As a textile expert with over twenty years in the industry, I understand the critical importance of material selection for fashion brands. The choice between modal and viscose rayon represents one of the most common dilemmas faced by designers and sourcing professionals today. Both fabrics offer unique advantages, but understanding their distinct characteristics is essential for making informed decisions that align with your brand values and product requirements.

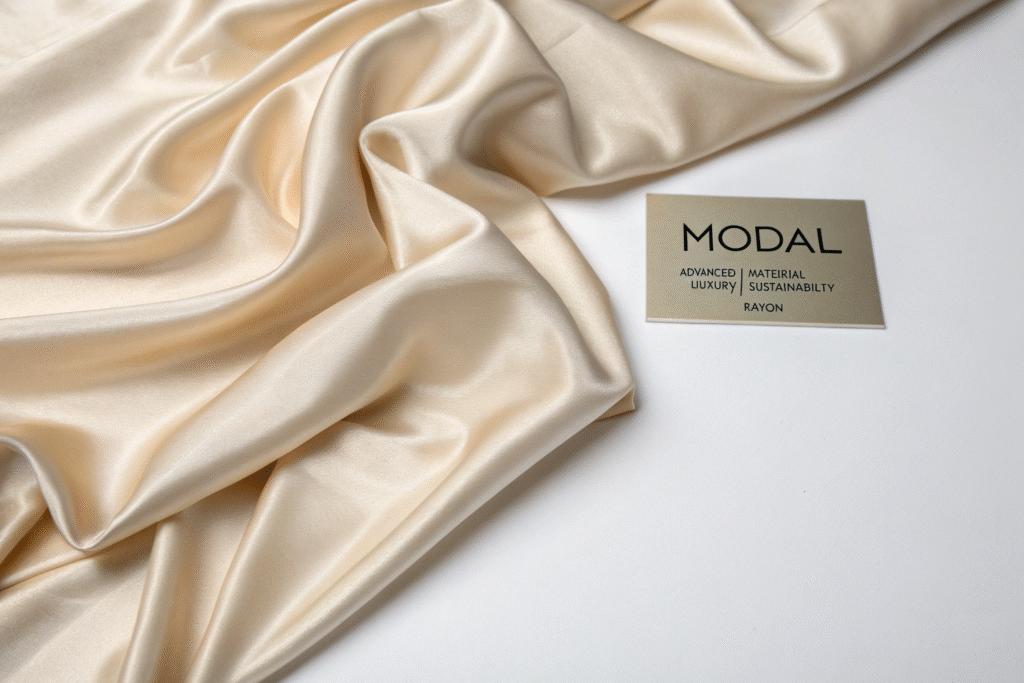

Modal and viscose rayon are both semi-synthetic cellulosic fibers derived from wood pulp, yet they differ significantly in their production methods and end properties. Modal is essentially an enhanced version of viscose, developed to address some of the limitations of traditional rayon while offering superior softness and environmental credentials. This fundamental distinction forms the basis for their different applications in the fashion industry.

Understanding Modal Fabric: Premium Quality and Benefits

Modal has emerged as a preferred choice for brands seeking to combine luxury feel with sustainable credentials. This advanced material represents the evolution of rayon technology, offering significant improvements over traditional viscose while maintaining the desirable characteristics that made rayon popular in the first place.

The production process begins with sustainably harvested beech trees, known for their rapid growth without requiring irrigation or pesticides. Through an advanced closed-loop system, the wood pulp undergoes transformation into fiber while recycling over 99% of water and solvents. This environmentally conscious approach not only reduces waste but also results in a stronger, more consistent fiber that maintains its integrity throughout the manufacturing process.

How Does Modal Production Ensure Quality and Sustainability?

The manufacturing excellence behind modal fabric begins with rigorous raw material selection. Beech wood from certified sustainable forests undergoes pulping to extract pure cellulose. This cellulose then enters a sophisticated closed-loop production system where solvents are continuously recovered and reused. This method not only minimizes environmental impact but also creates fibers with exceptional strength and consistency. The controlled manufacturing environment allows for precise quality monitoring at every stage, ensuring that the final fabric meets strict performance standards. Our commitment to sustainable fiber production aligns with the growing demand from global brands for environmentally responsible materials.

What Advantages Does Modal Offer for Fashion Applications?

Modal's unique properties make it particularly suitable for premium fashion applications. The fabric demonstrates exceptional softness that actually improves with repeated washing, making it ideal for items that require frequent laundering. Its high moisture-wicking capability—approximately 50% greater than cotton—ensures comfort in various wearing conditions. The fiber's natural smoothness provides excellent color retention, allowing for vibrant, long-lasting dyes that resist fading. Furthermore, modal's resistance to shrinkage and pilling ensures that garments maintain their original appearance through extended wear, reducing customer returns and enhancing brand reputation through consistent product quality.

Examining Viscose Rayon: Characteristics and Applications

Viscose rayon, often celebrated as "artificial silk," has maintained its popularity in the fashion industry due to its excellent drape and affordable luxury. Understanding its properties and manufacturing process helps brands make informed decisions about when this traditional material represents the optimal choice.

The production of viscose rayon involves a more chemically intensive process compared to modal. Wood pulp undergoes treatment with sodium hydroxide and carbon disulfide before being dissolved to create the viscose solution. This solution is then extruded through spinnerets into an acid bath to regenerate the cellulose fibers. While modern manufacturers have implemented improvements, the fundamental process remains more resource-intensive than modal production.

What Defines the Traditional Viscose Manufacturing Process?

The conventional viscose production method involves multiple chemical treatments that transform wood pulp into spinnable solution. The process begins with steeping wood pulp in sodium hydroxide to create alkali cellulose, which then reacts with carbon disulfide to form cellulose xanthate. This compound dissolves in dilute sodium hydroxide, creating the characteristic viscous solution that gives viscose its name. The solution is filtered, aged, and then extruded through spinnerets into a sulfuric acid bath where the filaments regenerate. This established manufacturing approach requires careful management to minimize environmental impact, with leading manufacturers increasingly adopting enhanced environmental and safety protocols to address production challenges.

When Does Viscose Rayon Represent the Optimal Choice?

Viscose rayon excels in applications where beautiful drape and fluid movement are primary considerations. The fabric's inherent characteristics make it particularly suitable for flowing garments like blouses, dresses, and skirts where a luxurious, silky appearance is desired. For brands operating in the fast-fashion segment or launching experimental collections, viscose provides an affordable entry point without compromising on aesthetic appeal. The material also serves as an excellent blending component, adding drape and softness when combined with other fibers like cotton or polyester. However, successful implementation requires careful attention to garment construction and care instructions to mitigate the fabric's tendency toward shrinkage and reduced strength when wet.

Comparative Analysis: Modal versus Viscose for Business Decisions

Making the right choice between modal and viscose requires careful consideration of multiple factors that impact both production outcomes and market reception. A systematic comparison enables brands to align material selection with their specific business objectives and customer expectations.

The decision matrix extends beyond simple cost calculations to encompass durability, sustainability credentials, and end-use performance. Brands must evaluate how each fabric's characteristics support their product stories and quality promises to consumers. This comprehensive approach ensures that material choices reinforce brand positioning while meeting practical requirements.

| Feature | Modal Fabric | Viscose Rayon |

|---|---|---|

| Softness | Exceptionally soft, improves with washing | Soft and silky initially, may stiffen over time |

| Strength | High strength, especially when wet | Moderate strength, weakens when wet |

| Environmental Impact | Lower impact, closed-loop processing | Higher impact, traditional chemical processing |

| Moisture Absorption | 50% higher than cotton | High absorption, lower than modal |

| Shrinkage Resistance | Excellent resistance | Prone to shrinkage |

| Cost | Premium pricing | Cost-effective |

| Ideal Applications | Premium apparel, activewear, lingerie | Flowing garments, fast fashion, blends |

How Do Sustainability Profiles Compare Between These Fabrics?

Modal generally demonstrates stronger environmental credentials due to its manufacturing technology and raw material sourcing. The closed-loop production system significantly reduces chemical emissions and water consumption compared to conventional viscose manufacturing. Beech trees, the primary raw material for modal, typically come from sustainable forestry operations that support ecosystem health. In contrast, traditional viscose production has faced scrutiny regarding chemical management and sourcing practices, though industry initiatives are driving improvement. Brands committed to sustainable forestry conservation should verify their suppliers' practices, while participation in industry improvement programs indicates serious commitment to responsible manufacturing.

Which Fabric Delivers Superior Business Value?

The value proposition varies according to brand positioning and product strategy. Modal offers compelling long-term value for established brands building reputation through quality and sustainability. The fabric's durability translates to reduced returns and higher customer satisfaction, while its environmental story supports premium positioning. Viscose provides immediate cost advantages for brands prioritizing accessibility and fast fashion cycles, though this approach requires careful management of quality expectations. A comprehensive value assessment should consider total cost of ownership, including potential impacts on brand perception and customer loyalty. The optimal choice balances initial investment against long-term brand building and customer retention objectives.

Strategic Sourcing Considerations for Quality Fabrics

Successful fabric sourcing requires attention to both technical specifications and supply chain reliability. The partnership with your supplier significantly influences not only product quality but also production timelines and overall business performance.

Establishing clear quality standards and communication protocols from the outset prevents misunderstandings and ensures consistent results. The most successful brand-supplier relationships combine technical expertise with transparent operations, creating foundations for long-term collaboration and continuous improvement.

What Supplier Qualifications Ensure Product Excellence?

Identifying qualified suppliers begins with verifying their technical capabilities and quality systems. Manufacturers with certified sustainable fiber sourcing demonstrate commitment to responsible production practices. In-house testing facilities, particularly those with international accreditation, provide objective quality verification throughout manufacturing. Responsive sampling processes indicate operational efficiency and respect for client timelines. Additionally, suppliers with specific experience in your target market better understand compliance requirements and consumer expectations, reducing adaptation challenges during product development.

How Can Brands Maintain Quality Through Production and Delivery?

Consistent quality requires systematic approaches to production management and logistics. Detailed technical specifications provide the foundation, while regular factory audits and pre-production samples verify understanding and capability. Integrated manufacturing facilities, controlling processes from weaving to finishing, minimize variability and improve coordination. For international shipments, particularly to the U.S., reliable logistics partnerships ensure timely delivery while tracking systems maintain visibility throughout transit. Establishing clear quality checkpoints and communication protocols with your supplier creates collaborative relationships focused on continuous improvement and problem prevention rather than reactive correction.

Conclusion

The comparison between modal and viscose rayon reveals two distinct materials serving different market segments and business objectives. Modal's superior softness, durability, and environmental profile support premium positioning and quality-focused branding. Viscose offers accessible luxury with excellent drape characteristics, serving price-sensitive markets and trend-driven collections.

Successful fabric selection requires honest assessment of your brand's values, customer expectations, and operational capabilities. Neither fabric represents a universally superior choice; rather, each serves specific purposes within a comprehensive product strategy. The most successful brands understand these distinctions and apply them strategically across their collections.

As you develop your next collection, we invite you to leverage our expertise in both modal and viscose fabrics. Our integrated manufacturing capabilities and quality systems ensure consistent results, while our experience with international markets provides valuable insights for product optimization. For personalized assistance with your fabric selection and production planning, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. We look forward to supporting your success with the right fabric choices for your unique requirements.