If you're sourcing performance fabrics, you've likely heard the term "ripstop." But what exactly makes this material so special, and more importantly, is it the right choice for your next product line? As a fabric manufacturer with over two decades in the textile hub of Keqiao, we often guide clients like you through the intricacies of technical textiles. Understanding the right fabric can be the difference between a product that thrives in the market and one that falls short.

Ripstop fabric is a lightweight, high-strength nylon or polyester material characterized by a reinforced grid pattern of thicker threads. This unique construction makes it highly resistant to tearing and ripping. You should use it in applications where durability, wind resistance, and light weight are critical, such as outdoor gear, sportswear, military equipment, and luggage. Its tear-resistant quality ensures product longevity even under stress.

Choosing the correct fabric is a pivotal decision that impacts your product's performance, cost, and customer satisfaction. Let's dive deeper into the world of ripstop fabric to ensure you have all the knowledge needed to make an informed sourcing decision.

What are the key features of ripstop fabric?

The distinct advantages of ripstop fabric go far beyond its famous name. Many buyers seek "tear-resistant" materials, but they don't always understand the engineering behind that promise. Let's break down the core features that make ripstop a go-to for demanding applications.

The most defining feature is its reinforced grid or box weave pattern. Thicker reinforcement threads are interwoven at regular intervals within a base of finer yarns, creating a structure that effectively stops rips from propagating. This is complemented by its high tensile strength, achieved through the use of strong synthetic fibers like nylon and polyester. Furthermore, manufacturers often apply durable water repellent (DWR) coatings and other functional finishes to enhance its performance.

How does the ripstop weaving technique work?

The magic lies in the specialized loom setup. During weaving, the thicker reinforcement yarns are interlaced in a crosshatch pattern, typically every 5 to 8 millimeters. When a puncture or tear occurs, the rip is prevented from spreading beyond a single small square in the grid. This technique is similar to the safety glass in a car windshield, which cracks but doesn't shatter. We utilize advanced weaving technology to ensure this grid is perfectly uniform, guaranteeing consistent protection across every meter of fabric we produce. The base fabric can be made from various materials, but the principle remains the same: a network of strong threads locking the structure in place.

What are the functional benefits for end-users?

For your customers, the benefits are tangible and directly impact product satisfaction. The primary benefit is extreme durability, leading to a longer product lifespan and reduced returns. Its lightweight nature does not add burden, making it ideal for packable items and activewear. The tight weave also offers inherent wind resistance, a key factor for outdoor apparel. Additionally, when treated with coatings, it becomes water-resistant and quick-drying. These functional perks are why major brands trust this fabric for everything from high-performance outerwear to reliable tactical gear.

What is ripstop fabric made from?

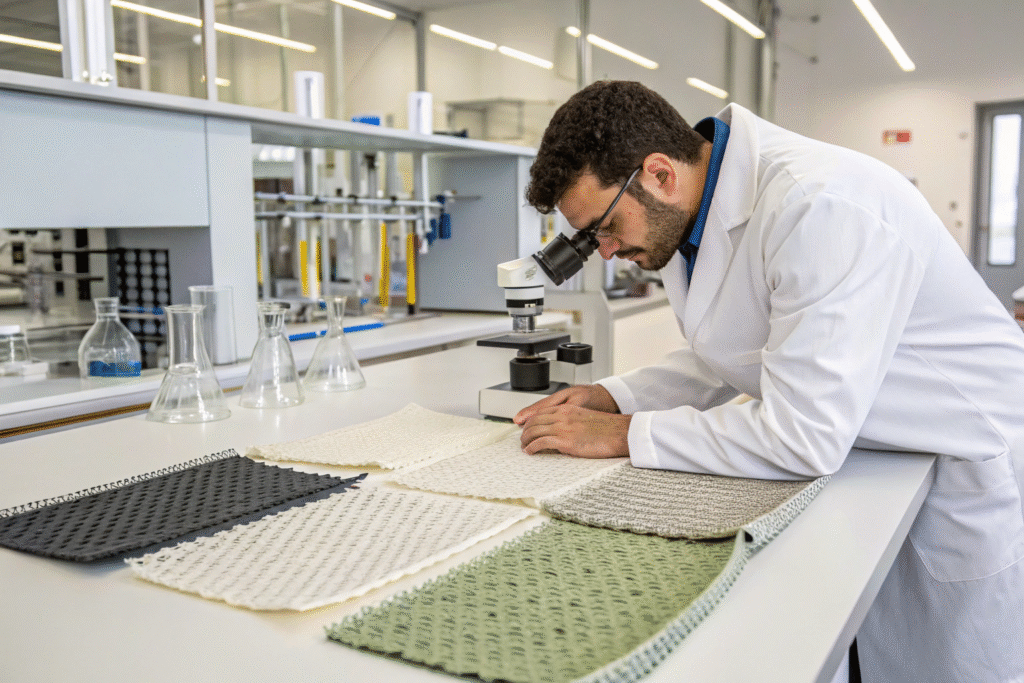

The composition of ripstop fabric is as crucial as its weave. While the grid defines its structure, the fiber content defines its character. Selecting the right base material is a strategic decision that affects everything from cost and feel to performance and sustainability. At our CNAS-certified lab, we rigorously test different blends to match the perfect fiber to your project's needs.

Traditionally, ripstop is made from nylon, which offers an excellent strength-to-weight ratio and good elasticity. However, polyester ripstop is also extremely popular due to its superior UV resistance and quick-drying properties. For more specialized applications, you can find ripstop made with cotton blends for a softer hand feel, or even advanced materials like aramid fibers for inherent flame resistance.

Why choose nylon ripstop?

Nylon ripstop, particularly Type 6,6 Nylon, is renowned for its exceptional toughness and abrasion resistance. It has a slight stretch, which provides greater comfort and freedom of movement for the end-user. This makes it a top contender for heavy-duty applications like camping tents, backpacks, and soft luggage that must withstand rough handling. However, it's important to note that nylon is susceptible to UV degradation over time unless it is specially treated. For us, ensuring consistent quality in nylon yarns is a non-negotiable part of our sourcing process.

Why choose polyester ripstop?

Polyester ripstop has become a dominant force in the market, and for good reason. It boasts high resistance to ultraviolet rays, making it perfect for products that will see prolonged sun exposure, like flags, sails, and outdoor furniture. It is also less absorbent than nylon, meaning it dries faster and is more resistant to water-based stains. From a manufacturing standpoint, our recycled polyester (rPET) ripstop is a major growth area, aligning with the global demand for sustainable textiles without compromising on performance.

What are the common applications of ripstop fabric?

Knowing where to apply this versatile fabric can unlock new product possibilities. Its unique combination of strength and low weight solves design challenges across multiple industries. We've supplied ripstop to clients in over 100 countries, and its uses continue to expand with innovation in coatings and finishes.

The most common applications are in the outdoor and tactical sectors. This includes items like lightweight jackets, windbreakers, hiking pants, camping tents, sleeping bags, and backpacks. Beyond that, it's widely used for flags, banners, sails, kites, and high-performance luggage. Its reliability also makes it a prime choice for military and workwear uniforms, as well as certain types of protective equipment.

How is ripstop used in outdoor and sportswear?

In outdoor apparel, ripstop is the guardian against the elements and rough terrain. It's strategically placed in high-abrasion areas like the shoulders, elbows, and knees of jackets and pants. This reinforces the garment exactly where it's needed without adding bulk or weight. The fabric's breathability, especially in nylon versions, makes it comfortable for high-output activities. We work with sportswear brands to develop custom ripstop solutions that incorporate moisture-wicking and eco-friendly finishes, meeting both performance and sustainability standards.

How is ripstop used in technical and military gear?

For technical and military applications, failure is not an option. Ripstop fabric is the foundation for gear that must perform in life-or-death situations. Its tear resistance ensures that a small snag won't compromise an entire uniform or shelter. In these sectors, the fabric is often treated with advanced finishes for flame resistance, infrared (IR) camouflage, and chemical or biological protection. The demand for these high-specification, functional textiles is a key driver of our R&D department's innovation cycle.

How to choose the right ripstop fabric supplier?

Selecting a supplier is the final, critical step in your ripstop journey. The right partner ensures consistent quality, reliable logistics, and value-added service. The wrong one can lead to production delays, cost overruns, and subpar products. Based on our two decades of experience serving global clients, here are the key factors you must evaluate.

Your choice should hinge on the supplier's technical expertise, quality control systems, and supply chain agility. Don't just focus on the price per meter; consider the total cost of ownership, which includes reliability, compliance, and the supplier's ability to support you from development to delivery. A supplier with a strong R&D department can also help you innovate and stay ahead of market trends.

What quality certifications should I look for?

Certifications are your objective proof of a supplier's commitment to quality. For ripstop fabric, insist on seeing evidence of international testing. Key certifications include the OEKO-TEX Standard 100, which verifies the fabric is free from harmful substances. For specific performance claims like UV protection or water resistance, look for test reports from independent labs like SGS or ITS. Our CNAS-accredited in-house lab provides these reports upfront, giving you peace of mind and streamlining your own compliance process. This rigorous approach is why we maintain a 98% client pass rate.

How does supplier location impact cost and efficiency?

Location directly affects your lead times and logistics costs. Sourcing from a textile cluster like Keqiao, China, provides unparalleled advantages. We are embedded in the world's largest textile ecosystem, giving us direct access to raw materials, specialized dyeing houses, and finishing partners. This proximity drastically reduces our production time, allowing for 48-hour sample development and quick bulk delivery. Furthermore, our established export channels and "Silk Road Keqiao" initiatives ensure resilient shipping from China to the U.S., mitigating the tariff and timeliness concerns that often worry American importers.

Conclusion

Ripstop fabric is a testament to how intelligent textile engineering can create solutions that are both incredibly durable and remarkably lightweight. From its unique reinforced grid structure to its versatile applications across outdoor, tactical, and technical fields, it offers a compelling balance of strength and functionality. The choice between nylon, polyester, or specialized blends ultimately depends on the specific performance requirements and end-use of your product.

Making the right fabric choice is fundamental to your product's success. With a clear understanding of ripstop's features, compositions, and uses, you are now better equipped to specify the ideal material for your next project. However, this knowledge is most powerful when paired with a reliable manufacturing partner who can deliver consistent quality and agile service. If you are looking to develop or source high-performance ripstop fabric for your clothing line or product order, let's start a conversation. For a direct consultation, please reach out to our Business Director, Elaine. She and her team are ready to help you bring your vision to life with professional expertise. Contact Elaine at elaine@fumaoclothing.com.