For manufacturers of outdoor gear and performance apparel, fabric failure due to tearing is a major concern. Ripstop fabric directly addresses this challenge through its unique reinforced grid structure, which prevents small tears from spreading while maintaining minimal weight.

Ripstop is a lightweight, high-strength material distinguished by its grid pattern of thicker threads woven at regular intervals. This construction creates barriers that contain tears within individual squares, making the fabric exceptionally tear-resistant without adding bulk.

What Makes Ripstop Fabric's Structure Unique?

The signature grid isn't a surface treatment but an integral part of the weave. Thicker reinforcement threads are interwoven in both warp and weft directions across a base of finer yarns, typically spaced 5-8 millimeters apart.

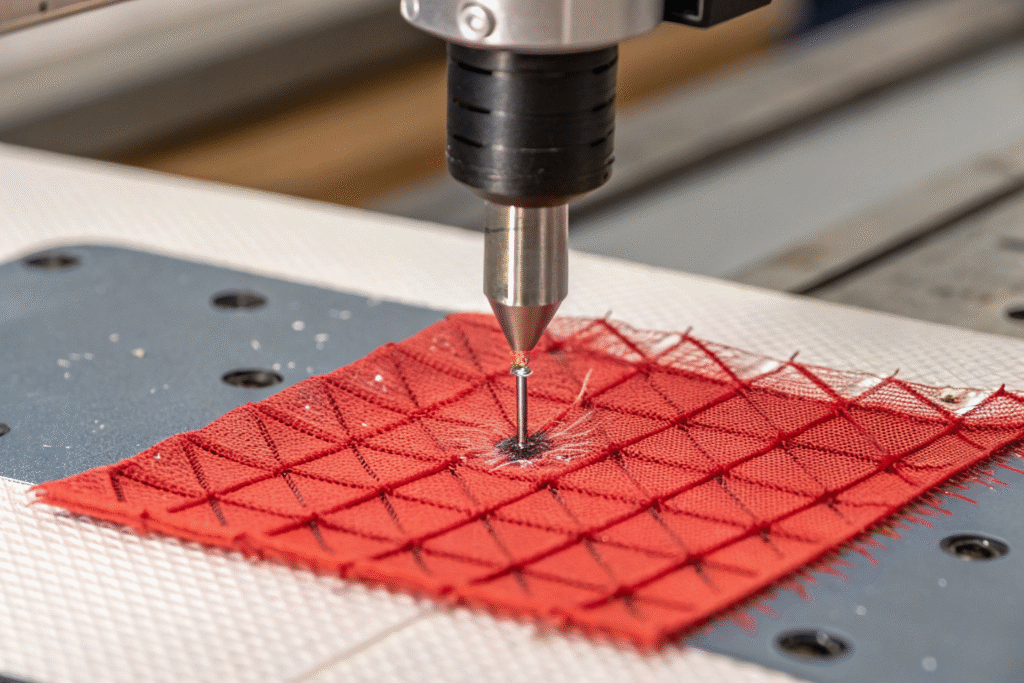

How is the ripstop grid manufactured?

The reinforced grid is created during weaving by programming the loom to interlace thicker threads at regular intervals. These stronger threads act as a built-in safety net, absorbing and distributing stress to prevent localized damage from spreading.

Which fibers are commonly used?

Material selection depends on application requirements. Nylon offers superior strength and elasticity for windbreakers and parachutes, while polyester provides better UV resistance for outdoor applications. Eco-conscious options include recycled polyester versions, and specialized uses may incorporate high-performance fibers like Kevlar.

How Does the Grid Pattern Stop Tears from Spreading?

The reinforced threads create a containment system where damage is limited to individual squares. When stress occurs, the thinner base material typically fails first, but the tear cannot pass through the stronger grid lines.

What's the science behind tear resistance?

The thicker grid threads possess significantly higher tensile strength, acting as barriers that absorb and disperse tearing energy. This localized containment principle enables manufacturers to maintain fabric lightness while ensuring reliability.

Are there variations in grid patterns?

Advanced versions may feature tighter spacing or alternative patterns like box or honeycomb weaves for enhanced protection. The specific configuration is tailored to application needs, balancing protection with weight and flexibility for different technical fabric requirements.

What Advantages Does Ripstop Fabric Offer?

The primary benefit is an exceptional strength-to-weight ratio, providing durability that surpasses standard woven fabrics of equivalent weight. This makes it ideal for weight-sensitive applications like backpacking equipment and ultralight outerwear.

How does it compare to other durable materials?

Unlike heavyweight alternatives like canvas, ripstop delivers comparable tear resistance with substantially less weight and better packability. The following table demonstrates key differences:

| Fabric Type | Weight (gsm) | Tear Strength | Packability |

|---|---|---|---|

| Ripstop Nylon | 30-60 | High | Excellent |

| Canvas | 300-500 | Very High | Poor |

| Standard Polyester | 50-80 | Low-Medium | Good |

What are its limitations?

Potential drawbacks include possible abrasion points at raised grid threads and the visible pattern, which may not suit all aesthetic applications. Additionally, the specialized manufacturing process typically results in higher costs compared to basic weaves.

How to Select the Right Ripstop Fabric?

Choosing the appropriate type requires analyzing your product's specific demands. Consider whether the primary need is abrasion resistance, puncture protection, or general tear resistance with lightweight packability.

What specifications should you verify?

Request technical data including denier thickness, GSM weight measurements, and certified test reports for tear strength (ASTM D2261). Discuss relevant certifications for waterproofing or flame resistance, and inquire about the supplier's quality control procedures to ensure consistent grid integrity.

Why choose an experienced manufacturer?

Partnering with specialists like Fumao Textiles ensures access to technical expertise in fiber selection, weave optimization, and finishing treatments. Our CNAS-accredited laboratory provides reliable performance data, and we manage the complete process from yarn sourcing to final inspection, guaranteeing products meet your exact technical specifications.

Conclusion

Ripstop fabric's grid construction provides an intelligent solution to tear propagation, offering exceptional durability without weight penalties. Understanding its manufacturing process, material options, and selection criteria enables informed decisions for creating reliable, high-performance products.

For developing rugged yet lightweight apparel or equipment, contact our Business Director Elaine at elaine@fumaoclothing.com to explore our ripstop fabric portfolio and discover the ideal material solution for your project.