If I had a dollar for every time a client asked me this question in a panic, I could probably buy another lace loom. Just last month, a designer from New York emailed us on Monday expecting a fully customized lace sample by Friday. The reality? Creating custom lace isn't like ordering a pizza—it's more like orchestrating a symphony where every musician needs the right sheet music and practice time. The lead time question doesn't have a single answer, but rather a range that depends entirely on how complex your design is, how much development is needed, and crucially, when in the Chinese production calendar you place your order.

The lead time for producing custom lace fabric from China typically ranges from 45 to 90 days for bulk production, starting from final design approval. This timeline breaks down into three key phases: Sampling & Development (15-30 days), Bulk Production (25-45 days), and Logistics & Shipping (5-15 days). For extremely simple recolors of existing patterns, it might be squeezed to 35 days. For intricate, brand-new designs requiring multiple sample revisions, it can stretch to 120 days. At Shanghai Fumao, we've perfected a parallel processing system that can shave 15-20% off industry averages, but even we can't defy the fundamental physics of thread and loom.

Why such a wide range? Because "custom lace" can mean anything from changing the color of an existing flower motif to engineering a completely new, multi-layer embroidered lace with metallic threads. The former is a sprint; the latter is a marathon with hurdles. Furthermore, placing an order in September (peak season) versus December (slower period) can add or subtract 3 weeks. This guide will demystify each stage of the timeline, share insider tips to accelerate your project, and show you how to plan realistically to avoid missing your critical market deadlines.

What Factors Most Impact Your Custom Lace Timeline?

Think of lead time as a recipe. The ingredients—your design complexity, quality standards, and order quantity—directly determine the cooking time. In early 2023, a French lingerie brand requested a lace with a unique, undulating leaf pattern that required a brand new Jacquard head for the loom. That single component took 21 days to machine before we could even weave the first sample meter. Conversely, a client from Miami in November simply wanted our best-selling geometric lace in a new neon coral shade; we had bulk fabric on the ship in 38 days flat.

The four most impactful factors are: 1. Design Originality, 2. Color Complexity, 3. Technical Specifications, and 4. Order Volume. A completely original design requires creating a digital technical file (CAD), which can take a week alone. More colors in the pattern mean more yarn sourcing and more complex dyeing/thread setup. Technical specs like adding elastane for stretch, achieving a specific weight, or getting a special eco-certification add sequential steps. Finally, while order volume has less impact on the per-day production rate, it determines the total run time on the looms and finishing machines.

How Does Pattern Complexity Affect Development Time?

The pattern is the master blueprint, and its complexity sets the pace.

- Simple Recolor/Modification (7-10 days): Using an existing pattern from our library of 30,000+ designs. We just adjust the color palette in the CAD file.

- New Pattern, Standard Weave (15-20 days): Creating a new CAD file, programming the loom (for Raschel or Jacquard), and producing the first physical sample.

- Intricate/High-Definition Pattern (25-35 days): Involves ultra-fine details, requiring high-gauge machinery and multiple sample revisions to perfect thread tension and clarity. Leavers-style lace patterns fall here.

For example, a request for a lace mimicking a specific antique Venetian design required our R&D team to analyze thread densities and create three sample iterations over 28 days to match the historical drape and motif clarity.

Why Do Material and Certification Requirements Add Weeks?

You can't rush science or bureaucracy.

- Specialty Yarns: Sourcing certified organic cotton, recycled polyester (rPET), or premium silk blends adds 5-10 days for yarn procurement and verification.

- Eco-Certifications: If you need GOTS, OEKO-TEX Standard 100, or specific compliance documentation, factor in 10-15 business days for lab testing and certification issuance after the bulk fabric is produced. This is often done in parallel but is a non-negotiable time block.

- Performance Treatments: Applying antimicrobial, moisture-wicking, or UV-protective finishes adds 3-5 days of post-production processing and testing.

A sportswear brand needed Bluesign® certified lace for a high-end activewear line last July. While the weaving was standard, the entire Bluesign® certification process for new fabric added a critical 12 days to the timeline that we had to account for from day one.

What Does a Realistic Production Timeline Look Like (Phase by Phase)?

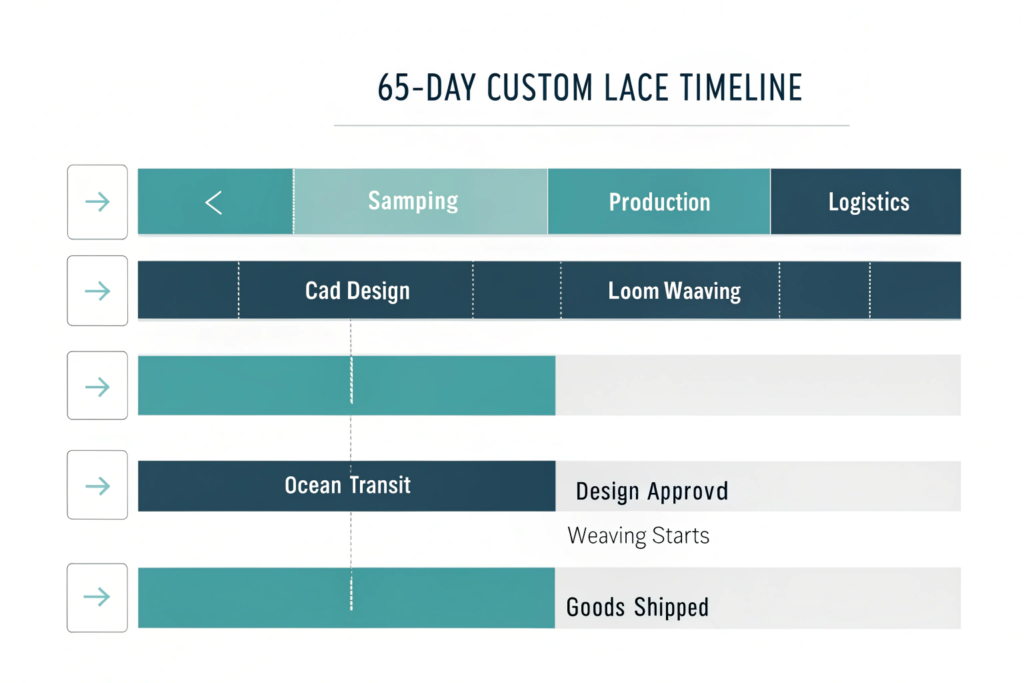

Let's break down a typical 65-day timeline for a moderately complex custom lace order placed during a standard production period (not peak season). This isn't a guess; it's based on hundreds of orders we've processed at Shanghai Fumao.

Phase 1: Design & Sampling (Days 1-22)

- Days 1-3: Technical discussion, design finalization, and CAD file creation.

- Days 4-10: First sample (lab dip/strike-off) production. This is a small swatch to confirm pattern, color, and hand-feel.

- Days 11-14: Courier sample to client for approval (we use DHL/FedEx).

- Days 15-18: Client feedback and request for revisions.

- Days 19-22: Production of second sample (pre-production sample) and final approval.

Phase 2: Bulk Production & QC (Days 23-52)

- Days 23-25: Material procurement (yarn dyeing if needed).

- Days 26-45: Loom weaving. This is the core, uninterrupted production time. A single Raschel loom might produce 50-100 meters per day depending on complexity.

- Days 46-50: Post-production finishing (washing, softening, heat-setting).

- Days 51-52: Final random inspection (AQL 2.5 standard), measuring, and rolling.

Phase 3: Logistics & Shipping (Days 53-65)

- Days 53-55: Packing, customs documentation preparation, and booking sea/air freight.

- Days 56-65: Ocean transit from Ningbo or Shanghai port to a major US West Coast port (e.g., LA/Long Beach). Air freight can reduce this to 3-5 days but at 4-5x the cost.

How Can the Sampling Process Be Accelerated?

The sampling phase is where most delays occur, usually due to back-and-forth communication. Here’s how to speed it up:

- Provide Perfect References: Send a physical swatch, high-resolution image, or Pantone codes. "Light blue" is subjective; Pantone 14-4319 TPX is precise.

- Consolidate Feedback: Review all aspects (color, pattern, weight, hand-feel) in one email. Multiple separate feedback rounds are the biggest time-killers.

- Use Digital Approvals: For color, approve a digital lab dip report first before requesting a physical sample. This can save a full week.

- Pay for Overnight Courier: For physical samples, the extra $50-$100 for overnight shipping saves 4-5 business days compared to standard express.

We had a client in London who mastered this. They created a dedicated "Sample Feedback Form" for their team, ensuring all stakeholders signed off internally before sending us a single, consolidated email. It cut their average sampling time from 28 days to 17.

What Are the Hidden Time Costs in Bulk Production?

The loom time is fixed. The hidden time costs are in the pre- and post-loom stages:

- Yarn Dyeing: If you need custom-dyed yarns (not stock colors), this adds 5-7 days before weaving can even begin.

- Loom Setup/Scheduling: Getting your specific design programmed and loaded onto an available loom in the production queue can take 3-5 days.

- Finishing & Testing: The mandatory finishing processes (washing, stabilizing) and final fabric quality tests for shrinkage and colorfastness take a fixed 4-6 days after the fabric comes off the loom. You cannot skip this.

How Do Chinese Holidays and Seasons Drastically Alter Lead Times?

This is the single most underestimated factor by Western buyers. The Chinese manufacturing calendar is not a suggestion; it is a law of physics. Ordering a custom lace on January 10th with a "60-day timeline" is a fantasy, because you've just hit the 3-4 week Chinese New Year (CNY) shutdown. I've seen promising brands collapse because they didn't plan for this.

Lead times can expand by 30-50% during peak seasons and come to a complete halt during major holidays. The two peak production seasons are March-May (preparing for Fall/Western holiday collections) and August-October (preparing for Spring/Summer). Factories are at 100-120% capacity. During these windows, add a minimum of 2-3 weeks to any standard lead time estimate for scheduling and resource contention.

What is the Absolute Deadline to Order Before Chinese New Year?

If you need goods produced before CNY, your bulk fabric must be completed and shipping at least 3 weeks before the holiday starts (dates vary each year between mid-January and mid-February).

If you need goods produced after CNY, the golden rule is: All pre-production must be locked 6 weeks pre-CNY. This means:

- Final design and sample approved.

- Deposit paid and production order confirmed.

- All raw materials (yarns) are physically in the factory.

This allows production to start literally the first week factories reopen. A major Swedish retailer we work with has their CNY-post-production orders fully sampled and raw materials warehoused with us by December 1st.

Can You Get Faster Delivery During Off-Peak Seasons?

Absolutely. The best windows for faster, smoother production are late June through July and mid-November through December. During these periods:

- Factories have open capacity. Your order gets immediate attention.

- Sampling is faster. R&D and sampling teams are less overwhelmed.

- Negotiation power may increase. You might get better pricing or more flexible MOQs.

- Logistics are smoother. Port congestion is lower, and freight rates are often more favorable.

Planning your development cycle to align bulk production with these off-peak windows is the mark of a sophisticated sourcing manager. For insights on seasonal logistics, reading about off-peak shipping advantages from China to Europe can offer strategic tips.

Conclusion

The lead time for custom lace from China is a dynamic equation, not a fixed number. It is the sum of your design's complexity, the rigor of your sampling feedback, the inevitable pace of loom physics, and the inescapable rhythm of the Chinese production calendar. Rushing any single phase usually compromises quality or leads to costly mistakes. The key to success is front-loaded planning and transparent communication with a supplier who has integrated control over the process.

Understanding this timeline empowers you to plan collections realistically, manage internal expectations, and hit your market windows with confidence. At Shanghai Fumao, we don't just give you a quote; we provide a detailed, phase-by-phase project plan with clear milestones. Our vertical integration and deep local partnerships in Keqiao allow us to navigate this complex timeline more efficiently than trading intermediaries. If you have a lace concept and a target delivery date, let's work backwards to build a feasible and reliable schedule. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to begin the conversation with a realistic timeline assessment.