You've found the perfect fabric sample—the hand feel is right, the color sings. The excitement is real. But then reality hits: how long until this small swatch transforms into 5,000 meters of fabric ready for your cutting table? If you're planning a production calendar based on generic "4-6 week" estimates you find online, you're setting yourself up for missed deadlines and frantic phone calls. The truth is, the journey from sample to bulk is a complex relay race with multiple hand-offs, and hidden bottlenecks can lurk at every stage.

So, what is the real timeline from fabric sample to bulk delivery? The honest answer is: It depends. A simple reorder of a stock fabric can take 3-4 weeks. Developing a new custom fabric—especially a technical or printed one—can easily take 10-14 weeks or more. The timeline isn't a single number; it's the sum of several distinct, often overlapping phases: Development & Sampling, Pre-Production Approval, Bulk Production, and Final QC & Logistics. Understanding each phase's variables is the key to accurate planning and avoiding costly delays.

The gap between expectation and reality often comes from underestimating the "invisible" work: lab dip revisions, waiting for specialty yarns, or mandatory fabric relaxation time after dyeing. A reliable supplier doesn't just give you a hopeful estimate; they provide a transparent, stage-gated schedule and communicate proactively. Let's break down the real-world timeline, phase by phase.

What Happens During the Development & Sampling Phase?

This is where your vision meets manufacturing reality. It's also the phase with the most variability and where timelines can expand silently. You're not just waiting for a sample; you're funding an iterative process of experimentation and refinement. The complexity of your request—a new fiber blend, a unique finish, a complex print—directly dictates the duration. Rushing this phase is the number one cause of bulk quality failures.

Think of this phase as the architectural blueprint stage for your fabric. Skipping steps or making rushed approvals here is like building a house on a faulty foundation—the problems will show up later, and they'll be much more expensive to fix. A professional supplier will manage this phase with clear milestones and realistic deadlines for each step.

How Long Do Lab Dips and First Samples Really Take?

The clock starts with your official sample request and deposit. For a custom color or new fabric development:

- Yarn Sourcing (1-2 weeks): If you need a special yarn (e.g., GOTS organic cotton, recycled cashmere blend), this can take time. Stock yarn is faster.

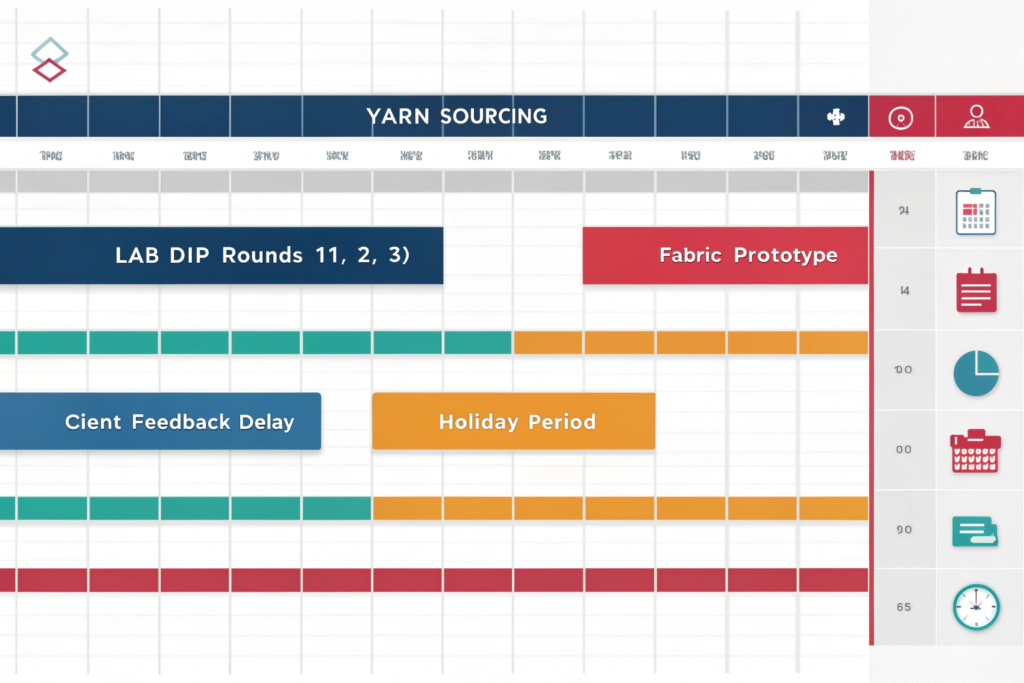

- Lab Dips (2-4 weeks): This is often 2-3 rounds of sending a color sample, getting feedback, and adjusting the dye recipe. Each round takes 5-7 working days. A "pass" on the first round is rare unless you're matching an existing standard perfectly.

- Knitting/Weaving Sample (Prototype) (2-3 weeks): Once the yarn and color are approved, a small sample of the actual fabric structure is made. This tests the weave/knit construction.

Case in point: In Q1 2024, a Dutch sportswear brand requested a custom double-knit with moisture-wicking yarn. Yarn sourcing took 12 days. The first lab dip failed (ΔE 4.5). The corrected second dip was approved on day 18. The first knit sample then revealed a tension issue causing unwanted curl. A revised sample was approved on day 38. The total development time was 5.5 weeks before bulk production could even be scheduled. This is why understanding the variables affecting textile development lead times is crucial for planning.

What are the Hidden Delays in Sampling?

These are the timeline killers that aren't always on the initial quote:

- Feedback Lag: Every day you take to review and comment on a sample adds a full day to the timeline. A 3-day delay on your end for each of 3 sample rounds adds over a week.

- Specialty Material MOQs: Some premium or eco-yarns have high minimum order quantities. Your supplier may need to aggregate orders with other clients, which can add time.

- Holiday Shutdowns: As noted in the opening example, if your sampling overlaps with Chinese New Year, Golden Week, or the National Day holiday, add 2-4 weeks of buffer.

- Third-Party Testing: If you require independent test reports (for Oeko-Tex, UV resistance, etc.) on the approved sample, this can add 1-2 weeks.

A clear lesson came from a US client who demanded a "3-week timeline" for a new jacquard. We explained the yarn lead time alone was 2 weeks. They insisted. The rushed first sample used a substitute yarn with a different luster, which they hated. They ultimately accepted the original 7-week timeline, but only after wasting 3 weeks and a sample fee. This is why partners like Shanghai Fumao provide a detailed, phase-based schedule upfront—it manages expectations and builds trust.

What is the Pre-Production Approval and Lead Time Lock?

Once the development sample is signed off, you enter a critical gateway: pre-production. This is your final checkpoint before the factory commits resources to your bulk order. It's where you confirm that the bulk-making machinery is set up exactly as the sample machine was. Skipping or shortening this step is extremely high-risk.

This phase also includes the often-overlooked "lead time" for securing production slots. In peak seasons (Mar-May, Aug-Oct), factory capacity is booked weeks in advance. Your order isn't just waiting in a queue; it's waiting for a specific machine or production line to become available. Locking in this slot is a formal commitment, usually involving a deposit.

What is a Bulk Approval Sample and Why is it Crucial?

Before mass production, a professional supplier will produce a Pre-Production Sample (PP Sample) or Bulk Approval Sample. This is made using the exact bulk yarns, on the actual production lines, following the finalized recipe. It's not another prototype; it's a simulation of bulk quality.

- Purpose: To catch any discrepancies between the hand-made development sample and machine-made bulk fabric.

- Timeline: Takes 1-2 weeks to produce after you give the go-ahead.

- What to Check: Weight, width, hand feel, color consistency, and any finishing effects must match the approved prototype.

In 2023, a UK brand skipped the bulk sample for a printed satin to save two weeks. The bulk order arrived with a slightly stiffer hand because the production printer applied more binder. The fabric was technically usable but didn't have the luxurious drape their samples promised, leading to a difficult negotiation over discounts. The cost of skipping pre-production validation in apparel manufacturing is almost always higher than the delay it aims to avoid.

How Do Factory Capacity and Seasonality Affect Lead Time?

The "production lead time" on your quote often starts after pre-production approval and after your production slot arrives. This is a key distinction.

- Off-Peak (Jun-Jul, Nov-Dec): Slots may be readily available. Bulk production could start within 1-2 weeks of approval.

- Peak Season (Mar-May, Aug-Oct): You may be quoted a 30-day production lead time, but the start date might be 3 weeks out due to backlog. Your total wait becomes 7+ weeks.

A savvy European fashion brand we work with plans around this meticulously. They aim to have all pre-production for their Autumn/Winter collection completed by late January. This ensures their bulk orders are first in line when factories ramp up after Chinese New Year, securing the best slots and avoiding the peak-season crunch. They've mastered strategic production planning for seasonal fashion lines.

What is the Breakdown of Bulk Production & Finishing?

The bulk run is often perceived as one monolithic block of time. In reality, it's a sequenced chain of specialized processes, each with its own duration and potential queue. A single delay at the dye house can stall everything after it. For a fabric that requires multiple post-weaving steps (like dyeing, printing, then a water-repellent finish), the timeline adds up quickly.

Understanding this breakdown helps you pinpoint delays and have more informed conversations with your supplier. Instead of asking "Where's my fabric?", you can ask "Has the greige fabric been released from the weaving mill to the dye house?" This demonstrates professionalism and gets you a more precise answer.

What Are the Stages of Bulk Fabric Production?

A typical custom fabric order flows like this:

- Greige Goods Production (Weaving/Knitting): This is creating the "raw" fabric. Duration: 7-15 days, depending on complexity and order quantity.

- Bulk Dyeing or Printing: This often has the longest processing time and is a major bottleneck.

- Dyeing: 7-10 days for processing, plus 3-5 days for mandatory cooling, drying, and stabilization (fabric needs to "rest" to prevent shrinkage).

- Printing (Rotary Screen): 10-14 days for setup, printing, and curing.

- Special Finishing: e.g., brushing, peach-skin, coating, laminating. Adds 5-7 days.

- Final Inspection and Packing: Fabric is run through inspection machines, graded, and rolled/packed. Adds 3-5 days.

For a standard dyed cotton poplin, the bulk production time might be 25-30 days. For a printed, coated performance fabric, it could be 40+ days. A client's order for a flame-retardant coated polyester for workwear took 42 days in bulk production alone because the coating factory had a queue, and each layer required curing and testing time.

How Does Order Quantity Impact the Timeline?

The relationship isn't always linear.

- Smaller Quantities (< 1,000 meters): May get done faster as they can be slotted into gaps, but per-unit costs are higher. Setup time (for dye baths, print screens) is a larger proportion of the total time.

- Large Quantities (10,000+ meters): Production runs longer, but setup time is amortized. However, larger lots increase the risk of quality variance across the batch, which can lengthen inspection time if issues are found.

The most efficient window is often the medium-sized order that fits neatly into a standard production batch at each sub-factory (weaving, dyeing). Our production planners are experts at optimizing fabric order quantities for cost and speed by understanding these batch economics at our partner mills.

How to Account for QC, Shipping, and Customs?

Your fabric isn't "done" when it rolls off the inspection machine. The final leg—ensuring it meets spec, getting it packed correctly, and moving it across the world to your door—is fraught with its own timing variables. This is where logistical expertise becomes as important as manufacturing skill. Underestimating this phase is why "the fabric is finished" doesn't mean "the fabric is in my warehouse."

A professional supplier manages this as a service, not just an afterthought. They should handle documentation, book cost-effective and reliable freight, and navigate customs procedures to prevent your shipment from being held at port. This capability is a key differentiator for companies like ours based in major hubs like Keqiao.

What Does Final QC and Shipping Prep Involve?

- 100% Inspection & Grading: Every meter is inspected on a backlit machine for defects, which are marked. The fabric is graded (e.g., "First Quality," "Second Quality"). This takes 1 day per 1,000-2,000 meters.

- Packing: How it's packed affects shipping cost and risk. Rolling on tubes vs. folding flat, vacuum-packing for down-proof fabrics—each has a time and cost implication. Allow 2-3 days.

- Documentation & Booking: Preparing commercial invoices, packing lists, certificates of origin, and booking sea/air freight space. This can take 3-5 business days, especially if you require specific test reports to be attached.

In a recent case, a client needed their wool fabric to be steam-pressed and folded on paper boards for premium retail presentation. This special packing request added two days but was essential for their brand image. Communicating such requirements early is key.

How Long is Realistic for Ocean and Air Freight?

This is often the most miscalculated part of the timeline.

- Ocean Freight (LCL - Less than Container Load): The most common for fabric orders. From East China port (e.g., Ningbo, Shanghai) to US West Coast:

- Port-to-Port: 18-25 days.

- Door-to-Door: Add 7-10 days for inland trucking on both ends, customs clearance, and deconsolidation. Total: 25-35 days.

- Ocean Freight (FCL - Full Container): Slightly faster transit, but you need enough volume (e.g., 15+ tons).

- Air Freight: 5-7 days door-to-door, but costs 4-6 times more.

Crucial: These are transit times after the vessel or plane departs. You must also account for cut-off times (2-5 days before departure to get goods to the port/airport) and potential port congestion. A reliable partner uses consolidated shipping services for textile imports to optimize cost and reliability for smaller shipments.

For an Australian client last November, we recommended air freight for a critical 800kg shipment of printed fabric to meet their Black Friday production. The extra cost was justified against the risk of losing the sales season. The fabric arrived in Sydney 6 days after leaving our warehouse. Planning for logistics must be part of the initial timeline discussion.

Conclusion

The real timeline from sample to bulk delivery is a mosaic of interconnected processes, each with its own pace and dependencies. It is rarely shorter than 8 weeks for a custom item and can reasonably extend to 14-16 weeks for complex developments, especially when factoring in shipping. The key to navigating this timeline is not to seek a mythical "fastest" supplier, but to partner with a transparent and experienced one who provides a detailed, phase-by-phase schedule, communicates proactively about bottlenecks, and has the integrated supply chain control to execute it reliably.

By understanding the depth of the development phase, the importance of pre-production validation, the sequence of bulk manufacturing, and the realities of global logistics, you can plan collections with confidence, build realistic cash flow projections, and manage your own customers' expectations.

If you are looking for a partner who provides clarity, manages complexity, and delivers on a committed timeline, we are built for this challenge. At Shanghai Fumao, our integrated control from yarn to shipment allows us to provide accurate tracking and proactive updates. Let's build a realistic and achievable timeline for your next fabric order. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to start a partnership grounded in transparency and reliable execution.