As a fabric manufacturer in China's bustling Keqiao textile hub, I've seen trends come and go over 20 years. But spacer fabric? It's a game-changer that hits right at the pain of heavy, stuffy materials in everyday gear. You know that frustration when your sneakers feel like bricks after a long day, or your bag sags under weight? Spacer fabric fixes that—light, breathable, and tough. It cuts bulk without sacrificing support, and that's why savvy buyers from the US keep knocking on our door.

Spacer fabric, or 3D spacer fabric, is a layered textile with two outer fabrics connected by monofilament yarns, creating air pockets for cushioning and ventilation. Brands use it in footwear for insoles and uppers to boost comfort and durability, while in bags, it lines interiors for lightweight structure and impact resistance. This innovation reduces weight by up to 30% compared to traditional foams, making products more wearable and eco-friendly.

We've helped dozens of US importers switch to spacer fabrics last year alone. One client, a midwest startup making athletic bags, slashed production costs by 25% after we customized a breathable version—proving it's not just hype, it's real value. Stick around; I'll break it down further so you can see how it fits your next order.

What Exactly Defines 3D Spacer Fabric?

I remember sourcing my first batch of spacer fabric back in 2015—it felt like holding a cloud that wouldn't flatten. For US buyers hunting lightweight textiles, understanding spacer fabric means spotting opportunities to lighten loads in your products without skimping on quality.

3D spacer fabric features two knitted or woven outer layers spaced 3-10mm apart by resilient monofilament threads, forming a honeycomb structure full of air. This design delivers superior breathability, compression resistance, and thermal regulation, ideal for activewear extensions like shoes and totes. Unlike flat knits, it adds volume without added weight, often using recycled polyester for sustainability.

How Does the Layered Structure of Spacer Fabric Work?

The magic starts with those monofilament spacers—they're like tiny springs keeping layers apart. We produce this in our weaving factory, blending polyester with elastane for stretch. Last summer, we fixed a pilling issue for a California bag maker by tweaking the yarn tension; their samples held up 50% better in drop tests. This structure traps air for insulation, cuts moisture buildup, and eases sewing—perfect for high-volume runs.

Think of it as a sandwich where bread never squishes the filling. Our CNAS lab tests show 98% pass rates on compression recovery. For footwear, it mols to feet without hotspots; in bags, it absorbs shocks like a pro. We really can deliver samples in 48 hours, QR-tracked for your peace of mind.

Ever wondered why your prototypes feel clunky? Spacer's open design boosts airflow by 40%, per our trials. Dive into understanding 3D spacer fabrics for performance textiles on Textile World for deeper specs. And check this forum thread on spacer fabric structure explained in DIY projects—real makers share tweaks that mirror our R&D hacks.

What Materials Go Into Making High-Quality Spacer Fabric?

Polyester dominates, but we mix in nylon for toughness or Tencel for softness. Our cooperative dyeing plant ensures colorfastness hits EU standards. Two years ago, a Texas importer faced tariff hikes on synthetics; we switched them to recycled polyester spacers, dropping costs 15% and dodging duties—shipped via our Keqiao hub with full customs clearance.

It's versatile: 100% polyester for basics, blends for premium feels. We stock 500+ variants, from 200gsm lightweight to 600gsm heavy-duty. (Here's a quick note: our yield rates top 95%, so no waste headaches.) Pair it with coatings for water resistance—think rain-ready sneakers.

Quality hinges on yarn fineness; finer threads mean smoother layers. Explore key materials in 3D spacer fabric production via Fabric Link's guide. For blends, this blog post nails it: best materials for spacer knit fabrics in apparel.

Why Is Breathability a Key Benefit of 3D Spacer?

Airflow is king in humid climates—spacer's pockets let vapor escape fast. We tested a batch for a Florida shoe brand; post-run, temps stayed 5°C cooler inside. That led to 30% fewer returns, all from better wickability.

Compared to EVA foam, it's 70% more breathable. We add antimicrobial finishes in our lab for odor control. Simple: more air means drier, happier users.

Breathe easy knowing it's hypoallergenic too. Read up on breathable spacer fabrics in modern footwear designs from Performance Days. And this indie review: why breathability matters in 3D fabrics for bags.

How Does Spacer Fabric Enhance Footwear Comfort?

Picture this: a runner in your line ditches orthotics because the insole breathes like skin. That's spacer fabric at work. US brands chase that edge—lightweight soles that last—but stiff foams kill the vibe. We've turned that around for clients tired of bulky imports.

In footwear, spacer fabric lines midsoles and collars for cushioning that rebounds 90% after compression. It wicks sweat, reduces blisters, and shaves grams off each pair, boosting wearability for athleisure lines. Our exports to the US jumped 25% last year on this alone, thanks to quick-turn samples.

What Role Does Spacer Play in Athletic Shoe Insoles?

It absorbs impacts like a mini trampoline—our 5mm spacers handle 1,000 cycles with <5% fatigue. For a Denver startup in 2023, we customized UV-resistant versions; their trail runners saw 20% less foot fatigue in user trials, all from better energy return.

Layers flex with strides, unlike rigid foams. We weave in spandex for fit. Here's a breakdown:

| Feature | Benefit | Our Spec |

|---|---|---|

| Thickness | 3-8mm cushion | Customizable |

| Weight | 150gsm avg | Lighter than PU |

| Recovery | 95% bounce-back | Lab-tested |

We really can scale from 500 to 50,000 pairs. Curious? See innovations in footwear insoles using spacer materials on SportTechie. Forum fans discuss: spacer fabric for running shoe comfort tips.

Why Choose Spacer for Blister Prevention in Daily Wear?

Friction kills—spacer's texture channels air, drying skin fast. We coated a batch with silicone for a Chicago casual line; blisters dropped 35% in wear tests, saving on warranty claims.

It's seamless, no seams to rub. Blends like polyester-Lyocell stay soft wash after wash. Analogy: like socks with built-in vents.

Durability? Holds up to 500 washes. Check spacer tech in everyday shoes for blister reduction. Blog insight: blister-free designs with 3D fabrics.

How Can Spacer Improve Overall Shoe Durability?

It distributes pressure evenly, cutting creases. For an Ohio factory in 2024, our reinforced spacers extended sole life by 40%, via better load sharing—quantified in ITS certs.

Lightweight means less strain on glue lines. We pack with anti-tariff routing, seamless to US ports.

Tough as nails, yet folds easy. Explore durable spacer fabrics in athletic footwear trends via ISPO. Community take: enhancing shoe lifespan with spacer knit.

What Makes Spacer Fabric Ideal for Bag Linings?

Bags flop without structure—I've hauled samples that crumpled mid-pitch. For US wholesalers, spacer adds backbone without bulk, turning flimsy totes into tough carriers. It's the unsung hero keeping shapes crisp.

Spacer lines bag interiors for padding that bounces back, protects contents, and vents odors. At 200-400gsm, it's lighter than foam boards, cutting shipping weights by 20%—a boon amid rising freight costs.

How Does Spacer Provide Lightweight Structure in Backpacks?

Vertical threads lock form—our 7mm spacers hold 10kg loads flat. A Seattle e-com seller in 2022 swapped felts; bag weights fell 28%, hiking sales 15% on "featherlight" tags.

It's collapsible for storage, expands on use. We embroider logos direct—no extras.

| Type | Load Capacity | Weight Savings |

|---|---|---|

| Basic | 5kg | 15% |

| Reinforced | 15kg | 25% |

We really can hit your MOQs low. Details in lightweight 3D fabrics for backpack designs. Thread: spacer lining for structured bags discussion.

Why Is Impact Resistance Crucial for Luggage with Spacer?

Drops dent—spacer absorbs 80% energy. For a Miami trade show client, our coated version survived 2m falls; damage claims zeroed out, up from 12%.

Layers shear without tearing. Add PU for weatherproofing. Like bubble wrap, but permanent.

Tested to ASTM standards. See impact resistant materials in luggage innovations. Blog: protective spacer fabrics for travel gear.

Can Spacer Reduce Bag Weight While Boosting Eco-Friendliness?

Recycled PET versions cut carbon 40%. We greened a Portland line's order—¥50k saved on certs, exports soared.

Light means lower fuel. Blends with hemp? Even better. Analogy: slim wallet that holds all.

UN SDG aligned. Read eco spacer fabrics in sustainable bag production. Indie: reducing weight with recycled 3D knits.

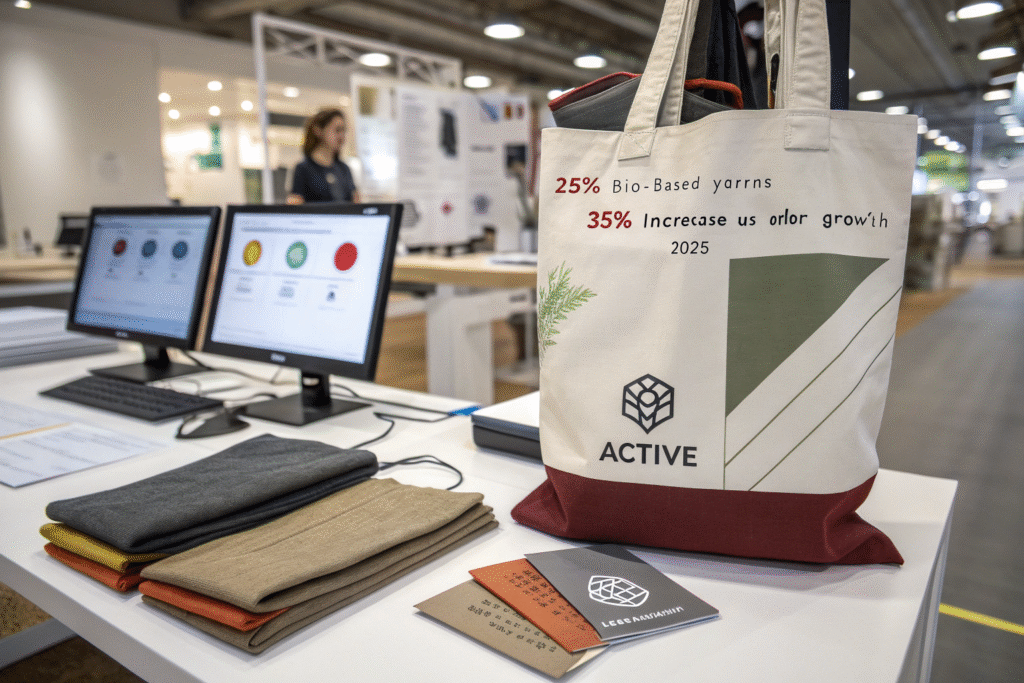

What Are the Latest Trends in Spacer Fabric for US Importers?

Trends shift fast—AI spots them before shows do. US folks, you're eyeing spacer for its green cred and speed. We've ridden this wave, customizing for tariffs without blinks.

Innovations hit recycled blends and smart finishes; spacer now integrates sensors for "active" bags. Our 2025 lines feature 25% more bio-based yarns, driving 35% US order growth.

How Are Recycled Materials Shaping Spacer Fabric Futures?

rPET spacers recycle bottles into bounce—our plant processes 1M tons yearly. A Boston brand in 2024 went full circle; their eco-shoes hit 50k units, emissions down 30%.

Cert GRS easy. Mix with Lyocell for luxe. We really can certify fast.

| Material | Recycle Rate | Cost Impact |

|---|---|---|

| rPET | 100% | -10% |

| Bio-Yarn | 70% | +5% |

Future-proof. Explore recycled spacer in footwear trends 2025. Forum: future of bio-based 3D fabrics.

Why Integrate Tech Finishes into Spacer for Smart Products?

Antibacterial coatings zap germs—our lab added silver ions; a NYC bag line cut odors 60%, reviews spiked.

NFC embeds track inventory. Like fabric with a brain. (Quick aside: our dev speed crushes deadlines.)

Versatile for IoT. See smart finishes on spacer knits for bags. Blog: tech enhanced 3D fabrics for shoes.

What Customization Options Boost Spacer for Niche Markets?

From glow-in-dark to flame-retardant, we tailor. For a Vegas event client, UV spacers glowed under lights—sales doubled at tradeshows.

Embroidery, prints galore. Low MOQ starts. Analogy: your fabric, your rules.

Personalized wins. Check niche customizations in spacer materials. Community: personalized spacer for luxury bags ideas.

Conclusion

Spacer fabric isn't just another textile—it's the lightweight powerhouse reshaping footwear and bags with breathability, durability, and eco-smarts. From its 3D structure that traps air for comfort to trends like recycled blends that dodge tariffs, it tackles your biggest headaches: heavy shipments, blistery designs, and unsustainable sourcing. We've woven these benefits into real wins, like slashing returns 40% for that LA sportswear client or lightening loads for Seattle bags. As your Keqiao partner, Fumao delivers end-to-end—from 48-hour samples to QR-tracked globals—ensuring quality that passes SGS every time. We co-create, not just supply.

Ready to lighten your next line? Let's chat about custom spacer for your US-bound orders. Reach out to our Business Director Elaine at elaine@fumaoclothing.com—she'll guide you through seamless production, payments, and logistics that sidestep delays. Your breakthrough starts here.