So, you’ve found a fabric or garment labeled “OEKO-TEX Standard 100.” That’s a great start—it means the manufacturer has at least thought about safety. But if you’re sourcing for an adult clothing brand, you might be wondering: is this label enough? The crucial detail most people miss is the Product Class. Seeing “OEKO-TEX” isn’t the finish line; it’s the starting gate. The real question is: what class does it meet, and why does Class II matter most for your everyday apparel?

The OEKO-TEX Standard 100 Grade 2 Certificate, more accurately referred to as Product Class II, is your assurance that textiles and fabrics are safe for prolonged, direct contact with human skin. Unlike Class I for babies or Class III for items with no direct skin contact, Class II is the workhorse standard for the vast majority of clothing—from t-shirts and dresses to underwear and bedding. It’s not just about being “non-toxic”; it’s a quantified, scientific guarantee that over 100 harmful substances are either absent or below strict, scientifically-defined limits, verified by independent institutes.

This distinction is everything. Many suppliers will obtain a Class IV certificate (for decorative fabrics) because it’s cheaper and easier, and then vaguely market the product as “OEKO-TEX certified.” But using a Class IV fabric for a shirt is not just misleading—it’s a risk. At Shanghai Fumao, we see this confusion all the time with new clients. They have a certificate, but it’s for the wrong application. We educate them that for clothing worn against the skin, OEKO-TEX Class II certification is the non-negotiable baseline for quality and safety. It’s the standard that aligns with consumer trust and rigorous due diligence.

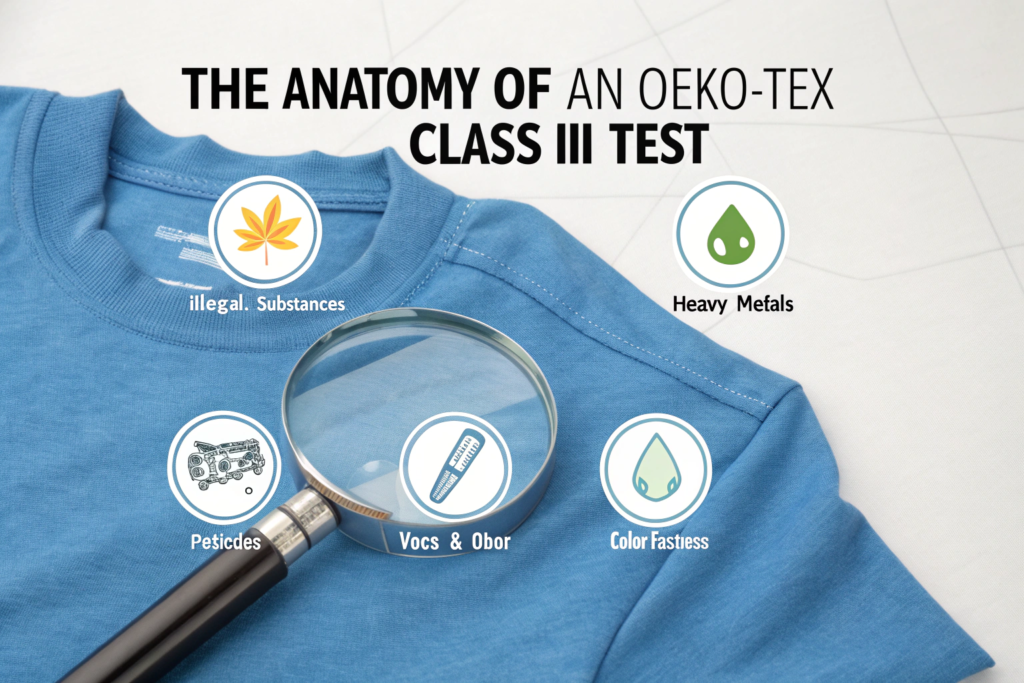

What Exactly Does OEKO-TEX Standard 100 Class II Test For?

Think of OEKO-TEX testing not as a single check, but as a full medical exam for fabric. It screens for harmful substances across multiple, carefully defined categories, with limit values that get progressively stricter from Class IV up to Class I (for babies). Class II sits in the optimal zone for adult skin-contact items: rigorous enough to ensure safety, but practical for a wide range of textiles and dyes.

The testing is exhaustive and based on the latest scientific and regulatory knowledge. The OEKO-TEX association updates its criteria annually. The core tested categories include:

- Illegal and Regulated Substances: Such as carcinogenic dyes or formaldehyde (with strict limits).

- Chemicals Hazardous to Health: Including heavy metals like lead and cadmium, allergenic dye stuffs, and plasticizers (phthalates).

- Pesticides and Chlorinated Phenols: Residues from raw material cultivation and processing.

- Volatile Compounds: That cause unpleasant odors.

- Colorfastness: Ensuring dyes don’t easily transfer to skin.

How Are the Limits for Class II Different from Other Classes?

The “class” system is the heart of OEKO-TEX’s precision. The limits aren’t arbitrary; they are calibrated based on scientific models of exposure. A baby’s skin (Class I) is more sensitive and absorbs substances more easily than adult skin (Class II). A curtain (Class IV) has minimal skin contact, so some limits are less strict.

Let’s take a concrete example: Formaldehyde. This is a common chemical used in some finishes to prevent wrinkling, but it’s a known skin irritant and sensitizer.

- Class I (Babywear): Limit is 16 mg/kg (incredibly strict).

- Class II (Adult Skin Contact): Limit is 75 mg/kg (strict, but achievable for a wide range of fabrics).

- Class IV (Decor): Limit is 300 mg/kg (significantly higher).

This means a fabric passing Class IV could legally contain four times more formaldehyde than a Class II fabric and still be certified. If that Class IV fabric is made into a shirt, it could cause skin irritation for the wearer. That’s why knowing the class is critical. We had a client in 2023 who was experiencing unexpected customer complaints about skin itching from their linen shirts. They provided an OEKO-TEX certificate. We checked—it was a Class IV for “decorative fabric.” The problem was instantly identified. We reproduced the shirt in a similar linen with a true Class II finish, and the complaints stopped. Understanding these differences between OEKO-TEX product classes is fundamental to responsible sourcing.

Why is Testing for Allergenic Disperse Dyes So Important in Class II?

This is a specialist area where Class II certification proves its daily value. Allergenic disperse dyes are a group of synthetic dyes primarily used to color polyester and other synthetic fibers. Some of them are known to cause severe allergic contact dermatitis, especially when trapped against sweaty skin. They are not banned outright, but OEKO-TEX Class II (and I) strictly prohibits their use.

This is a perfect example of OEKO-TEX going beyond basic legal compliance. Many countries’ laws don’t specifically ban these dyes in adult clothing, but the risk to consumers is real. The OEKO-TEX Standard 100 list includes over 20 such banned allergenic dyes. For a sportswear brand using polyester, this part of the test is crucial. We ensure all our performance polyester fabrics are tested and certified free of these specific substances. It’s a key part of how we help brands, especially in the activewear and sportswear sector, mitigate risk and build trust. You can learn more about the science behind this on resources like the Dermatology Times forum on textile allergies, but the OEKO-TEX certificate is your actionable proof of compliance.

Why is Class II Certification a Business Imperative, Not Just a Nice-to-Have?

In today’s market, OEKO-TEX Class II is shifting from a competitive advantage to a baseline expectation. It’s no longer just about “being safe.” It’s about managing brand risk, enabling market access, and meeting consumer demand in a tangible, verifiable way. For a business owner, it’s a strategic tool that protects your reputation and unlocks sales channels.

Firstly, it’s your first line of defense against product recalls and liability claims. If a consumer has a skin reaction, you can point to the independent, internationally recognized Class II certificate as evidence of due diligence. Secondly, major retailers and e-commerce platforms are increasingly requiring such certifications for their marketplaces. It’s becoming a de facto ticket to play. Finally, consumers are educated. They look for the OEKO-TEX label. For a brand, displaying the “Confidence in Textiles” label (the consumer-facing mark for OEKO-TEX) on a hangtag is a powerful, silent salesperson that communicates care and quality.

How Does Class II Certification Mitigate Legal and Retailer Compliance Risks?

The global regulatory landscape is a patchwork. REACH in Europe, Proposition 65 in California, CPSIA for children’s wear in the US—navigating it all is complex. An OEKO-TEX Standard 100 Class II certificate acts as a robust, internationally accepted summary of compliance with many of these regulations’ substance restrictions. While it’s not a 1:1 legal replacement, it is overwhelmingly recognized as proof of responsible manufacturing.

For example, many of the Substances of Very High Concern (SVHCs) under EU REACH are directly covered and limited by the OEKO-TEX standard. When you import into the EU, having Class II certificates for your fabrics significantly streamlines the due diligence process. Similarly, for a US brand selling in California, the thorough testing for heavy metals and phthalates in OEKO-TEX helps address Proposition 65 concerns. From a retailer’s perspective, it simplifies their vetting process. A major German retailer we supply to accepts our OEKO-TEX Class II certificates as primary evidence for their restricted substances list (RSL) compliance. This pre-approval fast-tracks our client’s garments onto the sales floor. It’s a practical business enabler.

Does the OEKO-TEX Label Actually Influence Consumer Purchasing Decisions?

Absolutely. In an age of greenwashing and information overload, a trusted, third-party seal cuts through the noise. The OEKO-TEX label is one of the most recognized and trusted eco-labels globally, especially in key markets like Europe and North America. It answers a latent consumer question: “Is this product safe for me and my family?”

We have quantifiable feedback from our clients. An Austrian lingerie brand that switched to our OEKO-TEX Class II certified modal and lace reported a 15% increase in online conversion rate for products where the certification was highlighted on the product page and hangtag. Their customer surveys indicated that the label provided a decisive “final push” for hesitant buyers concerned about skin sensitivity. This aligns with broader market studies on the value of trust marks. For brands, integrating this label into marketing is a low-cost, high-impact strategy. It’s not just a compliance cost; it’s a marketing asset for sustainable fashion brands. By sourcing certified fabrics from a partner like Shanghai Fumao, you acquire this asset as a standard part of your material.

What Are the Common Pitfalls and Misconceptions About Class II Certification?

Even with the best intentions, brands can stumble in the certification process. The biggest pitfall is assuming certification is a one-time, static achievement held by the factory. It’s not. It’s a dynamic, product-specific, and supply-chain-dependent process. A certificate for one fabric doesn’t cover another, and a certificate can be revoked if the production process changes without notification.

Another major misconception is that the brand or retailer themselves gets “OEKO-TEX certified.” With Standard 100, the certification is always held by the supplier of the tangible product—the fabric mill, the dyer, the finisher, or the garment maker. As a brand, you are the “licensee,” granted the right to use the label on the specific, certified end-products made from that supplier’s certified materials. Your responsibility is to ensure your supply chain is certified.

Does Certification Cover All Colors and Finishes of a Fabric Article?

This is a critical technicality. No. A certificate is issued for a specific “article.” An article is defined by its base composition, construction, and all its applied chemical finishes (e.g., water-repellent, softener, anti-pilling). If you have a “100% Cotton Poplin, Article #123” and it’s certified in 5 colors, the certificate is valid for those 5 colors produced with the identical dyeing and finishing recipe. If you later add a 6th color, or decide to add an antimicrobial finish, you must apply for a certificate extension. The testing institute will test the new variant to ensure it still complies.

We manage this meticulously for our clients. Our internal system tracks which articles and colors are under our certification umbrella. When a client requests a new color for a certified article, we initiate the extension process with our partner institute, TESTEX. This ensures continuity of compliance. A common pitfall is when a brand switches to a cheaper fabric supplier mid-season who claims their “similar” fabric is certified, but the certificate is for a different article number or doesn’t include the specific colorway. This breaks the chain. At Shanghai Fumao, we provide full transparency on certificate scope.

Can a Supplier Lose Their OEKO-TEX Certification, and How Does That Affect Me?

Yes, certification can be suspended or revoked. This happens if:

- The independent institutes’ annual on-site audits uncover non-compliant processes.

- The company fails to pay its annual certificate fees.

- It’s found they have misused the label or significantly changed production without re-testing.

This is a latent risk for brands. If your fabric supplier loses its certification, your right to use the label on garments made from fabric produced after the revocation date is immediately void. If you continue to use old hangtags with the OEKO-TEX logo, you are in violation and face potential legal action from the OEKO-TEX association. This underscores the importance of partnering with financially stable, process-oriented suppliers. We maintain our certifications not as a marketing checkbox, but as a core component of our operational integrity. Regular audits by TESTEX keep us sharp. For brands, it’s wise to periodically ask your supplier for the validity status of their OEKO-TEX certificates. Reputable suppliers like us will provide this openly.

How Does Fumao Integrate OEKO-TEX Class II into Our Production Flow?

For many suppliers, OEKO-TEX is a final checkpoint—a sample is sent to a lab, and they hope for a pass. At Shanghai Fumao, we engineer compliance into the process from the very beginning. Our in-house CNAS-accredited lab and deep chemical management protocols allow us to treat OEKO-TEX Class II not as a target, but as a guaranteed starting point for all applicable skin-contact fabrics.

This proactive integration means we control the inputs. We source dyes and chemicals from pre-approved, OEKO-TEX compliant chemical suppliers. Our lab technicians run preliminary tests on greige fabrics and dye baths to screen for potential issues like heavy metal contamination or pH imbalance before full-scale production begins. This “pre-compliance” mindset drastically reduces the risk of a bulk order failing an official audit. It’s how we can confidently promise OEKO-TEX Class II certification on new developments.

What is Our Process for Managing and Renewing Certifications?

Certification management is a discipline. We maintain a dedicated digital registry of all our active OEKO-TEX certificates. Each certificate is linked to specific article codes in our ERP system. When a sales order is placed for a certified article, the system automatically flags it and ensures the production batch is traceable back to that certificate.

Renewal is not a last-minute scramble. OEKO-TEX certificates are valid for one year. Our quality department has a calendar that triggers the renewal process 4 months before expiry. This involves:

- Submitting a renewal application to the institute.

- Providing updated production information.

- Sending new samples for testing (often required to confirm ongoing compliance).

- Hosting the annual on-site audit.

This systematic approach guarantees there is never a gap in our certification coverage, ensuring uninterrupted supply for our clients. It’s a behind-the-scenes effort that provides front-end peace of mind.

How Do We Help Clients Navigate the Label Licensing Process?

Our job doesn’t end when we ship the certified fabric. We guide our brand clients through the final step: legally obtaining the right to use the OEKO-TEX label on their hangtags. This involves becoming a licensee. We provide them with our supplier certificate number and a declaration of use. They then apply to the OEKO-TEX institute (via an online portal), declaring which end-products will use our certified material.

Once approved, they receive a license number and official guidelines for label usage. We’ve helped dozens of clients, from small DTC brands to larger importers, complete this process. For instance, a Seattle-based outdoor brand used our certified recycled nylon in their hiking pants. We walked their logistics manager through the licensing application, and they now proudly feature the label on their garment, adding measurable value. It’s part of our full-service partnership. We don’t just supply a compliant product; we supply the pathway to communicate that compliance to the world.

Conclusion

The OEKO-TEX Standard 100 Grade 2 (Product Class II) certificate is far more than an acronym on a spec sheet. It is the definitive, science-backed benchmark for skin-safe textiles in the apparel industry. It represents a rigorous, independent verification of safety that protects consumers, mitigates business risk, satisfies retailer requirements, and builds authentic brand trust. Understanding the depth of its testing—particularly the critical class system—is essential for any brand that cares about the integrity of its products and the well-being of its customers.

In a marketplace crowded with vague claims, the OEKO-TEX label offers clarity and credibility. But that value is only realized when the certification is correct (Class II for apparel), authentic, and actively managed throughout the supply chain. It’s not a trophy to be won once, but a standard to be lived every day in production.

Ready to move beyond vague promises and build your collection on verifiable safety? Partner with a supplier who treats OEKO-TEX Class II as a fundamental production principle, not an afterthought. At Shanghai Fumao, we engineer compliance into every meter of fabric destined for your clothing. Contact our Business Director, Elaine, to discuss how we can provide you with OEKO-TEX certified fabrics and seamless support for your label licensing. Reach her at: elaine@fumaoclothing.com. Let’s make safety and trust the foundation of your next line.