive, yet low-charging

- Common for bag linings, ESD jackets

- Source: Zhejiang Xinhongtai, TexLab Industries

Other options include:

- Nylon with carbon stripes (for tote bins and high-abrasion zones)

- Metallized PET + PE foam laminates (shock + static protection for HDDs or CPUs)

Learn more from ESD Systems and SCS.

Can Fabrics Be Combined with Foam?

Yes. Anti-static fabric + ESD foam laminates are widely used for:

- Custom trays for SMD packaging

- Laptop and server blade transport

- Sensitive optical module protection

Examples include foam-backed linings from Conductive Containers Inc. and lamination mills on Made-in-China.

Where to Find Trusted Anti-Static Fabric Suppliers?

Finding the right anti-static fabric supplier requires checking for test reports, export capability, and whether small MOQ or OEM rolls are available.

Top China-Based Suppliers with Export Readiness

-

Shaoxing Fumao Textile

- Specializes in ESD polyester and anti-static grid linings

- MOQ: 500m / color

- Custom ESD specs available

- Website: fumaofabric.com

-

Dongguan U-Protec

- Offers carbon-lined woven linings for trays and bags

- Ships globally with ESD test certificates

- U-Protec Anti-Static Textiles

-

Suzhou Lusheng

- Supplies black conductive grid fabrics with high strength

- Used by box makers in Shenzhen and Singapore

- Lusheng Antistatic Fabrics

Also browse Globalsources for verified suppliers with ISO 9001 or IEC certifications.

US and EU-Based Specialty Suppliers

-

Protektive Pak (Desco Industries) – USA

- ESD-safe totes and interior lining rolls

- www.descoindustries.com

-

Statguard Flooring (Illinois Tool Works) – USA

- Supplies conductive floor linings and bag linings

- www.statguardflooring.com

-

Schoeller Textil AG – Switzerland

- Offers conductive coatings on technical textiles

- Ideal for packaging and industrial garments

- www.schoeller-textiles.com

What to Check Before Ordering?

Before finalizing your purchase, especially if ordering in bulk for export, request the following documentation and samples to confirm functionality.

Which Test Reports Should Be Provided?

- Surface Resistivity (ASTM D257 or IEC 61340)

- Static Decay Time (FTMS 101C Method 4046)

- Charge Generation (per ISO 6356)

- Tensile strength & Abrasion resistance

Reputable suppliers will send these upon request or include them in their export spec sheet. For example, Intertek offers full test verification packages.

What Other Order Conditions Should You Confirm?

- MOQ (typically 100–500 meters per roll)

- Fabric width (most are 58"–60")

- Surface treatments: flame retardant, UV resistance

- Packaging: roll, box, or laminated sheets

- Export Incoterms: FOB / CIF / DDP

Consider setting up a virtual factory tour or requesting a cut swatch with stitched label for lab simulation. Visit Fumao's MOQ policy or contact sourcing platforms like Common Objective for sample verification.

Conclusion

Anti-static lining fabric is the backbone of safe electronics packaging—without it, every shipment risks catastrophic ESD damage. Whether you need conductive grid linings for tray systems or dissipative linings for tote bags, sourcing the right material with lab-verified resistance and export compliance is essential.

We recommend working with suppliers offering certified ESD fabrics, flexible MOQ, and export-ready documentation. For assistance on ESD performance specs, pricing per meter, or sample yardage, reach out to elaine@fumaoclothing.com.

We’ll help you line your packaging with the invisible layer that protects your tech—and your reputation.