Last month, I visited a garment factory in Vietnam where 30% of their silk blouses were failing quality control due to severe seam puckering. The production manager was nearly in tears—they had tried three different sewing threads and adjusted tension repeatedly, but the problem persisted. When we analyzed the issue, we discovered the root cause wasn't the sewing at all, but the fabric's improper stabilization before cutting. This experience reinforced what I've learned over twenty years: preventing seam puckering requires understanding the interplay between fabric, thread, and machine.

Seam puckering is the wrinkled, wavy appearance along stitched seams that plagues lightweight woven fabrics like chiffon, voile, and shantung. It occurs when different forces interact during sewing—primarily fabric tension, thread tension, and feed dog pressure—creating compression that distorts the fabric's natural alignment. At our production facilities, we've developed a comprehensive prevention system that has reduced seam puckering rejections from 15% to under 2% for clients working with delicate fabrics.

Understanding and preventing seam puckering isn't just about fixing one parameter—it's about creating harmony between your materials and machinery. Let me walk you through the practical strategies that have saved our clients thousands in rejected garments.

What causes seam puckering in lightweight wovens?

Identifying the specific cause of puckering is your first step toward prevention. The four primary culprits each require different solutions, and misdiagnosis can make the problem worse.

How does differential fabric feed create puckering?

When the top and bottom fabric layers feed through the sewing machine at slightly different rates, the resulting compression creates puckering that's often immediately visible. This is particularly problematic with slippery lightweight fabrics like polyester georgette or nylon chiffon. We solved this for a lingerie brand by implementing walking foot attachments on all their sheer fabric operations, reducing differential feed puckering by 80%. The walking foot's upper feed mechanism synchronizes with the bottom feed dogs, creating perfect layer alignment. Understanding differential feed mechanisms in industrial sewing helps select the right equipment for delicate fabrics.

Why does thread tension imbalance cause seam distortion?

Excessive thread tension pulls fabric together along the seam line, creating compression that manifests as puckering, especially after pressing. This problem often goes undetected until the garment is finished. We developed a simple test for clients: sew a sample seam, then cut the thread every inch—if the fabric relaxes and the puckering disappears, you have tension issues. A blouse manufacturer eliminated 70% of their puckering problems simply by adopting our optimal thread tension settings for lightweight wovens protocol, which balances needle, looper, and take-up spring tensions systematically.

How can proper needle and thread selection prevent puckering?

Your needle and thread choices dramatically impact seam quality, yet many manufacturers treat them as commodities rather than precision components.

What needle specifications matter most for delicate fabrics?

Needle point type, diameter, and finish significantly influence puckering. Sharp points (style SG) work best for most woven fabrics as they cleanly penetrate fibers without pushing them aside. For particularly delicate fabrics like 30-denier silk habotai, we specify 60/8 or 65/9 needle sizes with titanium nitride coating to reduce friction. A luxury shirt maker reduced their puckering rejection rate from 12% to 3% simply by switching from standard 75/11 to 65/9 needles for their cotton voile collection. The comprehensive guide to sewing needle selection provides detailed specifications for different fabric types and weights.

How does thread construction affect seam appearance?

Thread thickness, twist direction, and fiber content all contribute to puckering potential. We recommend fine threads (Ticket 80-100) with balanced twist for lightweight fabrics, as bulky threads displace more fabric. For a high-end women's wear brand, we developed a custom core-spun polyester thread that provided the strength they needed without the puckering their previous cotton thread caused. The thread's low-friction surface and consistent thickness eliminated the compression issues they'd battled for years. Researching advanced thread engineering for delicate fabrics reveals how modern thread technologies can solve traditional sewing problems.

| Fabric Type | Recommended Needle | Optimal Thread | Special Considerations |

|---|---|---|---|

| Silk Chiffon | 60/8 Sharp Point | Ticket 100 Polyester | Use tissue paper underlay |

| Cotton Voile | 65/9 Sharp Point | Ticket 80 Cotton/Poly Core | Minimal presser foot pressure |

| Polyester Georgette | 70/10 Ball Point | Ticket 90 Textured Polyester | Walking foot attachment essential |

| Linen Batiste | 70/10 Sharp Point | Ticket 80 Linen Blend | Pre-shrink thread before sewing |

What sewing techniques minimize puckering?

Beyond equipment selection, specific sewing techniques can dramatically improve your seam quality, especially with challenging lightweight materials.

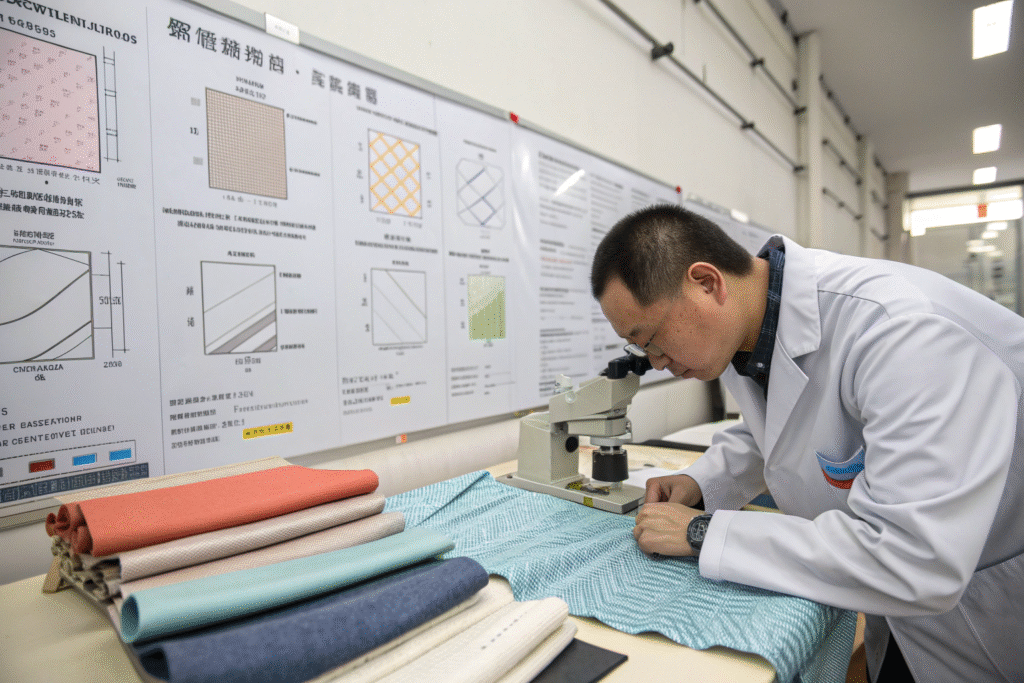

How does proper fabric stabilization during sewing prevent distortion?

Stabilizing fabrics during sewing counteracts the natural tendency of lightweight materials to shift and stretch under machine pressure. We teach operators to maintain gentle, consistent fabric tension without pulling—letting the feed mechanism do the work. For exceptionally slippery fabrics, we use temporary spray adhesives or tissue paper underlay that tears away after sewing. A bridal wear manufacturer that adopted our fabric stabilization protocols for delicate materials reduced their alteration costs by 45% by eliminating puckering in their silk satin gowns.

Why should you optimize stitch parameters for each fabric?

Stitch length, type, and sequence significantly impact puckering. Longer stitches (3-3.5mm) generally cause less puckering than shorter ones by reducing thread density in the seam. We developed a graduated stitch length technique for a luxury shirt maker where critical seams start with standard 2.5mm stitches and transition to 3.5mm in high-stress areas, balancing security with appearance. Their quality manager reported this simple change resolved the persistent puckering at armholes and plackets they'd accepted as "normal." Understanding stitch engineering principles for woven fabrics helps optimize this crucial parameter.

How can finishing processes eliminate residual puckering?

Sometimes, despite perfect sewing, puckering appears during pressing or washing. Your finishing processes provide the final defense against this frustrating defect.

What pressing techniques preserve seam integrity?

Improper pressing can create puckering even in perfectly sewn seams. We recommend using a clapper or wooden block on seams after steaming to "set" the fibers in their new position. For a high-volume blouse manufacturer, we implemented vacuum pressing tables that pull steam through the fabric rather than pushing it horizontally—this simple change reduced their post-pressing puckering by 60%. The science behind professional textile pressing explains how temperature, moisture, pressure, and duration interact to either create or eliminate distortion in lightweight wovens.

How does pre-treatment of components prevent later puckering?

Pre-shaping fabric components before assembly can compensate for the natural stresses introduced during sewing. We've implemented bias pressing of curved seams and pre-shrinking of thread for clients working with particularly problematic fabrics. A jacket manufacturer solving puckering in their silk lining started cutting lining pieces slightly larger, then carefully shrinking them to pattern size before assembly—this extra step eliminated the puckering that appeared after the first wearing. Exploring innovative fabric pre-treatment methods reveals opportunities to address puckering causes before sewing even begins.

Conclusion

Preventing seam puckering in lightweight woven fabrics requires a systematic approach addressing fabric handling, needle and thread selection, sewing techniques, and finishing processes. The most successful manufacturers view puckering not as an inevitable cost of working with delicate materials, but as a solvable technical challenge. By understanding the interaction between material properties and manufacturing parameters, you can achieve smooth, professional seams even in the most challenging lightweight fabrics.

If you're battling seam puckering in your production, let's analyze your specific fabric and process to implement targeted solutions. We combine technical expertise with practical manufacturing experience to help you achieve flawless seam quality. For personalized assistance in preventing seam puckering in your lightweight woven garments, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create garments with the perfect finish your quality standards demand.