If you've ever had a vibrant outdoor cushion fade to a dull shadow after one summer, or a uniform shirt change color after a single wash, you've experienced the limitations of conventional dyeing firsthand. The frustration of poor colorfastness is real, and it can cost you in returns, reputation, and revenue. There's a technology that promises to lock color in for the life of the fabric—solution dyeing. But what exactly is it, and is it worth the hype and potential premium for your product line?

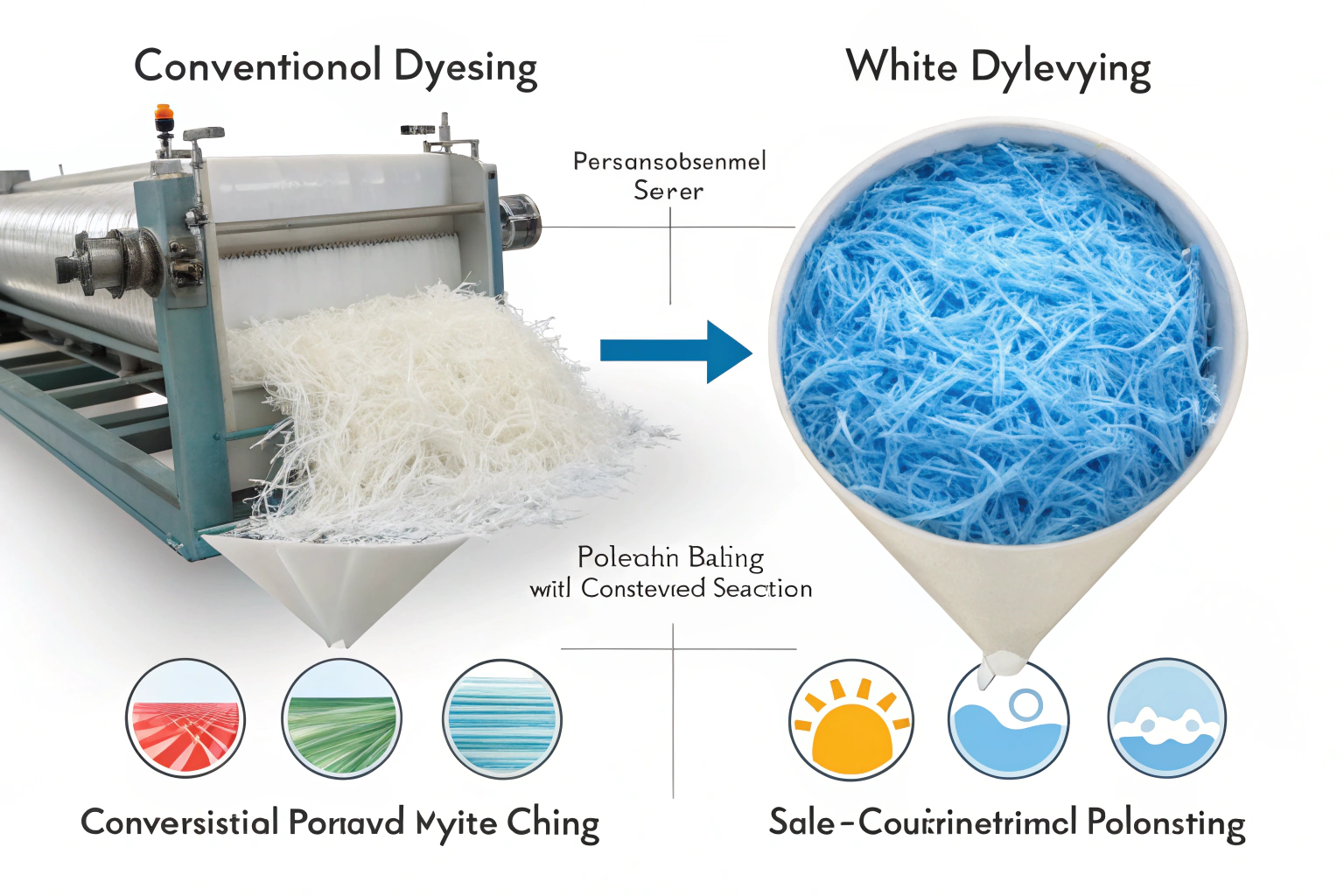

The core difference lies in when and how the color is added to the fiber. Conventionally dyed fabric (like yarn-dyed or piece-dyed) applies color to already-formed yarns or finished fabric, coating the surface. Solution-dyed fabric (also known as dope-dyed or spun-dyed) incorporates pigment directly into the liquid polymer before the synthetic fiber is even extruded into a solid filament, making the color an intrinsic part of the fiber itself. This fundamental difference drives vast divergences in colorfastness, environmental impact, and suitability for applications.

Knowing this definition is just the start. To make an informed sourcing decision, you need to understand the science behind the superior performance, the real cost-benefit analysis beyond the sticker price, the specific product categories where it delivers unbeatable value, and how to verify you're getting the genuine article from your supplier. Let's unravel the thread.

How Does the Solution Dyeing Process Create Inherent Color?

The magic happens at the very beginning of the fiber's life. Imagine making a colored candle versus painting a white candle. Solution dyeing is the former—the color is mixed into the molten wax itself. This isn't a surface treatment; it's a molecular integration.

In solution dyeing, masterbatch pigments or colorants are blended with the molten polymer (like polyester, nylon, or polypropylene) at a precise ratio before the extrusion process. This colored liquid "dope" is then forced through a spinneret to create continuous filaments that are already the target color. Because the pigment particles are dispersed throughout the entire cross-section of each filament, the color is locked in from the inside out. This is why you often hear it called "mass-coloration." The process is highly controlled and automated, leading to exceptional batch-to-batch color consistency. For a deeper look at the polymer science, resources like the technical overview of mass coloration processes for synthetics from fiber engineering publications are invaluable.

What are the key chemical and physical advantages of this integration?

The advantages stem from the color being an integral part of the fiber matrix:

- Unmatched Colorfastness: The color cannot be washed out or bleached because it's not sitting on the surface. It resists fading from UV exposure, chlorine, ozone, and harsh chemicals far better than surface dyes.

- Superior Consistency: Since the color is mixed in a liquid state, the distribution is homogenous. This eliminates side-to-center shading variations common in piece-dyed fabrics and virtually eliminates lot-to-lot color deviation.

- Enhanced Durability: The process can sometimes improve the fiber's resistance to degradation from sunlight (UV), as some pigments act as UV blockers.

We put this to the test in 2023 for a client supplying uniforms for a chain of swim schools. They had issues with chlorine fading. We switched them to a solution-dyed polyester pique. After 6 months of daily chlorinated wash tests, the solution-dyed fabric retained over 95% of its color strength, while the conventionally dyed counterpart faded by nearly 40%. The test method for colorfastness to chlorinated water (AATCC 162) became their new standard.

Are there limitations to the color palette in solution dyeing?

Yes, and this is a crucial trade-off. The palette is typically more limited compared to the infinite possibilities of piece-dyeing. Creating the masterbatch for very specific, complex shades (like certain heathers or deep, rich jewel tones) can be challenging and expensive. It's most cost-effective for high-volume, standard colors (blacks, navies, charcoals, reds, certain blues). Producing small batches of custom colors is often not economically viable due to the minimum polymer run requirements. This is why you often see solution-dyed fabrics in performance wear, outdoor furniture, and automotive interiors—where a defined color range meets extreme durability needs. For brands needing vast, seasonal color changes, conventional dyeing remains the flexible choice.

What Performance Gaps Exist Between Solution-Dyed and Piece-Dyed Fabrics?

The performance gap isn't subtle; it's often the difference between a product that lasts a season and one that lasts for years. When you subject fabric to real-world stress—sun, sweat, rain, and repeated washing—the method of dyeing becomes the dominant factor in its longevity.

The gaps are most pronounced in tests for colorfastness to light (AATCC 16) and colorfastness to crocking/rubbing (AATCC 8). Solution-dyed fabrics consistently achieve the highest ratings (e.g., Grade 4-5 on a 5-point scale) with minimal effort. For piece-dyed fabrics to approach similar levels, they often require expensive auxiliary chemicals (UV inhibitors, advanced fixatives) and perfect dyeing control, which increases cost and environmental load. Furthermore, solution-dyed fabrics have no issue with "grinning" — where fabric stretches and reveals undyed white fibers at the seams or elbows because only the surface was colored.

How does solution dyeing impact environmental sustainability metrics?

This is where solution dyeing shines, and it's a major driver for eco-conscious brands. The process is significantly more efficient:

- Water Usage: It virtually eliminates process water for dyeing. Conventional dyeing can use 100-150 liters of water per kilogram of fabric. Solution dyeing uses almost none in the coloration step.

- Chemical & Energy Use: No dyes, salts, or fixatives are needed downstream, reducing chemical pollution. It also saves the massive thermal energy required to heat dye baths and dry wet fabrics.

- Wastewater: It generates no colored effluent, a major pollutant in textile regions.

While the initial polymer production has an impact, the overall lifecycle assessment is favorable. For brands tracking Higg Material Sustainability Index (MSI) scores, solution-dyed synthetic fibers often score better. A European outdoor brand we partnered with in 2024 switched their flagship tent line to solution-dyed nylon specifically to reduce their water footprint, touting a 60% reduction in water use for the dyeing phase in their sustainability report.

In which applications is the performance gap most critical?

The gap dictates the fabric's very viability in certain fields:

- Outdoor & Technical Textiles: Awnings, marine covers, outdoor furniture, flags, tents. Constant UV exposure would destroy conventional colors.

- Automotive Interiors: Seats, carpets, and trim must withstand years of sunlight through glass without fading.

- Performance & Workwear: Uniforms for lifeguards, mechanics, and healthcare that face bleach, chemicals, and frequent industrial laundering.

- Geotextiles & Construction: Fabrics used in soil stabilization that are buried and need long-term integrity.

If your product will live in the sun, get wet with chlorinated or salt water, or face abrasive cleaning, the premium for solution-dyed is not an expense—it's an insurance policy. For example, sourcing solution-dyed olefin fabrics for indoor-outdoor carpets is now considered industry standard because of its stain and fade resistance.

How to Assess the True Cost and Value Proposition?

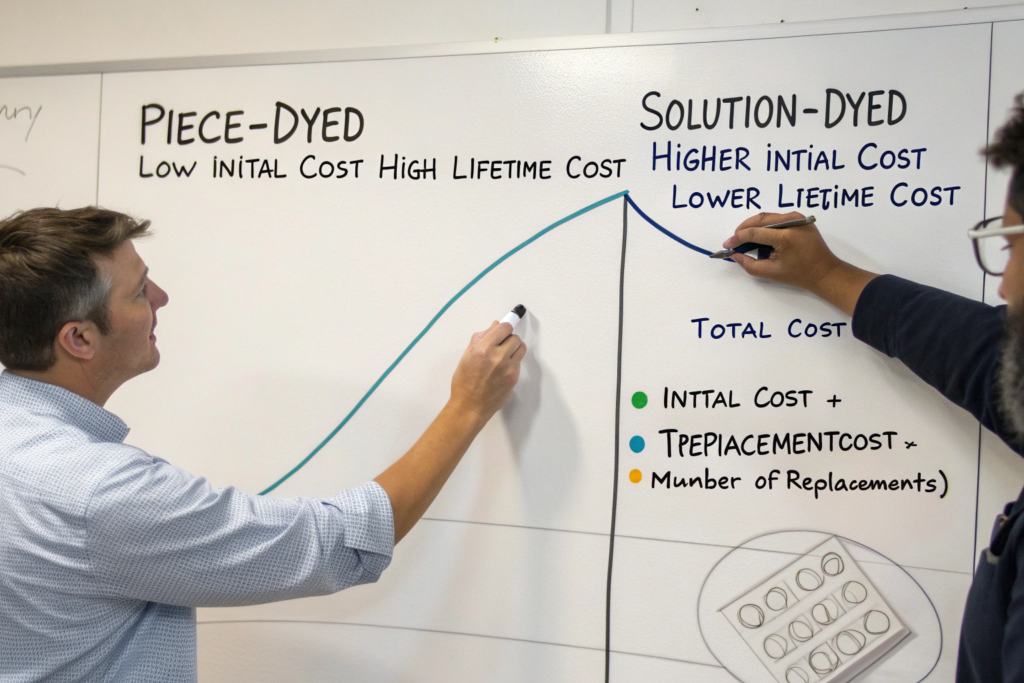

The upfront cost per meter of solution-dyed fabric is often higher. But true cost is measured per year of service, not per meter. You must calculate total cost of ownership (TCO), which includes replacement costs, customer dissatisfaction, and brand reputation damage from failing products.

A solution-dyed fabric might cost 15-30% more than a comparable piece-dyed option. However, if it lasts three times as long before fading unacceptably, the value is clear. For a furniture manufacturer, this means fewer warranty claims and a higher perceived quality. For a uniform company, it means not having to replace faded garments annually. The calculation must be explicit: (Cost of Fabric / Expected Lifespan in Years) = Annual Fabric Cost. Compare this figure between the two options. Often, the solution-dyed fabric wins on a multi-year horizon.

When does the higher initial cost of solution-dyed fabric become justified?

The justification threshold is crossed when any of the following are true:

- The Cost of Failure is High: If a faded product leads to a lost contract (e.g., corporate uniforms) or a costly warranty replacement (e.g., outdoor furniture sets).

- Longevity is a Key Selling Point: Your brand is built on "built to last" quality. The fabric's performance becomes a marketing asset.

- You Have High Sustainability Goals: The water and chemical savings align with your ESG reporting and resonate with your customer base.

- You Value Supply Chain Simplicity: The exceptional color consistency reduces quality control headaches, minimizes shade-batching issues in production, and speeds up approval processes.

In my experience, once clients run the numbers for a product meant to last more than 18-24 months, the justification becomes clear. We helped a US-based shade sail company make this switch. Their initial fabric cost rose by 20%, but they were able to extend their product warranty from 2 to 5 years and use it as a premium marketing feature, increasing their market share.

Are there hidden costs or downsides to solution dyeing beyond color limits?

Beyond the limited palette, consider:

- Minimum Order Quantities (MOQs): Because color is added at the fiber stage, the MOQs are typically tied to fiber production runs, which can be much larger than fabric dyeing MOQs. This can be a barrier for small brands.

- Lead Times: Creating a new color requires scheduling at the fiber producer, which can add weeks to your development timeline compared to a quick lab dip in a dye house.

- Inventory Risk: You must forecast color demand more accurately, as you're committing to a large quantity of a specific colored fiber.

These are operational challenges, not performance drawbacks. Partnering with a supplier like Shanghai Fumao that has strong relationships with major fiber producers can help mitigate these issues through shared forecasts and access to standard color banks.

How to Source and Verify Authentic Solution-Dyed Fabric?

In a market rife with claims, "solution-dyed" can be misused. Some suppliers might apply a very good pigment print or coating and call it solution-dyed. As a buyer, you need verification protocols to protect your investment.

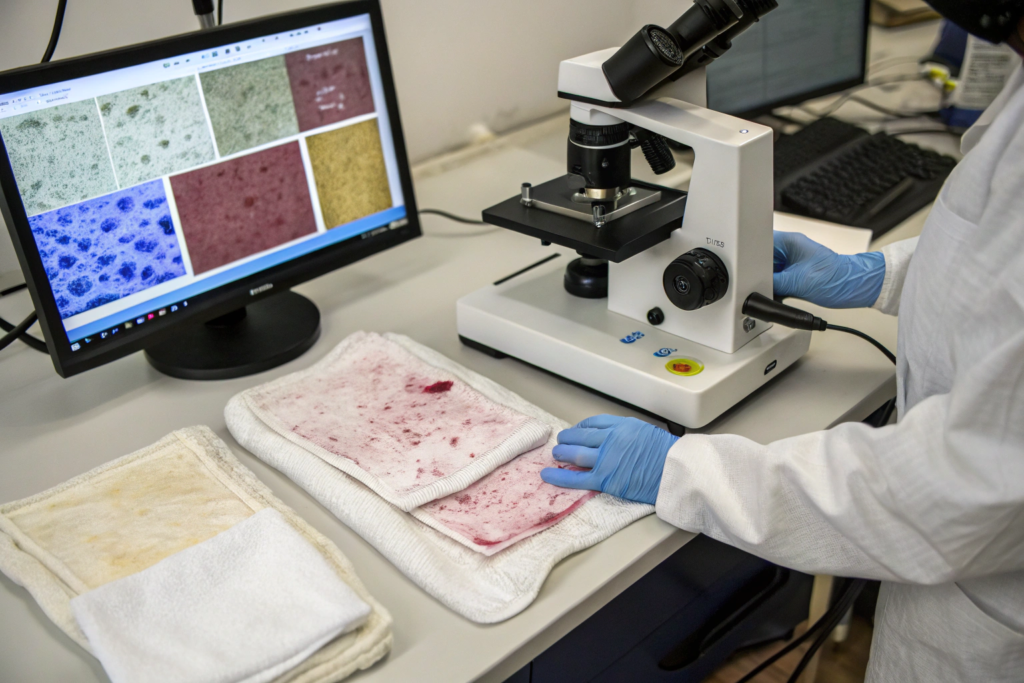

Authentic solution-dyed fabric will have consistent color throughout. The most basic test is to abrade the surface vigorously with a white cloth or sandpaper—if white dust appears or color transfers easily, it's likely surface-dyed. For a more definitive test, ask the supplier for a fiber cross-section microscopic image. A true solution-dyed fiber will show pigment particles evenly distributed across the entire circular cross-section. A conventionally dyed fiber will show a ring of color only on the periphery. Reputable suppliers should provide this evidence or a certification from their fiber source (e.g., from companies like Unifi, Aquafil, or Advansa).

What documentation and certifications should I demand from my supplier?

Don't just take their word for it. Require:

- Fiber Origin Certificate: A document from the fiber manufacturer stating the fiber is "spin-dyed," "dope-dyed," or "mass-colored," specifying the color code and lot number.

- Independent Test Reports: Reports from labs like SGS or ITS specifically for colorfastness to light (Xenon-arc) and washing. Look for high grades (4-5) with minimal change.

- Supplier's Declaration of Conformity: A signed statement that the fabric is produced with solution-dyed yarns as defined.

At Shanghai Fumao, we bundle a "Solution-Dyed Verification Pack" with every order, which includes the masterbatch invoice from the polymer stage, fiber cross-section photos, and pre-shipment test reports. This level of transparency is what builds long-term trust. For industry-standard guidance, refer to the Global Recycled Standard (GRS) or OEKO-TEX guidelines which have specific chains of custody for pre-consumer materials, often including mass-colored fibers.

How can I identify suppliers truly experienced with solution-dyed fabrics?

Look for suppliers who specialize in performance textiles, outdoor fabrics, or uniform fabrics—not just fashion cottons. Key indicators include:

- Product Range: They prominently feature solution-dyed polyester, nylon, or olefin in their catalog.

- Technical Language: They talk about "fiber-stage coloration" and understand MOQ implications.

- Proactive Offering: They suggest solution-dyed options when you describe an outdoor or high-wash application.

- Transparent Supply Chain: They can name their fiber suppliers and provide the documentation mentioned above.

A supplier who hesitates or cannot explain the technology is a red flag. Engaging in industry forums dedicated to performance textiles and technical fabrics can also yield reputable supplier recommendations and vetting advice.

Conclusion

The choice between solution-dyed and conventionally dyed fabric is a strategic decision that hinges on your product's performance requirements, lifecycle cost model, and brand values. Solution dyeing offers an unparalleled fusion of durability, colorfastness, and environmental efficiency for synthetic fibers, making it the undisputed champion for any application facing sun, weather, or rigorous wear. Conventional dyeing retains its vital role where unlimited color creativity, small batches, and natural fibers are paramount.

Ultimately, understanding this difference empowers you to specify the right tool for the job. It moves the conversation with your supplier from price per meter to value over time. If your designs demand colors that stand up to the elements and your brand stands for lasting quality, then investing in solution-dyed fabric is a clear path to greater customer satisfaction and reduced long-term costs. Ready to explore how solution-dyed fabrics can elevate your next collection? At Shanghai Fumao, we bridge the gap between advanced fiber technology and practical sourcing, providing verified, high-performance fabrics for brands that are built to last. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss integrating solution-dyed options into your supply chain.