You know that feeling when you touch a crisp cotton poplin shirt, the sturdy diagonal lines of your denim jeans, or the slippery smoothness of a satin evening gown? As a fabric supplier for over 20 years in Keqiao, I talk to buyers daily who love these textures but hit a wall when they need to specify how to create them. The secret isn't just in the fiber—it's in the weave. Many designers and brands struggle to translate their vision into technical specs because the world of fabric construction seems complex and opaque.

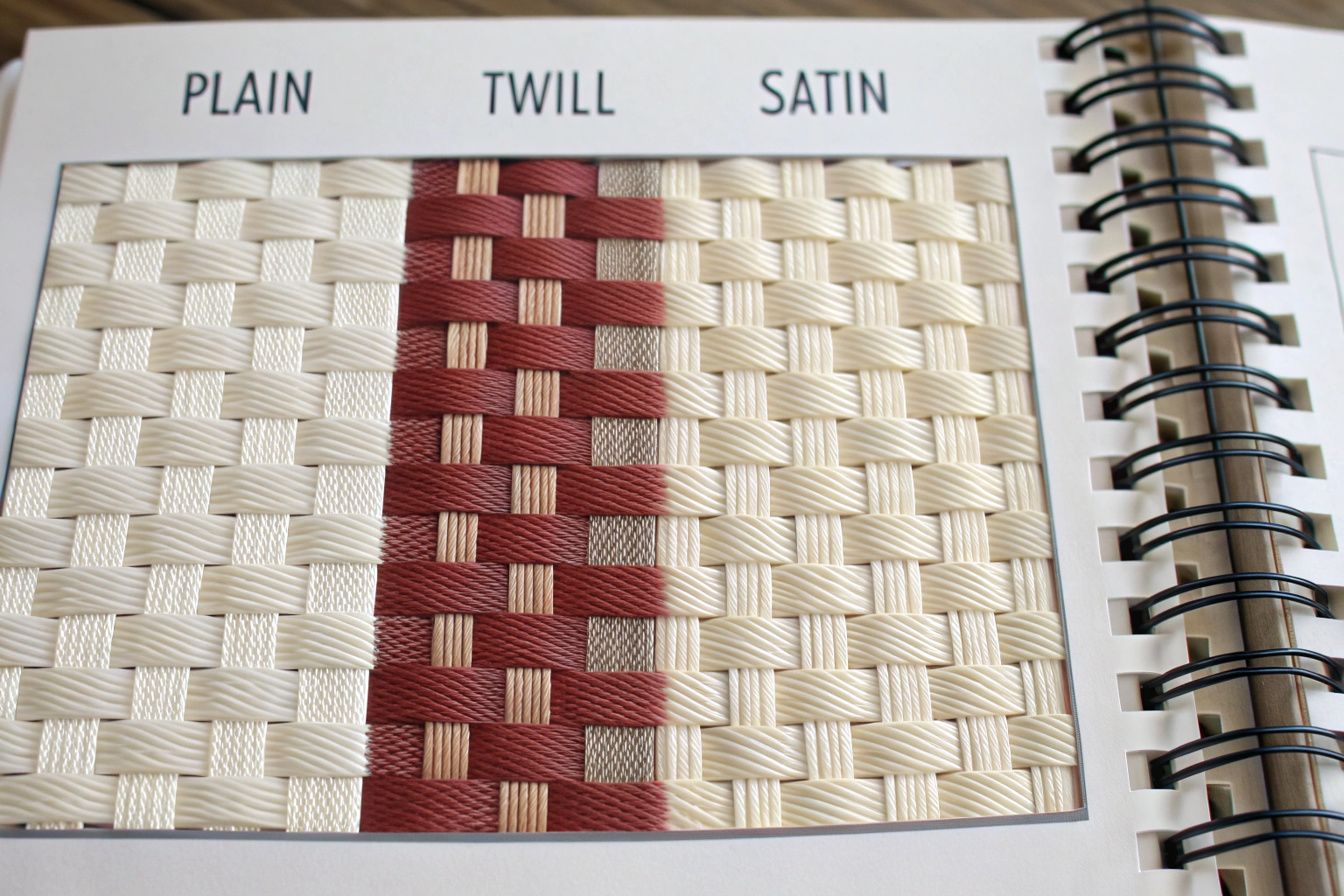

The process of weaving transforms yarn into fabric by interlacing lengthwise (warp) and crosswise (weft) threads. The three fundamental weaves—plain, twill, and satin—are the blueprint for nearly all woven textiles. Their unique interlacing patterns directly determine the fabric's appearance, durability, texture, and end-use. Mastering these basics is the first step to sourcing or developing fabrics with confidence, not guesswork.

Think of it like this: the fiber (cotton, silk, polyester) is the ingredient, but the weave is the recipe. You can have the same fine cotton yarn, but a plain weave gives you a breezy voile, a twill weave gives you a robust chino, and a satin weave gives you a lustrous sateen. Let's pull back the curtain on the loom and demystify how these three essential weaves are created and why they matter for your product.

How is Plain Weave Fabric Created and Where is it Used?

If fabrics had a default setting, it would be plain weave. It's the simplest, most common, and often the most cost-effective to produce. But "simple" doesn't mean "basic" in terms of application. From the delicate chiffon of a summer dress to the rugged canvas of a workwear jacket, plain weave is the chameleon of the textile world.

The rule is straightforward: each weft yarn passes over one warp yarn and under the next, alternating row by row. This 1:1 interlacing, like a perfect checkerboard, creates a fabric that is inherently strong, firm, and has a relatively flat surface. Because of the high number of interlacings, it's less prone to yarn slippage and is very stable. However, this tight construction can also mean it's less pliable and has a lower tear strength compared to other weaves. A key tip for sourcing: plain weave fabrics often have the same appearance on both sides.

What are the Most Common Types of Plain Weave Fabrics?

The plain weave family is vast. By simply changing the yarn thickness, density, or using fancy yarns, you get completely different fabrics. Here are some industry staples you definitely know:

- Poplin & Broadcloth: Made with fine yarns at a high density, resulting in a smooth, crisp, and slightly ribbed feel. The go-to for business shirts.

- Chiffon & Georgette: Ultra-fine yarns in a loose, sheer construction. Chiffon is smoother, while georgette has a crepe twist for a grainy texture.

- Taffeta: Uses filament yarns for a stiff, smooth handle and that characteristic rustling sound.

- Canvas & Duck: Employs thick, sturdy yarns for maximum durability. Perfect for bags and workwear.

In 2022, a Swedish outdoor brand approached us with a problem: their standard plain weave canvas for utility pouches was too stiff. We worked with our weaving factory to develop a balanced plain weave using a blend of organic cotton and recycled polyester, reducing the fabric weight by 15% while maintaining the required tensile strength.

Why is Plain Weave a Top Choice for Printing and Dyeing?

The flat, uniform surface of a plain weave makes it an ideal substrate for printing and dyeing. There are no prominent diagonal lines or long floats to distort the print pattern or cause uneven dye absorption. This is why most digital printing base fabrics are plain weaves.

For anyone looking into how to prepare fabric for digital printing in bulk, starting with a high-quality, consistently woven plain fabric is non-negotiable. Any weaving defects become glaringly obvious after printing. Our quality control includes a mandatory light-box inspection for every roll destined for print production to ensure that uniformity. The stability of the weave also means the fabric is less likely to shrink or distort dramatically during the printing and finishing processes.

What Defines the Diagonal Rib of a Twill Weave?

That iconic diagonal line on your jeans? That's the signature of a twill weave. It’s not just for looks; it's a functional masterpiece of textile engineering. The twill weave is created by a stepwise interlacing pattern where the weft yarn passes over (or under) two or more warp yarns, shifting one step to the right or left with each subsequent row. This offset creates the visible diagonal rib, or "wale."

This structure has major advantages. Because the interlacing points are fewer and the yarn floats are longer than in plain weave, twill fabrics are typically softer, more pliable, and denser. They have better resistance to tearing and hiding soil. However, twill fabrics are often "right" or "wrong" sided, with the diagonal more pronounced on one side.

How Do 2/1, 3/1, and Broken Twills Differ in Application?

The twill "formula" (like 2/1 or 3/1) tells you the warp/weft float sequence and directly impacts the fabric's hand and weight.

- 2/1 Twill: The weft goes under one warp, then over two. This creates a balanced, prominent diagonal. It's the classic structure for chino and gabardine.

- 3/1 Twill: The weft goes under one warp, then over three. This creates a more pronounced diagonal. It's used for sturdy denim and drill.

- Broken Twill (Herringbone): The diagonal direction reverses at regular intervals, creating a zigzag pattern. This helps reduce the fabric's natural torque or twisting tendency.

A practical example: Last year, a US workwear brand needed a fabric for mechanic's shirts. They wanted the durability of denim but with more stretch. We developed a 2/1 stretch twill using a cotton-polyester-spandex blend, achieving a fabric with 4-way stretch and a weight of 250 GSM that maintained the classic twill look and tear strength.

Why is Twill Weave Ideal for Durable Garments and Upholstery?

Twill’s inherent durability makes it king for hard-wearing applications. The dense yarn packing and diagonal structure distribute stress more evenly across multiple yarns, making it highly resistant to abrasion and tearing. In upholstery, a tightly woven twill can withstand constant friction far better than a plain weave of similar weight.

Furthermore, the diagonal line has a practical benefit: it helps hide dirt and wrinkles. Soil particles tend to settle in the tiny valleys of the rib, making stains less immediately visible. This "forgiving" nature is precisely why twill is used for uniforms and casual trousers. For brands developing performance apparel, understanding the comparative guide to twill vs plain weave for sportswear can be crucial.

What Gives Satin Weave Its Signature Lustre and Smoothness?

Satin weave is the magician of the fabric world—it creates dazzling brilliance and a sensuously smooth hand from the most ordinary fibers. The magic trick is in the structure: long, uninterrupted yarn "floats." In a satin weave, a weft yarn passes over four or more warp yarns and under only one before repeating the pattern in a non-adjacent, dispersed sequence. This minimizes the number of interlacing points on the fabric surface.

These long floats are what reflect light uniformly, creating that characteristic high-gloss shine. They also lie flat, creating an incredibly smooth surface. However, this beauty comes with trade-offs: the long floats are more susceptible to snagging, and the fabric can be less stable.

What is the Difference Between Satin, Sateen, and Duchess Satin?

This is a common point of confusion. The difference lies in the fiber used and the specific weave setup.

- Satin: Traditionally, this term refers to the weave structure made from filament yarns, like silk or polyester. The filament's continuous surface maximizes light reflection.

- Sateen: This is a satin weave made from staple fibers, most commonly cotton. The staple fibers scatter light slightly, giving sateen a softer, more subdued lustre. It's famous for bed sheets.

- Duchess Satin: This is a specific, heavyweight type of satin. It's woven very tightly with a high thread count and often has a slight stiffness, making it perfect for structured gowns and bridal wear.

In our work with Shanghai Fumao, we recently helped a UK-based lingerie brand solve a pilling issue on their sateen shorts. We switched to a long-staple, combed Egyptian cotton with a higher twist and tightened the weave density. This change eliminated the pilling and enhanced the fabric's durability by over 40%.

How are Satin Weaves Finished for Different Effects?

The journey from loom to final fabric is critical for satins. The finishing process can dramatically alter its character:

- Calendering: The fabric passes through hot, heavy rollers. This flattens the floats further, increasing the shine to a high-gloss finish.

- Mercerization (for cotton sateen): Treating the yarn or fabric with sodium hydroxide under tension. This increases its strength and adds a permanent, silky lustre.

- Embossing: Using engraved rollers to press a pattern into the fabric, creating a textured, matte/shiny contrast.

For designers, it's crucial to specify not just "satin" but the desired finish. A calendered polyester satin is perfect for a flashy costume, while a mercerized cotton sateen is ideal for high-end bedding. Resources like the CottonWorks™ fabric library provide excellent references for these different finishes.

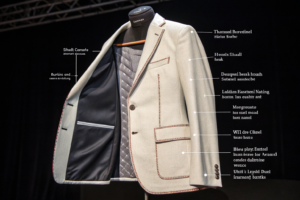

How Do You Choose the Right Weave for Your Product?

Now that you understand the core three, how do you make the right choice? It’s a balancing act between aesthetics, performance, and cost. There's no single "best" weave—only the best weave for your specific product's needs. Asking the right questions upfront saves countless headaches later.

Start with the end-use. Is it a structured blazer (favoring a tight twill or duchess satin)? Is it a flowy summer dress (favoring a light plain weave)? Is it upholstery that needs abrasion resistance (favoring a heavy twill)? Then, layer in functional needs: does it need stretch or moisture-wicking? Often, these properties are added through fiber choice and finishing, but the weave is the foundational canvas.

What Questions Should You Ask Your Fabric Supplier?

Don't just ask for "a cotton fabric." Engage with your supplier technically. Here are powerful questions to ask:

- "Can you provide the weave structure diagram or technical datasheet?" This confirms the exact construction.

- "What is the thread count and fabric weight (GSM)?" This quantifies density and heaviness.

- "How does this weave affect the fabric's shrinkage and stability?" Plain weaves are generally more stable than satins.

- "What finishing treatments do you recommend for this weave?"

When a Canadian activewear brand approached Shanghai Fumao to develop a quick-drying woven trekking pant fabric, this dialogue was key. They initially wanted a lightweight plain weave. Through discussion, we steered them towards a ripstop plain weave for tear resistance and paired it with a moisture-wicking finish. The result was a durable, functional fabric perfectly suited to their end-use.

How Can You Prototype and Test Different Weaves?

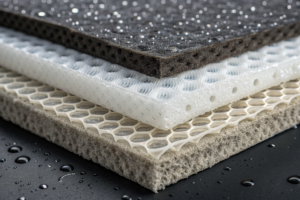

Never commit to a bulk order based on a swatch of a different weave. Always prototype with the exact base fabric. The drape, fit, and performance of a garment in a twill will be fundamentally different from one in a plain weave of the same fiber and weight.

Work with a supplier that offers small-batch sampling. Make a prototype garment and put it through real-world testing: wash it, abrade it, stretch it. Check for issues like seam slippage or twisting. The minor upfront cost of prototyping pales in comparison to the risk of a failed bulk production run. Engaging with community knowledge on platforms like The Weaving Forum for handweavers and professionals can also provide deep, practical insights.

Conclusion

The journey from a spool of yarn to the fabric in your hands is governed by the ancient art of weaving. Plain, twill, and satin are engineered blueprints that define a textile's soul—its strength, texture, drape, and character. Understanding these empowers you to make informed, strategic sourcing decisions.

This knowledge transforms you from a passive buyer into an active product developer. You can now communicate with precision, anticipate performance issues, and innovate with purpose.

Ready to turn this knowledge into a tangible product? At Shanghai Fumao, we collaborate on creating fabrics. With our deep roots in Keqiao's weaving ecosystem, we can guide you from selecting the perfect weave structure to perfecting the finish. Let's build the right fabric from the ground up. For a technical consultation, contact our Business Director, Elaine, at elaine@fumaoclothing.com.