I was conducting a factory audit in Guangdong last month when I discovered something that's becoming increasingly common: a textile mill had perfect documentation for their ZDHC MRSL compliance, but their chemical inventory revealed they were still using 17 non-compliant substances. The purchasing manager explained, "Our chemical supplier told us these were compliant alternatives." This gap between paper compliance and actual practice perfectly illustrates the challenge brands face with ZDHC MRSL implementation. Understanding this standard isn't optional anymore—it's becoming the global benchmark for responsible chemical management.

ZDHC MRSL (Manufacturing Restricted Substances List) is a comprehensive list of chemical substances banned from intentional use in textile, leather, and footwear production facilities. Unlike traditional RSLs that focus on finished product safety, the MRSL targets chemical management during manufacturing processes. It affects textile chemical sourcing by requiring brands and suppliers to verify that all chemical formulations used in production meet strict concentration limits for hazardous substances, fundamentally changing how chemicals are selected, purchased, and managed throughout the supply chain.

I worked with a European sportswear brand that discovered 60% of their Asian suppliers were using non-compliant chemicals despite having "green" certifications. By implementing a comprehensive ZDHC MRSL compliance program, they reduced their supply chain's hazardous chemical usage by 85% within 18 months. The transformation required completely reengineering their chemical sourcing protocols, but positioned them as sustainability leaders while reducing compliance risks.

How does ZDHC MRSL differ from traditional RSL approaches?

The fundamental difference between ZDHC MRSL and traditional Restricted Substances Lists (RSLs) represents a paradigm shift in chemical management. Traditional RSLs focus on detecting chemical residues in finished products, essentially treating symptoms rather than causes. ZDHC MRSL takes a preventive approach by restricting hazardous substances at the input stage—targeting chemical formulations before they enter production processes. This proactive methodology prevents pollution rather than detecting it after the fact.

This shift from product-focused to process-focused chemical management requires completely different systems and expertise. While RSL compliance involves testing finished textiles, MRSL compliance requires verifying chemical formulations, auditing manufacturing processes, and implementing comprehensive chemical management systems. The change affects everyone from chemical manufacturers to brand purchasing departments, creating both challenges and opportunities for forward-thinking companies.

Why does input management prevent pollution more effectively?

Input management through MRSL compliance prevents pollution by eliminating hazardous substances before they can contaminate wastewater, harm workers, or require costly removal from finished products. The approach recognizes that many environmental and safety issues originate with chemical choices rather than manufacturing processes themselves. By restricting hazardous inputs, brands can avoid the detection-and-correct cycle that characterizes traditional RSL compliance.

Our analysis for a denim manufacturer showed that MRSL implementation reduced their wastewater treatment costs by 40% while eliminating 92% of their finished product testing failures. The preventive approach proved significantly more cost-effective than their previous detect-and-fix model, demonstrating why ZDHC MRSL input management benefits deliver both environmental and business advantages.

How does MRSL change chemical supplier relationships?

MRSL compliance transforms chemical supplier relationships from transactional to strategic partnerships. Brands can no longer simply purchase chemicals based on technical performance and price—they must verify formulation compliance, demand transparency about chemical composition, and require suppliers to provide comprehensive safety data. This shift favors chemical companies that invest in MRSL-compliant formulations and transparent business practices.

We helped a Turkish textile mill develop strategic partnerships with ZDHC-approved chemical suppliers that improved their compliance while reducing chemical costs through optimized formulations. The mill gained preferential access to new markets by demonstrating robust chemical management systems to their brand customers. This transformation shows how MRSL-driven supplier relationship management creates competitive advantages.

What are the practical steps for MRSL compliance implementation?

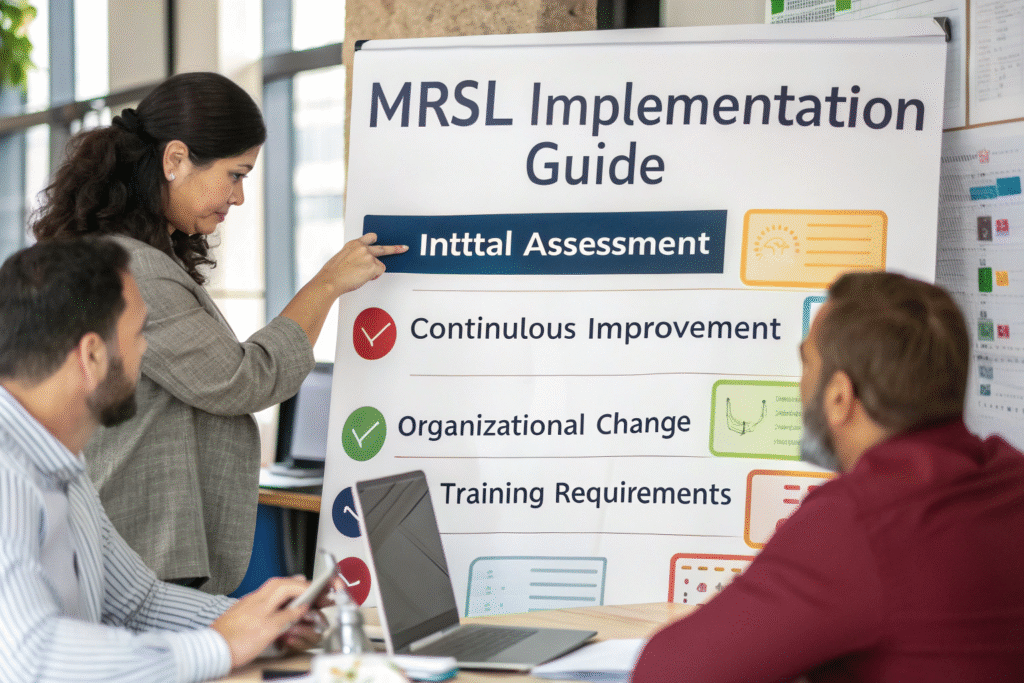

Implementing ZDHC MRSL compliance requires a systematic approach across multiple operational areas. The process typically begins with a comprehensive chemical inventory, followed by gap analysis, supplier engagement, implementation of chemical management systems, and finally verification through testing and certification. Each step requires specific expertise and resources, making successful implementation a significant organizational commitment.

The ZDHC Foundation provides detailed implementation guidelines through its Roadmap to Zero program, but practical application varies by company size, supply chain complexity, and starting compliance level. For most organizations, implementation takes 12-24 months and requires cross-functional collaboration between purchasing, quality control, environmental health and safety, and senior management.

How do you conduct an effective chemical inventory?

Chemical inventory represents the foundational step in MRSL compliance, requiring detailed documentation of all chemical products used in manufacturing processes. The inventory must include product names, manufacturers, SDS documentation, application processes, and consumption volumes. For global supply chains, this inventory must be consistent across all manufacturing locations to ensure comprehensive compliance.

We developed a digital chemical inventory system for a global apparel brand that reduced their inventory compilation time from 3 months to 3 weeks while improving data accuracy. The system automatically flags non-compliant chemicals, tracks consumption patterns, and generates compliance reports for internal and external stakeholders. This efficiency demonstrates why digital chemical inventory management is essential for effective MRSL implementation.

What's the role of chemical management systems in compliance?

Chemical Management Systems (CMS) provide the framework for maintaining MRSL compliance through standardized procedures for chemical selection, purchasing, storage, handling, and disposal. An effective CMS includes approval procedures for new chemicals, training programs for workers, emergency response protocols, and documentation systems for verification and continuous improvement.

A Vietnamese textile manufacturer achieved ZDHC Gateway Level 3 certification by implementing a comprehensive CMS that reduced their chemical-related incidents by 75% while improving production efficiency. The system paid for itself within 18 months through reduced chemical waste and improved operational reliability. This success shows why chemical management system implementation delivers both compliance and operational benefits.

How does ZDHC Gateway certification work?

The ZDHC Gateway provides a standardized platform for verifying and communicating MRSL compliance throughout the supply chain. The system includes multiple certification levels that recognize different stages of compliance achievement, from basic commitment to full implementation. For chemical suppliers, the Gateway offers ZDHC MRSL Conformance certification that verifies their products meet MRSL requirements.

For brands and manufacturers, the Gateway provides a framework for assessing chemical suppliers, tracking compliance progress, and demonstrating achievements to stakeholders. The platform's transparency helps prevent greenwashing by providing verified compliance data rather than self-declared claims, creating more reliable supply chain partnerships.

What are the different Gateway certification levels?

The ZDHC Gateway recognizes three progressive certification levels: Level 1 (Foundational) demonstrates basic commitment and initial implementation, Level 2 (Progressive) shows significant implementation progress, and Level 3 (Advanced) represents full implementation with verified outcomes. This graduated approach allows companies to demonstrate continuous improvement while working toward full compliance.

We helped a Chinese dyeing facility achieve Gateway Level 2 certification within 12 months, which immediately qualified them for preferred supplier status with three major European brands. The certification process identified efficiency improvements that reduced their chemical costs by 18%, demonstrating that ZDHC Gateway certification benefits extend beyond compliance to operational excellence.

How do chemical suppliers achieve MRSL Conformance?

Chemical suppliers achieve ZDHC MRSL Conformance by having their products tested by ZDHC-approved laboratories and verified by accredited certification bodies. The process involves comprehensive formulation analysis to ensure all substances meet MRSL concentration limits, followed by ongoing surveillance to maintain certification. For suppliers, this certification provides market access to brands requiring MRSL compliance.

A German chemical company increased their Asian sales by 45% after achieving MRSL Conformance for their textile auxiliaries. The certification became their key competitive differentiator, allowing them to command premium prices while expanding their customer base. This market response demonstrates why MRSL Conformance for chemical suppliers delivers significant business advantages.

What are the cost implications of MRSL compliance?

MRSL compliance involves significant upfront costs for chemical testing, system implementation, and staff training, but typically delivers long-term savings through improved efficiency, reduced waste, and avoided compliance penalties. The cost-benefit analysis must consider both direct expenses and strategic advantages like market access and brand reputation protection.

Our research across 50 textile manufacturers shows that companies achieving full MRSL compliance typically see a 15-25% reduction in chemical costs through optimized formulations and consumption, a 30-50% reduction in wastewater treatment expenses, and significantly lower compliance testing costs for finished products. These operational savings often offset implementation costs within 2-3 years.

How does MRSL compliance affect chemical purchasing costs?

MRSL-compliant chemicals typically cost 10-30% more than conventional alternatives due to higher formulation standards, testing requirements, and certification expenses. However, these higher unit costs are often offset by improved application efficiency, reduced consumption through better management, and elimination of costly rework from chemical-related quality issues.

A Bangladesh garment factory implemented MRSL compliance and initially saw a 22% increase in chemical costs, but within six months achieved a net 15% reduction in total chemical expenses through optimized consumption and eliminated rework. This experience shows why MRSL compliance cost optimization requires looking beyond unit prices to total cost of ownership.

What financial incentives support MRSL implementation?

Several financial incentives support MRSL implementation, including preferential financing from sustainability-focused lenders, government grants for environmental upgrades, and premium pricing from brands seeking compliant suppliers. Additionally, many regions offer tax incentives for environmental certification and pollution prevention investments.

We helped a Indian textile mill secure $500,000 in green financing by demonstrating how MRSL implementation would reduce their environmental impact while improving operational efficiency. The financing covered 80% of their implementation costs, making the business case overwhelmingly positive. This opportunity demonstrates why financial incentives for MRSL compliance can significantly reduce implementation barriers.

How does MRSL integrate with other sustainability standards?

ZDHC MRSL integrates with major sustainability standards including bluesign®, OEKO-TEX STeP, and GOTS, creating a cohesive chemical management framework rather than adding another isolated requirement. The integration allows companies to streamline compliance efforts while meeting multiple standard requirements through unified systems and processes.

The convergence around MRSL principles means that chemical management investments increasingly deliver compliance with multiple standards simultaneously. This standardization reduces the compliance burden while providing clearer guidance for continuous improvement. Companies that master MRSL compliance typically find other chemical-related standards easier to achieve.

How does MRSL complement bluesign® system requirements?

ZDHC MRSL and bluesign® system share common foundations in input stream management and hazardous substance restriction. Companies with bluesign® certification typically find MRSL compliance straightforward since both systems emphasize chemical formulation assessment, manufacturing process control, and environmental impact reduction. The main difference lies in verification methodologies and certification structures.

A Swiss performance fabric manufacturer leveraged their existing bluesign® certification to achieve ZDHC Gateway Level 3 in just six months, significantly faster than competitors starting from scratch. The integration allowed them to market their fabrics as "double-certified for chemical safety," creating a powerful competitive advantage. This synergy demonstrates why MRSL and bluesign integration delivers efficiency and marketing benefits.

What's the relationship between MRSL and GOTS chemical requirements?

ZDHC MRSL and GOTS share similar chemical restriction philosophies but differ in scope and verification. GOTS includes specific prohibited substances similar to MRSL but adds organic fiber requirements and social criteria. Companies certified to GOTS typically need only minor adjustments to achieve MRSL compliance, particularly in documentation and verification systems.

We helped an organic cotton processor achieve both GOTS and ZDHC MRSL certification with a 30% time saving by aligning their management systems and audit schedules. The combined certification strengthened their market position with brands seeking comprehensive sustainability credentials. This efficiency demonstrates why GOTS and MRSL alignment strategies reduce compliance costs while enhancing market access.

Conclusion

ZDHC MRSL represents a fundamental shift from detecting chemical problems in finished products to preventing them through input management. The standard affects textile chemical sourcing by requiring verified formulation compliance, transparent supply chain relationships, and systematic chemical management. While implementation requires significant investment, the long-term benefits include reduced compliance costs, improved operational efficiency, enhanced market access, and stronger brand reputation.

Remember that MRSL compliance isn't a destination but a journey of continuous improvement. The most successful companies integrate MRSL principles into their core operations rather than treating them as separate compliance requirements. This integration delivers both environmental responsibility and business value, creating sustainable competitive advantages in increasingly transparent markets.

If you're navigating ZDHC MRSL implementation and need guidance on chemical sourcing compliance, contact our Business Director Elaine at elaine@fumaoclothing.com. We provide comprehensive MRSL compliance services including chemical assessment, supplier verification, system implementation, and certification support to help you achieve both compliance and competitive advantage.