Imagine a world where your jacket not only keeps you warm but also monitors your heart rate, charges your phone, and changes color based on your mood or environment. This isn't science fiction; it's the imminent future shaped by smart fabrics and wearable technology. For apparel brands, textile suppliers, and product developers, the critical question is no longer if this future will arrive, but how to strategically position themselves within this transformative wave. The convergence of textiles, electronics, and data science is creating a new paradigm where functionality is woven directly into the fabric of our daily lives.

The future of smart fabrics and wearable technology lies in seamless integration, multifunctionality, and user-centric ecosystems. It will evolve from today's discrete, often clunky wearables toward truly "disappearing" technology—where sensing, power, and connectivity are intrinsic, durable, and washable components of the textile itself. Key drivers include advancements in conductive inks and yarns, miniaturized flexible circuits, energy harvesting, and robust data analytics, all moving towards creating intuitive, adaptive, and personalized second-skin interfaces. For industry professionals, this means transitioning from sourcing fabric to co-engineering integrated textile systems.

This shift represents both a monumental opportunity and a complex challenge. It demands new partnerships across the supply chain, from fiber chemists to software engineers. Let's explore the key dimensions shaping this future, from material innovations to market applications, and what it means for your business strategy.

What are the key material innovations driving smart textiles?

The foundation of the smart fabrics revolution is being laid in labs and R&D centers worldwide. The goal is to make technology as pliable, durable, and comfortable as traditional textiles. This requires fundamental innovations at the fiber and material level.

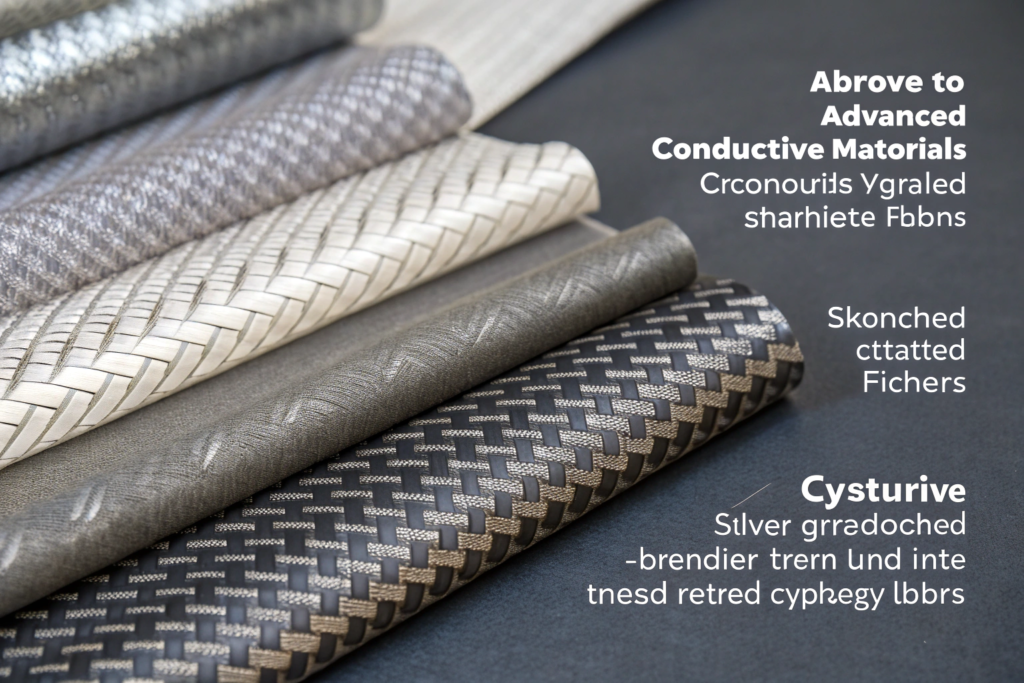

The most significant progress is in creating effective conductive pathways within fabrics. This is achieved through several approaches: conductive yarns (e.g., silver-coated, stainless steel-blended, or graphene-infused filaments), conductive inks printed directly onto fabric substrates, and the development of inherently conductive polymers. The challenge isn't just conductivity; it's achieving it without sacrificing the essential textile qualities of drape, hand feel, washability, and breathability. Parallel innovations are happening in energy—developing flexible batteries, supercapacitors that can be integrated into fabric layers, and mechanisms for harvesting energy from body movement (piezoelectric fibers) or temperature differences. Furthermore, material science is enabling new sensing capabilities through fibers that react to strain, pressure, moisture, or specific biochemicals.

How are conductive yarns and inks evolving for mass production?

Early conductive textiles were often stiff and fragile, limiting their application. Today, the focus is on high-performance, durable, and scalable solutions. At Shanghai Fumao, our R&D team has been working with partners on a next-generation silver-plated nylon yarn that maintains over 90% of its conductivity after 50 industrial wash cycles—a critical benchmark for practical apparel. For printing, advancements in nanoparticle-based conductive inks allow for finer, more flexible circuits that can be applied using standard rotary screen printing, dramatically lowering the production barrier. A major sportswear brand we collaborated with in 2023 used our engineered printed electrode system to create a heart-rate monitoring sports bra, moving away from rigid chest straps. The key to mass production is ensuring these materials can survive the cut-and-sew process and the end-user's lifestyle. Resources like industry analysis on the commercialization path for smart textiles provide valuable insights into scaling these technologies.

What role do graphene and other nanomaterials play?

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is a wonder material for smart textiles. It's not only highly conductive but also incredibly strong, thin, and flexible. Its applications range from creating ultra-sensitive strain sensors for motion capture to enabling efficient thermal regulation (fabrics that can be heated evenly with low power). Beyond graphene, nanomaterials are enabling functionalities like self-cleaning surfaces (using photocatalytic titanium dioxide nanoparticles) and enhanced UV protection. The integration of these materials often happens at the fiber extrusion stage or through advanced coatings. For instance, we've developed a prototype lining fabric infused with phase-change material (PCM) microcapsules for a client in the protective workwear sector, designed to actively buffer temperature changes for workers in extreme environments. While still evolving, forums like Technical Textiles Net often discuss the latest research and commercial applications of nanomaterials, highlighting both potential and current cost challenges.

How will wearable tech integrate seamlessly into daily apparel?

The future is not about wearing a computer on your wrist; it's about wearing a computer as your shirt. Seamlessness is the ultimate goal, encompassing aesthetics, comfort, and user experience. This requires a holistic design philosophy where technology is subordinate to the garment's primary purpose.

Integration will be achieved through invisible or minimalist design. This means embedding sensors and circuits in ways that are undetectable to the eye and touch, perhaps within layered fabric constructions or along seam allowances. Connectivity will move from bulky external dongles to textile-based antennas woven directly into the garment. User interfaces will shift from screens to haptic feedback (vibrations through the fabric) or auditory cues. Most importantly, power management will become more discreet, leveraging energy-harvesting methods and low-power Bluetooth standards to extend battery life or even create battery-free systems. The successful products will be those you forget are "smart" until you need their functionality.

What does "invisible technology" mean for garment design?

"Invisible technology" forces a fundamental shift from tech-centric to human-centric design. It means the designer starts with the wearer's need and aesthetic, not with the sensor's specifications. The electronic components must be as pliable and durable as a seam. In one of our flagship projects with a European fashion-tech startup last year, we co-developed a tailored blazer with integrated posture sensors for corporate wellness programs. The challenge was to house the flexible sensor array and micro-controller in the jacket's shoulder pad and inner cuff placket, maintaining the garment's sleek silhouette. The washable, coin-cell battery was discreetly housed behind a magnetic flap in the lining. This approach required close collaboration between our textile engineers, the client's fashion designers, and their firmware developers from day one—a new model of cross-disciplinary product development.

How will power and connectivity challenges be solved?

Power remains the single biggest hurdle. The future points towards distributed, flexible energy solutions. We are actively exploring two avenues with our partners: 1) Energy Harvesting: Using piezoelectric fibers in shoe insoles or jacket linings to convert walking motion into trickle charges, and 2) Flexible Energy Storage: Integrating thin, non-toxic supercapacitors that can be printed onto fabric and charged quickly. For connectivity, the move is towards e-textile protocols that are more robust than standard wires. This includes using conductive yarns as data buses within the fabric structure itself. Meanwhile, low-power wide-area networks (LPWAN) like LTE-M will enable garments to transmit data directly to the cloud with minimal energy draw. A practical resource for understanding these evolving infrastructure needs is analysis on the evolution of connectivity protocols for wearables, which details the trade-offs between range, power, and data rate.

What are the most promising applications beyond fitness tracking?

While fitness trackers popularized wearables, the next frontier is vast, moving into healthcare, occupational safety, fashion, and even mental wellness. The value shifts from tracking casual activity to delivering critical, actionable data and enabling new forms of interaction.

In healthcare, smart fabrics enable continuous, unobtrusive patient monitoring outside clinics—think of ECG-monitoring vests for cardiac patients or smart socks detecting early signs of diabetic foot ulcers. In industrial and military settings, they are vital for safety: uniforms that monitor vital signs for heat stress, detect toxic gases, or provide augmented reality (AR) guidance via integrated displays. In fashion, the focus is on expressivity and interaction—fabrics that change color or pattern, or garments that respond to environmental stimuli. Furthermore, the rise of the "metaverse" and digital identity is creating demand for haptic feedback suits that enhance virtual reality (VR) experiences, bridging the physical and digital worlds.

How will smart fabrics revolutionize healthcare and remote monitoring?

The potential here is to move from reactive to proactive and preventive care. A fabric-based biosensor can collect data 24/7, providing a richer dataset than a sporadic clinic visit. For example, we are part of a consortium developing a smart bedding system for elderly care facilities. The sheets use a grid of pressure and moisture sensors to monitor restlessness, incontinence, and even early signs of pressure sores, alerting staff discreetly. For home use, smart pajamas that monitor sleep quality and vital signs could become commonplace. The key to success in medical applications is not just sensor accuracy but also clinical validation, data security, and regulatory approval (like FDA or CE marking). The business model often shifts from selling a garment to providing a data-as-a-service platform. Industry observers track this shift through platforms like Medical Textiles Magazine, which covers the latest innovations at the intersection of textiles and medicine.

What is the role of smart textiles in professional and industrial safety?

This is one of the most immediate and high-impact applications. The core value is saving lives and reducing workplace injuries. Imagine a firefighter's coat with integrated thermal sensors mapping heat exposure through the suit, or a construction worker's vest that vibrates as a warning when someone is in a blind spot of heavy machinery. At Shanghai Fumao, we recently delivered a prototype fabric for utility workers that combined flame-resistant (FR) base material with printed temperature sensors and conductive threads for data transmission. This allowed for real-time monitoring of suit integrity and ambient heat. The adoption drivers in this sector are strong: corporate safety mandates, insurance incentives, and the tangible ROI of preventing accidents. The development process is highly specialized, requiring deep understanding of both safety standards (like ISO 11611 for welding) and harsh environment durability.

What are the major challenges to widespread adoption?

For all its promise, the path to a smart fabric-dominated future is not without significant obstacles. These challenges span technical, commercial, and social dimensions, and overcoming them will require concerted effort across the entire ecosystem.

The technical hurdles are foremost: achieving true washability and durability remains the holy grail. Electronics typically hate water, heat, and mechanical agitation—exactly what clothing endures. Ensuring data security and privacy is paramount, as garments collect intimate biological data. From a commercial perspective, high costs for materials and integration, coupled with a lack of standardized manufacturing processes, keep prices prohibitive for mainstream markets. There's also the challenge of user acceptance—overcoming skepticism about comfort, reliability, and the "creepiness" factor of constant monitoring. Finally, the end-of-life cycle presents a serious environmental concern, as smart textiles combine hard-to-recycle electronic waste with fabric waste.

How can the industry solve the durability and washability problem?

This is an engineering problem being attacked on multiple fronts. Encapsulation is a primary strategy: sealing electronic components in flexible, waterproof polymers before integrating them into the fabric. Another approach is to make the components themselves inherently washable. Our R&D is focused on creating robust interconnections—the points where conductive yarns connect to a microchip are typical failure points. We've had success using laser welding and anisotropic conductive films (ACF) to create bonds that survive repeated bending and washing. (Here's an insider note: our current benchmark is 50+ home wash cycles at 40°C without performance degradation, which we've achieved for simple sensor arrays). Furthermore, the industry is developing new textile-specific testing standards to replace those designed for rigid electronics. Collaboration with appliance manufacturers to create "smart garment" washing machine cycles is also on the horizon.

What are the cost and sustainability roadblocks?

The cost structure is currently top-heavy with R&D and low-volume, manual assembly. The tipping point will come with scalable, automated manufacturing processes, such as using existing textile machinery (e.g., warp knitting machines) to directly weave electronic functions. Sustainability is a two-fold issue: the environmental footprint of producing conductive materials (like silver) and the nightmare of recycling hybrid e-textiles. The future must embrace design for disassembly—think modular components that can be snapped out of a garment for separate recycling—and the development of biodegradable conductive materials. Progress in this area is slow but critical; the community often debates these topics on platforms like Textile Exchange's resources on circularity for smart textiles, which emphasize the need for lifecycle thinking from the outset.

Conclusion

The future of smart fabrics and wearable technology is not a distant dream but an unfolding reality, propelled by relentless material innovation and a growing understanding of human-centric design. It promises to transform our clothing from passive coverings into active, responsive partners in health, safety, expression, and connectivity. The journey from niche prototypes to mainstream wardrobe staples will be defined by our ability to solve the core challenges of seamless integration, durable performance, and sustainable lifecycles.

For brands, manufacturers, and suppliers, this evolution is a call to action. It demands investment in R&D, forging unconventional partnerships, and developing new skill sets. The winners will be those who view textiles not as an end product, but as a platform for innovation.

The fabric of the future is intelligent. Are you ready to weave it? At Shanghai Fumao, we are building the bridge between traditional textile excellence and this smart future. From sourcing advanced conductive fibers to providing integration-ready fabric platforms and connecting you with our network of technology partners, we are here to co-create the next generation of wearable products. If you have a vision for a smarter garment, let's turn it into a tangible, producible reality. Contact our Business Director Elaine to start the conversation: elaine@fumaoclothing.com.