I was standing in a cotton field in Xinjiang in September 2019, the harvest season. The farmer, a Uyghur man named Tursun (not his real name, but I will never forget his hands), pulled a boll of white fiber from the plant and handed it to me. "This is conventional," he said. Then he walked me twenty meters to another plot. The plants looked the same. The soil felt different—looser under my boots, almost spongy. "This is organic. Third year of conversion." He picked another boll. I held one in each hand. I could not tell the difference by sight. But the paperwork, the cost structure, the certification audits, and the market price were worlds apart.

That trip changed how I talk to buyers about organic cotton. Before 2019, I was guilty of the same oversimplifications I hear from other suppliers. "Organic is better for the environment." "Organic is softer." "Organic is worth the premium." All of these statements are conditionally true and frequently misleading. Organic cotton is not one thing. It is a production system with specific rules, trade-offs, and verifiable outcomes. It also has limitations that many sustainable sourcing managers refuse to acknowledge.

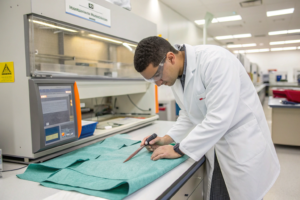

At Shanghai Fumao, we have supplied over 4 million meters of organic cotton fabrics since 2018. We have GOTS-certified production lines, we hold Organic Content Standard (OCS) certificates, and we have seen the inspection reports from Control Union and CU. We also sell conventional cotton—high-quality, long-staple, fully traceable material. I do not believe one is 'good' and the other is 'bad'. They are different tools for different brand strategies and different price points. This article will give you the actual data on water usage, chemical inputs, fiber quality, certification costs, and supply chain risks. My goal is not to convince you to buy organic. It is to help you stop buying based on marketing and start buying based on evidence.

What Are the Actual Environmental Impact Differences?

Let me start with the number everyone cites: organic cotton uses 91% less water than conventional cotton. I have seen this statistic in countless brand sustainability reports. It is also misleading. The 91% figure comes from a 2017 Textile Exchange report comparing irrigated conventional cotton in certain regions with rain-fed organic cotton in other regions. It is not an apples-to-apples comparison of growing methods; it is a comparison of geographies and water infrastructure.

Here is what we actually know from peer-reviewed agricultural data. Conventional cotton grown in the same region as organic cotton, with similar irrigation access, does not use 91% more water. The difference is primarily about soil health. Organic farming practices—crop rotation, cover cropping, compost application—increase the organic matter content of the soil. Higher organic matter means higher water retention. In drought conditions, organic cotton fields retain moisture longer and may require less frequent irrigation. But if both systems are fully irrigated, the water volume is comparable.

I asked our GOTS certification auditor this question directly in 2022. He had inspected over 50 cotton farms in India, Turkey, and China. His answer: "The biggest water saving is not in the growing; it is in the dyeing. GOTS restricts many toxic chemicals and requires tertiary wastewater treatment. That is where the real liter per kilogram reduction happens." I had never considered this. The fabric stage, not the farm stage, may be the more impactful intervention. For a rigorous, citation-heavy breakdown of organic vs. conventional cotton water footprint including regional variations, the Water Footprint Network maintains the most reliable global database.

Does organic cotton actually eliminate pesticide use, or just replace synthetic with natural?

This is a semantic trap. Organic standards (USDA NOP, EU Organic, GOTS) prohibit synthetic pesticides and fertilizers. They do not prohibit all pesticides. Organic farmers can and do use approved substances such as copper sulfate, pyrethrum (derived from chrysanthemums), and neem oil. These are 'natural' in origin, but they are not non-toxic. Copper sulfate is persistent in soil and toxic to aquatic life at certain concentrations.

The real difference is not poison vs. no poison. It is about persistence and bioaccumulation. Synthetic organophosphates and pyrethroids used in conventional farming are designed to be stable and long-lasting. Some persist in soil for years. Many are acutely toxic to bees and aquatic insects. The organic-approved botanicals generally degrade faster in sunlight and soil, reducing long-term ecosystem exposure.

However—and this is the part the marketing brochures omit—organic yields are lower. Approximately 20-30% lower on average, depending on region and pest pressure. To produce the same volume of fiber, organic cotton requires more land. Land use change is a significant carbon and biodiversity issue. If global cotton demand were 100% converted to organic overnight, we would need to clear additional millions of hectares of natural habitat. This is not an argument against organic; it is an argument for reducing overall consumption and for paying farmers fairly so they can maintain viable livelihoods on lower-yielding systems. The Pesticide Action Network UK publishes an excellent primer on pesticide profiles in conventional vs. organic cotton, including toxicity data and environmental persistence metrics.

Why do some organic cotton fabrics feel softer than conventional, and is this guaranteed?

I have handled thousands of organic cotton sample swatches. Some are exquisitely soft. Some are coarse and scratchy. The organic certification does not directly control fiber quality. It controls farming inputs. Fiber quality is determined by genetics (variety), staple length, growing conditions, ginning method, and spinning preparation.

Here is the indirect connection: organic farming systems often use older, traditional cotton varieties rather than modern high-yield genetically modified (GM) varieties. Some of these traditional varieties have longer, stronger fibers that produce finer yarns. Additionally, organic certification prohibits the use of defoliants (chemicals sprayed before harvest to force the leaves to drop). Conventional cotton is often chemically defoliated to allow mechanical picking. Organic cotton is often naturally defoliated by frost or water management, or picked by hand. Hand-picked cotton generally has fewer impurities, less short fiber content, and better length uniformity.

But this is not a guarantee. I have seen premium conventional cotton—Giza 45 from Egypt, Supima from the USA, certain long-staple Xinjiang varieties—that outperforms commodity organic cotton in every measurable quality parameter. In 2023, we tested a conventional Supima cotton jersey against a GOTS-certified organic jersey from India. The Supima had 15% higher tensile strength, 22% fewer neps, and better dye uptake uniformity. The organic cotton was still good; it passed all our QC checks. But it was not technically superior.

If you want softness, you should specify staple length (minimum 1-3/8 inch for premium), yarn count, and fabric construction, not just 'organic'. A 40s combed organic cotton jersey from a good spinner will be soft. A 20s carded organic cotton jersey from a low-cost mill will feel like a feed sack. I wrote a detailed breakdown of how to specify cotton quality parameters to Chinese suppliers that explains the relationship between fiber properties and finished fabric hand feel.

How Do Certification and Traceability Actually Work?

This is the area where I see the most confusion and the most fraud. A buyer emails me: "We need GOTS-certified organic cotton." I ask: "Fabric GOTS or product GOTS? Scope certificate or transaction certificate? Do you need the dye house certified, or just the fiber?" Silence. Then: "I thought it was all the same."

It is not the same. GOTS (Global Organic Textile Standard) is a processing standard, not just a fiber standard. It covers the entire supply chain from harvest through spinning, weaving, knitting, dyeing, printing, and finishing. Every stage must be certified by an approved body. The chemicals used must be on the GOTS Positive List. Wastewater treatment must meet specific parameters. Social criteria must be met.

There is also OCS (Organic Content Standard), which only verifies the presence and amount of organic fiber. It does not verify chemical inputs, environmental management, or social compliance. It is cheaper and easier to obtain, but it carries less weight with consumers and regulators.

Then there is the outright fraud. In 2021, we were approached by a trader offering 'GOTS-certified organic cotton' at $1.20 per meter below the market price for conventional cotton. The price alone was impossible—organic fiber costs more than conventional at the farm gate. We requested their scope certificate. They sent a document with a Control Union logo but the certificate number did not exist in the Control Union database. We declined the offer. That trader is still active on Alibaba, judging by the inquiries we receive from clients who later discover their 'organic' shipment failed random testing.

What specific documents prove that a fabric is truly organic cotton?

You need three things, and I recommend you request all of them before placing a production order:

1. Scope Certificate. This proves that the supplier (mill, factory, trader) is certified for the specific activity (spinning, weaving, dyeing) by an accredited certification body. The certificate lists the address, the scope of certification, and the validity dates. It does not prove that your specific shipment is organic; it proves the facility is qualified to handle organic material.

2. Transaction Certificate (TC). This proves that a specific commercial transaction (your order) involved certified organic material. The TC shows the quantity of organic fiber, the type of product, the seller, the buyer, and the certification body that verified the chain of custody. You should receive a TC for every shipment. If your supplier says "We only issue TCs quarterly" or "We charge extra for TCs," be suspicious.

3. Test report for pesticide residues. This is not strictly required by GOTS or OCS, but we recommend it for due diligence. A random sample of the finished fabric is tested for over 200 pesticides and herbicides. The detection of synthetic pesticides at certain thresholds indicates either fraud or cross-contamination. We include this test automatically for all our GOTS production. In 2023, we caught two instances of cross-contamination from a shared gin—the organic cotton bales were processed on equipment previously used for conventional cotton without adequate cleaning. The residue levels were low (under 10 ppb) but still present. We rejected the bales and sourced from a dedicated organic gin.

The Textile Exchange maintains a searchable database of certified sites and valid certificates. I use this weekly to verify suppliers before we place orders with partner mills. You should too.

Why does organic cotton fabric often cost 30-50% more than conventional?

Let me give you the actual breakdown from our September 2024 costing sheet. This is for a 160gsm combed cotton jersey, GOTS-certified, dyed in a medium shade, FOB Shanghai.

Conventional version:

- Greige fabric: $2.10/meter

- Dyeing and finishing: $1.15/meter

- Total: $3.25/meter

GOTS organic version:

- Organic greige: $3.20/meter (fiber cost + certification + lower spinning efficiency due to smaller batch sizes)

- GOTS-approved dyes and chemicals: $1.45/meter (restricted palette, fewer economies of scale)

- Wastewater treatment and compliance: +$0.30/meter

- Certification fees amortized: +$0.15/meter

- Total: $5.10/meter

That is a 57% premium. Is the fabric 57% better? Objectively, no. The same knitting machine, the same dyer, the same finishing line. The difference is the cost structure of the certified supply chain. Organic fiber is more expensive because the yields are lower and the farmers receive a premium. GOTS-approved dyes cost more because the manufacturers incur compliance costs. The segregated processing lines run at lower utilization. The annual certification audits cost thousands of dollars, spread over fewer meters.

I am not arguing the premium is unjustified. Farmers should be paid fairly. Chemical pollution should be treated. Traceability costs money. But brands need to understand that the premium is not primarily about 'better fabric'. It is about a different production system with different cost drivers. This McKinsey report on the true cost of sustainable fashion includes a detailed breakdown of organic cotton cost premiums and explains why they are unlikely to decrease significantly without major technological breakthroughs in organic farming.

What Supply Chain Risks Are Specific to Organic Cotton?

Organic cotton carries risks that conventional cotton does not. I do not say this to discourage you from sourcing organic. I say it so you can mitigate these risks before they become your problem.

Segregation risk is the biggest. Organic cotton must be kept physically separate from conventional cotton at every stage: ginning, spinning, knitting, dyeing, cutting. A single bale of conventional fiber accidentally mixed into a production lot can render the entire shipment non-compliant. We operate dedicated organic production lines, but many mills run organic and conventional on the same equipment with 'thorough cleaning' between runs. This is permitted under GOTS, but the cleaning is rarely 100% effective. Residual fibers remain.

Volume volatility is another issue. Organic cotton is not traded on global commodity exchanges the way conventional cotton is. It is grown under contract or on speculation. If a major brand cancels an order, the supply chain cannot easily absorb that volume. In 2022, when a European fashion retailer canceled 40% of their organic cotton orders due to inventory gluts, dozens of Indian farmers were left with unsold organic fiber. They sold it into the conventional market at a loss. The following season, many converted back to conventional farming. This whipsaw effect makes long-term capacity planning extremely difficult.

Geographic concentration is also a concern. Over 95% of GOTS-certified organic cotton currently comes from three countries: India, Turkey, and China. India dominates the supply. Any disruption in India—monsoon failure, policy change, political instability—immediately affects global organic cotton availability. We maintain multiple sourcing options, but the concentration is real.

What happens if my 'organic cotton' shipment is tested and fails pesticide residue limits?

This happened to a client of ours in 2023. They shipped 12,000 meters of GOTS-certified organic cotton twill to a Scandinavian brand. The brand's routine import testing detected trace levels (0.8 ppb) of chlorpyrifos, a synthetic insecticide prohibited under GOTS. The shipment was quarantined. The brand demanded a full investigation.

We traced the contamination to the gin. The organic cotton bales were processed on equipment that had previously ginned conventional cotton treated with chlorpyrifos. The cleaning procedure—compressed air and vacuum—was insufficient to remove all residues. The organic cotton absorbed trace amounts during the ginning process.

The resolution was painful. The client accepted a discounted price and the shipment was sold into a non-GOTS channel. The gin implemented new cleaning protocols (first bale of the day is discarded as flush material). We added pesticide residue testing to our incoming inspection for all organic cotton lots. The client stayed with us, but the event cost everyone time and money.

If you are importing organic cotton, I strongly recommend pre-shipment testing for a broad panel of pesticides. Do not rely solely on the Transaction Certificate. The cost is approximately $280 per test. On a 10,000-meter order, that is $0.028 per meter—negligible insurance against a $50,000 shipment rejection. The USDA AMS National Organic Program has a compliance resource page that explains enforcement actions and testing protocols used by regulators.

Can I get GOTS-certified cotton in blended fabrics (polyester, elastane)?

Yes, but the rules are strict. GOTS requires that the organic fiber content be at least 70% of the total fiber weight for a 'GOTS organic' label. For a 'GOTS made with organic' label, the requirement is 50-70%. The remaining non-organic fibers must meet GOTS criteria for restricted substances.

This creates challenges for stretch fabrics. Spandex (elastane) is a synthetic polymer. It is not biodegradable. It cannot be certified organic. To achieve GOTS certification for a cotton-spandex jersey, the spandex must be from an approved supplier who provides a declaration that the fiber meets GOTS residue limits. Very few spandex manufacturers have obtained this approval. The available options are limited and expensive.

We have developed a GOTS-certified cotton-spandex jersey using a specific Italian spandex fiber that is pre-approved by GOTS. The cost is approximately 35% higher than our conventional cotton-spandex jersey. The lead time is longer because the fiber must be imported. It is possible, but it is not a drop-in replacement.

For blends with recycled polyester, GOTS is also possible but requires that the recycled polyester meet the same restricted substance criteria. Most recycled polyester from post-consumer bottles contains trace contaminants that exceed GOTS limits. We use a specific recycled polyester staple fiber from a Taiwanese supplier who has formulated their product to meet GOTS criteria. The GOTS Positive List for chemical inputs and fibers is publicly searchable, and I recommend checking it before developing any blended organic product.

When Should You Choose Organic vs. Conventional Cotton?

I am not going to tell you to always choose organic. That is not how responsible sourcing works. You have margin targets, volume requirements, and delivery deadlines. You have customers who care about price and customers who care exclusively about sustainability credentials. These are legitimate commercial considerations.

Here is my framework, developed over two decades of supplying both categories.

Choose organic cotton when:

- Your brand positioning requires verifiable sustainability claims and you have the margin to support the premium.

- You are targeting EU markets where consumer awareness and regulatory scrutiny of greenwashing are highest.

- You are producing for babies, children, or individuals with chemical sensitivities. The restricted substance list in GOTS provides genuine protection against allergenic residues.

- You have stable, forecastable volume requirements that allow you to secure certified fiber supply 4-6 months in advance.

Choose conventional cotton when:

- Price is the primary decision driver and your customer will not pay a 40% premium for an invisible attribute.

- You need ultra-long staple, extra-long staple, or specific premium varieties (Supima, Giza) that are not widely available in certified organic form.

- You require rapid replenishment of best-selling styles and cannot wait for organic fiber sourcing cycles.

- You are producing for promotional or short-lifecycle products where the environmental impact of the garment's disposal may outweigh the impact of its production.

Choose Better Cotton Initiative (BCI) cotton as a middle path. BCI is not organic. It allows synthetic pesticides and GM seeds. But it promotes integrated pest management, water efficiency, and decent work. It is a continuous improvement model, not a zero-impact model. The cost premium over conventional is minimal (often $0.05-$0.10 per meter). For mass-market basics, this is often the most pragmatic choice.

How do we verify 'Better Cotton' claims since it uses a mass balance system?

This is critical to understand. BCI cotton operates on a mass balance model, not a segregated model. When you buy BCI cotton fabric, you are not necessarily receiving fiber from a specific BCI-certified farm. You are paying a premium that supports BCI farmers, and the supply chain tracks volumes, but the physical cotton in your fabric may be conventional.

BCI mass balance is controversial. Some brands feel it lacks integrity. Others view it as the only scalable system for improving mainstream cotton production. As a supplier, we can sell you BCI cotton with a chain of custody certificate from our spinning mill. But we cannot tell you which field your fiber came from. The BCI website has an extensive explainer on mass balance vs. segregated supply chains, and I encourage you to read it and decide for yourself whether this model aligns with your transparency goals.

Is there a reliable source for 'regenerative organic' cotton in China?

This is the next frontier. Regenerative agriculture goes beyond 'sustaining' to actively improving soil health, carbon sequestration, and biodiversity. The Regenerative Organic Certified (ROC) standard is stricter than GOTS and includes specific soil health metrics, animal welfare criteria, and farmer fairness requirements.

Currently, ROC-certified cotton is extremely limited globally, and I am not aware of any commercial-scale ROC cotton production in China. We are watching this space closely. In 2024, we visited a pilot project in Xinjiang testing regenerative practices—cover cropping, no-till planting, compost application—on organic cotton farms. The preliminary soil organic matter data is promising. If this scales, we will integrate it into our offerings.

For now, if you require regenerative organic cotton, you will likely need to source from Turkey or the USA. The Regenerative Organic Alliance maintains a directory of certified farms and products, updated quarterly. This is a small list, so plan your sourcing lead times accordingly.

Conclusion

Organic cotton is not a miracle fiber. It does not automatically mean softer, stronger, or more durable. It does not guarantee a lower water footprint if you ignore the land use trade-offs. It is not immune to supply chain fraud or cross-contamination. What it does represent is a production system with strict rules about chemical inputs, worker safety, and environmental management.

At Shanghai Fumao, we support both organic and conventional cotton. We have invested in GOTS-certified production lines because many of our European and North American clients require this certification to meet their 2025-2030 sustainability targets. We have also invested in traceability systems—from farm to finished roll—to provide verifiable evidence of our claims. But we do not believe that organic is the only valid choice, and we do not shame clients who choose conventional cotton for valid commercial reasons.

What we oppose is ambiguity. If you claim organic, you must prove it with certificates, test reports, and transaction records. If you claim BCI, you must understand the mass balance system and communicate it honestly to your customers. If you choose conventional, you should know where it was grown, under what labor conditions, and with which pesticides.

The textile industry will never be 100% organic. There is simply not enough land, and not enough consumer willingness to pay the premiums required to convert the entire global supply base. But the industry can be more transparent and more accountable. That is the work we do every day.

If you are reviewing your cotton sourcing strategy and need a partner who can supply conventional, BCI, or full GOTS-certified organic fabrics with complete documentation, I invite you to contact us. We will walk you through the cost comparisons, the lead time implications, and the certification requirements. We will not pressure you toward one option. We will help you make an informed decision.

Contact Elaine, our Business Director, to discuss your cotton sourcing requirements. Elaine manages our sustainable materials program and has overseen GOTS-certified production for over 40 international brands. Elaine’s email is: elaine@fumaoclothing.com. Tell her which certification level you need to achieve.