Let me tell you about Mrs. Anderson, a buyer for a boutique dermatology clinic's clothing line in Sweden. She came to us in 2022 desperate and frustrated. Her clinic's own-branded cotton loungewear, marketed for post-procedure sensitive skin, was causing unexpected irritation in about 3% of patients. Their supplier had provided "skin-friendly" fabric with a basic compliance report, but it wasn't enough. We switched her to a Product Class I (Baby Grade) OEKO-TEX® certified bamboo-cotton blend from our stock. The result? Complaints dropped to zero within six months, and she could finally guarantee her dermatologists' recommendations. This wasn't magic; it was the uncompromising, science-backed rigor of OEKO-TEX®'s highest grade solving a problem that generic "softness" could not.

OEKO-TEX® STANDARD 100 Product Class I (often called Baby Grade) is uniquely engineered for sensitive skin because it applies the world's strictest limits for harmful substances to textiles intended for the most vulnerable users: babies under 3 years old. For adults with sensitive skin, eczema, dermatitis, or chemical intolerances, using fabrics certified to this grade offers a "safe haven" level of assurance. It goes far beyond banning obvious toxins; it rigorously controls pH balance, eliminates allergenic dyes, enforces superior colorfastness (especially to saliva and sweat), and mandates skin-friendly finishes. In essence, it treats fabric not just as a material, but as a biocompatible interface for fragile skin.

You might think "organic cotton" or "natural fiber" is the answer for sensitive skin. But nature can be irritating (think of prickly plant residues), and the real risks often come from the processing—dyes, softeners, and finishes that "organic" standards don't fully regulate. OEKO-TEX® Grade 1 fills this critical gap with forensic precision. This article will dissect the specific chemical, physical, and biological parameters that make this grade the gold standard for sensitive skin, supported by our lab data and real client outcomes at Shanghai Fumao.

How Does Grade 1's Chemical Threshold Protect Delicate Skin Barriers?

Sensitive skin often has a compromised epidermal barrier, making it more permeable to chemicals. Irritation isn't always an allergic reaction; it can be a direct cytotoxic effect from substances that healthier skin might tolerate. OEKO-TEX® Class I enforces near-zero tolerance for a vast array of these substances, creating a chemical environment that minimizes the risk of both irritation and allergy.

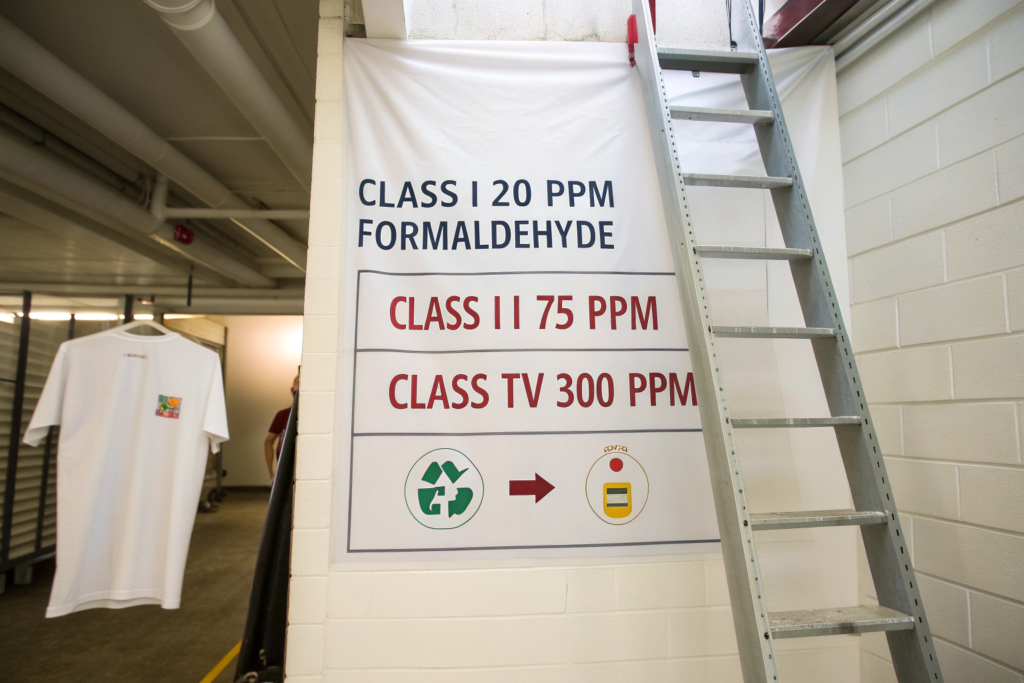

The core of this protection lies in its exceptionally low limits for formaldehyde, heavy metals, and phthalates. For example, the allowed formaldehyde limit for Class I is 20 ppm (parts per million), while for Class IV (decorative materials) it's 300 ppm. Formaldehyde resins are used for anti-wrinkle and durable-press finishes but are a known skin sensitizer. For someone with eczema, even trace amounts can trigger flare-ups. Similarly, heavy metals like nickel, chromium, or lead can be present as dye catalysts or contaminants and are common contact allergens. Class I's limits are so low they often require mills to use premium, high-purity dyes and chemicals, fundamentally changing the production recipe.

Why is the Complete Ban on Allergenic Disperse Dyes Critical?

This is a game-changer for synthetic blends, which are common in activewear and socks. Disperse dyes are used to color polyester and nylon. A specific subset of these dyes is classified as "allergenic." For the general population, the risk is low, but for individuals with sensitive skin or textile dermatitis, these dyes are a prime culprit. OEKO-TEX® Class I prohibits the use of all known allergenic disperse dyes entirely. This is a categorical ban, not a limit.

We had a client producing yoga leggings for a niche market of customers with autoimmune skin conditions. Their previous polyester fabric, while "OEKO-TEX® certified" to a lower class, still contained traces of a disperse dye that triggered reactions in a subset of users. By switching to a fabric certified to Class I (which uses a different, more expensive dye palette), they eliminated this issue completely. The certification provided a clear, binary filter: if it's Class I, those specific allergens are not present. Understanding the list of restricted allergenic dyes in textiles is crucial for dermatologists, and OEKO-TEX® Class I operationalizes this knowledge.

How Does pH Control Mimic the Skin's Natural Acid Mantle?

Healthy skin has a slightly acidic pH (around 4.5-5.5), known as the acid mantle, which inhibits bacterial growth and maintains barrier function. Alkaline substances can disrupt this, leading to dryness, itching, and increased susceptibility to irritation. OEKO-TEX® Class I requires fabrics to have a pH value in the nearly neutral to slightly acidic range, closely aligned with skin's natural state.

In our dyeing and finishing process for Class I fabrics, this means implementing a final "acid wash" or neutralization step that is meticulously controlled and tested on every batch. We don't assume it's right; we measure it. For a client making bedding for cancer patients (whose skin is often extremely sensitive due to treatments), this pH guarantee was as important as the fabric's softness. It ensured the fabric would not chemically stress the skin during prolonged contact. This level of control is what transforms a textile from inert to skin-compatible.

How Do Physical Performance Tests Guarantee Day-Long Comfort?

Chemical safety is foundational, but physical irritation—from friction, dye migration, or poor moisture management—can be just as problematic for sensitive skin. OEKO-TEX® Class I incorporates stringent performance tests that directly address these mechanical and practical triggers of discomfort. These tests ensure the fabric not only starts safe but stays gentle through use and care.

The most significant of these are the colorfastness tests to saliva, perspiration, and washing. For babies, the saliva test is obvious. For adults with sensitive skin, the perspiration test is vital. Sweat can act as a solvent, leaching dyes and finishes from fabric. If these substances then sit against skin in a concentrated form, they can cause "textile dermatitis." Class I mandates excellent fastness, meaning the color and finishing agents are chemically bound to the fiber and won't migrate easily. This reduces the chemical load on skin during physical activity or stress.

Why is "Saliva and Perspiration Fastness" a Non-Negotiable Test?

These tests simulate real-world abuse. The fabric sample is immersed in artificial saliva or acidic/alkaline perspiration solutions under controlled conditions, then assessed for color transfer. Achieving a high grade requires dyers to use high-quality, high-fixation dyes and thorough rinsing processes—which inherently means fewer loose chemical residues left in the fabric.

We apply this thinking to our entire Class I product development. For instance, when creating a moisture-wicking fabric for sensitive skin activewear, we don't just add a functional finish. We test the combination of that finish with the dye to ensure neither leaches under sweat simulation. In 2023, this protocol helped us develop a line for a US brand catering to athletes with eczema. Their post-launch customer feedback highlighted a notable reduction in "exercise-induced itch" compared to their previous line. The unseen discipline of fastness testing created a tangible comfort benefit.

How Does the Standard Address Dimensional Stability and Surface Smoothness?

Shrinkage and pilling are physical irritants. A garment that shrinks unevenly can create tight, chafing seams. Pilling creates a rough surface that mechanically irritates skin. While OEKO-TEX® doesn't have a direct "pilling test," the requirements for quality and the use of skin-friendly finishes indirectly promote better performance. Mills aiming for Class I are typically using higher-quality yarns and more controlled finishing processes to meet the chemical standards, which often results in better physical durability.

Furthermore, to avoid banned chemical softeners, mills are pushed toward mechanical finishing techniques (like enzyme washing or compacting) that create a durable, naturally soft hand feel without relying on silicone-based coatings that can wash out and leave fabric harsh. The result is a fabric whose gentle touch is built into its structure, not just sprayed on its surface. For those seeking guidance on non-irritating clothing for chronic skin conditions, the built-in durability of Class I fabrics is a key advantage.

What Role Do Raw Material and Production Process Controls Play?

You cannot achieve OEKO-TEX® Class I certification by testing a finished product alone. The "pass" is a result of controlling the entire production chain—from the selection of raw fibers to the final packaging. This systemic control is what guarantees consistency and makes it ideal for sensitive skin consumers who react unpredictably to variables.

The certification requires that all components—including sewing threads, elastics, prints, and appliqués—meet the Class I standards. This is crucial. A garment made from perfect fabric can be ruined by a nickel-containing snap or a phthalate-laden print. The factory must have a documented system for sourcing and verifying compliant trims. At Shanghai Fumao, for any Class I project, we provide a "trim kit" of pre-certified components to our garment partners or mandate they source from our vetted list. This closed-loop system eliminates unknown variables.

How Does This Affect Fiber Choice and Yarn Processing?

Not all fibers are created equal for this grade. While any fiber can be certified, the intense scrutiny often leads to a preference for fibers with naturally low irritancy potential, such as long-staple cotton, silk, bamboo lyocell, and certain high-quality micro-modal. The processing of these fibers is also scrutinized. For example, the bleaching of cotton for Class I must use peroxide-based processes rather than chlorine-based ones, which can leave harmful residues.

We specialize in bamboo-based fabrics (BAMSILK) for sensitive skin. To achieve Class I, we had to meticulously document our closed-loop lyocell-type production process, proving the solvents used are captured and recycled and don't remain in the fiber. This resulted in a fabric that is not only chemically pure but also exceptionally smooth at the microfibril level, reducing mechanical irritation. It's a case where the certification drove us to a superior, more sustainable production method.

Why is the Manufacturing Environment Itself Part of the Standard?

OEKO-TEX® certification includes an audit of the production site. Why? Because cross-contamination is a real risk. A factory producing Class I babywear on the same line as heavy, chemically-treated workwear without proper cleaning in between could lead to contamination. The standard requires measures to prevent this, such as segregated production runs or dedicated machinery.

This point resonates deeply with buyers from the medical textile sector. A hospital procurement officer once told me that seeing our Class I certification and understanding the factory control requirements gave him more confidence in our hygiene and consistency standards than a generic "clean room" claim. It showed a systemic understanding of contamination risk. For sensitive skin, where the trigger can be a single exposure, this environmental control is part of the product's safety.

How Can Brands Communicate This Benefit to Sensitive Skin Consumers?

For a brand, having an OEKO-TEX® Class I product is a powerful asset, but its value must be communicated effectively. Sensitive skin consumers are often savvy, skeptical, and hungry for credible information. They don't just want to hear "hypoallergenic"; they want to know why. The specificity of Class I provides the perfect narrative framework.

The communication should move from the generic to the specific. Instead of "gentle on skin," say: "Certified to OEKO-TEX® STANDARD 100, Product Class I (Baby Grade)—the world's strictest standard for harmful substances. It guarantees no allergenic dyes, skin-neutral pH, and superior colorfastness to sweat, making it ideal for sensitive skin or eczema." This language is rich with searchable keywords and addresses specific consumer fears.

What Marketing Assets Does a Certified Supplier Provide?

A good supplier should empower your marketing. At Shanghai Fumao, we provide our Class I brand partners with:

- Detailed Test Summary Excerpts: Anonymized data sheets highlighting key passed parameters (pH, formaldehyde "ND" for non-detectable).

- Explainer Content: Short videos or infographics on what Class I means versus other classes.

- Transparency Links: A unique ID that allows the brand (or even the end-consumer) to verify the certificate on the OEKO-TEX® website.

This turns a B2B certification into a B2C trust signal. A skincare brand we work with includes a hangtag with a QR code linking directly to the OEKO-TEX® certificate for that garment's fabric lot. This level of traceability is a ultimate proof point for a discerning customer.

Is There a Verifiable ROI for Brands Targeting This Niche?

Absolutely. The sensitive skin market is loyal and willing to pay a premium for proven efficacy. A European loungewear brand focusing on dermatological wellness launched a "SkinSleep" line using our Class I fabrics. They positioned it at a 35% premium over their standard line. Within a year, it became their top-rated product for customer satisfaction and had the lowest return rate in their history. The certification provided the justification for the premium and the evidence for the claim, driving both margin and loyalty. In markets where trust is paramount, building brand credibility through verifiable certifications is a proven strategy.

Conclusion

OEKO-TEX® STANDARD 100 Product Class I is not merely a stricter version of a textile standard; it is a holistic, system-based guarantee of biocompatibility. For individuals with sensitive skin, it offers a refuge from the chemical and physical irritants prevalent in conventional textiles. By enforcing the planet's most stringent limits on harmful substances, mandating skin-friendly pH and durable colorfastness, and controlling the entire production ecosystem, it creates a category of fabric where safety and comfort are engineered into every fiber.

For brands, sourcing Class I materials is a profound demonstration of commitment to a vulnerable and valuable consumer segment. It transforms a marketing claim into a verifiable, scientific promise. At Shanghai Fumao, we have dedicated a significant part of our R&D and production to mastering this standard because we believe in its power to deliver genuine well-being. If you are developing products for sensitive skin, eczema, dermatology, or simply the highest tier of everyday comfort, building on the OEKO-TEX® Class I foundation is the most responsible and effective choice. Contact our Business Director, Elaine, to explore our range of certified fabrics designed for the most delicate needs. Reach her at: elaine@fumaoclothing.com.