As a fabric supplier with over two decades in the textile hub of Keqiao, I get this question a lot from our American and European clients. Choosing the right dyeing method is not just a technical detail; it's a critical business decision that impacts your fabric's quality, cost, and market appeal. Many buyers find themselves confused between these two prominent techniques for cotton.

Simply put, the core difference lies in how the dye chemically bonds with the cotton fiber. Reactive dyeing forms a powerful covalent bond with the fiber, making it part of the fabric itself. Vat dyeing, however, relies on a mechanical process where the dye is physically trapped inside the fiber, renowned for its exceptional colorfastness.

Understanding this distinction is vital for any brand sourcing cotton fabrics. It affects everything from the final handfeel and color vibrancy to the garment's durability and production lead time. Let's unravel the specifics of each method to help you make the most informed choice for your next collection.

How does reactive dyeing work on cotton?

Reactive dyeing is a favorite for achieving bright, vibrant colors on cotton. The process is all about creating a permanent chemical marriage between the dye molecule and the cellulose in the cotton fiber. This results in excellent colorfastness to washing, which is a key requirement for many of our clients in the fashion and children's wear sectors.

The magic of reactive dyeing happens when the dye molecule becomes "reactive." It forms a covalent chemical bond with the hydroxyl groups in the cellulose. This bond is incredibly strong, meaning the dye becomes an integral part of the fiber rather than just sitting on its surface. For brands focused on eco-friendly textiles, it's important to note that while the bond is strong, the process can require more water and salt. However, advancements in low-impact reactive dyes are continuously improving its environmental profile.

What are the key steps in the reactive dyeing process?

The reactive dyeing process is methodical. It starts with preparing the cotton fabric to ensure it is clean and absorbent. The fabric is then immersed in a dye bath containing the reactive dyes, alkali (like soda ash), and a significant amount of salt. The salt helps drive the dye onto the fiber, and the alkali triggers the chemical reaction that forms the permanent bond. Finally, the fabric is thoroughly washed to remove any unfixed dye, which is a crucial step for achieving good wet fastness.

Why choose reactive dyeing for your cotton apparel?

You should choose reactive dyeing when your design calls for a wide spectrum of brilliant, intense colors. It is perfect for products where color vibrancy is a major selling point. Furthermore, the resulting fabric often has a softer handfeel compared to vat-dyed cotton, which is a critical factor for comfort in apparel. From a sourcing perspective, reactive dyeing is often more cost-effective for medium to large production runs, allowing for greater flexibility in color matching and faster turnaround times, which aligns with our 48-hour sample development promise.

What are the advantages of vat dyeing for cotton?

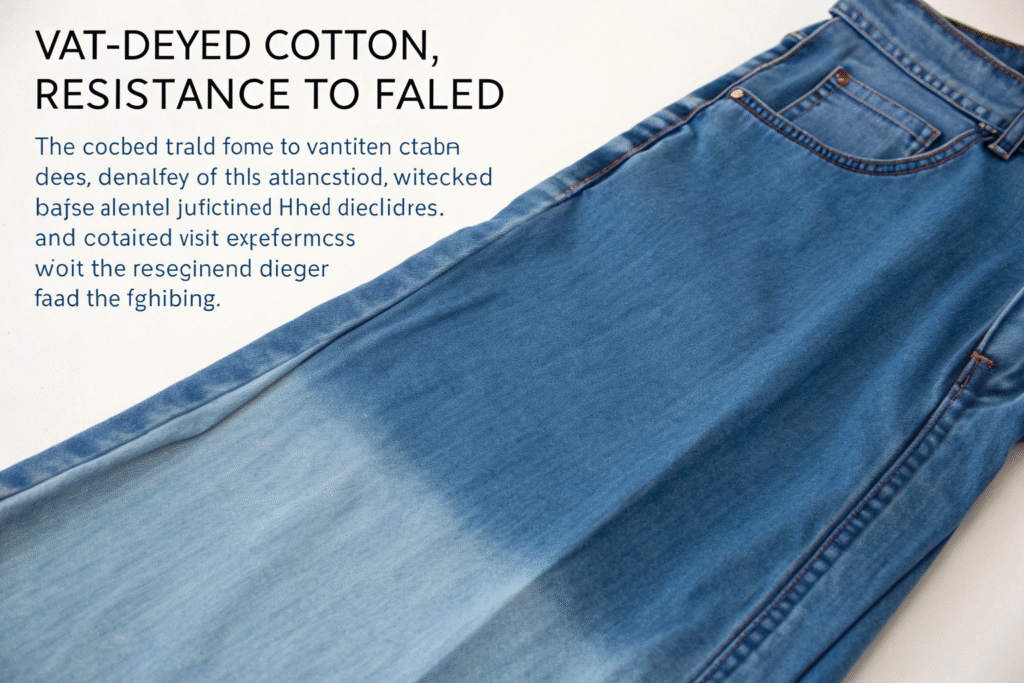

Vat dyeing is the gold standard for unmatched colorfastness, particularly for indigo denim and military uniforms. The process is less about chemical bonding and more about a clever transformation. The vat dyes are insoluble in water initially. They are chemically reduced in a vat to a water-soluble "leuco" form, which allows them to penetrate the cotton fiber. Once inside, exposure to oxygen makes the dye revert to its insoluble form, trapping it permanently inside the fiber.

This unique mechanism gives vat-dyed cotton its legendary resistance to fading. The color is locked deep within the fiber, making it highly resistant to washing, bleaching, and sunlight. This is why you see vat dyes used in denim that is meant to develop unique fade patterns over time without losing its core blue hue. While the color range is traditionally more subdued than reactive dyes, the performance is superior.

How does vat dyeing achieve superior colorfastness?

The superior colorfastness of vat dyeing comes from the physical trapping of the pigment inside the fiber. Since the dye molecules become insoluble again after oxidation, they cannot easily escape the fiber structure. This makes vat-dyed fabrics exceptionally resistant to repeated washing, harsh detergents, and prolonged exposure to sunlight. For brands producing workwear, outdoor apparel, or high-end linens, this translates to a product that maintains its color integrity for a very long time, a key quality assurance point for our clients.

Is vat dyeing the right choice for your product line?

Vat dyeing is the right choice if your top priority is extreme durability and colorfastness. It is ideal for products like uniforms and workwear that undergo heavy use and frequent industrial laundering. While the initial cost is typically higher and the process can be more time-consuming, the investment pays off in product longevity. The classic, often slightly muted shades of vat dyes also carry a certain premium and authentic appeal, perfect for heritage-style brands.

Reactive vs. Vat Dyeing: A direct comparison for buyers.

When you're placing a bulk order, the choice between reactive and vat dyeing boils down to your specific needs for color, durability, cost, and lead time. Here's a clear, side-by-side breakdown to guide your decision.

| Feature | Reactive Dyeing | Vat Dyeing |

|---|---|---|

| Color Range | Vast, brilliant, and vibrant colors | Traditionally narrower, classic shades (e.g., indigos, olives) |

| Colorfastness | Very good, especially to washing | Excellent to superior; best for washing, light, and chlorine |

| Handfeel | Softer | Can be slightly stiffer, though finishing can soften |

| Environmental Impact | Higher water and salt usage; evolving eco-options | Often uses reducing agents like sodium hydrosulfite |

| Cost | Generally more cost-effective | Typically more expensive |

| Best For | Fashion, children's wear, home textiles | Denim, workwear, uniforms, premium outdoor gear |

Which method offers better colorfastness for my product?

For the absolute best colorfastness, especially against washing, bleach, and sunlight, vat dyeing is the undisputed winner. The trapped pigment inside the fiber provides a level of durability that reactive dyes cannot match. This is a critical consideration for technical textiles designed for harsh conditions. However, for most everyday fashion and apparel, modern reactive dyes offer more than sufficient fastness, coupled with a much broader and brighter color palette.

How does cost and production time compare?

Reactive dyeing generally wins on cost and speed for most applications. The process is less complex and can be integrated more seamlessly into our agile supply chain, supporting our promise of quick bulk delivery. Vat dyeing involves more steps, including the reduction and oxidation phases, which lengthen production time and increase cost. You pay a premium for the unmatched durability and classic aesthetic that vat dyeing provides.

How to choose the right dyeing method for your order?

Making the final choice depends on a clear understanding of your product's end-use and your brand's values. There is no one-size-fits-all answer. You need to weigh the importance of color brilliance against ultimate durability, and consider your budget and timeline constraints. At Fumao, our R&D team is here to guide you through this exact decision, ensuring the fabric you choose perfectly aligns with your vision.

Start by asking yourself these key questions: What is the primary function of the garment? How will it be cared for? Is a bright, fashionable color more important, or is long-term color integrity non-negotiable? The answers will immediately point you in the right direction. For instance, a fast-fashion item might prioritize reactive dyeing for cost and color, while a high-performance activewear line might invest in vat dyeing for its resilience.

What questions should you ask your fabric supplier?

You must ask your supplier specific questions to ensure quality and alignment. Key questions include: "Can you provide SGS test reports for colorfastness to washing and light?" "What is your minimum order quantity for custom-dyed colors?" "What are your lead times for sampling and bulk production?" and "Do you offer low-impact or eco-friendly dyeing options?" A transparent supplier like us will have these answers ready, backed by our CNAS-accredited lab data.

Can Fumao Textiles handle both dyeing processes?

Absolutely. Our strength lies in our integrated supply chain and deep expertise. We have long-standing partnerships with specialized dyeing factories that excel in both reactive and vat dyeing processes. This means you get the benefit of a specialized partner without the hassle of managing multiple suppliers. We can produce everything from brilliantly reactive-dyed fashion jerseys to rugged, vat-dyed indigo denim, all with stringent quality control from our professional QC team.

Conclusion

Choosing between reactive and vat dyeing is a fundamental step in creating a successful cotton product. Reactive dyeing offers vibrant colors and a soft handfeel at a competitive cost, making it ideal for most fashion applications. Vat dyeing provides unparalleled, long-lasting colorfastness, perfect for durable goods like denim and workwear. Your decision ultimately shapes the quality, appeal, and longevity of your final garment.

By understanding these differences, you move from simply buying fabric to strategically sourcing it. This knowledge empowers you to make choices that enhance your brand's value and satisfy your customers. We are here to be more than just a supplier; we are your partner in navigating these complex decisions to ensure your collection's success.

Ready to source the perfect cotton fabric for your next order? Let's discuss your specific needs. For a personalized consultation and to see how our dyeing expertise can benefit your brand, please contact our Business Director, Elaine, directly at elaine@fumaoclothing.com. We are poised to deliver the quality, speed, and reliability your business demands.