Discovering that your clothing contains illegal levels of chemicals or fails safety standards after production is every brand's nightmare. The financial costs of recalls, destroyed inventory, and brand damage can be catastrophic. At Fumao, we've seen too many brands learn about product safety compliance the hard way—usually when customs officials are rejecting their shipments or customers are reporting allergic reactions.

Asking the right safety questions before production begins separates professional manufacturers from risky suppliers. You need to verify chemical compliance, physical safety, documentation accuracy, and the manufacturer's testing protocols. The most dangerous assumption is that "someone else" is handling safety—ultimately, the brand bears responsibility regardless of where manufacturing occurs.

If you want to sleep well knowing your clothing won't harm customers or generate regulatory penalties, here are the essential safety questions to ask any manufacturer before placing your order.

What Chemical Compliance and Restricted Substances Questions Reveal True Safety Standards?

Chemical safety represents the most complex and rapidly evolving compliance area. Many manufacturers still use restricted substances simply because "that's how we've always done it," without tracking regulatory changes. Your questions need to uncover both their current compliance status and their systems for staying current with new restrictions.

Begin by asking for their Restricted Substances List (RSL)—every reputable manufacturer should maintain an updated, comprehensive RSL based on global regulations. Then dig deeper into how they implement this list throughout their supply chain. The most telling answers come from asking about specific substance categories rather than general compliance claims.

Which Specific Substances Should You Ask About?

Focus your questions on high-risk substance categories that frequently cause compliance failures:

Heavy Metals:

- "What's your testing frequency for cadmium, lead, and mercury in prints and dyes?"

- "Do you test for heavy metals in all substrate colors or just darks?"

Formaldehyde:

- "What's your maximum formaldehyde limit across all product categories?"

- "How do you prevent formaldehyde cross-contamination from shipping materials?"

PFAS and PFCs:

- "Do you offer PFAS-free DWR alternatives?"

- "What's your phase-out timeline for all PFAS chemistry?"

Azo Dyes:

- "How do you verify your dye suppliers don't use banned amines?"

- "What's your testing protocol for azo dyes across all colorways?"

A European children's wear brand discovered their manufacturer was only testing darks for heavy metals, missing cadmium in a bright yellow print that would have resulted in €50,000+ in EU regulatory penalties.

What Documentation Proves Chemical Compliance?

Request specific documentation rather than accepting verbal assurances:

- Test Reports: Third-party laboratory reports (SGS, Bureau Veritas, Intertek)

- Chemical Inventory: Complete list of chemicals used in production

- Supplier Declarations: Signed statements from chemical suppliers

- Certifications: Oeko-Tex, bluesign®, GOTS certificates if applicable

The most transparent manufacturers provide a chemical management system that tracks every substance from receipt through application. Ask to see their system—if they hesitate or can't produce documentation within 24 hours, consider this a major red flag.

How to Verify Physical Safety and Quality Testing Protocols?

Physical safety extends beyond chemicals to include mechanical hazards, durability issues, and performance failures. Your questions should uncover both their testing protocols and their philosophy toward safety margins versus minimum compliance. Manufacturers focused on true safety exceed standards rather than barely meeting them.

Ask about their in-house testing capabilities versus third-party validation. While in-house testing provides speed and cost efficiency, it should always be supplemented by periodic third-party verification to prevent conflicts of interest. The most reliable manufacturers maintain CNAS or ISO 17025 accredited laboratories with regular audit schedules.

What Physical Tests Are Non-Negotiable for Different Product Categories?

Safety testing should be category-specific rather than one-size-fits-all:

Children's Wear:

- "Do you conduct small parts testing according to ASTM F963/CPSC requirements?"

- "What's your pull-test protocol for buttons, snaps, and embellishments?"

- "How do you ensure drawstrings meet CPSC safety guidelines?"

Performance Wear:

- "What flammability testing do you conduct for sleepwear or technical layers?"

- "How do you validate UV protection claims with UPF testing?"

- "What's your testing protocol for thermal protection in outerwear?"

General Apparel:

- "How do you test colorfastness to perspiration and rubbing?"

- "What's your pilling resistance standard for knit fabrics?"

- "Do you conduct seam strength testing under wet and dry conditions?"

The table below shows critical tests by product category:

| Product Category | Mandatory Tests | Recommended Additional Tests | Regulatory Standards |

|---|---|---|---|

| Children's Wear | Small parts, drawstring safety, flammability | Phthalates, lead in substrates | CPSIA, ASTM F963 |

| Intimate Apparel | Colorfastness to perspiration, formaldehyde | pH value, allergen screening | Oeko-Tex Standard 100 |

| Outerwear | Zipper strength, water resistance, flammability | PFAS screening, thermal insulation | REACH, CPSC |

| Athletic Wear | Seam strength, stretch recovery, colorfastness | Antimicrobial efficacy, odor testing | ISO, AATCC methods |

A US brand avoided potential lawsuits by discovering their manufacturer wasn't testing seam strength on athletic wear, which would have failed during intense exercise.

How Do You Verify Testing Frequency and Sample Selection?

The testing approach reveals as much as the tests themselves. Ask these probing questions:

- "What percentage of production batches do you test?"

- "How do you select samples for testing—first pieces, random, or problem-focused?"

- "What's your protocol when a test fails?"

- "Do you test final products or just raw materials?"

Manufacturers committed to safety test every production batch and maintain statistical sampling plans. They should also have clear escalation procedures for failures, including root cause analysis and preventive action implementation. The best manufacturers test at multiple stages: raw materials, in-process, and finished goods.

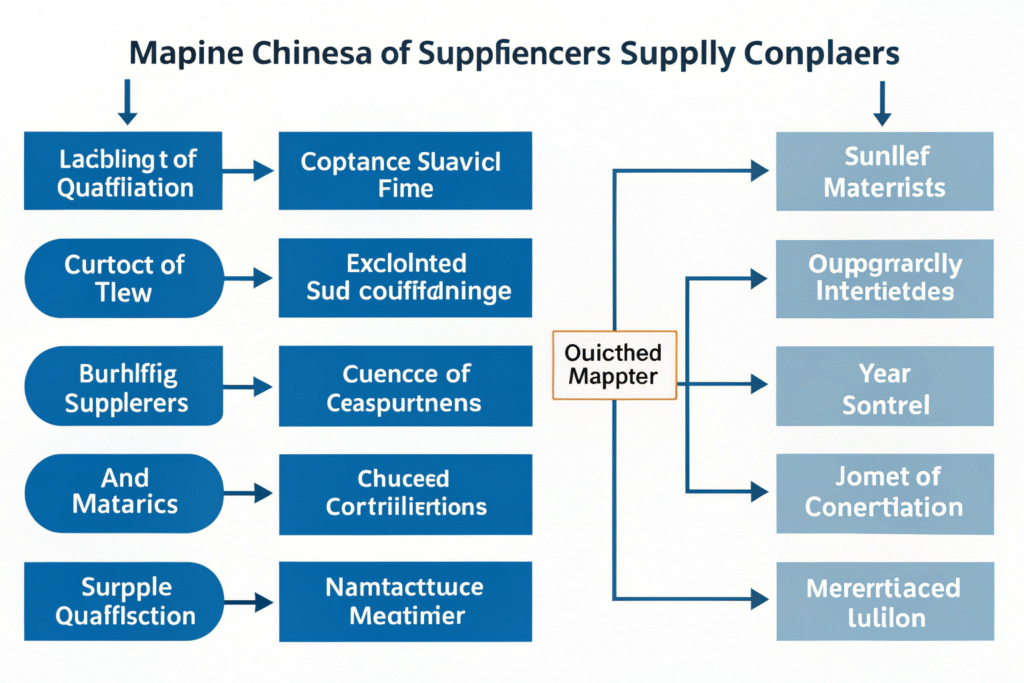

What Supply Chain Transparency Questions Uncover Hidden Risks?

Your manufacturer's direct operations might be compliant, but their suppliers could introduce unacceptable risks. The most dangerous safety issues often originate deep in the supply chain where visibility is poorest. Your questions need to trace compliance back to raw material origins.

Begin by mapping their supply chain—ask for a visual representation showing all tiers of suppliers. Then drill down into their supplier qualification and monitoring processes. Manufacturers who truly control safety can immediately identify every supplier for each component and provide evidence of their compliance status.

How Deep Does Their Supply Chain Visibility Extend?

Ask specific questions about different supply chain tiers:

Tier 1 (Direct Suppliers):

- "Can you provide chemical inventories from your dye houses and finishing facilities?"

- "How often do you audit your fabric mills for compliance?"

- "What's your process for approving new chemical suppliers?"

Tier 2+ (Raw Material Suppliers):

- "Do you trace fibers back to their origin farms or production facilities?"

- "How do you verify recycled content claims from yarn suppliers?"

- "What documentation do you require from trim and accessory suppliers?"

A luxury brand discovered their "Italian leather" trim actually came from a Bangladeshi supplier with questionable chemical management—something they only uncovered through persistent supply chain questioning.

What Certification Systems Do They Maintain?

Certifications provide independent verification of safety systems, but not all certifications are equal. Ask about:

- System Certifications: ISO 9001 (quality), ISO 14001 (environmental)

- Product Certifications: Oeko-Tex Standard 100, bluesign®, GOTS

- Social Compliance: BSCI, SMETA, WRAP

More important than the certifications themselves is how they're implemented. Ask to see audit reports and corrective action records—these reveal whether certifications represent real commitment or just paperwork exercises.

What Documentation and Legal Protection Should You Require?

Proper documentation provides your safety net when issues arise. Many brands discover too late that their manufacturer can't or won't provide necessary documentation for customs clearance or regulatory defense. Your questions should establish clear documentation requirements before production begins.

The most critical documents include test reports, certificates of compliance, material safety data sheets, and import documentation. However, equally important are the contractual protections that define responsibility when safety failures occur. Many manufacturers use broad limitation of liability clauses that leave brands bearing most financial risk.

What Legal Protections Should Your Manufacturing Agreement Include?

Beyond technical questions, address these legal and contractual aspects:

- Warranties: "Do you provide explicit compliance warranties for all target markets?"

- Indemnification: "What's your indemnification process for regulatory violations?"

- Testing Responsibility: "Who bears costs for third-party verification testing?"

- Recall Coverage: "What's your responsibility and cost-sharing in recall situations?"

The safest manufacturers stand behind their compliance with strong warranties and shared risk. Be wary of suppliers who avoid specific commitments or limit liability to the purchase price—this signals low confidence in their safety systems.

How Should Documentation Be Delivered and Maintained?

Establish clear documentation protocols:

- Delivery Format: "Can you provide digital documentation with each shipment?"

- Retention Period: "How long do you maintain testing records?"

- Accessibility: "What's your process for retrieving historical documentation?"

- Updates: "How do you communicate regulatory changes affecting my products?"

A UK retailer successfully defended against a trading standards investigation by producing five years of test documentation from their manufacturer—something that would have been impossible without established documentation protocols.

How to Assess Their Proactive Safety Culture and Continuous Improvement?

The manufacturer's safety culture ultimately determines whether compliance is a ongoing commitment or a temporary condition. Companies with strong safety cultures anticipate problems rather than reacting to them. Your questions should uncover whether safety is truly embedded in their operations.

Look for evidence of continuous improvement rather than static compliance. The best manufacturers regularly review their processes, invest in new testing equipment, and proactively address emerging regulatory trends. They should be able to describe specific safety improvements made in the past year, not just claim general compliance.

What Questions Reveal Their True Safety Priorities?

Ask questions that separate rhetoric from reality:

- "What safety improvements have you implemented in the past year?"

- "How do you stay ahead of emerging regulatory changes?"

- "What safety training do production staff receive annually?"

- "How are safety metrics incorporated into management bonuses?"

The answers should be specific and measurable. A manufacturer truly committed to safety can immediately describe recent equipment upgrades, training programs, or process improvements.

How Do They Handle Safety Failures and Near-Misses?

The response to problems reveals more than compliance during smooth operations:

- "Can you share an example of a safety issue and how it was resolved?"

- "What's your process for communicating potential safety issues to customers?"

- "How do you use near-miss incidents to prevent future problems?"

Manufacturers with strong safety cultures are transparent about past issues and can demonstrate how they've systematically addressed root causes. Those who claim they've "never had a problem" are either dangerously inexperienced or dishonest.

Conclusion

Asking comprehensive safety questions transforms your role from passive customer to active risk manager. The most dangerous approach is assuming safety is someone else's responsibility—ultimately, brands bear liability for the products they sell, regardless of where manufacturing occurs. The right manufacturer will welcome your safety questions as evidence of professional partnership.

The safest manufacturers differentiate themselves through transparency, documentation, and proactive communication. They provide specific evidence rather than general assurances and view safety as a shared responsibility rather than a compliance burden. If your current manufacturer hesitates or provides vague answers to these questions, consider this a significant warning sign.

At Fumao, we've built our reputation on safety transparency—providing complete documentation, maintaining rigorous testing protocols, and welcoming customer safety audits. If you're evaluating manufacturers and want to discuss specific safety requirements for your products, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let us demonstrate how true safety partnership protects your customers and your brand.