The world of textile manufacturing is undergoing a silent revolution. Anti-gravity weaving—a term used to describe ultra-lightweight tension-controlled loom processes—has begun to redefine how high-performance fabrics are engineered. Especially in sectors like aerospace, sportswear, and industrial protection, buyers now demand fabrics that are not only feather-light but structurally precise, chemically resistant, and custom-woven for their end-use.

Anti-gravity loom woven textiles aren’t floating in space, but they mimic gravity-defying characteristics: low GSM, high tensile strength, and exact warp/weft alignment using cutting-edge tension-control looms or vertical weaving machines. For global buyers, especially those sourcing from Asia, understanding where to find these materials and how to verify their capabilities is the key to building next-gen products.

What Are Anti-Gravity Looms and How Do They Work?

While the name might sound like science fiction, “anti-gravity” refers to an emerging loom category that maintains ultra-fine fiber alignment by minimizing gravitational slack. These include vertical looms, tension-adjusted air-jets, and servo-controlled rapier systems, all of which produce tighter, lighter, and more stable fabrics.

They are particularly suited for technical textile production where micron-level alignment matters—think ballistic fabric, aerospace components, or nano-coated apparel bases.

How Do These Looms Differ from Traditional Ones?

Traditional shuttle looms and water-jets rely heavily on horizontal tension and gravitational pull to guide the yarns. In contrast, anti-gravity systems use electromagnetic tensioning, vacuum-aided yarn feeding, or zero-contact vertical setups that eliminate sagging or stretch distortion—critical when working with carbon fiber, aramid, or ultra-fine nylon.

Learn about loom innovations by Karl Mayer or review weaving technologies from ITMA.

What Fabrics Can Be Made Using Anti-Gravity Systems?

Fabrics made include:

- Carbon/Kevlar hybrid weaves

- E-glass or S2-glass technical meshes

- TPU-laminated lightweight nylon for aerospace

- Aramid-woven composites for helmets or gloves

See examples at Techtextil Frankfurt or browse Fiberline composites.

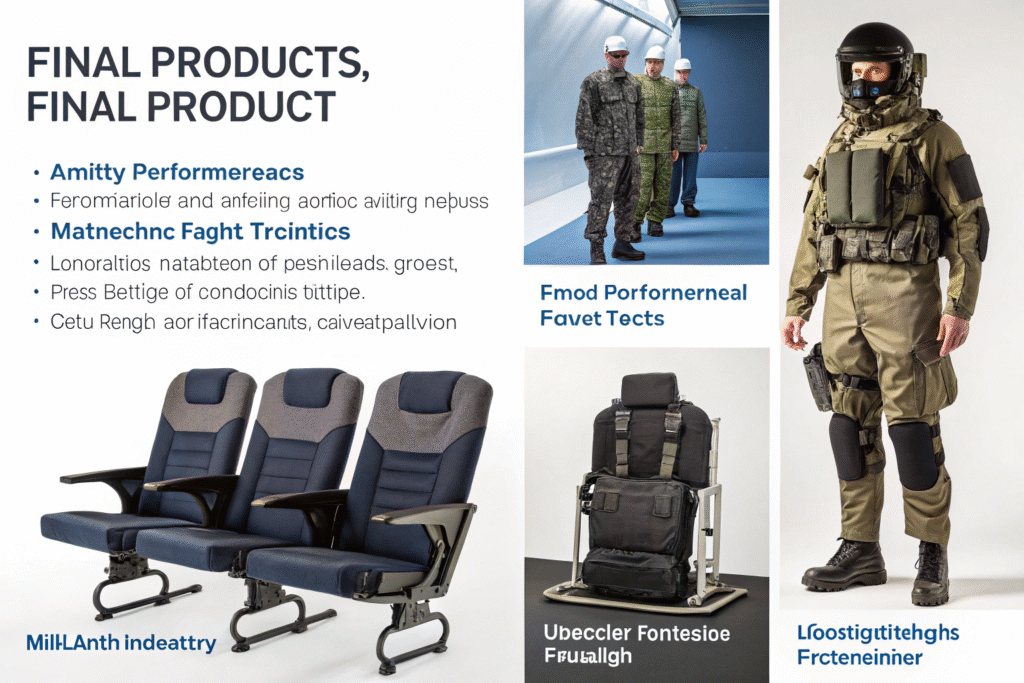

Which Applications Need Anti-Gravity Woven Technical Textiles?

Lightweight doesn’t mean fragile. Many buyers are sourcing these fabrics for sectors where strength, heat-resistance, and weight reduction are critical. Whether you’re building helmets, anti-abrasion wear, or ultralight drones—precision-woven technical textiles give you a competitive edge.

Why Are These Textiles Important for Aerospace and Defense?

In aerospace, every gram saved matters. Anti-gravity loom textiles like carbon-aramid hybrids reduce structural weight while withstanding extreme conditions. In defense, slash-resistant and flame-retardant materials need tight weaves with consistent yarn density—achievable only on advanced looms.

Explore NASA-approved textile specs or mil-spec aramid solutions.

Can Sportswear Brands Use These Fabrics?

Yes. High-end cycling, sailing, and trail gear use Dyneema®, Spectra®, and Kevlar® blends woven into mesh or ripstop formats. These offer abrasion resistance, low GSM, and thermal regulation—ideal for ultramarathons or tactical movement.

Read about Dyneema® performance in sports or see cycling gear using woven aramids.

Where Are These Technical Fabrics Manufactured in Asia?

Keqiao, China is a global powerhouse in fabric innovation. At Fumao Fabric, we work closely with specialized weaving partners using vertical looms and digital warp-control systems. Our teams help clients worldwide integrate these fabrics into complex product builds.

We’ve supported U.S. and EU buyers in sourcing anti-cut gloves, ballistic panels, and performance shells using our hybrid Kevlar-poly fabric lines.

Which Chinese Factories Offer These Loom Technologies?

Only a select few fabric clusters have invested in such equipment. Look for:

- ISO 9001 + GRS Certified mills

- CNAS lab-tested woven structures

- Capability for aramid, basalt, or carbon fiber handling

- Custom GSM and width specification options

Discover options at China Textile City or find CNAS-accredited labs.

Why Partner with Fumao for Sourcing These Fabrics?

We offer:

- Custom development (weft density, fiber blend, surface coating)

- In-house testing for warp strength, tensile elongation, and layering resistance

- Ready-to-ship MOQ: 300m

- Live remote loom inspection via video stream

Visit our technical textile page or learn about fabric tensile standards.

How to Evaluate the Performance of Woven Technical Textiles?

Before bulk purchasing anti-gravity woven fabrics, buyers must demand comprehensive lab testing. From tensile strength to chemical resistance, each roll should meet its targeted industrial specification. Fumao’s lab provides batch reports based on ASTM, ISO, and EU directives.

What Are the Critical Tests for Anti-Gravity Woven Fabric?

| Property | Test Standard | Relevance |

|---|---|---|

| Tensile Strength | ASTM D5034 | Pull resistance |

| Tear Resistance | ISO 13937 | Edge performance |

| Flame Retardancy | ISO 15025 / NFPA 701 | Heat protection |

| Abrasion Resistance | ASTM D4966 | Surface wear |

| Air Permeability | ISO 9237 | Breathability for gear |

See ASTM fabric test index or browse ISO textile safety protocols.

Can These Fabrics Be Laminated or Coated?

Yes. At Fumao, we frequently apply TPU, PU, silicone, or carbon coatings to enhance water resistance, grip, or anti-static properties. Anti-gravity woven fabrics offer excellent bonding due to consistent weave pressure and smooth surfaces.

Learn about PU coating processes or explore textile lamination technology.

Conclusion

Anti-gravity loom woven technical textiles represent the future of performance fabric engineering. With lightweight structure, superior alignment, and high functional adaptability, these fabrics are critical in industries where every gram and micron counts.

At Fumao Fabric, we help global buyers access this next-gen category with real transparency. From weaving to testing, from digital QC to delivery, we streamline your innovation goals into real fabric performance.

For custom quotes or swatch kits, reach out to our Business Director Elaine at elaine@fumaoclothing.com. Let us help you build smarter, lighter, and stronger with every woven inch.