If your brand cares about the planet, your fabric choices must reflect that. But finding a balance between sustainability, performance, and comfort is not easy.

Tencel™ blends are ideal for eco-friendly clothing because they use sustainably sourced wood pulp, consume less water, and biodegrade faster than synthetic options—without compromising softness or durability.

As a fabric manufacturer, I’ve worked with Tencel™ for over 10 years. It consistently outperforms expectations in both environmental and product quality benchmarks.

Why Do Fashion Brands Prefer Tencel™ Fabrics?

Sustainability isn’t just a trend—it’s a mandate. But not every "green" fabric lives up to the promise.

Fashion brands prefer Tencel™ because it offers traceable sustainability, exceptional softness, and strong consumer appeal. Brands like Levi’s, Patagonia, and Stella McCartney use it in everything from denim to activewear.

Why are global labels shifting to Tencel™?

| Brand | Tencel™ Usage Example |

|---|---|

| Levi's | Eco-denim with Tencel™ for less water use |

| H&M Conscious | Blended basics in Tencel™-cotton |

| Patagonia | Performance tees with Tencel™ lyocell |

| Tentree | 100% Tencel™ shirts for low-impact fashion |

| Reformation | Dresses using Tencel™ + viscose blends |

Tencel™ is produced by Lenzing, a company with a strict closed-loop process and wood sourcing from FSC-certified forests. Brands know they can use the Tencel™ logo and claim verified environmental benefits.

Why do my clients request it?

My clients often tell me their customers specifically ask for “Tencel” by name. It has become shorthand for premium eco-consciousness. Unlike vague terms like “natural” or “green,” Tencel™ comes with scientific backing and brand trust.

Tencel™ vs. Cotton: Which is More Sustainable?

Cotton may be natural—but it’s not always gentle on the environment.

Tencel™ is more sustainable than conventional cotton because it requires 80% less water, avoids harmful pesticides, and is made in a closed-loop system that recycles 99% of solvents.

What are the environmental differences?

| Feature | Tencel™ | Conventional Cotton |

|---|---|---|

| Water Usage | Low (rain-fed forests) | High (2,700L per shirt) |

| Land Use | FSC woodlands | Agricultural land |

| Pesticides | None | Heavy use |

| Biodegradability | High | Moderate |

| Chemical Process | Closed-loop | Open system (polluting) |

When customers ask about sustainability, I like to show this simple example:

A single cotton T-shirt takes over 2,000 liters of water to make. A Tencel™ shirt takes under 400 liters—with nearly all chemicals recycled in the process.

What about organic cotton?

Organic cotton is a great step forward, but still requires arable land and irrigation. Tencel™ grows from trees—often on slopes or marginal lands not usable for crops.

For brands targeting eco-conscious millennials and Gen Z, Tencel™ sends a clearer, stronger message.

Are Tencel™ Blends Comfortable and Durable?

Sustainable is good—but only if it feels right and lasts long.

Tencel™ blends are known for silky comfort, high breathability, and surprising durability, especially when combined with cotton, polyester, or spandex.

How do Tencel™ fabrics feel?

If you’ve worn a Tencel™ modal pajama set or a lyocell tee, you know the answer: soft, silky, cool to the touch. The fibers are smooth and fine, unlike scratchy synthetics or stiff traditional cotton.

What makes it durable?

On its own, Tencel™ lyocell is moderately strong. But when blended, it enhances both comfort and longevity:

| Blend Composition | Benefit |

|---|---|

| Tencel™ + Cotton | Stronger weave, better moisture management |

| Tencel™ + Polyester | Wrinkle resistance, fast drying |

| Tencel™ + Spandex | Stretch and recovery, ideal for activewear |

Our factory produces Tencel™ blends with different surface finishes: peach-skin, sanded, or enzyme-washed, depending on the brand’s target use.

One client from California launched a Tencel™-spandex maternity legging. Feedback? “Feels like butter, doesn’t pill, washes perfectly.” That’s the power of fiber engineering.

How Tencel™ Fabric Production Supports Sustainability?

Eco-claims are easy to make. Tencel™ backs it up with verified processes.

Tencel™ fabric is made in a closed-loop system using wood pulp from certified forests. Over 99% of water and solvents are recycled, making it one of the cleanest textile production systems available.

What does “closed-loop” really mean?

It means that the solvents used to turn wood into fiber—typically amine oxides—are reused again and again. Unlike viscose (which emits toxic chemicals into rivers), Tencel™ has near-zero emissions.

| Sustainability Factor | Tencel™ Process |

|---|---|

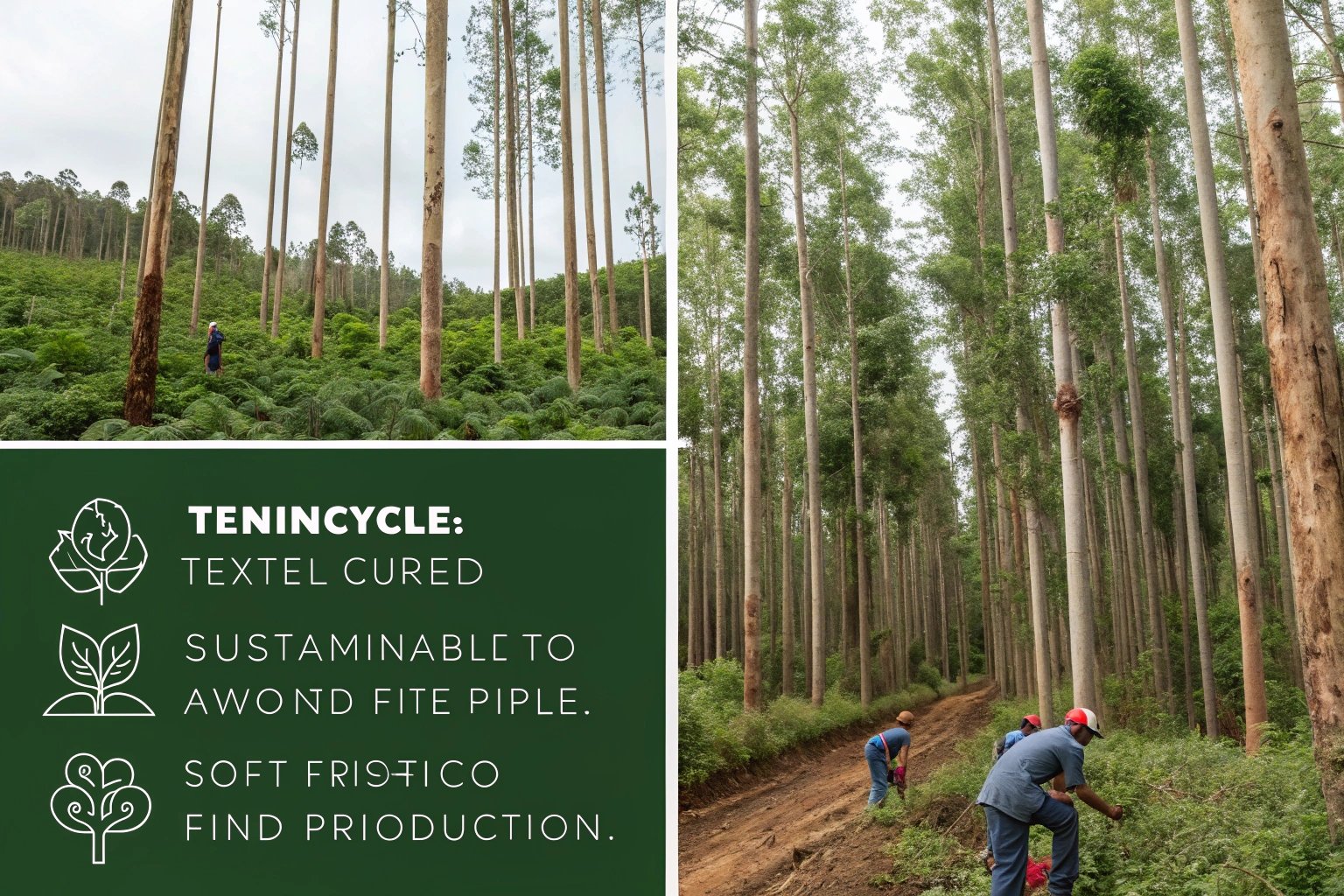

| Wood Source | FSC-certified eucalyptus |

| Solvent Use | Non-toxic, reused |

| Energy Use | Renewable sources |

| Waste Output | Minimal |

| CO2 Emissions | Low |

What about the raw material?

The wood used is grown on fast-growing eucalyptus plantations. No rainforest is touched. No food crops are displaced.

How do we support this as a supplier?

At Fumao, we work directly with certified Tencel™ yarn mills and ensure that any blending partners follow dyeing protocols that minimize water waste. Our printing lines also use OEKO-TEX inks, so the entire production stays within green compliance.

For clients needing documents, we provide:

- Lenzing Certificate of Authenticity

- GRS or OEKO-TEX certificates for blended fabrics

- CNAS lab reports for colorfastness and pilling

Conclusion

Tencel™ blends offer the rare mix of softness, sustainability, and style. For fashion brands serious about reducing their footprint, choosing Tencel™-based fabrics is a smart and scalable solution. At Fumao, we make it easy to integrate these fabrics into your next eco-forward collection.