Powernet fabric is a specialized material. I frequently discuss it with international clients. Many buyers seek quality fabrics from China. They want cost-effective solutions. Powernet often comes up in shapewear conversations. Understanding this fabric helps make better sourcing decisions.

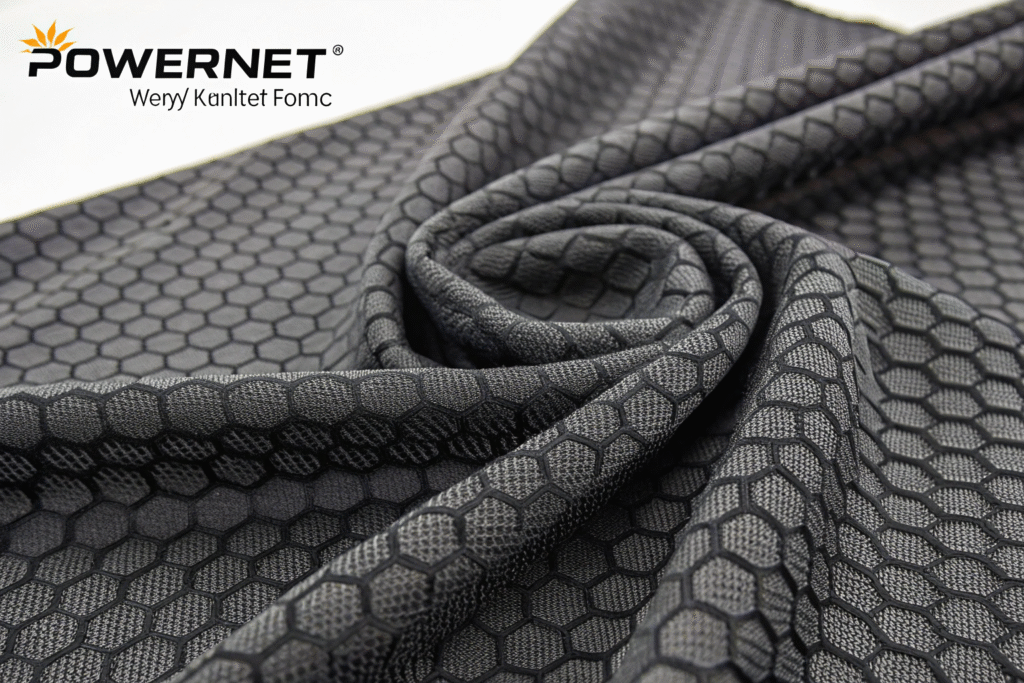

Powernet is a power stretch knitted fabric. It offers exceptional control and durability. This warp-knitted material typically uses nylon and spandex. These fibers provide four-way stretch and strong compression. Powernet is indeed ideal for shapewear. It delivers firm control and effective silhouette smoothing. The fabric also provides good breathability and recovery. Its unique structure supports high-performance garments.

Let us explore Powernet fabric in detail. This knowledge will help your shapewear collection planning.

What are the key properties of Powernet fabric?

Powernet fabric has distinct construction and performance features. Clients sometimes confuse it with other stretch meshes. Knowing these properties ensures you get the right quality.

Powernet is a warp-knitted fabric. This differs from weft-knitted jersey. The warp-knitting technique often uses Raschel knitting machines. This process creates a dense hexagonal mesh pattern. The structure enables both control and breathability. The fabric is strong and durable. It provides significant compression without shape loss. Its four-way stretch allows multidirectional movement. This creates a comfortable, conforming fit for shapewear.

How does construction influence performance?

Powernet's construction determines its performance. The warp-knitting process interloops yarns vertically. This creates a stable, non-curling fabric. The stability prevents shapewear from rolling down. The hexagonal mesh allows skin breathing. This addresses a common user concern. Knit density relates directly to control level. Higher gauge knitting produces denser Powernet. This offers firmer control for compression garments. Our CNAS-accredited lab tests tensile strength and elongation. We ensure every batch meets global performance standards.

Which materials are typically used?

Nylon and spandex form the common Powernet blend. Nylon provides strength and durability. Spandex delivers stretch and recovery. Spandex content ranges from 15% to 30%. This depends on the desired compression level. Our Keqiao factory produces various Powernet blends. We offer eco-friendly options like Recycled Polyester with spandex. European clients increasingly request these. Material blend affects hand feel and compression. It also impacts garment durability.

Why is Powernet considered superior for shapewear?

Shapewear brands consistently choose Powernet for specific reasons. The fabric delivers both compression and comfort. This combination encourages repeat customer use. Repeat business benefits buyers directly.

Powernet offers a balanced performance profile. It provides better control and recovery than other knits. Jersey and Spandex Mesh can lose shape over time. Powernet maintains compressive force through multiple washes. Its structure enables excellent sculpting capabilities. The fabric smooths silhouettes without visible lines. This feature represents a key consumer selling point. It leads to fewer product returns and higher satisfaction.

How does Powernet compare to other control fabrics?

Consider this comparison with Ciré fabric. Buyers often ask about these differences.

| Feature | Powernet Fabric | Ciré (Satin) Fabric |

|---|---|---|

| Structure | Warp-knit, mesh | Warp-knit, high-gloss surface |

| Breathability | High (due to mesh) | Low |

| Compression | Firm, multi-directional | Light, restrictive |

| Recovery | Excellent | Good |

| Common Use | Full-body shapers, high-waist briefs | Lingerie, camisoles, light control |

Powernet clearly wins for firm, breathable control applications. Double Brushed Polyester offers softness but minimal compression. It cannot replace performance shapewear.

What durability advantages does it offer?

Durability creates customer value. Powernet resists deformation well. The interlocked loop structure withstands repeated stretching and washing. It maintains original shape and compression level over time. This reliability is vital for shapewear. These garments endure significant stress. Our quality control includes colorfastness and shrinkage testing. We verify performance after multiple washes. This ensures customer satisfaction and builds brand loyalty.

How to source high-quality Powernet fabric from China?

China sourcing can be efficient and cost-effective. Buyers have specific concerns about quality and logistics. Our integrated factory addresses these concerns directly.

Sourcing starts with supplier verification. Choose manufacturers with proper facilities. Weaving factories should have dyeing and finishing partnerships. Ask about testing protocols. Request SGS reports for composition and performance. Our QR code tracking provides real-time batch data. This system guarantees 98% pass rates and ensures complete transparency.

Which quality certifications matter?

Certifications provide objective quality proof. For apparel Powernet, seek Oeko-Tex Standard 100 certification. This verifies the absence of harmful substances. US market requires CPSC compliance. Eco-friendly products need GRS (Global Recycled Standard) certification. We maintain multiple certifications. We share these documents openly to build trust and streamline compliance.

How to maintain consistency and timeliness?

Consistency requires rigorous Quality Control. We implement three inspection stages. We check raw materials first. We monitor the knitting process next. We examine final fabric before shipping. Our integrated supply chain ensures timeliness. The dyeing factory is located nearby. This reduces production lead times significantly. We provide overseas warehousing options too. This approach minimizes shipping delays and simplifies US customs clearance.

What are the sustainable options in Powernet fabric?

Green textile demand is growing rapidly. Our European clients drive 30% annual growth in eco-exports. Sustainable shapewear has become a market differentiator.

Sustainable Powernet is now available. We developed high-performance versions using Recycled Nylon. This material often comes from post-consumer waste. We combine it with GRS-certified spandex. These fabrics match virgin material performance. They have lower environmental impact. We also experiment with Tencel™ Lyocell blends. These work well for softer segments. Traditional nylon-spandex remains best for maximum compression.

What eco-certifications are available?

Certifications validate sustainability claims. Global Recycled Standard (GRS) tracks recycled content. Oeko-Tex Standard 100 focuses on human ecology. Bluesign® offers comprehensive manufacturing audits. It checks environmental impact and worker safety. We invest in these certifications actively. They assure partners about our global standards compliance.

How do cost and performance compare?

Recycled Powernet has cost implications. Recycled nylon costs 10-15% more than virgin nylon. Collection and purification processes justify this premium. The price difference is shrinking gradually. Marketing appeal often justifies the extra cost. It aligns with brand sustainability goals like UN SDGs. Performance remains nearly identical. Our tests confirm similar compression and recovery properties. You can choose sustainability without sacrificing performance.

Conclusion

Powernet fabric offers unique benefits for shapewear. Its construction provides exceptional compression and durability. The fabric maintains breathability and recovery. These features make it ideal for intimate apparel. Sustainable options now expand its applications further.

We can help develop your shapewear line. Our team handles fabric development through final shipping. We ensure a seamless production process. Contact our Business Director Elaine for specific needs. Her email is elaine@fumaoclothing.com. Let us create value for your brand together.