As a fabric manufacturer based in Keqiao, I've seen the global demand for certified sustainable textiles explode, especially for GOTS. Just last week, a client from California asked us, "Can I use recycled polyester in my GOTS-certified organic cotton collection?" The answer isn't straightforward, and getting it wrong can cost you your certification. Many brands struggle to understand what inputs GOTS actually permits beyond basic organic cotton.

GOTS certification governs acceptable fiber types, processing methods, and chemical inputs across the textile supply chain. The certification sets strict criteria for organic fiber content, approved chemical inputs, and environmental and social compliance throughout production. Understanding these requirements is crucial for any brand aiming to market truly sustainable textiles.

Navigating GOTS requirements feels like learning a new language initially, but it's essential for accessing the European and North American markets. Let's break down exactly what you can and cannot use under this certification.

Which Fiber Types Qualify for GOTS Certification?

Not all natural fibers are created equal in the eyes of GOTS. I've had clients assume their bamboo viscose automatically qualifies, only to face disappointment. The certification specifically focuses on fibers from organic agriculture.

The key fiber types permitted under GOTS are organic cotton, organic wool, organic linen (flax), and organic hemp. These fibers must be certified from the farm level, following strict standards that prohibit synthetic pesticides and GMOs. For animal fibers like wool, animal welfare standards are equally important. We helped an Austrian brand in 2023 develop a GOTS-certified baby wear line using organic cotton and organic wool, requiring traceability back to certified farms in Turkey and Australia.

What about recycled fibers and synthetic blends?

GOTS does allow some recycled fibers, but with important limitations. Recycled synthetic fibers can only be used in GOTS-certified textiles if they're blended with the required minimum percentage of organic fibers. For a product to be labeled "GOTS organic," it must contain at least 95% certified organic fibers. The "made with organic" label requires at least 70% organic fibers.

The standard permits recycled materials primarily to address textile waste, but they don't count toward the organic fiber content percentage. We recently navigated these requirements for a German activewear brand seeking how to incorporate GOTS approved recycled materials into their yoga line. The key was maintaining the 70% organic cotton while using 25% recycled polyester for durability.

How do fiber processing methods affect eligibility?

The GOTS certification doesn't stop at the raw fiber—it extends through every processing stage. From spinning and weaving to dyeing and finishing, each step must comply with strict environmental and technical criteria. Even if you start with certified organic cotton, using non-approved dyes or auxiliaries will void the certification.

We learned this firsthand when a Dutch client wanted to add specific functional finishes to GOTS certified fabrics for their maternity wear line. The moisture-wicking treatment they initially requested wasn't GOTS-approved, so our R&D team had to develop an alternative using permitted chemistry. This is where having a CNAS-certified lab becomes invaluable for testing compliance throughout production.

What Chemical Inputs Are Permitted in GOTS Production?

The chemical restrictions represent where GOTS gets truly technical. When we first pursued GOTS certification for our dyeing facilities, I was surprised to learn that approximately 80% of the chemicals we routinely used were non-compliant.

GOTS maintains a comprehensive list of approved and restricted chemical inputs, covering everything from dyes and auxiliaries to process chemicals. The standard strictly prohibits heavy metals, formaldehyde, aromatic solvents, GMOs, and numerous specific substance groups known to be hazardous. All permitted inputs must meet stringent biodegradability and toxicity requirements. Our transition to compliant chemistry required significant investment in 2022, but it ultimately reduced our water treatment costs by 30%.

Which dye classes meet GOTS compliance?

The certification permits most natural dyes and specific synthetic dyes that meet their toxicity and biodegradability criteria. Reactive, direct, and vat dyes are commonly used in GOTS production, provided they don't contain prohibited azo compounds or heavy metal mordants.

We've developed a specialized library of GOTS-compliant dyes that still offer vibrant color options. For a Swedish children's wear client in early 2024, we created 15 custom colors using only approved dyes, achieving the bright palette they needed while maintaining certification. The key challenge was achieving colorfastness without restricted chemical fixatives, which we solved through modified dyeing procedures.

How are auxiliary chemicals regulated?

Auxiliaries—including wetting agents, detergents, softeners, and sizing chemicals—face equally strict scrutiny. GOTS prohibits alkylphenol ethoxylates (APEOs), complexing agents like EDTA, and many conventional softeners. Instead, manufacturers must use approved biodegradable alternatives.

Finding effective substitutes was our biggest hurdle. For instance, we replaced standard silicone softeners with GOTS certified biodegradable softener alternatives based on vegetable derivatives. The performance difference was minimal, but the cost increased by about 15%. This is a crucial cost factor brands must understand when budgeting for GOTS-certified production. The certification also strictly regulates bleaching agents, permitting oxygen-based bleaching while prohibiting chlorine bleaching.

How Does GOTS Certification Impact Processing Methods?

GOTS regulation extends beyond materials to how we manufacture textiles. Our dyeing partner had to completely overhaul their wastewater treatment system to meet GOTS requirements before we could certify our joint operations.

The standard mandates that all wet-processing units must have functional wastewater treatment plants with specific purification standards. For knitted fabrics, we must monitor and control shrinkage without prohibited chemicals. In weaving, sizing agents must be biodegradable or easily removable. The social compliance components—including safe working conditions, no forced or child labor, and fair wages—are equally non-negotiable. Implementing these changes across our supply chain took nearly 18 months but ultimately made us a more responsible manufacturer.

What are the wastewater treatment requirements?

GOTS requires that all wet-processing facilities treat wastewater to specific standards before discharge. The chemical oxygen demand (COD) must be reduced to levels that typically require biological treatment systems. We invested ¥2.3 million in upgrading our primary dyeing factory's treatment plant in 2023, which allowed us to recycle 40% of process water—a benefit we hadn't initially anticipated.

The certification also mandates strict monitoring and recording of water and energy consumption. This data tracking has helped us identify inefficiencies and reduce utility costs by approximately 12% across our operations. For brands concerned with environmental impact, this level of transparency provides credible evidence of sustainable manufacturing practices beyond just the fiber content.

How does GOTS address quality and technical performance?

Some manufacturers fear that GOTS restrictions compromise quality, but this isn't necessarily true. While certain performance finishes are restricted, many functional properties can be achieved through mechanical or physical methods instead of chemical treatments.

For instance, instead of using durable water repellents containing PFCs (which are prohibited), we can achieve similar effects through technical fabric constructions for performance without chemicals. We developed a GOTS-certified weather-resistant fabric for a Norwegian outdoor brand using tight weaving techniques and a mechanical calendering process. The result met their waterproof requirements without banned chemicals. Similarly, we can create wicking properties through fiber blending and specific knit structures rather than chemical coatings.

What Documentation Proves GOTS Compliance Through the Supply Chain?

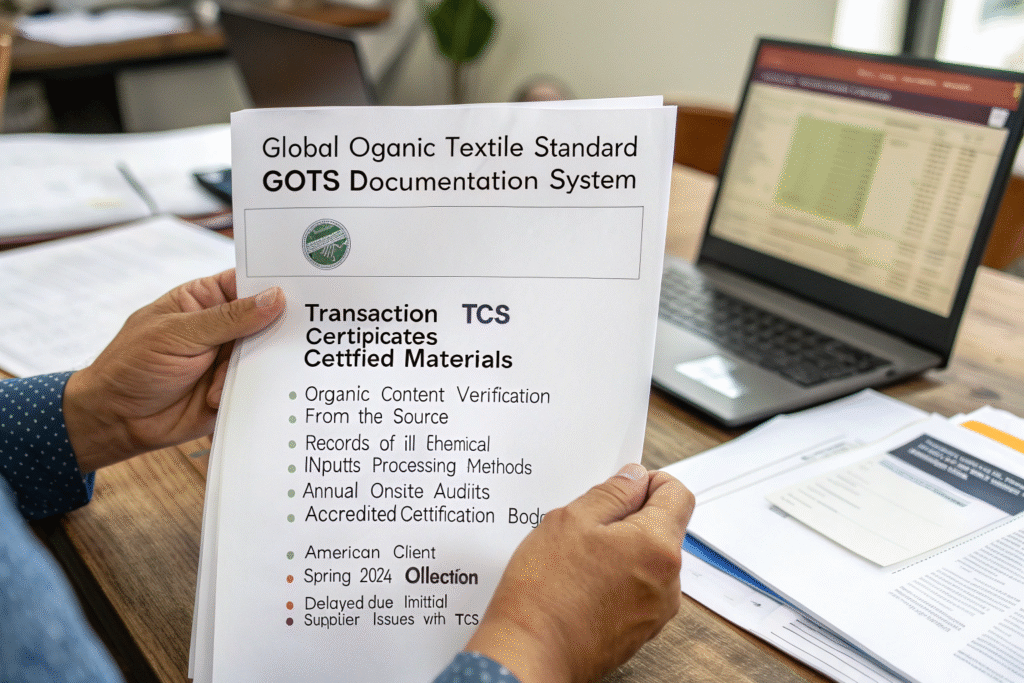

Paperwork might seem boring, but in GOTS certification, it's your ticket to market credibility. I've seen brands lose entire shipments because their transaction certificates didn't match their material quantities.

The GOTS documentation system requires transparency at every stage. This includes transaction certificates (TCs) that track certified materials from one certified entity to another, organic content verification from the source, and records of all chemical inputs and processing methods. Each certified operation in the chain must undergo annual onsite audits by an accredited certification body. Our American client learned this the hard way when their initial supplier couldn't provide proper TCs, delaying their Spring 2024 collection by six weeks.

What are the labeling and composition requirements?

GOTS has specific labeling rules that depend on the organic content percentage. Products with 95% or more organic fibers can be labeled "GOTS organic," while those with 70-94% organic fibers can use the "made with organic" label. All such labeling must reference the certification body by name and include their license number.

The certification also requires clear identification of the non-organic portion of the product, which cannot consist of conventional fibers of the same type as the organic fibers (to prevent mixing). We help brands navigate these requirements through our complete guide to GOTS labeling requirements implementation, ensuring their hangtags and marketing claims remain compliant. This is particularly important for brands using recycled content alongside organic fibers, as the percentages must be clearly communicated.

How does the transaction certificate system work?

The TC system is the backbone of GOTS traceability. Each time certified material changes hands between certified entities, a new TC must be issued. This creates an unbroken chain of custody from the farmer to the final product. The TC includes details like quantities, product descriptions, and certification details of both buyer and seller.

We've integrated this TC system with our digital inventory management, allowing clients real-time visibility into their certification status. For a UK-based e-commerce brand, we developed a QR code system that links directly to the GOTS TCs for each batch, providing their customers with unprecedented supply chain transparency. This level of traceability has become a significant selling point in markets where greenwashing concerns are high. Proper documentation might seem burdensome, but it's what separates legitimate GOTS claims from empty marketing statements.

Conclusion

Navigating GOTS certification requires understanding permitted fibers, approved chemical inputs, compliant processing methods, and rigorous documentation. The certification isn't just about starting with organic cotton—it governs every chemical, process, and business practice along your supply chain. From our experience helping over 30 brands achieve GOTS certification, the investment in compliance pays dividends in market access, consumer trust, and often operational efficiency through reduced waste and chemical usage.

The sustainable textile market continues to evolve, with GOTS remaining the gold standard for organic textiles. Brands that master its requirements position themselves for success in the increasingly transparency-driven fashion industry. If you're looking to develop GOTS-certified collections with a partner that has navigated these waters successfully, we should talk. Our technical team can help you select compliant materials, processes, and documentation systems that align with your brand vision and values.

Contact our Business Director Elaine today to discuss how we can help you develop compliant, sustainable textile collections: elaine@fumaoclothing.com. We'll provide a free initial consultation to review your project requirements and identify the most efficient path to GOTS certification for your products.