You're looking at two fabric swatches—one with crisp, vibrant plaid, the other a solid, uniform color. They feel similar, but their price tags tell a different story. Why does one cost more, and which one is right for your clothing line? The answer lies in a fundamental choice made before the fabric is even woven: yarn-dyed or piece-dyed?

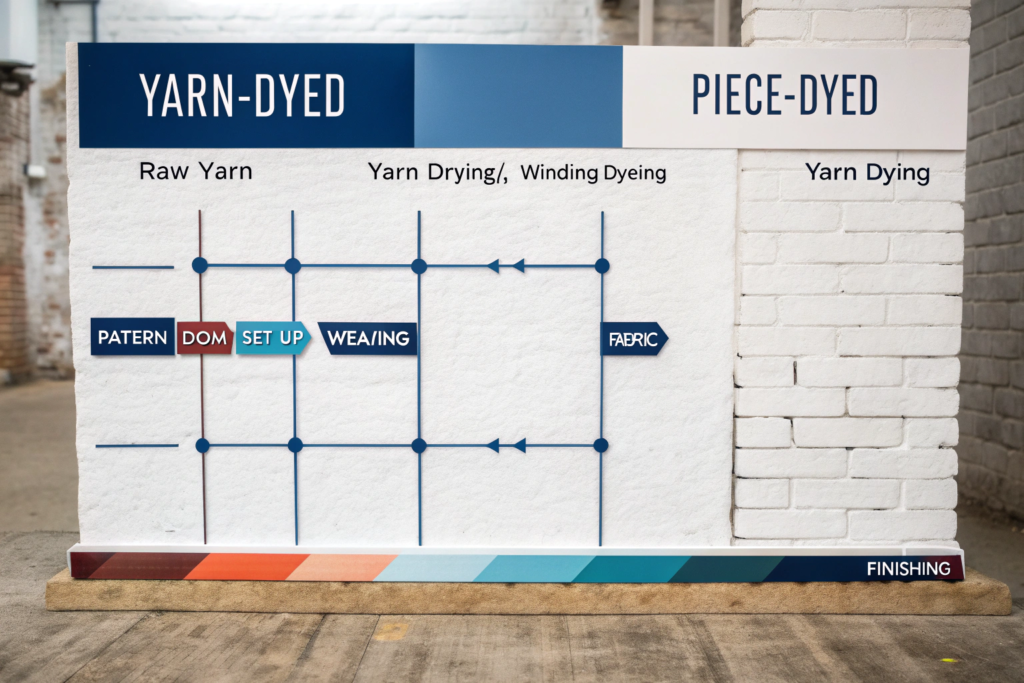

The core difference is all about timing. Yarn-dyed means the individual threads (yarns) are dyed before weaving. Piece-dyed means the entire woven fabric is dyed as one continuous piece afterward. This simple distinction in the production sequence creates massive differences in aesthetics, cost, durability, and application.

As a fabric supplier in Keqiao for over two decades, I explain this to buyers daily. Choosing the wrong dyeing method can blow your budget or ruin your design vision. Let's break down exactly how each process works, where they shine, and—most importantly—how to make the right choice for your specific product.

How does the dyeing sequence affect fabric appearance?

The dyeing sequence doesn't just affect cost; it fundamentally determines what your fabric can look like. Yarn-dyed fabrics offer complex, multi-color patterns. Piece-dyed fabrics deliver flawless, solid colors. It's the difference between painting individual bricks before building a wall (yarn-dyed) and painting the whole wall one color afterward (piece-dyed).

This difference in process directly dictates the design possibilities, the consistency of color, and even the tactile hand-feel of the final textile. Understanding this will immediately clarify why certain fabrics look and behave the way they do.

What are the visual and textural hallmarks of yarn-dyed fabrics?

Yarn-dyed fabrics are the kings of patterns. Because the yarns are pre-dyed, they can be arranged in endless combinations during weaving to create:

- Stripes, Checks, and Plaids: Think of classic Oxford shirt fabrics, gingham, or tartan wool. The patterns are woven into the fabric's structure.

- Jacquards and Dobbies: Intricate, raised patterns like those found in brocade or damask are only possible through yarn-dyed techniques.

- Heather or Melange Effects: By weaving together yarns of different colors (e.g., black and white cotton), you get a subtle, heathered grey look.

The color also tends to be richer and more saturated within each yarn. Texturally, yarn-dyed fabrics often have more character. A yarn-dyed chambray feels subtly uneven and vintage, while a piece-dyed version feels more uniform. For anyone looking to source authentic tartan or plaid weaving techniques, yarn-dyeing is the non-negotiable, traditional method.

Why do piece-dyed fabrics excel in color uniformity?

Piece-dyeing is the master of solid, consistent color. Since an entire roll of finished fabric is immersed in a dye bath, every fiber on the surface and within the core of the fabric gets exposed to the dye equally (in theory). This results in:

- Perfectly Solid Colors: Essential for basic tees, jeans (for most standard indigo denim is actually piece-dyed), and uniform workwear.

- Easier Color Matching: It's simpler to match a specific Pantone color by adjusting a dye bath for one fabric roll than by dyeing thousands of yarn spools identically weeks apart.

- Softer Initial Hand Feel: The dyeing process acts as a final finishing step, often softening the fabric.

However, a potential downside is "cross-dye" effects in blends. If a fabric is a blend of polyester and cotton, and you use a dye that only adheres to one fiber, you can get a unique two-tone look—which can be a defect or a desired feature. Understanding cross-dyeing effects on polyester-cotton blends is crucial for achieving predictable results.

What are the cost and production time implications?

Here's the business reality: yarn-dyed fabrics are almost always more expensive and take longer to produce than piece-dyed fabrics. The price difference isn't arbitrary; it's a direct reflection of a more complex, riskier, and resource-intensive manufacturing process. Your choice will directly impact your budget and lead time.

Understanding the "why" behind the cost helps you negotiate and plan better. It's not just about the dye; it's about inventory, waste, and production flexibility.

Why is yarn-dyed fabric more expensive?

The cost premium comes from multiple stages:

- Complex Inventory Management: A mill must stock thousands of spools of yarns in hundreds of colors, tying up massive capital.

- Higher Minimum Order Quantities (MOQ): To run a dye lot for a specific color of yarn economically, you need to dye a large volume. This means you must commit to large quantities of each colored yarn before even knowing if the final fabric will sell.

- Increased Production Steps: The process involves dyeing yarn, drying it, winding it onto cones, and then setting up the loom with precise color patterns (which is slower). More steps mean more labor, energy, and machine time.

- Greater Risk of Defects: If one yarn color runs out or has a quality issue mid-weave, the entire fabric piece is ruined.

For example, a New York-based shirt brand wanted a custom small-check pattern in Q3 2023. The yarn-dyed version had a 3,000-meter MOQ and a 45-day lead time, costing $8.5/meter. A similar-looking printed alternative (simulating yarn-dye) had a 1,000-meter MOQ, a 20-day lead time, and cost $5/meter. They chose yarn-dyed for its superior authenticity and durability.

How does piece-dyeing offer speed and flexibility?

Piece-dyeing is the agile, fast-fashion enabler. Its advantages are:

- Lower MOQs and Faster Turnaround: You can weave vast quantities of "greige" (raw, undyed) fabric and store it. When an order comes in for a specific color, you simply dye the required length. This allows for managing fabric inventory with greige goods programs, drastically reducing lead times from weeks to days.

- Cost-Effectiveness for Solids: The process is streamlined, with less yarn waste and lower inventory costs.

- Easier Color Adjustment: If a color isn't quite right after the first dye run, you can often over-dye or adjust the recipe for the next batch more easily.

This is why basic t-shirts, sweatshirt fleece, and solid chinos are almost always piece-dyed. At Shanghai Fumao, when a German fast-fashion client needs 10,000 meters of a "color of the month" for trousers, our piece-dyeing partners can turn that around in 10 days from greige to finished fabric. It’s simply not feasible with yarn-dyeing.

How does colorfastness and durability compare?

This is where the technical superiority of one method often becomes clear. The durability of the color isn't just about the dye stuff used; it's about how deeply and thoroughly it penetrates the fiber. The dyeing sequence has a profound impact on how well a fabric wears and ages over time.

For products that face frequent washing, abrasion, or sunlight, this isn't a minor detail—it's a critical factor in customer satisfaction and product longevity.

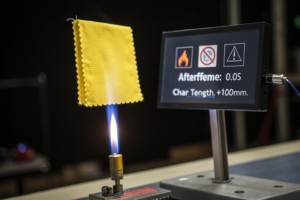

Is yarn-dyed fabric more colorfast?

Generally, yes, yarn-dyed fabrics offer superior colorfastness, especially to washing and abrasion. Here’s why:

- Thorough Penetration: During the yarn-dyeing process, the dye solution has full, 360-degree access to every filament in the loose yarn bundle, allowing for deep, core-level penetration.

- Locked-In Color: The dyed yarn is then "locked" into the fabric structure by the warp and weft. When the surface abrades, you reveal more of the same color underneath, not a different base color.

A classic test is to rub a yarn-dyed chambray shirt sleeve vigorously. The white and blue yarns may become more pronounced, but the blue won't readily transfer onto the white. This inherent durability is why high-end uniform shirts (like those for airlines or restaurants) and heirloom-quality linens are yarn-dyed.

Can piece-dyed fabrics achieve good durability?

Yes, but it requires excellent dyeing technique and often, more expensive dyes. The challenge with piece-dyeing is that the dense, woven structure can resist dye penetration, sometimes leading to:

- Ring Dyeing: Where only the outer surface of the yarns is colored, leaving a white core. This fabric is more prone to showing white "grinning" when stretched or abraded.

- Lower Rub Fastness: Color may transfer more easily in high-friction areas (like denim on denim).

However, modern piece-dyeing with advanced machinery (like jet dyeing machines that force dye through the fabric under pressure) and high-quality reactive dyes can produce extremely durable, colorfast solid fabrics. The key is to work with a dye house that knows how to optimize dye penetration in piece-dyeing processes. For instance, the piece-dyed performance polos we supply for a European brand use a special atmospheric dyeing process to ensure the moisture-wicking polyester fibers are dyed as thoroughly as possible, achieving a Grade 4-5 colorfastness to washing.

When should you choose one over the other?

This is the decision matrix. Your choice shouldn't be based on a vague notion of "quality" but on specific, practical requirements of your product, market, and business model. Each method has its ideal application, and sometimes, a compromise like "yarn-dyed look" via printing might be the smartest choice.

Let's make it actionable. Use the following criteria to guide your selection and avoid costly mistakes in fabric development.

What product categories demand yarn-dyed fabrics?

Choose yarn-dyed when your design and quality priorities are non-negotiable:

- Shirting: Dress shirts with stripes, checks, or plaids. The pattern is integral and must withstand frequent laundering.

- Suiting & Tailoring: Classic wool flannels, tweeds, and pin-striped suit fabrics. The color depth and pattern are key to the luxury feel.

- High-End Home Textiles: Luxury bed linens (like percale stripes), decorative upholstery fabrics, and high-quality towels where colorfastness is critical.

- Traditional/Ethnic Apparel: Fabrics like Madras, Tartan, or Ikat, where the authenticity of the woven pattern is the product's soul.

A client from Italy sourcing fabric for their signature line of yarn-dyed striped shirting for luxury brands would never consider piece-dyeing. The visual depth, the slightly irregular texture of the stripe, and the knowledge that the collar will withstand years of wear without fading unevenly are worth the 40% cost premium.

When is piece-dyeing the smarter business choice?

Opt for piece-dyed fabrics when your priorities are speed, cost, and solid colors:

- Basic Apparel: T-shirts, polo shirts, sweatshirts, solid-color underwear, and loungewear.

- Fast Fashion & Large Volume Basics: When you need to react quickly to color trends with large volumes of solid-color bottoms, dresses, or tops.

- Products where color consistency is paramount: Corporate uniforms, hotel linens in a single brand color, or medical scrubs.

- Blended Fabrics: Where you want to use cross-dyeing to create unique heathered effects cost-effectively.

For a start-up activewear brand focused on solid leggings and tops, piece-dyed polyester-spandex blends are the only viable choice. They offer the best combination of performance, color consistency, and affordable MOQs, allowing the brand to test the market with 500-meter orders instead of committing to 5,000 meters of pre-dyed yarn.

Conclusion

The choice between yarn-dyed and piece-dyed fabrics is a foundational decision in textile sourcing, with far-reaching consequences for your design possibilities, product cost, lead time, and end-user satisfaction. Yarn-dyeing is the artisanal, pattern-centric method that delivers unparalleled depth, authenticity, and colorfastness for premium products. Piece-dyeing is the efficient, flexible workhorse that enables rapid, cost-effective production of solid-color fabrics at scale.

There is no universally "better" option—only the right tool for the job. The most successful brands and product developers understand the strengths and limitations of each process. They specify yarn-dyed for heritage shirting and luxury linens without hesitation, and they leverage piece-dyeing for agile, trend-responsive basics, fully aware of the trade-offs. This knowledge transforms a technical detail into a strategic advantage.

Need help navigating this critical choice for your next collection? At Shanghai Fumao, we provide not just the fabrics but the expertise. Our team can guide you through the selection process, from developing custom yarn-dyed patterns with our extensive color library to sourcing high-performance piece-dyed fabrics from our network of certified dye houses. Let's ensure your fabric foundation is perfect for your vision and your business. Contact our Business Director, Elaine, to discuss your project: elaine@fumaoclothing.com.