You're browsing fabrics for a new t-shirt line, and you see two options: "100% Cotton Jersey" and "100% Cotton Poplin." Both are labeled for shirts, but one stretches easily in your hands, the other is crisp and firm. Or perhaps you've heard "jersey" is a knit, but then see "woven cotton." What's the deal? Is "jersey" always stretchy, and why does this confusion even exist?

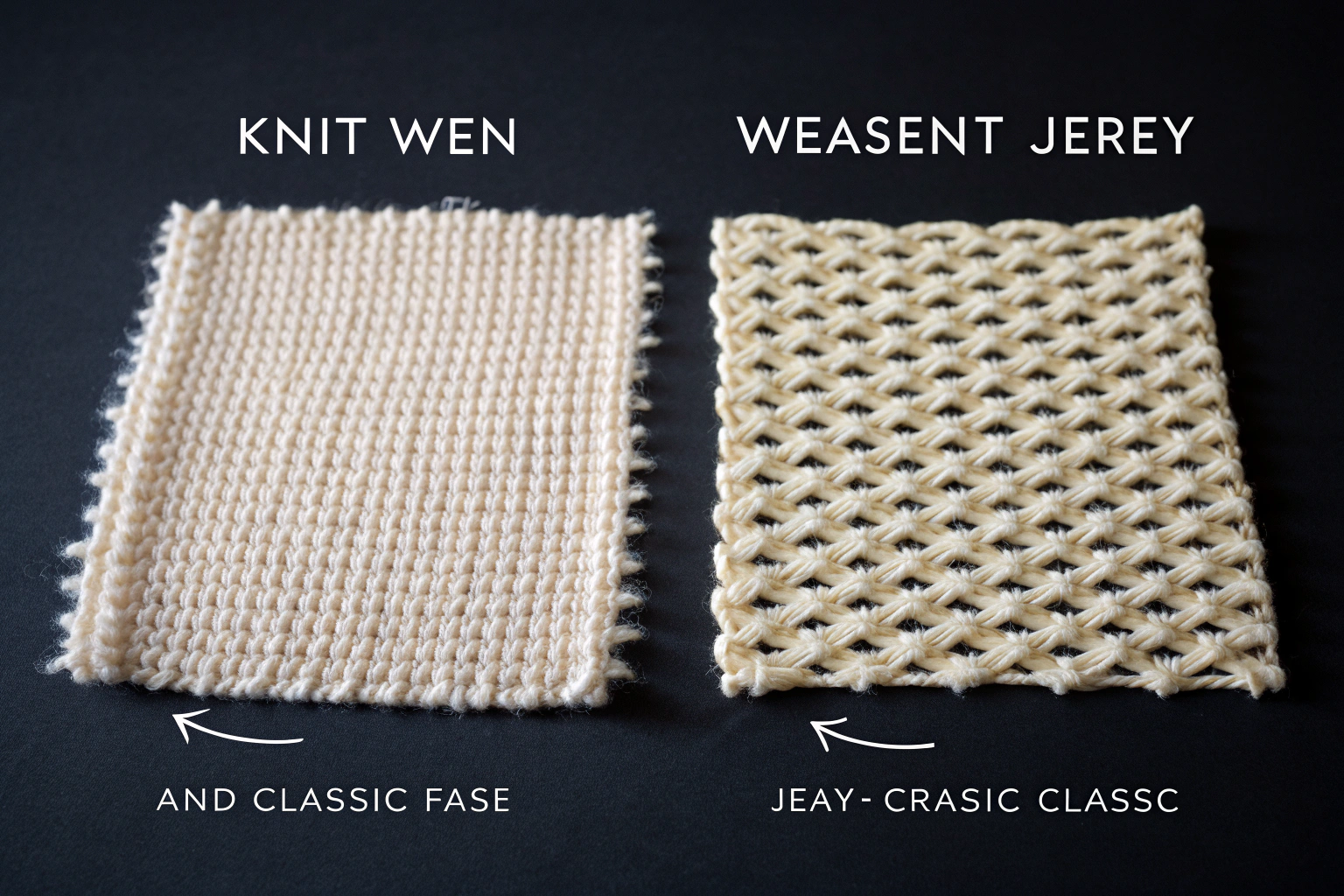

Here's the core truth that clears the fog: "Jersey" specifically refers to a type of knit fabric structure. The term "woven jersey" is a misnomer and a source of immense industry confusion. When people say it, they are almost always mistakenly referring to a lightweight, plain-woven cotton fabric like poplin or voile, which has no inherent stretch. Real jersey is inherently stretchy because of how it's made—by interlooping yarns, not interlacing them.

As a fabric supplier in Keqiao, I correct this misconception daily with designers and buyers. Understanding this fundamental division—knit vs. woven—is more critical than the fiber content when it comes to how a garment will behave, fit, and feel. Let's permanently settle this and explore what real jersey is, what people mistake for jersey, and how to choose correctly for your project.

What is true jersey (a knit fabric)?

True jersey is the foundational knit fabric. It's named after the Isle of Jersey, where it was originally produced for fishermen's sweaters. Its defining characteristic is its construction method: weft knitting. A single continuous yarn is looped horizontally across the fabric width, creating rows of interconnected loops. This looped structure is the source of its magic—and its stretch.

Think of it like a chain-link fence versus a brick wall. The chain links (knit) can move and stretch; the bricks and mortar (woven) are locked in place.

How is jersey knit constructed, and why does it stretch?

Jersey is produced on circular knitting machines (for tubes of fabric) or flatbed machines (for open-width fabric). The basic stitch is the knit stitch, which creates the smooth, flat face of the fabric. The back of classic jersey shows the purl stitch, a bumpier texture.

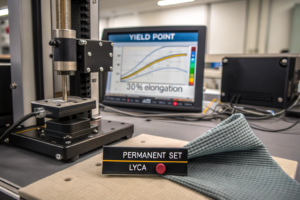

- The Stretch Mechanism: Because each loop can be pulled and distorted into the space of its neighboring loops, jersey fabric has natural give primarily in the widthwise direction (cross-grain). This is its mechanical stretch, present even in 100% cotton jersey.

- Adding Elasticity: When elastane (Lycra®) is added to the yarn (even 2-5%), it introduces powered stretch and, more importantly, recovery—the ability to snap back to its original shape after stretching. This is crucial for fitted garments.

A key specification for any jersey is its GSM (grams per square meter). A lightweight t-shirt might be 140-160 GSM, a medium-weight polo 180-220 GSM, and a heavy sweatshirt 300+ GSM. This tells you more about the fabric's substance than terms like "lightweight" or "heavy."

What are the different types of jersey fabrics?

Not all jersey is created equal. The fiber content and finish create vastly different hands and uses.

- Cotton Jersey: The everyday hero. Breathable, absorbent, soft. Can be combed for extra smoothness and less pilling. Used in most t-shirts.

- Polyester Jersey & Microfiber Jersey: Often used in performancewear and activewear. Offers moisture-wicking, quick-drying, and excellent durability. Has a slicker hand.

- Viscose/Rayon or Bamboo Jersey: Known for its superb drape, silky feel, and vibrant dye uptake. It's more fluid and less elastic than cotton jersey, making it popular for draped tops and dresses. (It can also be heavier and less durable when wet).

- Interlock Jersey: A double-knit variation. It's made with two sets of needles, creating a fabric that is thicker, more stable, and has the same smooth face on both sides. It has less stretch than single jersey and is less likely to curl at the edges. Ideal for polo shirts, babywear, and higher-quality t-shirts.

In our work with a sustainable athleisure brand, we developed a jersey blend of 50% organic cotton, 45% recycled polyester, and 5% Lycra®. This gave the softness of cotton, the performance and eco-cred of rPET, and the essential recovery for yoga wear—showcasing how jersey can be engineered.

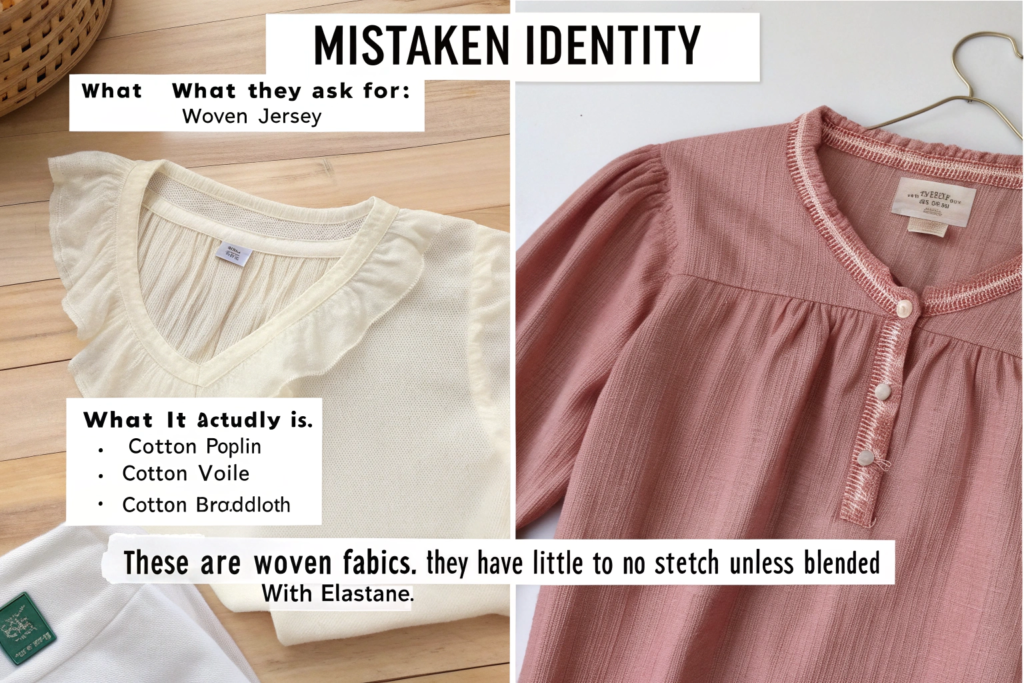

What do people mistakenly call "woven jersey"?

This is where the mix-up happens. When a buyer or designer asks for "woven jersey," they are typically envisioning a lightweight, plain-woven cotton fabric with a soft hand, often used in blouses, shirts, and lightweight dresses. They are describing the fabric's weight and feel, not its construction.

The fabrics they are actually referring to are stable wovens with zero mechanical stretch unless elastane is added.

Is it poplin, voile, or broadcloth?

These are the usual suspects. All are plain weaves but differ in yarn fineness and finish.

- Poplin: A plain weave using fine yarns, often with a slight ridge effect. It is crisp, smooth, and holds a sharp crease. It's what classic dress shirts are made from. When made in lightweight cotton, it can feel soft and be mistaken for a "woven jersey."

- Voile: A very lightweight, semi-sheer plain weave made from highly twisted yarns. It has a slightly crisp, breezy hand. Used in floaty blouses and curtains.

- Broadcloth: Similar to poplin but with a lighter weight and a softer, more fluid finish (often achieved through calendaring or mercerizing). This is likely the #1 fabric mistakenly called "woven jersey." It's soft, drapes nicely, but is fundamentally a woven.

The critical test: Try to stretch it widthwise. A true woven will have minimal give (maybe 1-3%). A knit jersey will stretch easily 20-50% or more.

Why does this confusion happen in sourcing?

The confusion stems from a few industry habits:

- Historical Branding: Some fabric mills or wholesalers in certain markets have incorrectly labeled lightweight woven cottons as "jersey" for decades, and the misnomer stuck.

- Focus on Hand-Feel: Buyers touch a soft, lightweight broadcloth and associate that feel with the softness of cotton jersey, leading to a verbal mix-up.

- Lack of Technical Clarification: Conversations skip the crucial "knit or woven?" question and jump straight to fiber and weight.

To avoid costly mistakes, always ask for the fabric's "construction" first. A reputable supplier will clarify: "This is a knitted cotton jersey" or "This is a woven cotton poplin." At Shanghai Fumao, our spec sheets always lead with Knit/Woven in bold.

How do their properties affect design and manufacturing?

Choosing between a knit (jersey) and a woven (poplin/broadcloth) isn't a subtle adjustment; it's a fundamental decision that ripples through every subsequent step of product development, from pattern-making to the choice of sewing machine. They are different species.

Getting this wrong means patterns that don't fit, seams that pucker or pop, and garments that fail in wear.

How does stretch impact pattern making and fit?

This is the most significant implication.

- Knit (Jersey) Patterns: Are drafted with negative ease. The pattern is deliberately cut smaller than the body measurements because the fabric will stretch to fit. The amount of negative ease depends on the jersey's stretch percentage (e.g., a 25% stretch fabric requires a specific grade rule). Patterns are simpler, with fewer darts, as the fabric contours to the body.

- Woven (Poplin/Voile) Patterns: Are drafted with positive ease or exact measurements. The fabric does not stretch, so the pattern must include enough wearing ease through design elements like darts, seams, and pleats to allow for movement. Fit is achieved through tailoring, not fabric stretch.

Using a woven pattern for a knit fabric will result in a baggy, ill-fitting garment. Using a knit pattern for a woven fabric will result in a garment that is too tight and may rip at the seams.

What are the key sewing and finishing differences?

The machinery and techniques differ completely.

- Sewing Knits (Jersey):

- Needle: Requires a ballpoint or stretch needle. A universal needle will pierce and break the yarns, causing runs.

- Stitch: Requires stitches that stretch with the fabric: zigzag stitch, overlook (serger), or coverstitch. A straight lockstitch will pop under tension.

- Handling: Knits curl at the cut edges and can stretch out while sewing if not handled carefully (using walker feet or tissue paper can help).

- Sewing Wovens (Poplin, etc.):

- Needle: Uses a sharp universal or microtex needle.

- Stitch: Standard straight lockstitch is perfectly adequate.

- Finishing: Woven seams must be finished to prevent fraying (serged, pinked, bound). Knit seams do not fray, but are serged for neatness and stretch.

A factory set up for wovens cannot efficiently sew knits without retooling and retraining, and vice versa. This is a critical factor in selecting a manufacturing partner.

How to source and specify correctly to avoid mistakes?

The onus is on you, the buyer or designer, to use precise language and demand precise information. Assumption is the mother of all sourcing errors, especially here. Building a failsafe specification habit will save you time, money, and frustration.

Your goal is to eliminate all ambiguity from your requests and approvals.

What terminology should you always use?

Banish the term "woven jersey" from your vocabulary. Instead, be specific:

- If you want stretchy t-shirt material: Ask for "Cotton Knit Jersey" or "Single Jersey." Specify GSM and stretch/recovery percentage if known.

- If you want a crisp, non-stretch shirting: Ask for "Cotton Poplin" or "Cotton Broadcloth." Specify weight (e.g., 120 GSM) and finish (e.g., mercerized).

- If you want a soft, drapey woven for a blouse: Ask for "Lightweight Cotton Voile" or "Mercerized Cotton Broadcloth."

Always lead with the construction (Knit or Woven), then the fiber (Cotton, Polyester, etc.), then the specific type (Jersey, Interlock, Poplin, Voile).

What must be on your fabric specification sheet?

A tech pack for fabric should leave no room for interpretation. For any fabric, include:

- CONSTRUCTION: [ ] Knit [ ] Woven (Circle one prominently).

- If Knit: Type: Single Jersey / Interlock / Rib / etc.

- If Woven: Weave: Plain (Poplin) / Twill / Satin / etc.

- Fiber Content: e.g., 100% Cotton, 95% Cotton 5% Elastane.

- Weight: GSM (e.g., 180 GSM) or oz/yd².

- For Knits: Stretch & Recovery Percentage (e.g., Widthwise stretch: 30%, Recovery: >95%).

- For Wovens: Thread Count (optional but helpful, e.g., 120x80).

- Finish: e.g., Mercerized, Brushed, Peach Finish.

When in doubt, request a physical swatch and physically test it. Stretch it yourself. Does it recover? Look at the edge—does it curl (indicative of knit) or fray (indicative of woven)?

Conclusion

The difference between knit jersey and what is often mislabeled as "woven jersey" is foundational, not semantic. True jersey is a knitted fabric, defined by its interlooped construction that grants inherent stretch and recovery, revolutionizing pattern-making and enabling comfort-focused apparel like t-shirts and activewear. The so-called "woven jersey" is, in fact, a category of lightweight, plain-woven fabrics such as poplin, voile, or broadcloth—materials prized for their crispness or soft drape but possessing no mechanical stretch. Confusing these two leads to catastrophic errors in design, fit, and manufacturing, as they demand completely different approaches to patterning, sewing, and finishing.

Clarity in sourcing is non-negotiable. By eliminating the misleading term "woven jersey" from your lexicon, specifying construction (knit vs. woven) first, and demanding detailed technical data—especially stretch percentages for knits—you ensure the fabric you source is the fabric you need. This precision transforms potential production disasters into smooth, successful product development.

Whether you need the comfortable stretch of true cotton jersey or the crisp structure of a cotton poplin, specifying correctly is the first step. At Shanghai Fumao, we provide clarity and quality across both worlds, from a vast library of knit jerseys to a full range of precise woven shirting fabrics. Let's ensure your next project starts on the right thread. Contact our Business Director, Elaine, for expert sourcing guidance: elaine@fumaoclothing.com.