As a fabric manufacturer with over two decades in China's textile industry, I frequently help clients choose between these printing methods. The right choice significantly impacts your design outcome, production costs, and timeline.

The fundamental difference lies in process and application: rotary screen printing uses rotating cylindrical screens for continuous high-speed production, ideal for large orders with repeating patterns. Flatbed printing employs flat screens that lower onto stationary fabric, enabling intricate designs but at slower speeds. Your specific needs for volume, detail, and budget determine the optimal method.

What is the main difference in the printing process?

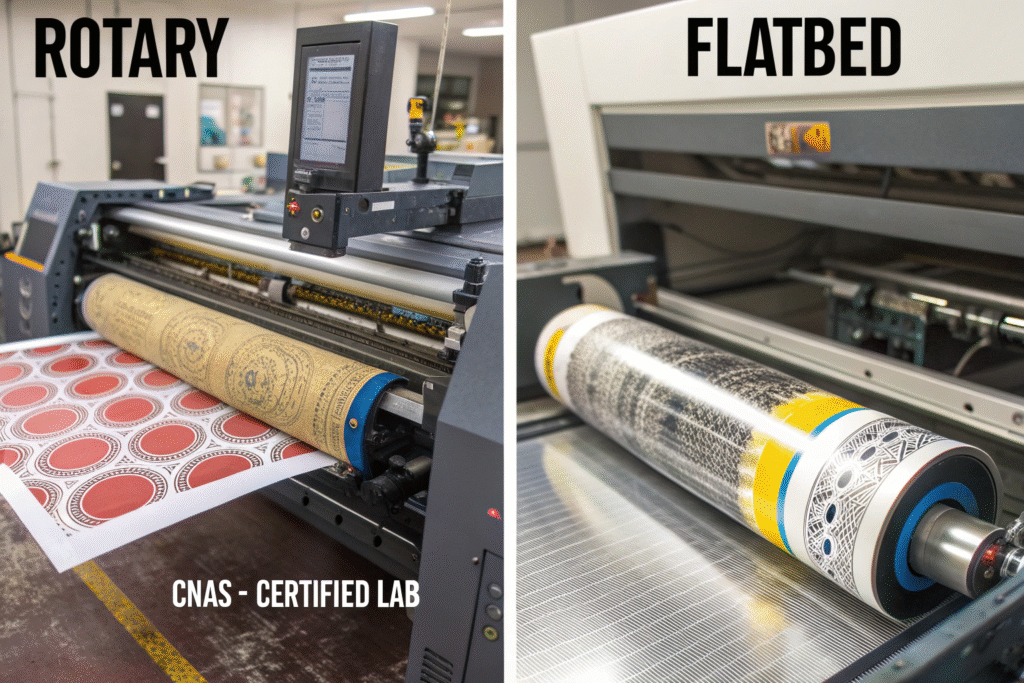

The core distinction begins with the machinery. Rotary systems feature metal cylinders that rotate continuously as fabric moves beneath them. Flatbed systems use stationary screens that lift and lower while the fabric advances intermittently.

Rotary printing excels in speed and volume, with fabric moving constantly under rotating screens. Flatbed printing prioritizes precision, with screens lowering onto stationary fabric sections. This mechanical difference dictates their ideal applications - rotary for mass production, flatbed for complex designs.

How does each method serve different production needs?

Rotary printing's continuous operation achieves speeds exceeding 100 meters per minute, making it perfect for bulk orders. The seamless cylinders ensure consistent pattern repetition across thousands of meters, which is why major brands rely on it for quick bulk delivery. Modern rotary machines handle up to 16 colors while maintaining efficiency.

Flatbed printing accommodates heavier fabrics and specialized materials that wouldn't work with rotary systems. The stationary printing phase allows for thicker ink application and extreme precision, making it ideal for premium fashion and technical textiles requiring perfect design execution.

Which method delivers superior print quality?

Both techniques achieve excellent results but excel in different aspects. Rotary printing provides consistent color coverage across large areas, while flatbed captures fine details and complex graphics.

Rotary printing ensures uniform color application across continuous runs, perfect for solid color fields. Flatbed printing achieves sharper details and photorealistic images through controlled ink deposition. The choice depends on whether your priority is consistency or complexity.

How do technical factors influence final quality?

Ink application methods significantly affect outcomes. Rotary systems use internal squeegee blades to force paste through mesh onto moving fabric, creating thin, even layers. Flatbed systems employ moving squeegees that push viscous ink through high-mesh screens, allowing heavier deposits for special effects and reflective properties.

Screen technology further differentiates results. Rotary's nickel cylinders provide durability for long runs but limit detail. Flatbed's fine mesh screens enable intricate patterns and tiny text reproduction. Our CNAS-certified lab ensures optimal screen and ink combinations for each project's requirements.

Which printing method is more cost-effective?

Cost efficiency depends entirely on order quantity. Rotary printing becomes economical for large runs, while flatbed suits smaller batches despite slower production speeds.

Rotary printing proves cost-effective for orders exceeding 5,000 meters, spreading setup costs across more fabric. Flatbed printing works better for orders under 1,000 meters, with lower initial costs outweighing slower production. This cost structure guides our recommendations for clients at different scales.

How do setup costs and operational value compare?

Rotary printing requires expensive nickel cylinder engraving for each color, justifying high minimum order quantities. This investment pays off through high-speed production and minimal per-meter costs for large quantities.

Flatbed printing involves cheaper screen preparation, reducing barriers for small orders. While slower per meter, it enables market testing and design experimentation without major commitments. Our agile R&D approach helps clients balance these factors based on their business needs.

How to select the right printing method?

The decision involves evaluating your design requirements, order quantity, timeline, and fabric type. Each method serves distinct purposes, and understanding your priorities ensures optimal results.

Choose rotary printing for high-volume production of repeating patterns with solid colors. Select flatbed printing for detailed graphics, specialized effects, or smaller quantities where design complexity outweighs cost concerns. Clear communication of your requirements ensures proper method selection.

What factors ensure optimal method selection?

Begin by discussing your design specifications and quantity needs with your supplier. Request samples from both methods to compare results firsthand. Understand the exact MOQs and production timelines for each approach to align with your schedule.

Consider future scalability and potential design changes. For maximum flexibility in sampling, digital printing offers an alternative without screen requirements. Our integrated supply chain provides all options, with QR code tracking ensuring transparency throughout production.

Conclusion

Rotary and flatbed printing serve complementary roles in textile manufacturing. Rotary excels in efficient mass production, while flatbed delivers premium quality for complex designs. The optimal choice depends on balancing your volume requirements with design ambitions.

At Fumao Textiles, we guide clients through these technical decisions to achieve their specific goals. Our comprehensive services ensure quality execution regardless of method, handling logistics and compliance challenges seamlessly. When ready to advance your fabric printing project, contact Business Director Elaine at elaine@fumaoclothing.com for expert guidance and production support.