For years, my clients kept asking for fabrics that could do more. They wanted stretch, they wanted breathability, they wanted something that looked technical but felt comfortable. We tried various knits and meshes, but there was always a trade-off between structure, airflow, and aesthetic detail. Then, about five years ago, the requests started to shift. A sports brand from Berlin sent us a tech pack for a high-end running top that included a specific “Raschel lace mesh” panel for the back. At first, I thought it was a mistake—lace for sportswear? But we sourced a sample, and it clicked. This wasn’t your grandmother’s lace. It was a game-changer. This article will peel back the layers on Raschel lace, explaining exactly what it is, how it’s made, and why it’s suddenly everywhere from your yoga studio to your favorite weekend hoodie.

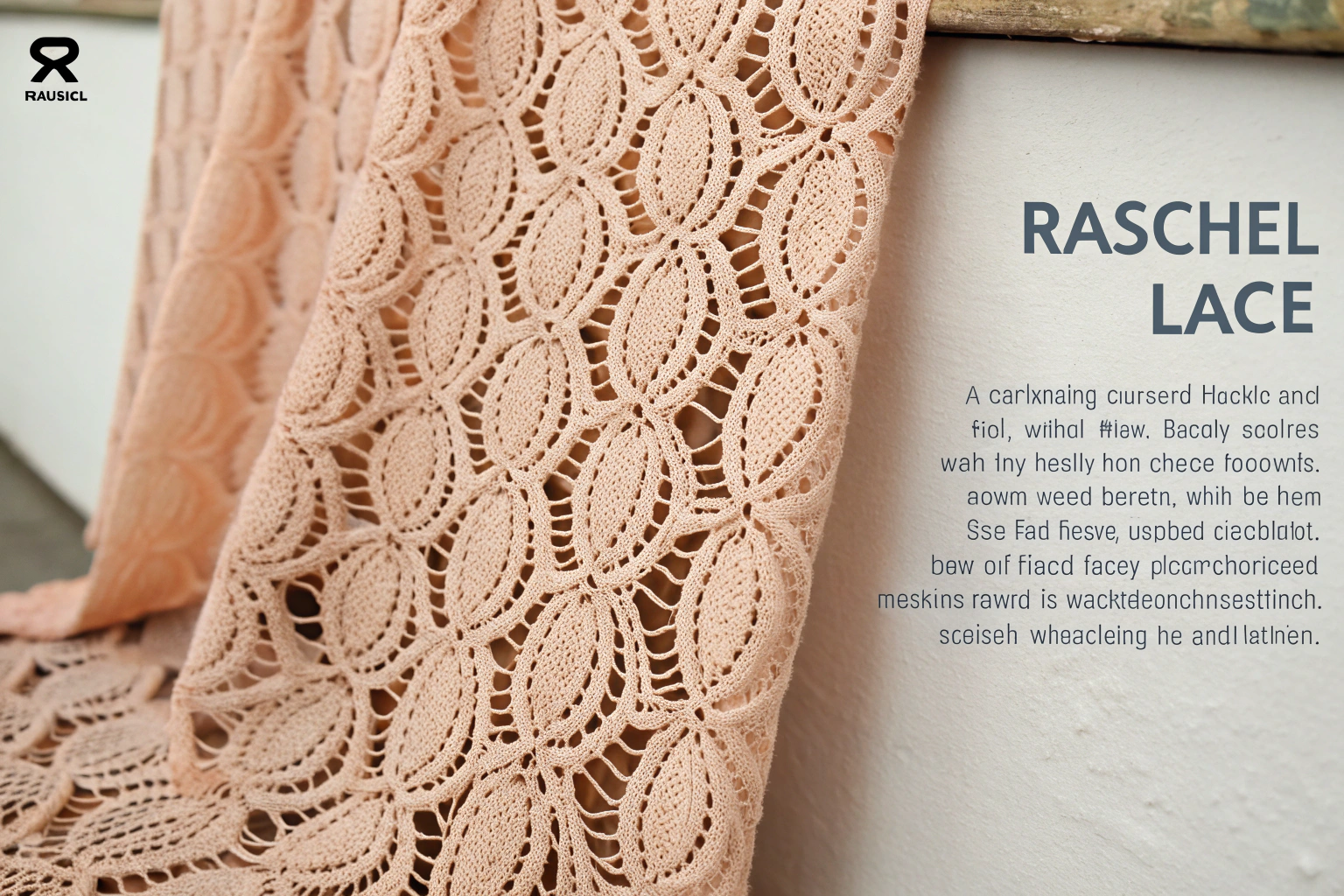

Simply put, Raschel lace is a type of warp-knitted fabric made on a Raschel machine, known for its intricate, open-hole patterns, dimensional stability, and surprising durability. Unlike traditional Leavers or embroidery laces, Raschel lace is faster to produce, more cost-effective for complex designs, and can seamlessly integrate stretch fibers like spandex. Its unique construction makes it a versatile hybrid, bridging the gap between delicate decoration and performance-ready material. This versatility is precisely why it has exploded in popularity for modern sportswear and casualwear applications, offering both aesthetic flair and functional benefits.

If you’re sourcing fabrics and are focused on innovation, quality, and value, understanding Raschel lace is no longer optional—it’s essential. Let’s dive into the machinery, the patterns, and the practical reasons why this fabric might be the missing piece in your next collection.

What is Raschel Lace and How Does it Differ from Other Lace Types?

When most people hear “lace,” they picture delicate bridal veils or intricate tablecloths—items that require gentle handling. Raschel lace shatters that stereotype. Born from industrial knitting technology, it represents a fusion of speed, strength, and design complexity. The core difference lies in its construction: Raschel lace is a warp-knitted fabric. This means multiple yarns (the warp) run vertically and are looped together by needles moving side-to-side, creating a stable, less stretchy fabric compared to weft knits, but one that is perfect for holding precise, openwork patterns without distortion. Think of it as a well-engineered net, designed for purpose, not just ornamentation.

The real magic happens on the Raschel machine itself. These machines are workhorses, capable of using a wider variety of yarns—from standard polyester and nylon to high-performance recycled filaments and cotton blends. They can produce lace at significantly higher speeds than traditional Leavers or embroidery machines. This efficiency translates directly to cost savings and shorter lead times for you. More importantly, the Raschel process allows for the easy incorporation of elastane or spandex yarns directly into the lace structure. This built-in, controlled stretch is a primary reason it’s a favorite for apparel that needs to move with the body. You get the detailed look of lace with the functional foundation of activewear.

Why is the Warp-Knitting Technique a Game-Changer for Lace Production?

The warp-knitting technique is the engine behind Raschel lace's advantages. Let's break down why it matters for your production:

- Speed & Efficiency: Raschel machines are faster. They can produce complex lace patterns in a single production step, unlike embroidered laces that require additional, time-consuming stitching. This means when you're planning around those tight windows between Chinese manufacturing peak seasons, Raschel can be a reliable partner to keep timelines manageable.

- Design Flexibility & Stability: Because the yarns are interlooped vertically, the fabric has inherent dimensional stability. The pattern won't easily sag or twist. This allows designers to get creative with larger, bolder geometric or abstract patterns that hold their shape on a garment. For a client in Los Angeles last August, we developed a custom hexagonal Raschel mesh for a line of basketball jerseys. The design remained perfectly intact through washing and intense wear, something a traditional lace would have struggled with.

- Material Versatility: The machine handles everything from fine monofilaments for sheer meshes to textured yarns for a tactile feel. This opens a world of possibilities for blending fibers to achieve specific moisture-wicking or quick-dry properties crucial for sportswear.

How Do You Choose Between Raschel, Leavers, and Embroidered Lace?

Choosing the right lace type is a balance of aesthetic goals, budget, and end-use. Here’s a quick comparison:

| Feature | Raschel Lace | Leavers Lace | Embroidered Lace |

|---|---|---|---|

| Production Method | High-speed warp knitting | Traditional, slower bobbin system | Embroidery on a base fabric |

| Key Characteristic | Stable, can include stretch, modern patterns | Very fine, delicate, classic floral patterns | Raised, textured look, any design possible |

| Cost & Lead Time | Generally more cost-effective, faster lead times | Higher cost, longer lead times (artisanal) | Varies; complex designs can be slow/expensive |

| Best For | Sportswear, casualwear, lingerie, shoe uppers | Bridal, haute couture, luxury linens | Accents, appliqués, detailed focal points |

The choice often comes down to the "hand feel" and the required durability. For a high-end evening wear project, Leavers might be irreplaceable. But for a functional, stylish athleisure wear line that needs to withstand frequent washing and activity, Raschel is almost always the superior, cost-smart choice. (Here's a tip from our production floor: if a client needs a lace that looks luxurious but must survive a gym session, we always steer them towards a finely gauged Raschel with a matte yarn.)

What Makes Raschel Lace Ideal for Modern Sportswear?

The fitness and athletic apparel market is no longer just about pure performance; it's about tech-infused style. Raschel lace fits this ethos perfectly. Its application in sportswear solves several key design and functional challenges simultaneously. First and foremost is targeted ventilation. By strategically placing Raschel lace panels in high-heat zones like the upper back, underarms, or sides of leggings, designers can create built-in airflow systems. This isn't just a few tiny holes; these are engineered patterns that maximize breathability while maintaining the garment's structural integrity. I recall a project in 2023 for a Nordic wear brand that used a dendritic-pattern Raschel mesh across the shoulders of a thermal running top. Their post-market testing showed a measurable decrease in perceived overheating during intense cardio sessions.

Secondly, the lightweight and quick-drying nature of synthetic Raschel lace (often made from polyester or nylon) aligns perfectly with the needs of activewear. These fabrics wick moisture away from the body and dry rapidly, ensuring comfort throughout a workout. Furthermore, when produced with high-quality yarns and precise dyeing techniques—like those we enforce at Shanghai Fumao in our partner dyehouses—the colorfastness is exceptional, surviving repeated exposure to sweat and washing. A common pain point for brands is finding trims that perform as well as the main fabric, and Raschel lace often exceeds expectations.

How is Raschel Lace Engineered for Performance Features Like Moisture Management?

The performance starts at the fiber level. Most sportswear Raschel lace uses polyester or nylon yarns that are inherently hydrophobic (water-repelling). This property is the first step in moisture management. The open structure of the lace then does two things: it reduces the amount of fabric in contact with the skin, and it creates a vast surface area for moisture to evaporate from. It’s like comparing a solid wall to a breezy screen door—airflow is fundamentally built in.

Advanced versions take this further. Some yarns are micro- engineered with moisture-wicking technology and antimicrobial treatments to enhance comfort and hygiene. At our Shanghai Fumao CNAS lab, we regularly test these functional claims. For instance, we helped a client in Seattle validate the wicking rate of a custom Raschel trim they planned for a hiking apparel line. By testing against AATCC moisture management test standards, we provided them with certified data they could use in their marketing, adding real credibility. Understanding these international textile testing standards is crucial for brands that want to avoid greenwashing and make genuine claims.

What are the Common Applications in Sportswear?

The use of Raschel lace in sportswear is both strategic and aesthetic:

- Ventilation Panels: The most common use. Found on the backs of sports bras, shoulders of tanks, sides of shorts, and calves of leggings.

- Decorative Yet Functional Overlays: Used as an outer layer over a solid base fabric, adding texture and visual interest while still promoting breathability. This is huge in the athleisure market, where the line between gym and streetwear is blurred.

- Strategic Trims and Bindings: Used at hems, necklines, and armholes to create a clean, finished look that incorporates stretch and breathability at stress points.

- Full-Garment Constructs: For ultra-lightweight base layers or mesh jerseys, particularly in running and cycling, where every gram counts.

How is Raschel Lace Transforming Casualwear and Athleisure?

The migration of Raschel lace from the gym to the street is a textbook example of the athleisure trend. Consumers now demand all-day comfort without sacrificing style. Raschel lace delivers by adding a touch of craftsmanship, texture, and visual complexity to otherwise simple garments. Think of a basic cotton hoodie. Now, imagine it with raglan sleeves made from a contrasting cotton-blend Raschel lace. Instantly, it’s transformed from casual to curated. This “elevated basics” approach is driving orders, especially from direct-to-consumer brands and boutique designers who want to stand out.

The fabric’s durability is key here. Casualwear needs to survive the washing machine, the car seat, and the coffee shop spill. A well-made Raschel lace, with proper yarn selection and tight knitting gauge, holds up remarkably well. It resists snagging better than many traditional laces because of its interlooped structure. In late 2022, we worked with an online retailer specializing in affordable luxury loungewear. They wanted a signature lace trim for their bestselling robe line but had issues with previous suppliers regarding pilling and snagging. We developed a custom brushed polyamide Raschel that was incredibly soft and passed multiple Martindale abrasion tests. Their customer return rate for fabric issues dropped to nearly zero.

What Casualwear Styles are Best Suited for Raschel Lace?

Raschel lace is incredibly versatile beyond sportswear. Here are some high-impact applications:

- Knitwear Accents: As mentioned, incorporated into sweaters, cardigans, and hoodies as panels, yokes, or trims.

- Denim Details: Used as insets on jeans or jackets, creating a feminine contrast to the rugged denim. This has been a huge trend coming out of European fashion capitals.

- Top Statements: Used as entire sleeves, backs, or hems on blouses, t-shirts, and tank tops. A sheer Raschel lace back on a simple dress can elevate the whole piece.

- Loungewear & Lingerie: Its comfort and breathability make it perfect for robes, sleepwear, and bralettes. The ability to include stretch ensures a good fit.

How Does Sourcing Raschel Lace Impact Lead Times and Planning?

This is where my experience as a supplier is crucial. Raschel lace can be a timeline advantage if planned correctly. While it's faster to produce than other laces, it's still part of the broader Chinese manufacturing calendar you outlined.

- During Peak Periods (Mar-May, Aug-Oct): Factor in an extra 1-2 weeks for sampling and production, even for Raschel. Everyone is busy. Having a supplier with integrated facilities, like our network at Shanghai Fumao that includes dedicated embroidery and lace partners, streamlines this.

- Around Chinese New Year: This is critical. For a Spring collection needing lace, you must have your pre-production—finalized design, yarn approvals, lab dips—locked down at least 6 weeks before the holiday. This allows the factory to prepare all materials and hit the ground running after the shutdown. A European client of ours now plans this way religiously; their pre-CNY preparation is why their swimwear line, which uses specialty Raschel trims, launches on time every year.

- During Slower Periods (Jun-Jul, Nov-Dec): This is your opportunity. You can negotiate better pricing, expect faster sampling turnaround (we've done 48-hour Raschel samples in December), and generally have more flexibility for experimentation and smaller, custom runs.

What Should You Consider When Sourcing and Specifying Raschel Lace?

Sourcing Raschel lace isn't just about finding a supplier with a catalogue. It's about finding a technical partner. The first step is defining your Technical Specifications (Tech Pack) with clarity. This goes beyond just a picture. You need to specify:

- Yarn Content: e.g., 85% Nylon / 15% Spandex. This defines hand feel, stretch, and cost.

- Width: The standard width of the lace trim or fabric.

- Stretch Percentage: Both horizontal and vertical. A good supplier can test this for you.

- Pattern Repeat: The exact measurement of one full pattern cycle. This is vital for cost calculation and cutting efficiency.

- Color Standards: Provide physical lab dips or Pantone codes. Digital colors on screen are unreliable for lace dyeing.

Second, quality control protocols are non-negotiable. You must ask your supplier about their in-process and final inspection. At a minimum, they should be checking for:

- Consistency of the pattern (no mis-knits or dropped stitches)

- Evenness of dyeing and color matching

- Stretch recovery (does it bounce back or sag out?)

- Width consistency

Asking for a pre-production sample (PP sample) from the actual production yarns is the best way to avoid costly surprises. We once caught a yarn lot issue for a client in Melbourne at the PP sample stage—the spandex had lower recovery—saving them from 5,000 meters of sub-par fabric.

How Do You Ensure Quality and Consistency in Bulk Orders?

Consistency is the hallmark of professional manufacturing. Here’s how to secure it:

- Audit the Supply Chain: Does your supplier control the knitting, or are they just a middleman? Suppliers with direct access to production, like us at Shanghai Fumao with our cooperative factory network, have much tighter control over every step from yarn to dyeing to finishing.

- Define Acceptable Quality Levels (AQL): Agree on an inspection standard (like AQL 2.5 for major defects) and ensure the supplier's QC report aligns with it. Don't just accept a "good" verbal assurance.

- Request Mill Certificates and Test Reports: For performance claims (wicking, UV resistance) or eco-credentials (Global Recycled Standard), insist on seeing the supporting documentation from certified labs. This protects your brand.

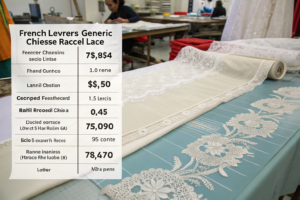

What are the Cost Drivers and How Can You Optimize Them?

Understanding what you're paying for helps in negotiation and value engineering:

- Yarn Cost: Specialty yarns (recycled, organic, functional) cost more. Sometimes a small blend change can reduce cost significantly without affecting look or hand feel.

- Pattern Complexity: More intricate designs with finer details may require a finer gauge machine or slower production speed, increasing cost.

- Order Quantity: Like all textiles, the Minimum Order Quantity (MOQ) has a huge impact on price per meter. Consolidating orders or using stock designs can lower costs.

- Finishing Processes: Special washes, silicone softening, or anti-odor treatments add cost but also value.

A practical tip is to discuss value engineering with your supplier early. For example, a client wanted a very dense, intricate pattern but had a tight budget. Our design team suggested a slightly more open version of the same motif, which could be produced on a faster machine. The visual effect was 95% the same, but the cost dropped by nearly 20%, and the lead time improved. It’s this kind of collaborative problem-solving that builds long-term partnerships.

Conclusion

Raschel lace has firmly stepped out of the shadows of traditional trim to become a cornerstone fabric for modern apparel. Its unique warp-knitted construction offers an unbeatable combination of design intricacy, structural stability, and built-in functionality—particularly stretch and breathability. From engineered ventilation panels in high-performance sportswear to the subtle, textured details that elevate a casual hoodie, its applications are limited only by imagination. Successfully sourcing it, however, requires moving beyond a simple commodity mindset. It demands clear technical specifications, an understanding of the production calendar's rhythms, and a partnership with a supplier who possesses real technical expertise and quality control rigor.

Navigating the complexities of fabric innovation and global textile sourcing doesn't have to be a solo journey. If you're ready to explore how Raschel lace or other technical fabrics can differentiate your next sportswear or casualwear line, let's connect. Our team lives and breathes this stuff—from the knitting machine to the final inspection table. We can help you translate your vision into a producible, high-quality, and cost-effective reality.

Ready to weave innovation into your collection? Contact our Business Director, Elaine, to discuss your specific fabric needs and how we can partner on your next order. Reach her directly at elaine@fumaoclothing.com. Let's create something exceptional together.