Imagine this: you’re a brand selling premium organic cotton hoodies. Your marketing is built on sustainability. Then, a journalist’s investigation reveals your “organic” cotton was mixed with conventional cotton from a questionable source two tiers down your supply chain. Your brand reputation shatters overnight. This isn’t a nightmare scenario; it’s a daily risk in today’s complex, multi-layered textile industry. The root cause? A total lack of verifiable, tamper-proof transparency.

So, what’s the solution? Enter blockchain. But it’s not a magic wand. The role of blockchain in fabric supply chain transparency is to act as an immutable, decentralized digital ledger that creates a single, shared version of the truth for every stakeholder—from the cotton farmer to the consumer. It doesn’t automatically make your supply chain ethical or sustainable. Instead, it provides the unchangeable proof that verifies—or exposes—your claims.

Think of it like a digital passport for your fabric roll that cannot be forged, lost, or edited by any single party. For a buyer navigating the complexities of ethical fabric sourcing from Asia, this shifts the paradigm from “trust me” to “verify for yourself.” I’ve seen firsthand in Keqiao how this technology is moving from hype to practical application, and it’s solving some of our most painful industry problems.

Why Is Our Current Supply Chain System So Opaque?

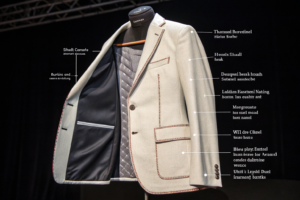

The traditional textile supply chain is a labyrinth. A single garment can involve over a dozen entities: farmer, ginner, spinner, weaver/knitter, dyer, finisher, garment factory, brand, distributor, and retailer. Information is passed through emails, PDFs, Excel sheets, and paper certificates. At each handoff, data can be lost, misinterpreted, or even intentionally altered. This fragmentation creates massive blind spots.

The core problems are:

- Data Silos: Each company keeps its own records. There’s no shared, accessible platform.

- Fraud Vulnerability: Certificates can be forged, and labels can be misapplied. It’s notoriously difficult to verify if a batch of GOTS-certified organic cotton truly contains 100% certified fiber from farm to final product.

- Inefficiency: Tracing a quality defect or verifying a sustainability claim requires days of emails and phone calls across time zones.

For example, in 2023, we assisted a major European sportswear brand in investigating a recycled polyester supply claim. Using traditional methods, it took three weeks to get shaky paperwork from four different sub-suppliers. With a blockchain pilot we later implemented, the same verification took three minutes by scanning a barcode that showed the entire journey, including the plastic bottle source.

What Specific Supply Chain Pain Points Does Blockchain Target?

Blockchain isn’t for tracking everything. It’s uniquely suited for high-value, high-risk verification points:

- Provenance & Origin: Proving where a raw material (e.g., cotton, wool) physically came from. This is critical for sourcing conflict-free materials and validating “local” or “regional” claims.

- Certification & Compliance: Attaching immutable digital certificates (for organic, recycled content, fair labor) to specific material batches. This prevents “certificate swapping.”

- Custody & Transformation Tracking: Logging each transfer of ownership and recording transformations (e.g., bale of cotton -> yarn -> greige fabric -> dyed fabric). This creates an auditable chain of custody.

- Quality & Test Data: Linking permanent quality control and laboratory test reports (for colorfastness, shrinkage, safety) to a production batch, making them instantly accessible to downstream partners.

How Does This Differ from a Centralized Database?

This is the crucial distinction. A traditional database is owned and controlled by one company (like a brand or a factory). They can alter or delete records. A blockchain is decentralized. Once data (a “block”) is verified and added to the “chain,” it is cryptographically sealed and distributed across a network of computers. No single entity—not the brand, not the factory, not even the blockchain platform provider—can go back and change it. This creates inherent trust among parties who may not fully trust each other.

How Does Blockchain Actually Work in a Textile Supply Chain?

Let’s walk through a simplified, real-world example for a batch of organic cotton jersey fabric:

- Step 1: Onboarding & Digitization: The organic cotton farm is onboarded onto the blockchain platform. When they harvest a bale, they create a digital “token” or “asset” on the blockchain. This token’s first entry includes data like: Farm ID, location (GPS coordinates), harvest date, batch number, and a digital copy of their organic certification. This is Block 1.

- Step 2: First Transfer: The farm sells the bale to a spinner. The transaction is recorded on the blockchain: “Bale #123 transferred from Farm A to Spinner B on [Date].” The spinner receives the physical bale and scans a code to accept the digital token, confirming receipt. This is Block 2.

- Step 3: Transformation: The spinner processes the cotton into yarn. They update the token: “Bale #123 transformed into Yarn Lot #456.” They attach their processing details and any new test reports. Block 3.

- Step 4: Continued Journey: This process repeats at the knitter (“Yarn #456 knitted into Greige Fabric Lot #789”), the dyer (“Lot #789 dyed Navy Blue, QC Report Attached”), and finally the garment factory. At Shanghai Fumao, when we ship the finished fabric, we add the final block with shipping details, our final inspection report, and the digital bill of lading link.

The final garment’s QR code allows anyone to trace this entire, unbroken journey back to the original farm record in Block 1.

What Are the Technical Requirements for Participants?

Adoption requires some tech lift, but it’s becoming easier.

- Digital Identity: Each participant (farm, factory) needs a verified digital identity on the network.

- Data Input Points: This can be as simple as a smartphone app for a farmer to scan a barcode and log a transaction, or an API integration with a factory’s ERP system for automated data posting.

- Consensus Mechanism: The network must have rules for validating transactions. In permissioned blockchains common in supply chains, known entities validate each other’s entries, making the process faster and more energy-efficient than public chains like Bitcoin.

Can Data Be Faked at the Point of Entry?

This is the “garbage in, garbage out” challenge. Blockchain guarantees the data after entry cannot be changed, but it cannot guarantee the initial physical data is truthful. If a farmer lies about using pesticides, that lie is immutably recorded. Therefore, blockchain must be combined with physical verification and robust auditing. The technology’s power is that once an auditor verifies and logs a farm’s practices, that verification becomes a permanent, trusted part of that farm’s digital identity for all future transactions.

What Are the Tangible Benefits for Brands and Sourcers?

For professionals like you managing risk and brand value, blockchain delivers concrete ROI beyond marketing buzz.

1. Risk Mitigation & Compliance: It provides audit-proof evidence for regulations like the EU’s upcoming Corporate Sustainability Due Diligence Directive (CSDDD) and the U.S. Uyghur Forced Labor Prevention Act (UFLPA). You can demonstrate with data that your supply chain excludes high-risk regions or labor practices. This is invaluable for navigating forced labor compliance in apparel imports.

2. Supply Chain Efficiency & Cost Reduction: A shared source of truth eliminates reconciliation disputes between partners. A 2022 pilot we ran with a UK retailer cut the time spent on resolving invoice disputes related to shipment delays and quality claims by over 65%, because all parties were looking at the same, immutable timeline of events.

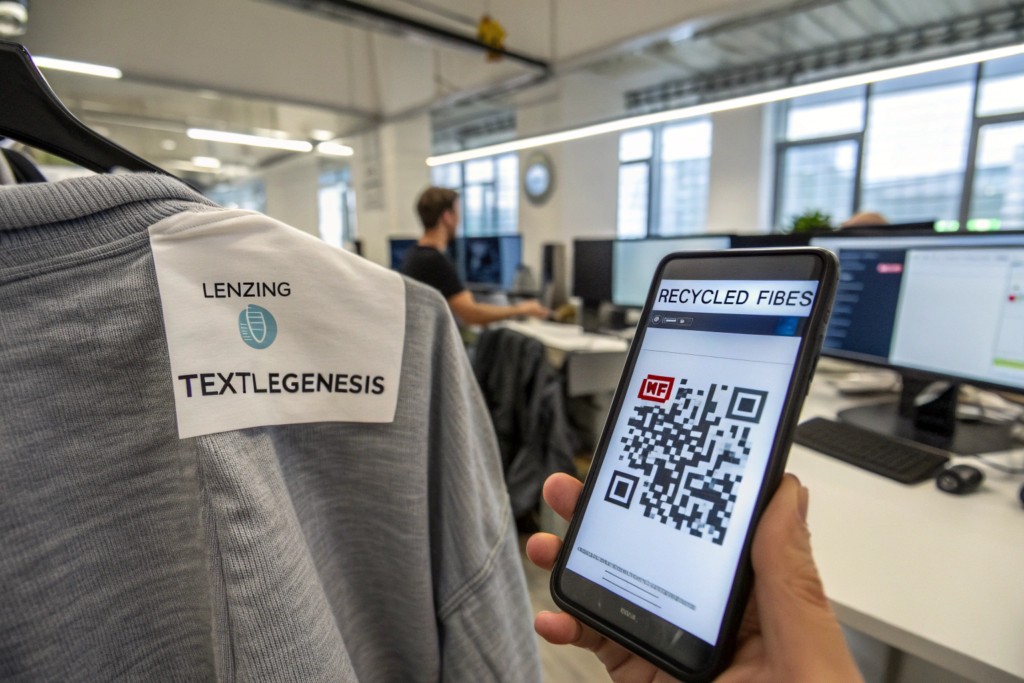

3. Enhanced Brand Equity & Consumer Trust: You can offer true transparency. A consumer scanning a garment’s QR code doesn’t just see a marketing story; they see the verified journey. This transforms sustainability from a vague claim into a compelling, trusted narrative. Platforms like The TextileGenesis™ platform (now part of WFX) are pioneering this for fibers like Lenzing™ and recycled materials.

4. Faster Problem-Solving: If a quality defect is found in a final garment (e.g., inconsistent dye), you can instantly trace it back through the blockchain to the exact dye lot and even the specific machinery used, enabling targeted recalls and process fixes.

What Are the Current Limitations and Challenges?

The technology is promising but not yet plug-and-play.

- Adoption Hurdle: The entire chain must participate to be fully effective. Getting small-scale farmers or low-tech factories onboard is a challenge.

- Cost and Complexity: Initial setup, integration, and training require investment. The ROI is long-term and strategic, not immediate.

- Data Standardization: The industry lacks universal data standards. What one company logs as “organic” and another logs as “sustainable” may differ. Initiatives like The Interoperable Ledger Project by the Blockchain in Transport Alliance (BiTA) are working on such standards.

- Privacy Concerns: Companies are wary of sharing sensitive cost and capacity data on a shared ledger. Permissioned blockchains can control data visibility (e.g., a factory’s internal costs are hidden, but its certification status is public).

Is Blockchain the Future, and How Do I Get Started?

Blockchain is a foundational technology for the future of transparent supply chains, but it will be one tool among many, integrated with IoT sensors, AI, and traditional ERP systems. It won’t replace relationships, but it will make them more accountable.

A Practical Starter Guide for Sourcers:

- Start with a Pilot: Don’t try to map your entire supply chain. Choose one high-value, high-risk product line (e.g., your core organic cotton T-shirt or recycled ocean plastic jacket).

- Choose the Right Partners: Work with a fiber producer or fabric mill that is already investing in traceability. Major fiber companies like COTTON USA, Lenzing (Tencel™), and Unifi (Repreve®) have active blockchain traceability programs. Partnering with a forward-thinking manufacturer like Shanghai Fumao gives you access to these pre-vetted digital supply chains.

- Define Clear Objectives: Are you aiming for marketing storytelling, regulatory compliance, or quality control? Your goal will shape the data you choose to track.

- Educate Your Team and Supply Chain: This is a change management project. Explain the “why” and provide support to your suppliers.

- Verify, Then Trust: Use the blockchain data to inform, but not replace, your physical auditing and quality control processes. Let them work in tandem.

What Are the Alternatives or Complementary Technologies?

Blockchain isn’t the only path. Digital Product Passports (DPPs), as mandated by the EU Strategy for Sustainable and Circular Textiles, will require a QR code linking to key product information. Blockchain is a strong backend candidate to secure DPP data. Other tools include:

- DNA and Molecular Tagging: Applying undetectable biological or chemical markers to fibers at the source for forensic-level verification.

- IoT & RFID: Using physical tags and sensors to track location and condition (temperature, humidity) in real-time throughout logistics.

The most robust system will likely combine several of these technologies.

Conclusion

The role of blockchain in fabric supply chain transparency is not to be a silver bullet, but to be the ultimate truth-telling engine. It replaces fragile promises with cryptographically secured facts. For brands, it turns supply chain management from a defensive liability into a proactive brand asset and a powerful risk mitigation tool. For conscious consumers, it provides the clarity they increasingly demand.

The journey toward full transparency is complex and requires collaboration across the entire industry. However, the direction is irreversible. The brands and suppliers who start experimenting, building partnerships, and integrating this technology today will be the ones who define the ethical and efficient supply chains of tomorrow. They will be the ones whose claims are unshakeable because they are written in code, not just on paper.

If you are ready to move beyond opaque supply chains and build verifiable transparency into your products, the conversation starts with choosing the right foundational partners. At Shanghai Fumao, we are actively integrating blockchain and digital passport technologies into our operations for key sustainable product lines. We can guide you through pilot programs, connect you with certified traceable fiber sources, and provide the physical quality assurance to match the digital promise. To explore how to make transparency a core part of your next fabric sourcing project, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let’s build a supply chain you can prove, not just promote.