As a fabric supplier with over two decades in the industry, I've seen many clients face hurdles with fire safety standards. You're sourcing drapery fabrics, you need them to be safe, and you need them to pass specific tests to enter the market. The question of NFPA 701 often comes up, and it's more than just a technicality; it's a critical requirement for commercial spaces, hotels, and even some residential applications.

Simply put, NFPA 701 is the Standard Methods of Fire Tests for Flame Propagation of Textiles and Films. It measures how a fabric sample burns and how quickly flames spread. To pass, your drapery fabric must be tested by an accredited laboratory, and often needs to be either inherently flame-resistant or treated with a flame retardant finish.

Navigating the specifics can seem complex, but with the right partner who understands both the standards and practicalities of fabric production, it becomes straightforward. Let's break down what you need to know.

What is the NFPA 701 test method?

When you hear "NFPA 701," it's easy to think of it as a single test. However, it's a set of procedures designed for different scenarios. The standard exists to assess how fabric will perform if exposed to a small ignition source.

The most common test method for drapery fabrics is the NFPA 701 Small Scale test. This involves suspending a conditioned fabric sample in a special chamber. A controlled flame is applied to the bottom for a specified time. After removal, technicians measure after-flame time, char length, and flaming debris.

How does the laboratory testing process work?

The lab procedure is meticulous to ensure consistent results. First, fabric samples are conditioned in a standard atmosphere to control humidity and temperature. The sample is mounted vertically in the test frame. A methane gas flame with precise height is applied for 45 seconds. Key metrics include after-flame time and char length. A pass requires after-flame time under 2 seconds and char length under 6.5 inches. These precise measurements make CNAS-accredited lab testing essential for reliable certification.

What are the different test classifications?

It's critical to specify the correct test. NFPA 701 has several test methods, and using the wrong one can invalidate certification. Test 1 covers free-hanging fabrics like draperies and curtains. Test 2 covers fabrics attached to substrates like wallcoverings. The standard provides clear guidelines on which test to apply based on fabric weight and application. Understanding this distinction is vital. You can't assume a fabric passing one test will pass another. Always consult with suppliers about the correct NFPA 701 standard for your specific application.

How to make drapery fabric pass NFPA 701?

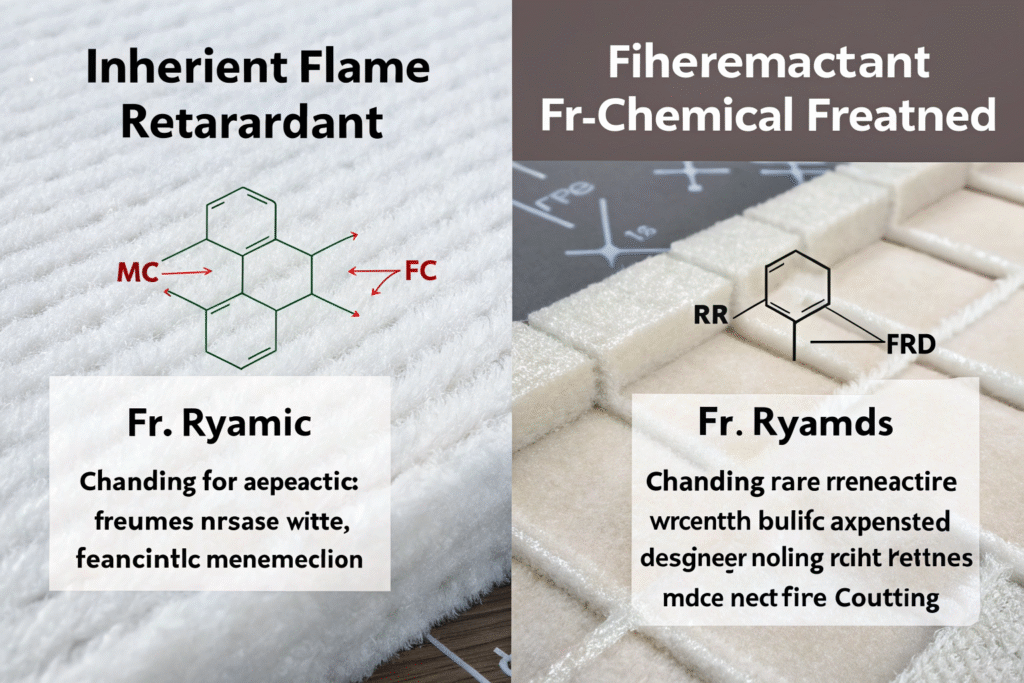

Passing NFPA 701 isn't about luck; it's about strategy and preparation. From my experience working with international buyers, there are two primary paths to compliance. The first uses inherently flame-resistant fibers. The second applies flame retardant finishes during processing.

The inherent FR approach uses fibers like modacrylic, certain aramids, or FR-rayon with fire resistance built into their chemical structure. This is permanent. The chemical treatment approach applies FR chemicals through padding or coating processes. This is effective but requires careful management as finishes can be affected by laundering.

Which inherent fibers naturally meet requirements?

For permanent solutions that won't degrade with cleaning, inherent FR fibers are ideal. Modacrylic is popular for draperies as it's soft, drapes well, and offers excellent flame resistance. Wool also has good inherent FR properties. For technical applications, fibers like Nomex are used. Choosing fabrics blended or made from these fibers significantly increases passing chances without additional treatments. This simplifies supply chains and provides consistent products. We guide clients through this selection process to balance performance, aesthetics, and cost.

How reliable are chemical treatments?

Flame retardant finishing is extremely effective when done correctly. The process impregnates fabric with chemicals that interfere with combustion. These work by forming protective char, releasing non-flammable gases, or cooling the fabric. Effectiveness depends on chemical quality and application precision. We partner with leading chemical suppliers using controlled conditions for even application and proper curing. Conducting testing after cleaning ensures finish durability, especially for draperies requiring periodic cleaning.

How to ensure consistent NFPA 701 compliance?

Getting one batch to pass is an achievement, but ensuring every shipment remains compliant builds real business reliability. Consistency is the biggest challenge and requires rigorous quality control systems. This is core to our service, knowing single failures can disrupt production and damage brands.

Our process starts with raw materials. We verify FR properties of incoming yarns or greige goods. During production, we monitor FR treatment application, checking for evenness and add-on percentage. The most critical step is post-production testing. We don't rely on old certificates. For every new batch, we pull samples for testing. This proactive approach catches deviations before shipping.

Why test every production batch?

Batch-to-batch testing is non-negotiable because variations happen. Different dye lots, weaving tension changes, or finishing temperature fluctuations can affect FR performance. Relying on old test reports for new batches is risky. We institute batch-specific certification policies. This means each shipment comes with a test report from an accredited lab corresponding to that specific production run. This documentation proves compliance and satisfies due diligence requirements.

What documentation proves compliance?

Proper documentation is your safety net. When fabric passes, you should receive a formal test report from an accredited laboratory. This report clearly states the tested standard, results, and "PASS" conclusion. It includes fabric description, lot number, and test date. Beyond test reports, reliable suppliers provide Certificates of Compliance attesting shipped goods conform to requirements. We provide complete documentation packages, smoothing import processes and regulator communications.

Why choose vertically integrated NFPA 701 suppliers?

The complexity of achieving NFPA 701 compliance reveals a key advantage: working with vertically integrated suppliers. When fabric suppliers control production chains—from weaving and dyeing to finishing and testing—processes become more reliable, faster, and cost-effective.

Vertical integration means managing processes holistically. We select proper base fabrics for FR treatment, ensure dyeing doesn't interfere with FR chemicals, and control finishing curing parameters. This control minimizes test failure variables. Our CNAS-certified lab allows preliminary testing, saving time and money before formal external lab certification.

How does integration control costs?

Cost control comes from efficiency and reduced waste. Managing multiple stages avoids markups and communication gaps from dealing with independent factories. We troubleshoot issues in real-time. If finishing problems are detected, we adjust processes immediately without waiting for separate supplier responses. This direct control translates to consistent products and stable pricing, addressing price concerns without sacrificing NFPA 701 quality requirements.

How does this simplify logistics?

Logistics is a major pain point, and integration streamlines it. We handle packaging, inspection, and consolidation under one roof. For US-bound goods, our experience shipping certified fabrics smooths customs processes. Having correct, batch-specific documentation readily available prevents delays. While we cannot claim immunity from all US tariff regulations, our expertise ensures proper goods classification and documentation, minimizing unexpected fee risks. We turn complex journeys from Keqiao factories to your door into single, manageable processes.

Conclusion

Navigating NFPA 701 for drapery fabrics is detailed but manageable. It starts with understanding test methods, moves to strategically selecting compliant fabrics, and is secured by rigorous batch testing and documentation. The goal isn't just passing tests, but reliably delivering safe, quality products to build trustworthy brands.

The entire process smoothens significantly with partners having expertise, vertical integration, and quality control commitment this standard demands. If you're producing NFPA 701 compliant drapery or apparel orders with partners handling complexities, we can help. For direct conversations about specific needs, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Ensure your next fabric shipment is beautiful, fully certified, and safe.