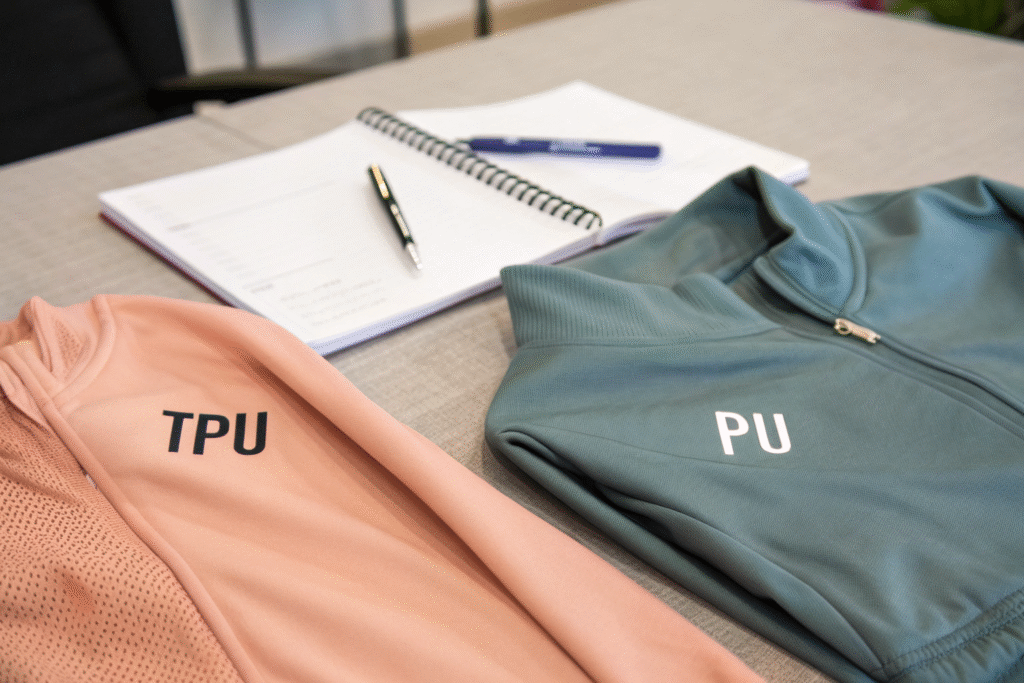

If you're sourcing waterproof fabrics for your apparel line, you've likely encountered the terms TPU and PU coating. You know they are crucial for performance, but the differences can be confusing. Choosing the wrong one can impact your product's quality, cost, and market appeal. This isn't just a technical detail; it's a key decision that affects your bottom line and brand reputation. Understanding the distinction helps you make smarter sourcing choices, ensuring you get the right fabric for your specific needs without overpaying.

So, what exactly sets TPU and PU apart? In simple terms, both are polymer coatings used to make fabrics waterproof, but they have different chemical structures and properties. TPU (Thermoplastic Polyurethane) is generally more durable, environmentally friendly, and flexible, especially in cold conditions. PU (Polyurethane) is a versatile and cost-effective option that provides excellent waterproofing but may be less robust over time. Your choice depends on the application, desired performance, budget, and sustainability goals.

This guide will break down the TPU vs PU debate in clear, practical terms. We will explore their unique characteristics, advantages, and ideal uses. By the end, you will have a clear understanding of which coating is the best fit for your next outdoor, sportswear, or functional apparel project. Let's dive into the specifics to help you make an informed decision.

What are the key differences between TPU and PU coatings?

When you need to choose a coating for waterproof fabrics, the core differences matter. TPU and PU are both effective, but they serve different purposes. TPU is known for its superior elasticity and resistance to oils, greases, and abrasion. PU is celebrated for its cost-effectiveness and versatility. The main difference lies in their chemical composition. TPU is a thermoplastic, which means it can be melted and reshaped. PU is a thermoset polymer, which sets permanently after curing. This fundamental distinction impacts everything from durability to recyclability.

How does chemical structure affect performance?

The performance of a coating starts with its chemistry. TPU's thermoplastic nature gives it a distinct advantage in flexibility and resilience. The polymer chains can slide past each other when heated, allowing for re-melting and reforming. This translates to a coating that can withstand repeated stretching and bending without cracking. This makes TPU ideal for products like inflatable boats, heavy-duty tarps, and technical outdoor gear that face extreme conditions. PU, as a thermoset, forms a tight, cross-linked network during curing. This creates a strong, durable film that is excellent for creating a waterproof barrier. However, this structure can be more prone to becoming brittle over time, especially when exposed to UV radiation or very cold temperatures. For applications where extreme flexibility is not the primary concern, PU offers a reliable and strong seal.

Which coating offers better durability and environmental resistance?

Durability is a top priority for buyers. In this area, TPU generally has the edge. Its inherent resistance to abrasion means the coating is less likely to wear thin from friction. TPU also performs better when exposed to chemicals like oils or solvents, which can break down PU coatings over time. From an environmental perspective, TPU is often considered more sustainable. It can be recycled more easily because it can be re-melted. Some types are also biodegradable. PU is not typically biodegradable and is more challenging to recycle. However, it's important to note that high-quality PU coatings can still offer excellent longevity for many applications, such as rain jackets or tents, where they are not subjected to constant harsh abrasion. For the highest level of performance and environmental consideration, TPU is often the preferred choice.

What are the advantages of using TPU coating?

TPU coating brings several strong benefits to the table, especially for brands focused on high-performance and eco-friendly products. Its exceptional durability directly translates to longer product life, which reduces waste and improves customer satisfaction. The material's flexibility ensures comfort and functionality in dynamic applications. Furthermore, TPU's environmental profile is a significant advantage in today's market, appealing to a growing segment of conscious consumers.

Why is TPU considered more environmentally friendly?

Sustainability is a major concern for modern brands. TPU is often highlighted for its greener credentials compared to traditional PU. Firstly, TPU can be recycled efficiently. Since it is thermoplastic, it can be melted down and reused in new products, supporting a circular economy. Secondly, advancements have led to the development of bio-based TPUs derived from renewable resources, reducing reliance on fossil fuels. Some TPU variants are also designed to be biodegradable under specific industrial conditions, although this is not universal. While not all TPU is eco-friendly, the material itself offers more pathways for sustainable manufacturing than thermoset PU. At our facility, we offer a range of eco-friendly fabrics with certified recycled TPU coatings to help our clients meet their sustainability targets.

How does TPU enhance product lifespan?

The long-term value of a product is key. TPU coating significantly extends the life of waterproof fabrics through its physical properties. Its high abrasion resistance means the coating doesn't easily scrape off during use or cleaning. Its excellent low-temperature flexibility prevents the coating from cracking in cold weather, a common failure point for other coatings. This resilience ensures that the waterproof barrier remains intact for a longer period. This means your customers will have jackets, bags, or equipment that last for more seasons. This durability builds brand trust and reduces returns. We rigorously test the abrasion resistance of our TPU-coated fabrics in our CNAS-certified lab to guarantee they meet the demands of your market.

What are the benefits of choosing PU coating?

PU coating remains a highly popular choice for very good reasons. Its primary advantage is cost-effectiveness, making it accessible for a wide range of products and budgets. The manufacturing process for PU is well-established and highly efficient, allowing for rapid production times. It also provides a excellent balance of waterproofing performance and versatility, able to be applied to various fabric types with a soft hand feel that is desirable for apparel.

Is PU coating a cost-effective solution for bulk orders?

For large volume orders, PU coating is often the most economical option. The raw materials for PU are generally less expensive than those for TPU. The application process is also highly optimized for speed and scale, which helps keep production costs down. This cost efficiency does not necessarily mean low quality. It means you can achieve reliable waterproof protection for your products without exceeding your budget. This is particularly important for brands producing seasonal lines or items where the absolute highest level of abrasion resistance is not critical. Our agile supply chain and partnerships with dyeing and coating factories allow us to offer competitive pricing on large quantities of PU-coated fabrics without compromising on our strict quality control.

Can PU coatings provide a softer hand feel?

The tactile quality of a fabric, known as the hand feel, is crucial for wearer comfort. PU coatings excel in this area. They can be formulated to create very thin, flexible layers that do not significantly stiffen the base fabric. This results in a garment that remains soft and pliable, which is highly preferred for clothing like rain jackets and pants where freedom of movement and comfort are important. While TPU coatings have improved in this regard, they can sometimes impart a slightly more robust or rubbery feel to the fabric. For applications where a soft, quiet, and comfortable fabric is a top priority, PU is often the superior choice. We work with our coating factory partners to develop custom PU formulations that deliver the exact hand feel your designs require.

How to select the right coating for your specific application?

Making the final choice between TPU and PU comes down to your product's specific end-use, performance requirements, and budget. There is no one-size-fits-all answer. A high-end mountaineering shell has different needs than a fashion raincoat. By asking the right questions, you can pinpoint the optimal coating and avoid over-engineering or under-specifying your fabric.

What questions should you ask when comparing TPU and PU?

Start with a clear checklist for your project. What is the primary environment? For extreme cold or high abrasion, TPU is likely better. Is weight a critical factor? Both can be made lightweight, but PU often has an edge in ultra-light applications. What is your target price point? PU is more budget-friendly. How important is sustainability to your brand story? TPU offers stronger green credentials. What about the desired hand feel? PU is typically softer. By answering these questions, you move from a technical comparison to a practical business decision. We recommend discussing these factors with your fabric supplier during the fabric development stage to ensure the best outcome.

What are the common applications for each coating type?

Understanding where each coating is typically used provides a great shorthand for selection. TPU is the go-to for demanding applications: high-end outdoor gear (backpacks, climbing shells, ski wear), military equipment, inflatable products, and medical textiles where durability and safety are paramount. PU is incredibly versatile and widely used in: fashion outerwear, raincoats, lightweight tents, shower curtains, and footwear where cost-effectiveness and a soft hand feel are key.

| Coating Type | Ideal Applications | Key Reason |

|---|---|---|

| TPU | Technical outdoor gear, inflatable boats, military apparel, heavy-duty tarps | Superior abrasion resistance, cold flexibility, durability |

| PU | Fashion rainwear, lightweight jackets, casual bags, shower curtains | Cost-effective, soft hand feel, reliable waterproofing |

Conclusion

Choosing between TPU and PU coating is a critical step in developing successful waterproof fabrics. TPU stands out for its exceptional durability, environmental benefits, and performance in harsh conditions. PU offers a reliable, cost-effective, and comfortable solution for a wide array of applications. Your decision ultimately hinges on balancing performance needs with budget and sustainability goals. There is no outright winner, only the best choice for your specific product.

By understanding these differences, you can communicate more effectively with your supplier and make confident decisions that enhance your final product. The right coating not only ensures waterproofness but also contributes to the quality, longevity, and market appeal of your brand's offerings. We hope this guide has clarified the TPU vs PU debate for you.

If you are ready to source high-quality TPU or PU coated fabrics for your next collection, Shanghai Fumao is here to help. We provide end-to-end solutions from custom coating development to final packaging and shipping. Our expert team can guide you to the perfect material choice for your designs. Contact our Business Director, Elaine, today at elaine@fumaoclothing.com to discuss your specific requirements and start your order. Let us help you create exceptional waterproof apparel that your customers will love.