As a fabric supplier with over twenty years of experience in China's textile industry, I frequently help clients choose between rotary and flatbed printing. This decision directly impacts your project's cost, quality, and delivery timeline—especially important for U.S.-bound shipments where efficiency matters.

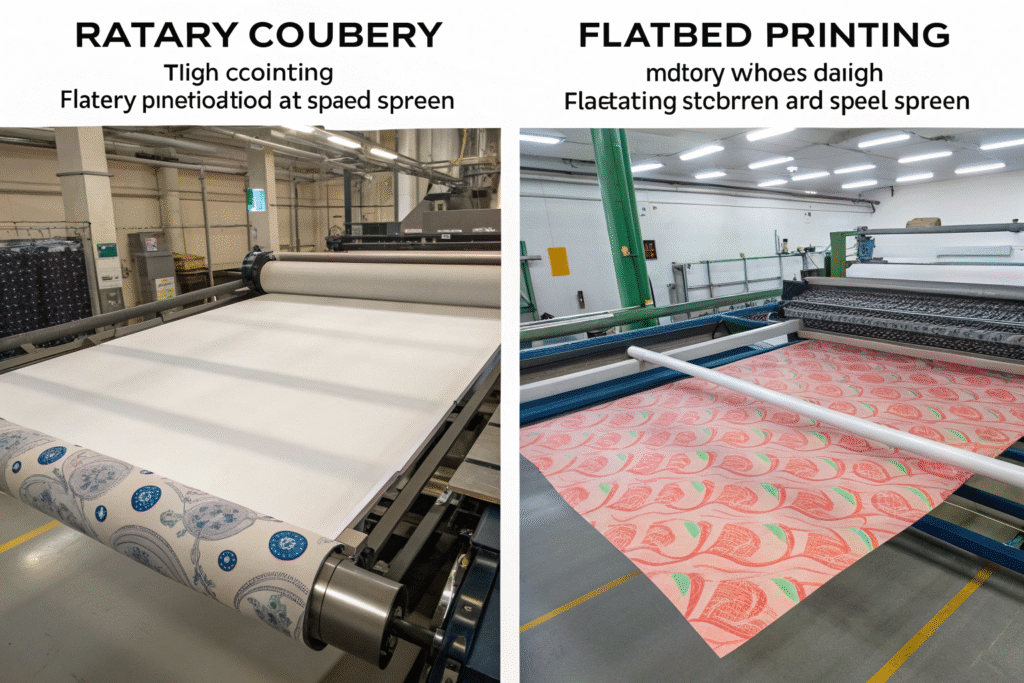

Rotary screen printing uses rotating cylindrical screens to apply color continuously to moving fabric, making it ideal for large orders. Flatbed printing employs stationary screens that lower onto the fabric step-by-step, providing superior detail for smaller batches. Your choice depends primarily on order volume, design complexity, and budget.

Making the wrong choice can result in material waste, budget overruns, and delayed deliveries. Let me break down the key differences to help you select the best method for your needs.

What is the main difference in the printing process?

The fundamental distinction lies in the mechanical operation and ink application method. While buyers often focus on price per meter, the printing process itself significantly influences overall costs and outcomes.

Rotary printing is a continuous process where fabric moves under rotating screens at high speed. Flatbed printing operates intermittently—the fabric stops, a screen lowers to print, lifts up, and the fabric advances to the next position. This core mechanical difference determines production speed, design capabilities, and cost structure.

How does the rotary screen printing mechanism work?

In rotary printing, fabric rolls feed continuously beneath metal cylinders, each etched with part of your design. As fabric moves rapidly, paste pumps inside each rotating cylinder while an internal squeegee forces it through the mesh onto the textile. Multiple cylinders (up to 16) apply different colors simultaneously. This high-speed process suits massive orders, and our partnerships with local dyeing factories ensure quick bulk delivery that meets tight schedules for international clients.

How does the flatbed printing machine operate?

Flatbed printing uses a stationary table where fabric is placed. Flat screens containing mesh stencils position over the material, and a squeegee moves across each screen to transfer ink in a single stroke. After printing, the screen lifts, the fabric advances, and the process repeats. Though slower, this method offers exceptional registration and ink deposition, making it preferred for high-end fashion where sharpness and color saturation are crucial.

Which method delivers superior print quality?

Print quality requirements vary by application. While rotary printing works well for bold patterns, flatbed excels where precision matters most.

Flatbed printing typically achieves sharper detail and richer color saturation because the stationary printing process allows heavier ink application and perfect registration. Rotary printing produces good quality for most commercial applications but may struggle with extremely fine details at high production speeds.

When does flatbed printing achieve sharper results?

Flatbed printing outperforms with designs featuring fine lines, intricate details, or large solid color areas. The stationary process prevents smudging and enables thicker ink layers, creating more vibrant, opaque results. This quality advantage makes it ideal for premium materials like cashmere blends and luxury upholstery fabrics where visual and tactile excellence are paramount.

What are the design limitations of rotary printing?

Rotary printing's high-speed operation can create minor "saw-tooth" effects on straight horizontal lines due to the screen mesh. Extremely fine details may clog screens, and pattern repeat size is limited by cylinder circumference. While modern advancements have minimized these issues, rotary printing remains best suited for commercial applications rather than the most demanding design work.

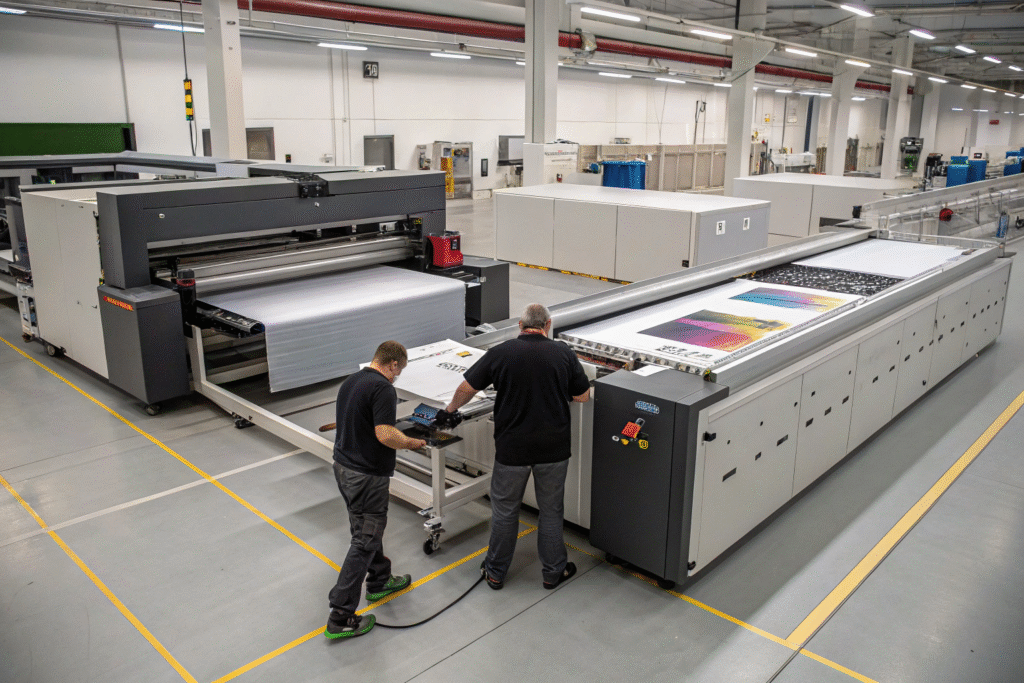

How do cost and production speed compare?

Understanding the cost-speed relationship helps optimize your printing investment across different order volumes.

Rotary printing is significantly faster and more cost-effective for large quantities, achieving speeds exceeding 70 meters per minute. Flatbed printing operates at 5-15 meters per minute but has lower setup costs, making it economical for sampling and short runs.

| Order Size | Recommended Method | Cost Efficiency | Production Speed |

|---|---|---|---|

| 1,000 - 3,000 meters | Flatbed | Higher per meter | Slower |

| 5,000+ meters | Rotary | Lower per meter | Faster |

Why is rotary printing more economical for bulk orders?

Although rotary screens cost 3-5 times more to engrave than flat screens, this investment spreads across thousands of meters, dramatically reducing per-unit cost. The high production speed also lowers labor and overhead expenses. For orders exceeding 20,000 meters, these economies of scale make rotary printing exceptionally cost-efficient.

When does flatbed printing provide better value?

For orders under 5,000 meters, flatbed's lower setup costs typically deliver better return on investment. The reduced initial investment benefits startups, niche brands, and market-testing initiatives. This approach supports agile inventory management while enabling smaller collections to reach market faster with minimal financial risk.

Which printing method is more sustainable?

Environmental impact has become a crucial consideration for global brands, influencing printing method selection.

For small runs, flatbed printing typically generates less waste during setup. For large volumes, modern rotary systems with enclosed paste mechanisms reduce dye liquor waste. Ultimately, sustainability depends more on ink selection and factory practices than the printing method itself.

How do resource requirements differ between methods?

Modern rotary equipment with enclosed systems recirculates ink, minimizing waste, while high-speed operation reduces energy consumption per meter. Flatbed printing's precise application controls material usage effectively. Our partner factories employ advanced water treatment and hold eco-certifications, ensuring responsible production regardless of printing method.

Are eco-friendly inks available for both methods?

Both systems accommodate sustainable ink options, including water-based pigments and low-impact reactive dyes. Our significant green investment ensures we can meet sustainability goals across all printing technologies, aligning with international environmental standards and client expectations for responsible manufacturing.

Conclusion

Selecting between rotary and flatbed printing involves balancing volume needs with quality requirements and sustainability goals. Rotary printing excels in high-volume production with cost efficiency, while flatbed printing offers superior detail for smaller batches.

As an established Asian fabric manufacturer, we provide both printing methods through certified partner factories. Our expertise ensures you receive optimal solutions tailored to your specific requirements. For personalized guidance on your next project, contact Business Director Elaine at elaine@fumaoclothing.com. Let's transform your fabric concepts into market-ready products.